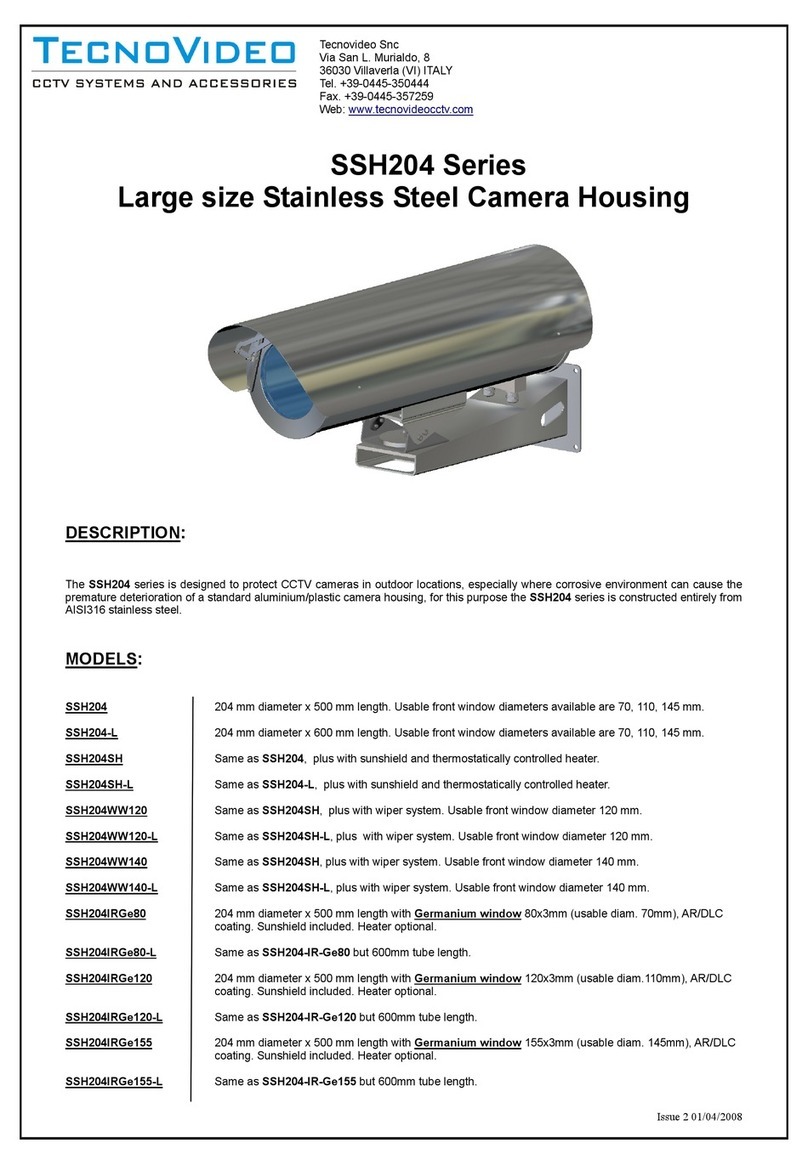

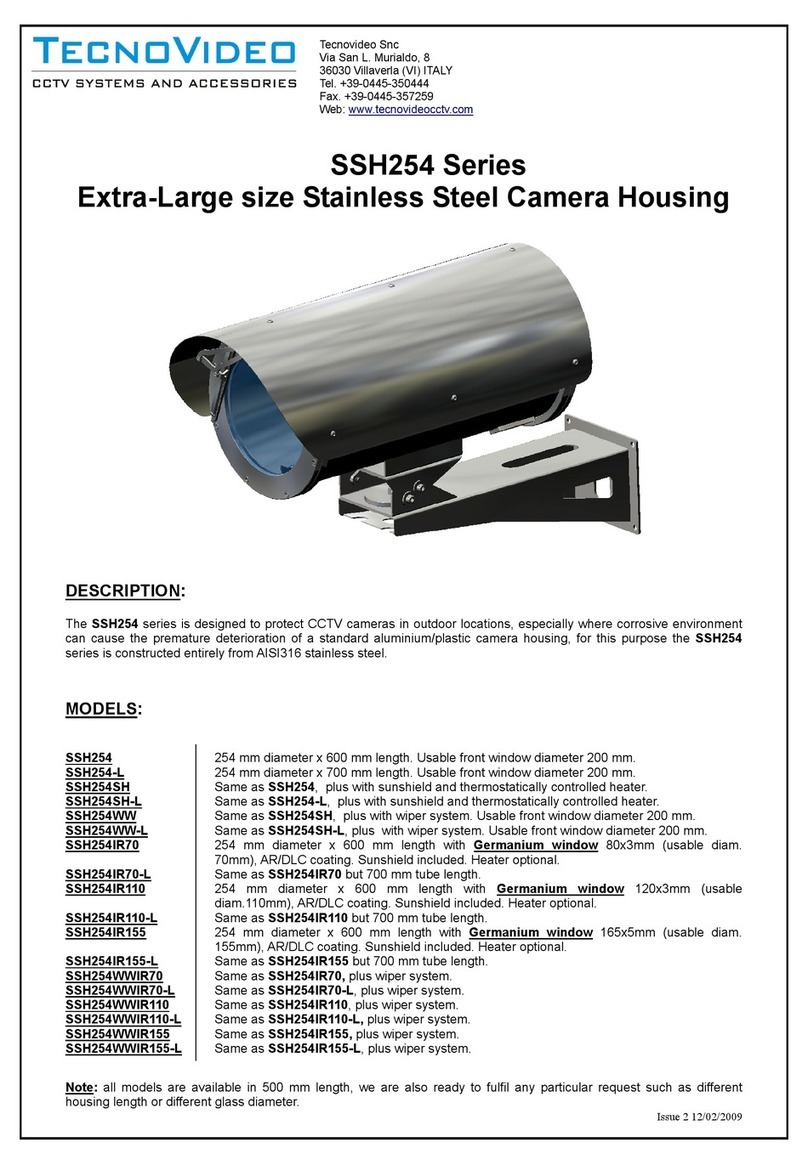

DESCRIPTION

The 129AC series is well suited to protect CCTV equipment in hot and corrosive environments. The 129AC series perfectly fills

the gap between locations which need a liquid cooling system and locations which don't need any cooling systems at all. The

main cooling system used is a Vortex Tube, which converts the air inlet into two streams (one hot and one cold .

The 129AC series is entirely built in AISI316L stainless steel. 1/4" air nozzle is available as an option for all models.

MODELS

129AC Camera housing (L=360 mm . Usable front window diameter: 70 mm; thickness 5mm.

129ACIR 0 Camera housing (L=360 mm . Usable front window diameter: 70 mm; Germanium window, thickness

3 mm, AR/DLC coating.

CERTIFICATIONS

EN 61000-6-3:2007 and 50130-4:1995 + A1:1998 + A2:2003 (EMC – Electromagnetic Compatibility

60950-1:2006 + A11:2009 (LVD – Safety

INSTALLING THE CAMERA

i

Prior to installation and operation, read carefully all instructions the in this manual and heed all warnings.

Unpack this equipment and handle it carefully. If the package appears to be damaged, notify the shipper immediately.

Use the original packaging to transport the unit. Disconnect power supply before moving it. In case of returning the

equipment, the original packaging must be used.

Make sure that the installation surface can support at least four times the weight of the unit in normal operating conditions.

In case of excessive external stress (e.g. vibration, strong winds or impact , the equipment may need additional means of

protection.

Proper stainless steel hardware should be carefully chosen to fasten the unit to the surfaces.

Use caution when lifting and assembling the unit. It is recommended that non-slip protective gloves be worn during

installation. The unit could bear sharp edges.

To maintain the IP rating of the unit, adequate cable glands must be used. The unit must be tightly closed when operating.

The internal pressure inside the housing must never exceed 0,5 bar.

Vortex tube surface and hot air outlet could reach very hot temperature.

A screwdriver slot is available to adjust the temperature/flow ratio. Do not operate on the screwdriver slot when the Vortex

tube is working.

For security reasons, do not install the unit in the proximity of water containers and never push objects or pour liquids into

the unit. The unit can be safely used in damp environments or outdoors, as long as the connectors are properly sealed.

Video and data cables should not share the same conduit with supply voltage cables. Whenever EMC is an issue, adequately

shielded cables must be used.

Open only the covers pointed out in this installation manual. Other covers should be open only by the manufacturer.

This equipment has been designed to fit in harsh environments requiring little or no maintenance. Suggested inspection

interval is 6 months, but extremely harsh environments may require more frequent inspection and maintenance checks. On

each inspection check the O-ring seals and the eventual window wiper blade integrity. Replace them if necessary.

Check cables, electrical connections and mounting hardware for integrity and tightness. Replace or tighten any

damaged/loose part.

h

Before performing any operation, turn off the power. The installation of the unit can be performed only by qualified

personnel in accordance with the regulations in force. Do not connect the unit to a supply circuit unless the installation is

completed.

An all-pole mains switch with an opening distance between the contacts at least 3 mm in each pole must be incorporated

in the electrical installation. The switch must be equipped with protection against the fault current towards the ground

(differential and the overcurrent (magnetothermal, maximum 15A . It must be very quickly recognizable and readily

accessible. A suitable blow fuse must also be installed for protection.

For connection to the mains, use a multipolar cable having minimum 3x1,5 mm2 (15 AWG . The main cable must be at least

protected by an ordinary PVC sheath.

Fasten all the cables inside the housing with cables ties or other fixing means to avoid the electrical contact with

surrounding parts in case that terminal blocks screw off.

Electrical connections (such as plugs and cords must be protected from potential hazardous environmental factors (e.g.

foot traffic, hitting objects .

Ensure that the unit case is properly earthed, connecting all the earth ground studs. Earth cable should be about 10mm

longer than the other cables on the connector, in such way that it won't be accidentally disconnected if the cable is

stretched or pulled.

When leaving the unit unused for long periods, disconnect supply cables.

2