Tecumseh AEA4440YXA Product guide

Service Data Book

Sold By

American Refrigeration Supplies Inc.

Wholesale Distribution

North America

A LOOK AT SERVICE SAFETY

Genera Service Safety Precautions

1

1

GENERAL SERVICE

SAFETY PRECAUTIONS

I.

Introduction . . . . . . . . . . . . . . . . . . . . . . . . 2

II.

Trained Personnel Only . . . . . . . . . . . . . . 2

III.

Terminal Venting and Electrocution . . . . . 2

IV.

Refrigerants and Other Chemicals. . . . . . . 4

V.

Compressor Remo al . . . . . . . . . . . . . . . . 4

VI.

System Flushing, Purging, and Pressure

Testing for Leaks . . . . . . . . . . . . . . . . . . . . 4

VII.

System Charging . . . . . . . . . . . . . . . . . . . . 5

VIII.

Pre ention of Water-Utilizing System

Explosions . . . . . . . . . . . . . . . . . . . . . . . . . 6

IX.

Start Capacitor O erheating. . . . . . . . . . . . 7

X.

System E acuation . . . . . . . . . . . . . . . . . . 7

XI.

Follow the Labels . . . . . . . . . . . . . . . . . . . 7

2

Chapter 1

I.

Introduction

In the interest of promoting safety in the refrigera-

tion and air conditioning industry, Tecumseh Prod-

ucts Company has prepared the following

information to assist service personnel in safely

installing and servicing equipment. This section

covers a number of topics related to safety. However,

it is not designed to be comprehensive or to replace

the training required for professional service person-

nel.

II.

Trained Personne On y

Refrigeration and air conditioning devices are

extremely complicated by nature. Servicing, repair-

ing, and troubleshooting these products should be

done only by those with the necessary knowledge,

training, and equipment.

III.

Termina Venting and

E ectrocution

Improperly servicing, repairing, or

troubleshooting a compressor can lead

to electrocution or fire due to terminal

venting with ignition. Follow the pre-

cautions below to avoid serious injury

or death from electrocution or terminal

venting with ignition.

A.

Fire Hazard from Termina

Venting with Ignition

Oil and refrigerant can spray out of the compressor

if one of the terminal pins is ejected from the her-

metic terminal. This “terminal venting” can occur as

a result of a ground fault (also known as a short cir-

cuit to ground) in the compressor. The oil and

refrigerant spray from terminal venting can be

ignited by electricity and produce flames that can

lead to serious burns or death. When spray from ter-

minal venting is ignited this is called “terminal vent-

ing with ignition.” See Figures 1-1 through 1-3 for

detail.

B.

Termina Venting and E ectrocution

Precautions

To reduce the risk of electrocution, serious burns, or

death from terminal venting with ignition:

➤

Disconnect ALL electrical power before

removing the protective terminal cover.

Make sure that all power legs are open.

(NOTE: The system may have more than one

power supply.)

➤

Never energize the system unless: 1) the pro-

tective terminal cover is securely fastened,

and 2) the compressor is properly connected

to ground.

Figures 1-4 through 1-6 illustrate the different

means of fastening protective terminal covers.

➤

Never reset a breaker or replace a fuse with-

out first checking for a ground fault (a short

circuit to ground).

An open fuse or tripped circuit breaker is a

strong indication of a ground fault. To check

for a ground fault, use the procedure outlined

in “Identifying Compressor Electrical

Problems” on page 47.

➤

Be alert for sounds of arcing (sizzling, sput-

tering or popping) inside the compressor. If

you hear these sounds, IMMEDIATELY get

away.

➤

Disconnect power before servicing.

Always disconnect power before servicing,

unless it is required for a specific

troubleshooting technique. In these situations,

use extreme caution to avoid electric shock.

WARNING

!

Never service, repair, or troubleshoot

unless you are a professional air condi-

tioning/refrigeration service person.

Improper servicing can lead to serious

injury or death from fire, electric shock,

or explosion.

A LOOK AT SERVICE SAFETY

Genera Service Safety Precautions

3

Figure 1-1.

Compressor with (1) protecti e

terminal co er and (2) bale strap

remo ed to show (3) hermetic

terminal.

Figure 1-2.

Close-up iew of hermetic

terminal showing indi idual

terminal pins with power leads

remo ed.

Figure 1-3.

Close-up iew of hermetic terminal

after it has ented.

Figure 1-4.

Compressor with (1) protecti e

terminal co er held in place by (2)

metal bale strap.

Figure 1-5.

Compressor with (1) protecti e

terminal co er held in place by (2)

nut.

Figure 1-6.

Compressor with (1) snap-in

protecti e terminal co er.

4

Chapter 1

IV.

Refrigerants and Other

Chemica s

Contact with refrigerant, mixtures of refrigerant and

oil, or other chemicals can cause a variety of injuries

including burns and frostbite. For example, if refrig-

erant contacts skin or eyes it can cause severe frost-

bite. Also, in the event of a compressor motor

failure, some refrigerant and oil mixtures can be

acidic and cause chemical burns.

To avoid injury, wear appropriate protective eye-

wear, gloves, and clothing when servicing an air con-

ditioning or refrigeration system. Refer to your

refrigerant supplier for more information.

If refrigerant or mixtures of refrigerant and oil come

in contact with skin or eyes, flush the exposed area

with water and get medical attention immediately.

V.

Compressor Remova

Failure to properly remove the compressor can result

in serious injury or death from electrocution, fire, or

sudden release of refrigerant and oil.

Follow these precautions when removing a compres-

sor from a system:

➤

Disconnect ALL electrical power.

Disconnect all electrical power supplies to the

system, making sure that all power legs are

open. (NOTE: The system may have more

than one power supply.)

➤

Be sure refrigerant is recovered before

removing compressor.

Attempting to remove the compressor before

removing all refrigerant from the system can

cause a sudden release of refrigerant and oil.

Among other things, this can:

•Cause a variety of injuries including

burns and frostbite.

•Cause a fire if a torch is used to discon-

nect tubing.

•Expose the service person to toxic gas.

To avoid serious injury or death, be sure to

remove and recover all refrigerant before

removing the compressor.

➤

Use a tubing cutter, not a torch.

Use a tubing cutter to remove the

compressor. A torch can cause

even trace amounts of refrigerant

to decompose and release toxic

fumes. In addition, using a torch

to remove the compressor can cause a fire. If

you ignore this recommendation and use a

torch, be prepared to extinguish a fire.

VI.

System F ushing, Purging,

and Pressure Testing for

Leaks

Failure to properly flush, purge, or pressure test a

system for leaks can result in serious injury or death

from explosion, fire, or contact with acid-saturated

refrigerant or oil mists.

Follow these precautions when flushing/purging a

system or pressure testing a system for leaks:

➤

Use flushing products according to the man-

ufacturer’s instructions.

➤

To purge a system, use only dry nitrogen.

➤

When pressure testing for leaks, use only

regulated dry nitrogen or dry nitrogen plus

trace amounts of the serial label refrigerant.

➤

When purging or pressure testing any refrig-

eration or air conditioning system for leaks,

never use air, oxygen or acetylene.

•Oxygen can explode on contact with oil.

•Acetylene can decompose and explode

when exposed to pressures greater than

approximately 15 PSIG.

•Combining an oxidizing gas, such as oxy-

gen or air, with an HCFC or HFC refrig-

erant under pressure can result in a fire or

explosion.

A LOOK AT SERVICE SAFETY

Genera Service Safety Precautions

5

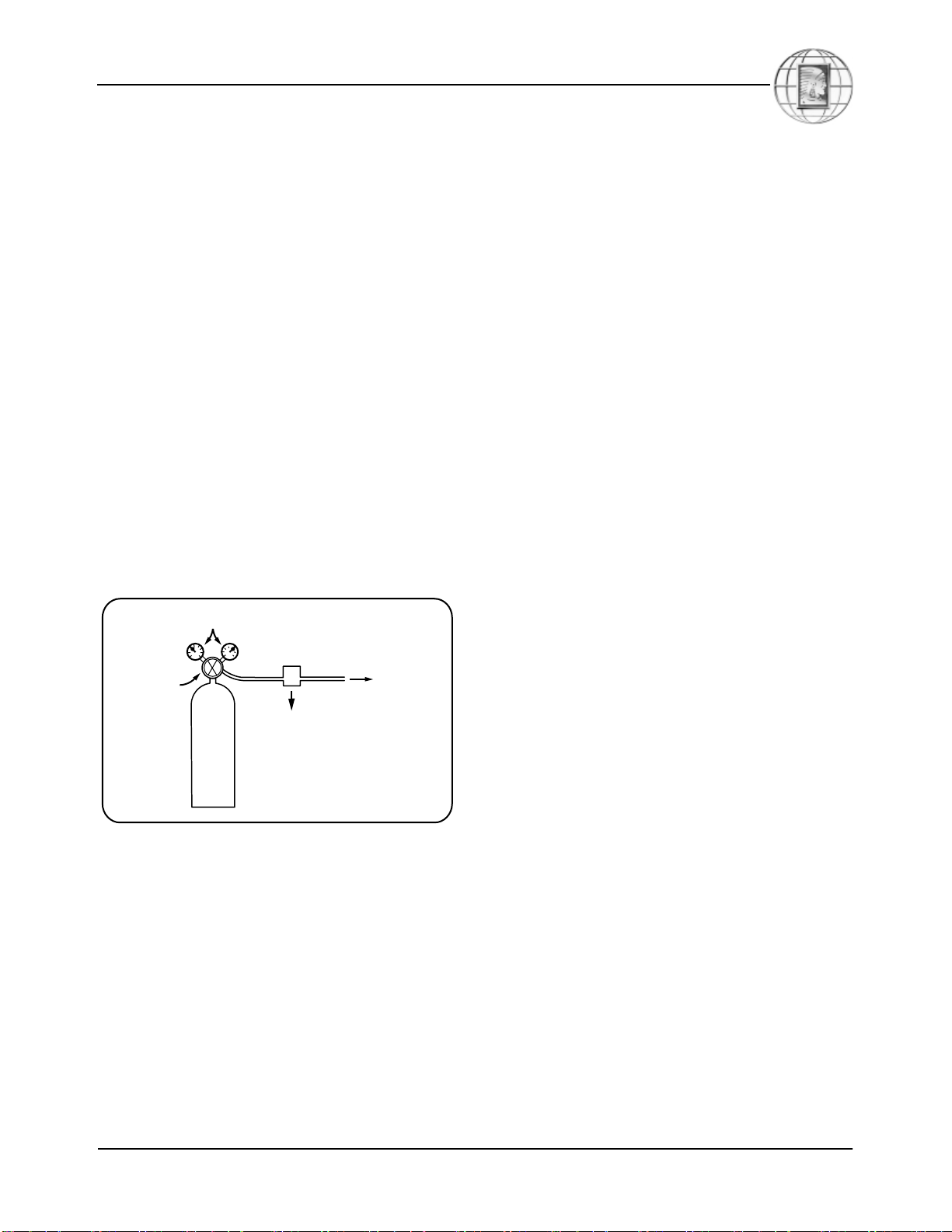

➤

Use a pressure regulating valve and pressure

gauges.

Commercial cylinders of nitrogen contain

pressures in excess of 2000 PSIG at 70°F. At

pressures much lower than 2000 PSIG, com-

pressors can explode and cause serious injury

or death.To avoid overpressurizing the system,

always use a pressure regulating valve on the

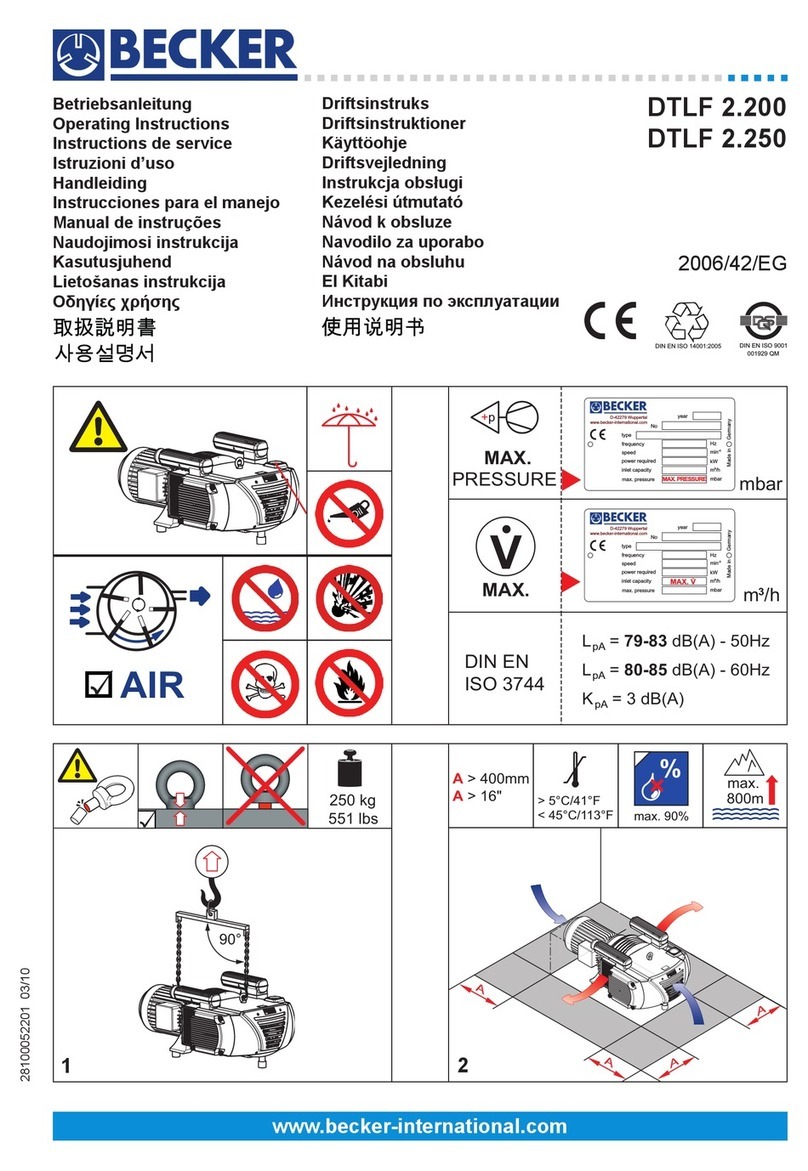

nitrogen cylinder discharge (see Figure 1-7).

The pressure regulator must be able to reduce

the pressure down to 1 or 2 PSIG and main-

tain this pressure.

The regulating valve must be equipped with

two pressure gauges:

•one gauge to measure cylinder pressure,

and

•one gauge to measure discharge or down-

stream pressure.

➤

Use a pressure relief valve.

In addition to a pressure regulating valve and

gauges, always install a pressure relief valve.

This can also be a frangible disc type pressure

relief device. This device should have a dis-

charge port of at least 1/2” MPT size. The

valve or frangible disc device must be set to

release at 175 PSIG (see Figure 1-7).

➤

Do not pressurize the system beyond 150

PSIG field leak test pressure.

When field testing a system for leaks, 150

PSIG is adequate test pressure.

➤

Disconnect nitrogen cylinder and evacuate

the system before connecting the refrigerant

container.

Disconnect the nitrogen cylinder and release

the pressure in the system before connecting a

refrigerant container to the system. The higher

pressure gas in the system can explode the

refrigerant container.

VII.

System Charging

Failure to properly charge the system can result in

serious injury or death from explosion or fire.

Follow these precautions when charging a system:

➤

Do not operate the compressor without

charge in the system.

Operating the compressor without a charge in

the system can damage the hermetic terminal.

As always, to avoid serious injury or death

from terminal venting with ignition, never

energize the compressor unless the protective

terminal cover is securely fastened.

➤

Use proper refrigerant.

Use only the serial label refrigerant when

charging the system. Using a different refriger-

ant can lead to excess system pressure and an

explosion. Use of a refrigerant other than the

serial label refrigerant will void the compressor

warranty.

➤

Do not overcharge a refrigeration or air con-

ditioning system.

Overcharging a refrigeration or air condition-

ing system can result in an explosion. To avoid

serious injury or death, never overcharge the

system. Always use proper charging tech-

niques. Limit charge amounts to those speci-

fied on the system equipment serial label or in

Figure 1-7.

Dry nitrogen cylinder with attached

pressure regulating and relief al es and

pressure gauges needed for pressure

testing for leaks and purging.

Regulating

Val e

Gauges

To System

Relief Val e

175 PSIG Setting

6

Chapter 1

the original equipment manufacturer’s service

information.

Overcharging the system immerses the com-

pressor motor, piston, connecting rods, and

cylinders in liquid refrigerant. This creates a

hydraulic block preventing the compressor

from starting. The hydraulic block is also

known as locked rotor.

Continued supply of electricity to the system

causes heat to build in the compressor. This

heat will eventually vaporize the refrigerant

and rapidly increase system pressure. If, for

any reason, the thermal protector fails to open

the electrical circuit, system pressure can rise

to high enough levels to cause a compressor

housing explosion.

VIII.

Prevention of Water-Uti izing

System Exp osions

In certain water-utilizing refrigeration systems,

water can leak into the refrigerant side of the system.

This can lead to an explosion of system compo-

nents, including but not limited to, the compressor.

If such an explosion occurs, the resulting blast can

kill or seriously injure anyone in the vicinity.

A.

Systems at Risk of Exp osion

Water-utilizing systems that have single-wall heat

exchangers may present a risk of explosion. Such

systems may include:

•water source heat pump/air conditioning sys-

tems, and

•water cooling systems, such as icemakers, water

coolers, and juice dispensers.

Water-utilizing systems that have single-wall heat

exchangers present a risk of explosion unless they

have either:

•a high pressure cut-out which interrupts power

to ALL leads to the compressor, or

•an external pressure relief valve.

B.

How an Exp osion Occurs

If the refrigerant tubing in the heat exchanger devel-

ops a leak, water can enter the refrigerant side of the

system. Water entering the refrigerant side can come

in contact with live electrical connections in the

compressor causing a short circuit or a path to

ground. When this occurs, extremely high tempera-

tures can result. The heat build-up creates steam

vapor that can cause excessive pressure throughout

the entire system. This system pressure can lead to

an explosion of the compressor or other system

components.

C.

Service Procedures

In light of the risk of explosion, be especially alert

for signs of water leaking into the refrigerant side of

the system. Whenever servicing or troubleshooting a

water-utilizing system, always check to see if it has

either a pressure relief valve or a high pressure cut-

out as previously described. If the system does not

have at least one of these, DISCONNECT ALL

ELECTRICAL POWER and look for indications

that water has leaked into the refrigerant side of the

system. These indications may include:

•Observation of or a report of a blown fuse or

tripped circuit breaker.

•Signs that water has leaked to the outside of the

system.

•Reports that the system has made gurgling or

percolating noises.

•A history of loss of refrigerant charge without a

leak being found in the system. NOTE: Com-

mon leak detection methods will not detect a

water-to-refrigerant leak in the system’s heat

exchanger(s).

•Observation of or a report of the compressor

giving off an unusual amount of heat.

If ANY of these indications are present, do the fol-

lowing checks to determine if water has leaked into

the refrigerant side:

Step 1:

Check for a Ground Fau t (a Short to

Ground).

Check the compressor for a ground fault (also

known as a short circuit to ground) using the proce-

dure outlined in “Identifying Compressor Electrical

Problems” on page 47.

A LOOK AT SERVICE SAFETY

Genera Service Safety Precautions

7

•If a ground fault does not exist, go to Step 2.

•If a ground fault does exist, keep the power off.

WARNING! To avoid electric shock, electro-

cution and terminal venting with ignition, do

not energize a compressor that has a ground

fault. Mark and red tag the compressor to indi-

cate that there is a ground fault. Do not recon-

nect the power leads. Tape and insulate each

power lead separately. Proceed to Step 2. Do

not replace the compressor or energize the sys-

tem before performing Step 2.

Step 2:

Check for Water in the System

Once the compressor is cool to the touch, open the

system process valve slightly to see if any water

comes out of the system. WARNING! Opening the

system process valve while the compressor is hot

can cause severe burns from steam coming out of

the valve.

If ANY water comes out of the process valve, the

entire system must be replaced. See “D. Replacing a

Single-Wall Water-Utilizing System”.

If water does not come out of the process valve,

there is still a possibility that some water has leaked

into the refrigerant side of the system. To address

this possibility, determine if the system has a history

of losing refrigerant charge without a leak being

found or repaired.

If you find ANY indication of a history of losing

refrigerant charge without detection of a leak, this is

a sign that refrigerant has leaked in the water inside

the heat exchanger. The entire system must be

replaced. See “D. Replacing a Single-Wall Water-

Utilizing System”.

If you do not find any indication of a history of loss

of charge without detection of a leak, you still need

to install:

•a high-pressure cut-out which interrupts power

to ALL leads to the compressor, or

•an external pressure relief valve.

Also, if you found a ground fault in the compressor

in Step 1, replace the compressor before applying

power to the system.

D.

Rep acing a Sing e-Wa Water-Uti izing

System

When replacing a single-wall water-utilizing system,

replace the system with one that has:

•a double-wall heat exchanger(s), or

•a high-pressure cut-out which interrupts power

to ALL leads to the compressor, or

•an external pressure relief valve.

IX.

Start Capacitor Overheating

An overheated start capacitor can burst and spray or

splatter hot material which can cause burns. Apply-

ing voltage to a start capacitor for more than a few

seconds can cause the capacitor to overheat.

Check capacitors with a capacitance meter, and

never check a capacitor with the power on.

X.

System Evacuation

Never use a compressor to evacuate a system.

Instead, use a high vacuum pump specifically

designed for that purpose.

Never start the compressor while it is under deep

vacuum. Always break a vacuum with refrigerant

charge before energizing the compressor.

Failure to follow these instructions can damage the

hermetic terminal. As always, to avoid serious injury

or death from terminal venting with ignition, never

energize the compressor unless the protective termi-

nal cover is securely fastened.

XI.

Fo ow the Labe s

Tecumseh Products Company compressors have

labels and markings with important information.

For your safety and the safety of others, read the

labels and markings on the product.

A LOOK AT SERVICE SAFETY

9

2

MODEL AND

APPLICATION

INFORMATION

I.

Compressor Model Number Codes . . . . .10

II.

Condensing Unit Model Number Codes. .11

III.

Serial Label Information . . . . . . . . . . . . . .12

IV.

Basic Application Information for

Hermetic Compressors . . . . . . . . . . . . . .14

10

Chapter 2

I.

Compressor Mode Number Codes

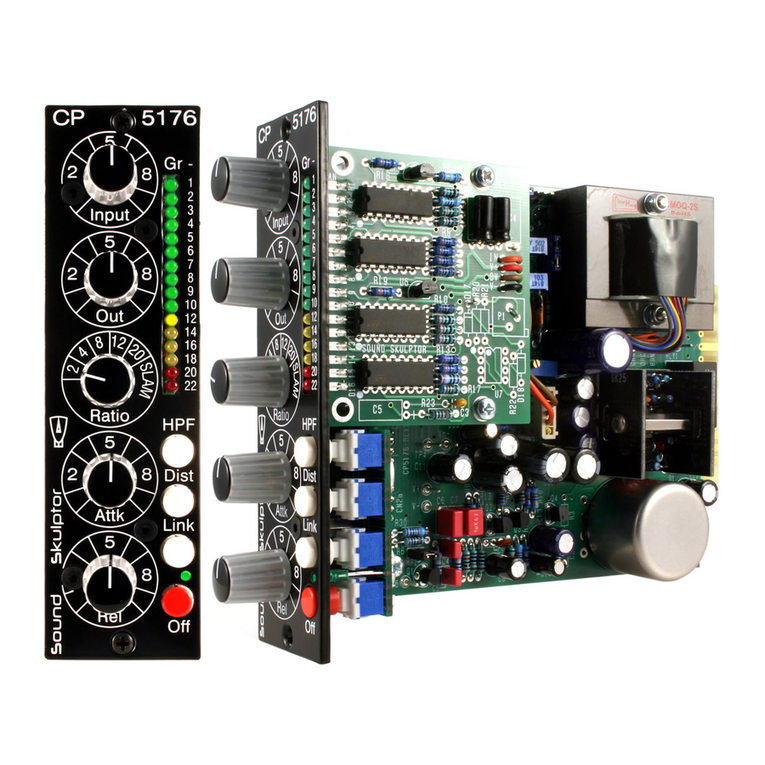

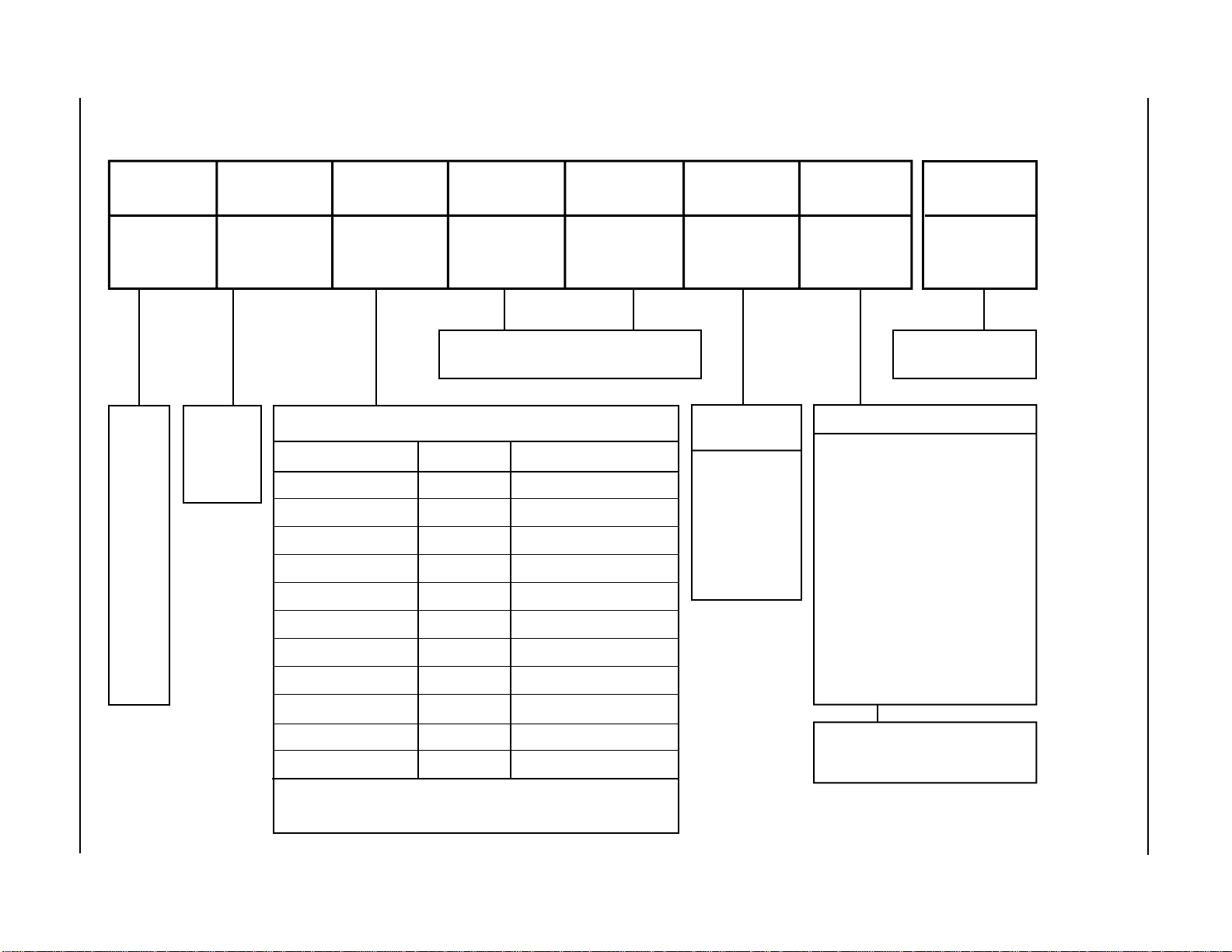

Figure 2-1.

Compressor model number codes.

AE XAA44 Y40

Compressor

Family

XC

Condensing

Units

Release

Variant

(Generation)

Number of

Digits In Rated

BTU Capacity

First Two

Digits of Rated

BTU Capacity

Application Refrigerant Voltage

AE

AG

AH

AJ

AK

AN

AV

AW

AZ

RG

RK

SA

SF

TP

A = 1st

B = 2nd

C = 3rd

Etc.

Primary Application Parameters

E ap. Temperature

1. Low

2. Low

3. High

4. High

5. Air Cond.*

6. Medium

7. Medium

8. Air Cond.

9. Commercial

0. Commercial

A. Medium/Low

*Application "5" compressors when applied to condensing

units become application "4" in the unit's model number.

Motor Starting Torque

Normal

High

Normal

High

Normal

Normal

High

Normal

High

Normal

Normal

Rating Pt.

-10°F

-10°F

+45°F

+45°F

+45°F

+20°F

+20°F

+49°F

+20°F

+20°F

+20°F

Primary

Refrigerants

A=R12

B=R410A

C=R407C

E=R22

J=R502

Y=R134a

Z=R404A/R507

XA=115-60-1; 100-50-1

XB=230-60-1; 200-50-1

XC=220-240-50-1

XD=208-230-60-1; 200-50-1

XF=208-230-60-3; 200-240-50-3

XG=460-60-3; 380-420-50-3

XH=575-60-3; 480-520-50-3

XN=208-230-60-1; 200-220-50-1

XP=220-60-1; 200-50-1

XT=200-230-60-3; 200-220-50-3

XU=100-60-1; 100-50-1

XV=265-60-1

AB=115-60-1; 90-50-1

Voltage Codes

See unit information

on next page.

In this example (4) total digits, with

the first two (40), or 4,000 BTU capacity.

Note: For explanations of

oltages not listed, contact

Tecumseh Products Company.

A LOOK AT SERVICE SAFETY

Mode and App ication Information

11

II.

Condensing Unit Mode Number Codes

Figure 2-2.

Condensing unit model number codes.

AEA4440YXA XC

A Standard Unit

B Std. Unit w/Recei er Tank

C Std. Unit w/Tank & BX Cable

D Std. Unit w/BX Cable

E,F,K Physical Design Variant (Conduit)

G,H,J,L,P Physical Design Variant (Standard)

M Ad anced Commercial Design

N Ad anced Commercial Design

S Customer Special

T Interconnect Compressor

U Water Cooled — Ad . Commercial Design

V Electrical Special (Conduit Design)

W Water Cooled Unit

X Interconnect Unit

Y Air Water Cooled Unit

Z Electrical Special (Standard Unit)

Unassigned Letters: R

The etters I, O and Q are e iminated

Fan Cooled

Water Cooled

Air Water Cooled

Recei er Tank

BX Cable

See B/M

Accumulator

Interconect

Compressor

1.

1. E=E aporati e Condensate Units. X=A holding character, reser ed for future use.

2. Condensing Unit Features, see chart below.

2.

12

Chapter 2

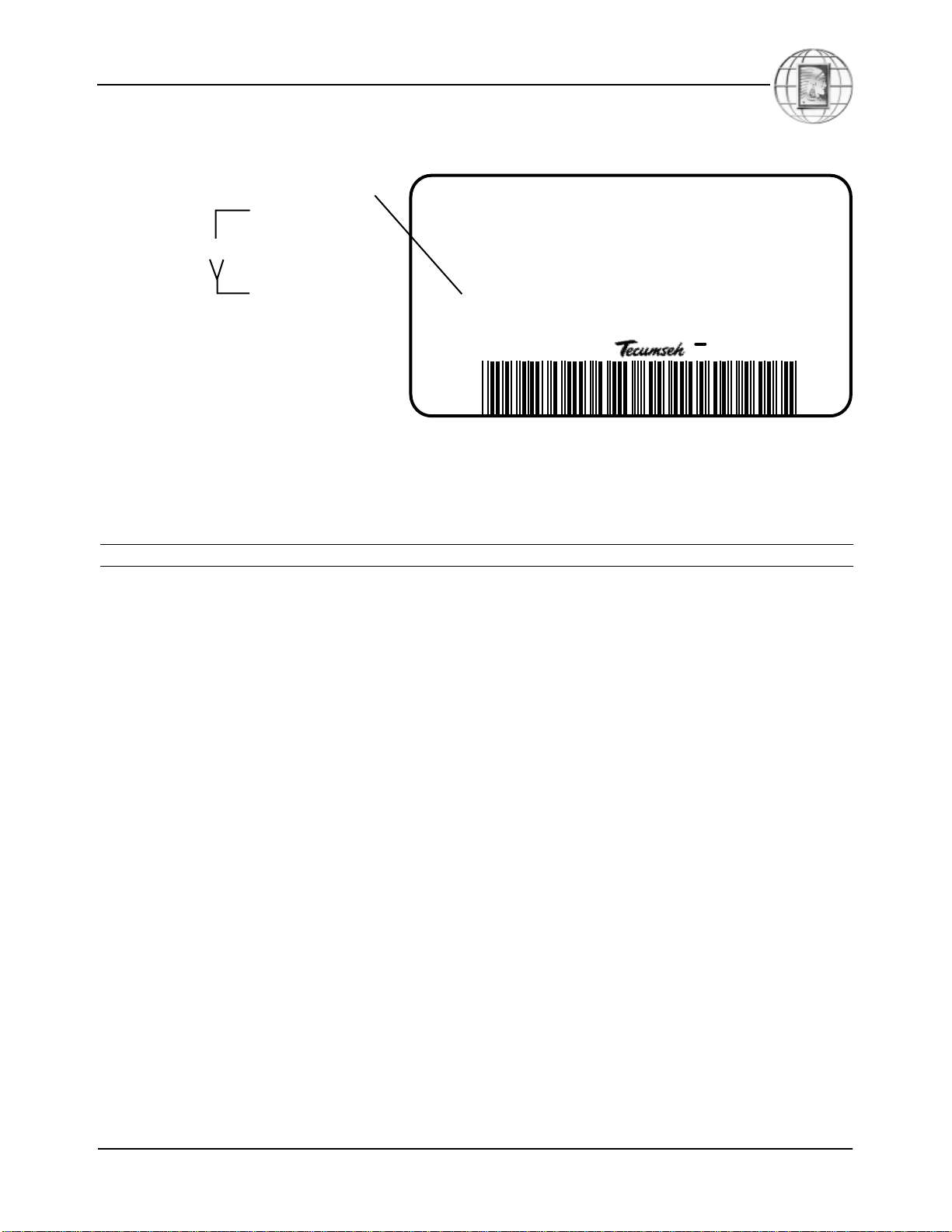

III.

Seria Labe Information

The only source for complete compressor informa-

tion is on the compressor serial label. On earlier

compressors, the serial plate is usually spotwelded

on the upper housing of the compressor. For current

compressors, the serial label is affixed in the same

location. Both describe the characteristics of the

compressor.

The months are identified as identified in Table 2-1.

Figure 2-3.

Compressor serial label.

AH301FT - 077

SE1490C

V230/208Hz60

V200 Hz50 PHI USA

LRA103.0

AH5540E

P

281254

Serial Number

Compressor

Model Number

Bill of Material Number

Phase

Electrical Rating

VOLTS - HERTZ

Second letter indicates month

(see Table 2-1), next 2 digits indicate

day of the month, following 2 digits

indicate year.

Figure 2-4.

Compressor serial plate.

A LOOK AT SERVICE SAFETY

Mode and App ication Information

13

HP.

1

Manufacturing Code Date

Month = September

Year = 2000

0J0

COMPRESSORS VOLTAGE EVAP.

RANGE (ºF)

THERMALLY

PROTECTED

L.R.A. E.A.

NO

FANS:

NO.

MAX.

FUSE OZ.

CHARGE

MAX. CKT. BKR.

(HACR. TYPE PER NEC.) REFRIG.

PROTECTED PH.

52594-1

HI SIDE LO SIDE

DESIGN PRESSURE P.S.I.

MIN. CIRCUIT

AMPACITY

F.L.A. E.A.

PH. 60 HZ 50 HZ

58.88.8

1

0J00066332

2C234-9

AKA9446EXAXC

1.4

20 R-22 444

12.4 350 150

1115 -10F TO +45F

35W

SER

EM

®

MOD

(1P) MADE IN USA

1THERMALLY

R.L.A. E.A.

P

The letter represents the month (see Table 2-1).

The numbers represent the year.

Figure 2-5.

Condensing unit serial label.

Tab e 2-1: Seria Labe Month Identifiers

January - A March - C May - E July - G September - J No ember - L

February - B April - D June - F August - H October - K December - M

14

Chapter 2

IV.

Basic App ication Information

for Hermetic Compressors

Tecumseh hermetic compressors are engineered to

do specific air conditioning and refrigeration tasks.

Hermetic compressors are designed for a particular

evaporator temperature range and a specific refriger-

ant.

A.

Evaporator Temperatures

The key specification is the evaporator temperature

of the system. Compressors which are operating out-

side their design evaporator temperature range can

be expected to have poor pumping efficiency and

experience motor problems.

Tecumseh hermetic compressors are designed for

one of the following evaporator temperature ranges

shown in Table 2-2.

B.

Refrigerant

Use only the serial label refrigerant when charging

the system. Using a different refrigerant can lead to

excess system pressure, damage to the compressor

and an explosion. For example, using R-502 in a

compressor designed for R-12 can lead to higher

operating pressures that can overload the bearings

and overwork the motor. Use of a refrigerant other

than the serial label refrigerant will void the com-

pressor warranty.

Tab e 2-2:

Evaporator Temperature Ranges

App ication Approved Evaporator

Temperatures

Air Conditioning +32ºF to +55ºF

Impro ed Performance Air Conditioning +32ºF to +57ºF

Heat Pump (Appro ed Models) -15ºF to +55ºF

High E aporator Temperature +20ºF to +55ºF

Medium E aporator Temperature -10ºF to +30ºF

Low E aporator Temperature

(Normal Torque Motor) -30ºF to +10ºF

Low E aporator Temperature

(High Torque Motor) -40ºF to +10ºF

Commercial 0ºF to +50ºF

A LOOK AT SERVICE SAFETY

Compressor Motor and Component Information

15

2

3

COMPRESSOR MOTOR

AND COMPONENT

INFORMATION

I. Single Phase Compressor Motor Types . 16

II. PSC Motor Starting . . . . . . . . . . . . . . . . . 18

III. Hermetic Compressor Thermal

Protectors . . . . . . . . . . . . . . . . . . . . . . . . 19

IV. Compressor Motor Starting Relays. . . . . 27

V. Selecting Capacitors . . . . . . . . . . . . . . . . 32

VI. Identification of Terminal Pins. . . . . . . . . 34

VII. Fuse and Circuit Breaker Sizing . . . . . . . 36

16

Chapter 3

I. Sing e Phase Compressor

Motor Types

Tecumseh hermetic compressors contain motors

designed for specific requirements of starting torque

and running efficiency. There are four general types

of single phase motors, each distinctly different from

the others. Each type of motor may have two to four

different configurations depending on the compres-

sor components.

A. Resistance Start—Induction Run (RSIR)

This motor, also known as a split-phase motor, is

used on many small hermetic compressors up

through 1/3 HP. The motor has low starting torque

and must be applied to completely self-equalizing

capillary tube systems such as household refrigera-

tors, freezers, small water coolers, and dehumidifi-

ers. This motor has a high resistance start winding

which is not designed to remain in the circuit after

the motor has come up to speed. A relay is necessary

to perform the function of disconnecting the start

winding as the motor comes up to design speed.

Three types of relays are used with this motor:

•a current relay,

•a wired-in Positive Temperature Coefficient

(PTC) relay, or

•a module Positive Temperature Coefficient

(PTC).

B. Capacitor Start—Induction Run (CSIR)

The CSIR motor is similar to RSIR except a start

capacitor is included in series with start winding to

produce a higher starting torque. This is commonly

used on commercial refrigeration systems through

3/4 HP. Two types of relays are used with this

motor:

•a current relay, or

•a potential relay.

Figure 3-1.

RSIR motor diagram with current relay.

Line 1

Line 2

Ground

Control

Relay - Current

External Thermal

Protector

Start Winding

Main Winding

Compressor - Unit

Ground

C

S

R

Figure 3-2.

RSIR motor diagram with wired-in

PTC relay.

4 T M Thermal Protector

Identified Conductor

(115 Volt Only - Neutral)

Line 1

Line 2

Ground

Start Winding

Main Winding

PTC Relay

Compressor - Unit

Ground

Alt. 3/4" Thermal Protector

Control

C

S

R

Figure 3-3.

CSIR motor diagram.

Line 1

Line 2

Ground

Control

Relay - Current

External Thermal

Protector

Start Winding

Main Winding

Compressor - Unit

Ground

S

R

C

A LOOK AT SERVICE SAFETY

Compressor Motor and Component Information

17

C. Capacitor Start and Run (CSR)

This motor arrangement uses a start capacitor and a

run capacitor in parallel with each other and in

series with the motor start winding. This motor has

high starting torque, runs efficiently, and is used on

many refrigeration and air conditioning applications

through 5 HP. A potential relay removes the start

capacitor from the circuit after the motor is up to

speed. This motor may use either:

•an external thermal protector, or

•an internal thermal protector.

D. Permanent Sp it Capacitor (PSC)

Here a run capacitor is in series with the start wind-

ing. Both run capacitor and start winding remain in

the circuit during start and after motor is up to

speed. This normal starting torque motor is suffi-

cient for capillary and other self-equalizing systems.

No start capacitor or relay is necessary. For addi-

tional starting torque, a proper start assist kit may be

added (see Figure 3-6). Some start assist kits may

include:

•a wired-in Positive Temperature Coefficient

(PTC) relay, or

•a module Positive Temperature Coefficient

(PTC) relay.

This motor may use either:

•an external thermal protector, or

•an internal thermal protector.

PSC motors are basically air conditioning compres-

sor motors and are very common up through 5 HP.

Figure 3-4.

CSR motor diagram.

Relay -

Potential

Compressor -

Unit Ground

Line 1

Line 2

Ground

Start Winding

Main Winding

Control

External or Internal

Thermal Protector

C

S

R

Figure 3-5.

PSC motor diagram.

Compressor -

Unit Ground

External or Internal

Thermal Protector

Run Capacitor

Line 1

Line 2

Ground

Start Winding

Main Winding

Control C

S

R

Figure 3-6.

PSC motor diagram with start assist kit

that includes a module PTC relay.

Line 1

Line 2

Ground

Compressor -

Unit Ground

PTC

Relay

Plug-In

Run Capacitor

PTC Starting and

Protector Package

Thermal Protector

Start Winding

Main Winding

C

C

C2

C1

N

S

R

18

Chapter 3

II. PSC Motor Starting

Tecumseh Products Company has pioneered in

encouraging the development of Permanent Split

Capacitor compressor motors. This type of motor

eliminates the need for potentially troublesome and

costly extra electrical components (start capacitors

and potential motor starting relays). (See Figure

Figure 3-7.)

To fully realize the capabilities of this simplified type

of compressor motor, it is necessary to understand

its starting and operating characteristics and the

field conditions which can affect it.

The following conditions affect PSC motor starting:

•Low voltage: Reduces motor starting and run-

ning torque. A 10% voltage drop reduces a

motor’s starting ability by 19%. Low voltage

can cause no start, hard start, light flicker, and

TV screen flip flop.

Minimum starting voltage for the compressor

when it is attempting to start (locked rotor) is:

•Unequalized system pressure: Head and suc-

tion pressures must be equal and not more than

170 psig. Refrigeration metering device (cap

tube or TX valve) should equalize system pres-

sures within 3 minutes. Unequal system pres-

sure may be caused by excessive refrigerant

charge, short cycling thermostat, or system

restriction.

•Circuit breaker or fuse trips: Branch circuit

fuses or circuit breakers sized too small will

cause nuisance tripping (see “Fuse and Circuit

Breaker Sizing” on page 36). If the fuse or cir-

cuit breaker trips, see “Identifying Compressor

Electrical Problems” on page 47 for electrical

troubleshooting techniques.

•Electrical components: A failed run capacitor

will not allow the compressor to start, and it

will trip the thermal protector. See “Identifying

Compressor Electrical Problems” on page 47

for electrical troubleshooting techniques.

Figure 3-7.

Circuit diagram for PSC compressors.

Compressor -

Unit Ground

External or Internal

Thermal Protector

Run Capacitor

Line 1

Line 2

Ground

Start Winding

Main Winding

Control C

S

R

Tab e 3-7: Minimum Starting Vo tage

Seria Labe Vo tage Min. Vo tage for Start

115 103

208 188

230 207

230/208 198

265 239

A LOOK AT SERVICE SAFETY

Compressor Motor and Component Information

19

III. Hermetic Compressor Therma

Protectors

Hermetic compressor motors are protected from

overheating by thermal protectors built into or

mounted in contact with the compressor motor. See

the Electrical Service Parts Guide Book for correct

replacement thermal protectors. Typical wiring dia-

grams are shown on pages 51 to 82.

The thermal protector device (see Figure 3-8), when

firmly attached to the compressor housing, quickly

senses any unusual temperature rise or excess current

draw. The bi-metal disc within the thermal protec-

tor (see Figure 3-9) reacts to either excess tempera-

ture and/or excess current draw by flexing

downward, and disconnecting the compressor from

the power source.

Figure 3-8.

External thermal protector. (Models AE,

TP, TH, AK, AJ, CAJ, AZ, RK, RG, TW,

and some CL.)

Figure 3-9.

Bi-metal disc.

Open Closed

Figure 3-10.

AE refrigeration compressor

showing (1) hermetic terminal,

(2) thermal protector, (3) thermal

protector clip, (4) push-on relay,

(5) protecti e terminal co er, and

(6) bale strap.

Figure 3-11.

AE refrigeration compressor with

the thermal protector and relay

assembled.

20

Chapter 3

A. Interna Therma Protectors

Internal thermal protectors are completely internal

and tamper-proof.They cannot be by-passed.

Sing e Phase Motor Therma Protectors

Internal thermal protectors detect excess heat and/or

current draw. They are located in the following sin-

gle phase motors: AB, AW, AH, AV, and AG.

3-Phase Motor Therma Protectors

The 31HM and 32HM on-winding motor protec-

tors are 3-phase line break, automatic reset devices

wired in series with each phase at the neutral point

and mounted on the windings. They are used in AB,

AG, AV, and AN models.

Tab e 3-2: Facts About Therma Protectors

Externa Line-Break Therma

Protectors

•Currently used on all AE, AK, AZ, RK, and AJ models

•Sense motor current and housing temperature or combination

thereof

•Break line current when tripped

•Generally do not protect against loss of charge

•When, by design, no air flow passes o er housing, a special

“static” thermal protector must be used

•Are designed for specific compressors and their intended

application. Make no substitutions

•Will not protect motor if compressor is operated outside its

e aporator temperature range

Interna Line-Break Therma

Protectors

•Currently used on all AH, AB, AV, AG, AW, and most AN and SF

models

•Sense motor current and motor winding temperature or

combination thereof

•Break line current when tripped

•Generally protect against loss of charge

•Will not protect motor if compressor is operated outside its

e aporator temperature range

•Not repairable or replaceable

Line Vo tage-E ectronic Protection

Modu e

(NOTE: For more specific details

consult the authorized wholesaler.)

•Currently used on some AN and SF models

•Employs use of solid state temperature sensors in motor

windings and compressor discharge muffler

•Sensor resistance alues change with temperature ariations

•Module will interrupt power to the contactor coil when resistance

alues of sensors exceed the specified range. This power

interruption thus stops the compressor motor

•Module pro ides protection against:

•Abnormal locked rotor conditions

•Loss of refrigerant

•High compressor discharge temperatures

•Excessi e current conditions

•Time delays of 3 to 5 minutes occur on power interruption or

sensor trip

Table of contents

Other Tecumseh Compressor manuals