TeeJet 844-AB User manual

844-AB Sprayer control 1

Software 4.03

Chapter 1 – Introduction

This User Guide provides information for

software version 4.03.

Make sure that all hardware components are

properly installed and tested. Before starting

the programming process, confirm that the

console and all sensors are working properly.

IMPORTANT!

Before beginning, review the following

Program Guidelines that control the

programming process.

To exit any Setup Mode, press and hold the

Program key for 3 seconds. The inputs are

stored and the computer will exit Program

Mode.

To increase the value of a programmable

digit, press the Plus key. To decrease the

value, press the Minus key. These keys are

located directly to the right of the display. For

some program steps, press and hold the Plus

and Minus keys to quickly change the values.

Press the Plus and Minus keys once to

increment/decrement the values by one

unit.

Press and hold the Plus and Minus keys

simultaneously to reset the value to “0” or

begin automatic calibration.

Press the Program key to advance the system

to the next program step. After the final

program step is complete, the console will

finish the programming loop and return to the

initial programming step.

System Setup mode contains the options that

customize the controller to the sprayer or

sprayer components. These include

calibration steps and parameters that seldom

change once programmed.

Application Setup mode contains settings that

are frequently changed (tip spacing, number

of tips per boom section, density, nozzles

used, and target application rate).

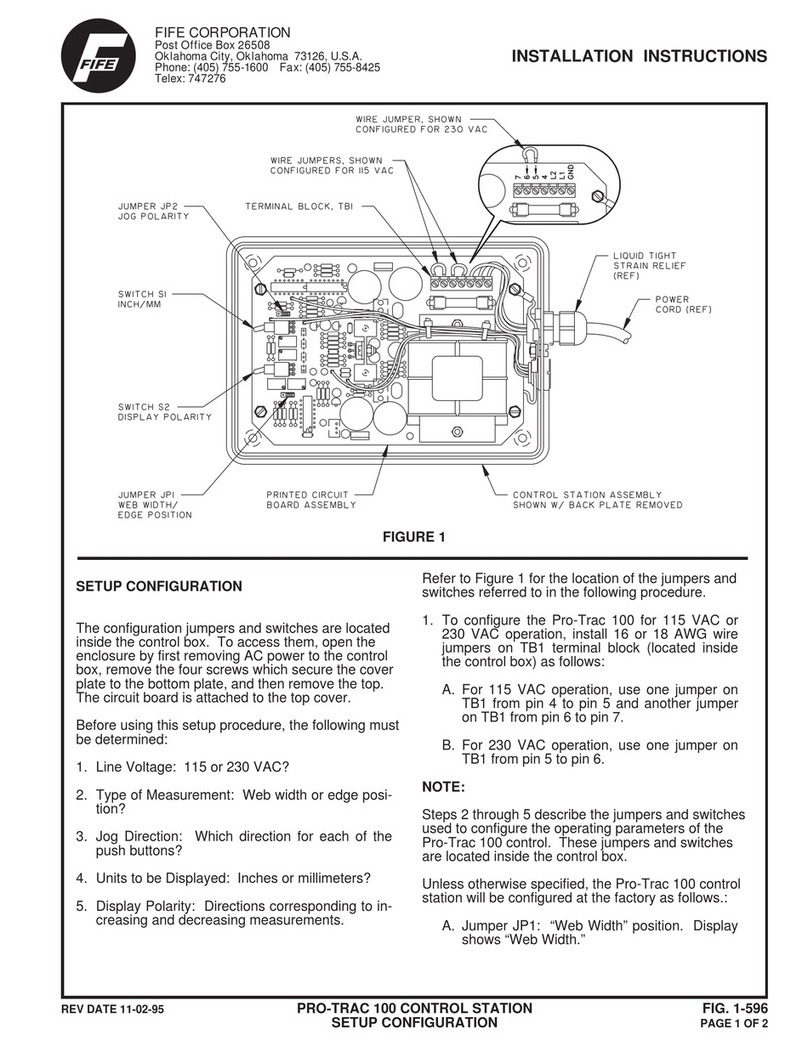

Figure 1-1: 844-AB Console

Power On the Console

The 844-AB console can be powered on by

pressing the Program key one time. The

console will initially display the software

version at the top of the screen and the serial

number of the console at the bottom of the

screen. After approximately 5 seconds, the

console will enter into swath width view.

Press the Program key to advance to normal

Operations mode.

Figure 1-2: Power On the Console

4.03

4.03 4.03

4.03

ABL

ABL ABL

ABL

999

999 999

999

5555

55555555

5555

1 2 3 4 5 6 7 8 9 10

11

12

844-AB Sprayer control 2

Software 4.03

Power Off the Console

To power off the 844-AB console, press and

release the Minus and Program keys

simultaneously.

The console will save new information (area

and volume counters) to memory before it

powers down.

“Off” will be displayed on the console, followed

by a 5-second countdown, indicating the

console is about to power down. The console

also has an automatic power down feature.

This is described in further detail

in the Feat ures section of this User Guide.

Figure 1-3: Power Off the Console

OFF

OFFOFF

OFF

5

55

5

1 2 3 4 5 6 7 8 9 10

11

12

844-AB Sprayer control 3

Software 4.03

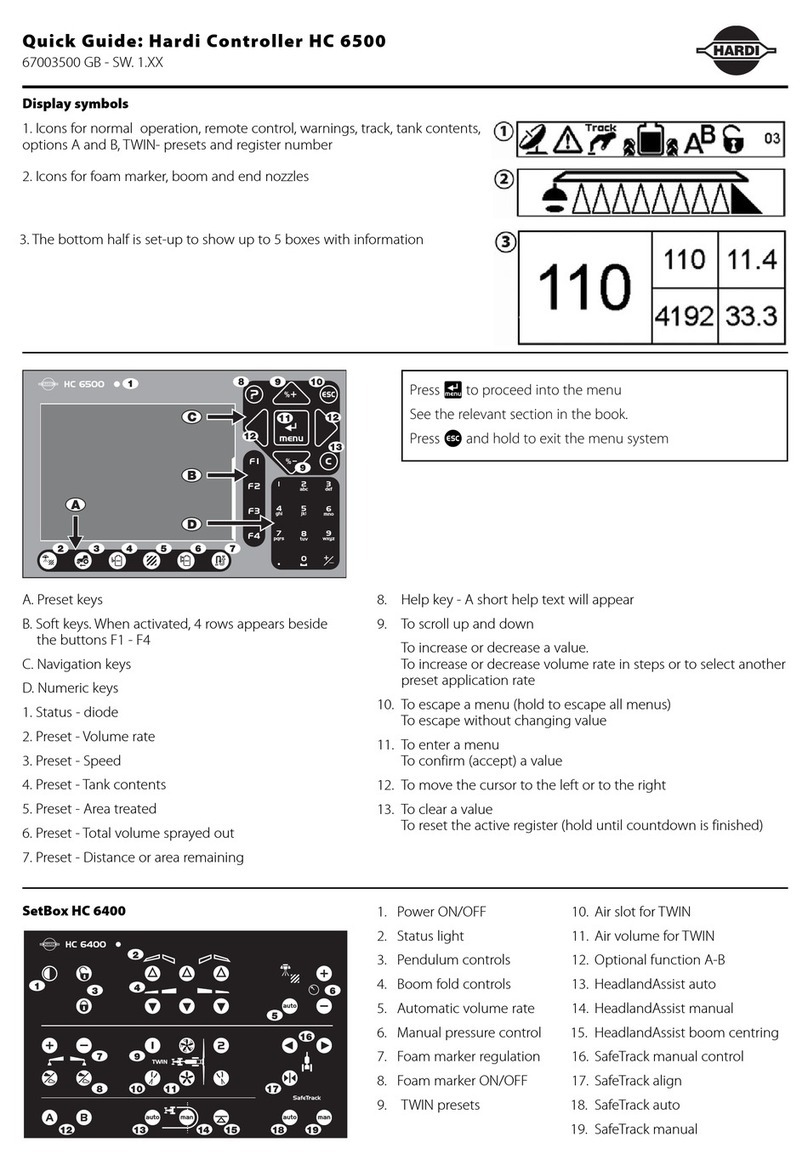

Chapter 2 – Application mode

The 844-AB gives the possibility of working in

two different ways to fit the application.

Therefore, the console should be set up and

consequent programming and working

features will be dependant of the chosen

mode.

Airblast mode

This mode is designed to work with Airblast

sprayers, mostly spraying on two sides (Left

and Right) with the possibility to switch on or

off sections in the height.

The working width is defined by the distance

between two rows of trees.

This mode is called AB (airblast).

Figure 2-1: Airblast (AB) principle

Vineyard mode

This mode is designed to work with vineyard

sprayers that are spraying horizontally.

Several rows are covered and sections can be

switched on or off to adapt the working width.

Each section covers a number of faces.

The working width is defined by the number of

faces and the row width.

One or more nozzles can be spraying each

face. If all nozzles spraying on a face are not

equal, they should be considered as a unique

nozzle and the total flow has to be set up in

the configuration menu.

But all faces have to be sprayed equally.

This mode is called HC (airblast).

Figure 2-2: Airblast (AB) principle

844-AB Sprayer control 4

Software 4.03

Chapter 3 - OEM Setup

OEM Setup mode contains the options that

customize the controller to the sprayer or

sprayer components.

These include calibration steps and

parameters that will never change once

programmed.

To enter System Setup mode, power off the

console. Press and hold the Plus and Minus

keys simultaneously. While holding the Plus

and Minus keys, also press the Program key

four times (within 3 seconds) and then

release all keys to enter OEM Setup mode.

Press and hold the Program key for three

seconds to exit OEM Setup mode. Changes

will be saved to the console’s memory.

Application type

As explained above, the 844-AB is capable of

working in either Airblast (AB) or Vineyard

(HC) mode.

Use the Plus and Minus keys to switch from

AB to HC mode.

Press the Program key to accept the value

and advance to the next program step.

Figure 3-1: Application Type Selection

AB

ABAB

AB

typ

typtyp

typ

1 2 3 4 5 6 7 8 9 10

11

12

Number of sections

This will determine the maximum number of

sections available on the sprayer.

In AB mode, only even values are allowed

(2,4,6).

In HC mode, all values between 1 and 7 are

allowed.

Figure 3-2: Number of Sections

4

44

4

nr

nrnr

nr

sec

secsec

sec

1 2 3 4 5 6 7 8 9 10

11

12

Minimum voltage

This will determine the minimum voltage that

can be applied to the regulation valve.

If too low, the valve won’t fine tune the dose

rate. If too high, the valve could have some

unstable regulation.

Figure 3-3: Minimum voltage

3.5

3.53.5

3.5

min

minmin

min

volt

voltvolt

volt

1 2 3 4 5 6 7 8 9 10

11

12

844-AB Sprayer control 5

Software 4.03

Dead Band

This will determine the regulation dead band.

This setting will avoid continuous regulation

when the dose rate is very close to the target

doise rate.

If too low, the valve could have some

unstable regulation. If too high, the real dose

rate could be far away from the target.

Figure 3-4: Dead band

1

11

1

.5

.5.5

.5

STp

STpSTp

STp

bnd

bndbnd

bnd

1 2 3 4 5 6 7 8 9 10

11

12

Rotation speed

This will determine the time needed by the

regulation valve to travel at maximum speed

from fully close to fully open.

Lowering this value will make the regulation

slower. Increasing this value will make the

regulation faster.

Figure 3-5: Rotation speed

6

66

6

rot

rotrot

rot

spd

spdspd

spd

sec

secsec

sec

1 2 3 4 5 6 7 8 9 10

11

12

Display stable

This will determine allowed tolerance on the

displayed dose rate. If the difference between

the real and the target dose rates is smaller

than it, the target will be displayed.

Figure 3-6: Display stable

5

55

5

dsp

dspdsp

dsp

stbl

stblstbl

stbl

1 2 3 4 5 6 7 8 9 10

11

12

Total area

This counter is a hidden counter that can be

reset only by the manufacturer.

It shows the total area covered since last

reset.

Figure 3-7: Total area

tot

tottot

tot

134

134134

134

1 2 3 4 5 6 7 8 9 10

11

12

Ha

844-AB Sprayer control 6

Software 4.03

Maximum speed

This counter is a hidden counter that can be

reset only by the manufacturer.

It shows the maximum speed reached by the

sprayer.

Figure 3-8: Maximum speed

5.

5.5.

5.

high

highhigh

high

1 2 3 4 5 6 7 8 9 10

11

12

Km/h

Memory option

This feature enables the user counters.

Select NO to disable this feature or YES to

enable it.

Figure 3-9: Memory option

NO

NONO

NO

mem

memmem

mem

1 2 3 4 5 6 7 8 9 10

11

12

Tank content

This features enables a tank content counter.

This counter should be set after filling the tank

and will count down according to the sprayed

volume. A zero value will disable this feature.

Figure 3-10: Tank content

|=

|=|=

|=

=

==

=

|

||

|

0

00

0

1 2 3 4 5 6 7 8 9 10

11

12

844-AB Sprayer control 7

Software 4.03

Chapter 4 - System Setup

For AB and HC MODE

System Setup mode contains the options that

customize the controller to the sprayer or

sprayer components.

These include calibration steps and

parameters that will rarely change once

programmed.

To enter System Setup mode, press and hold

the Plus and Minus keys simultaneously.

While

holding the Plus and Minus keys, also press

the Program key twice (within 3 seconds) and

then release all keys to enter System Setup

mode.

Press and hold the Program key for three

seconds to exit System Setup mode. Changes

will be saved to the console’s memory.

Units of Measurement

The 844-AB is capable of working in either

US, SI (Standard International metric) or SI -

l/100 m units. Use the Plus and Minus keys to

switch units.

Press the Program key to accept the value

and advance to the next program step.

Figure 4-1: Units of Measurement Selection

SI

SISI

SI

1 2 3 4 5 6 7 8 9 10

11

12

P

RO

Figure 4-2: Units of Measurement

Reset to Default

If units of measurement changes were made,

the console will display a message asking if

program parameters should be reset to default

before advancing to the next screen. Use the

Plus or Minus keys to select either “Yes” or

“No” on the screen. Press the

Program key to accept the value and advance

to the next program step.

Note:

If changes were not made to Units of

Measurement, this step will be skipped and

the screen will advance to Sensor

Selection.

Figure 4-3: Reset to Default US

yes

yesyes

yes

res

resres

res

def

defdef

def

1 2 3 4 5 6 7 8 9 10

11

12

844-AB Sprayer control 8

Software 4.03

Sensor Selection

The 844-AB can accommodate a flow meter,

pressure transducer, or both. Sensor

Selection instructs the console which sensor is

being used on the sprayer.

The default value is “FLO” (flow-based

system)

using a flow meter. To maintain this setting,

press the Program key to advance to Flow

Meter Pulses.

To change the setting to “PRS” (pressure

based system), use the Plus or Minus keys to

select “PRS” . Press the Program key to

advance to Flow Meter Pulses.

NOTE:

Pressure-based regulation is used only

with linear tips. For non-linear tips,

ALWAYS select flowbased regulation. Most

tips are linear and may be used with

pressure-based regulation. ConeJet

tips are non-linear.

If both sensors have been installed on the

sprayer, this step will determine which sensor

will be used.

If “FLO” is selected, the flow meter will be

used to control flow and the pressure

transducer will be used only to display actual

pressure. If “PRS” is selected, the pressure

transducer will be used to control flow and

display the actual pressure. Flow meter

signals will be ignored.

The regulation mode determines the following

program steps. If “FLO ” is selected, the next

Setup Mode screen displayed will be the

calibration step for the flow sensor (refer to

Flow Meter Pulses). If “PRS” is selected, the

next Setup Mode screen displayed will be the

calibration step for the pressure transducer

(flow sensor calibration will be skipped).

Figure 4-4: Sensor Selection

FLO

FLOFLO

FLO

1 2 3 4 5 6 7 8 9 10

11

12

P

RO

Flow Meter Pulses

During the Flow Meter Pulses step, the

symbol (flow meter turbine) will flash at the top

of the console. The flow meter calibration

number can be entered manually from the

factory-calibrated flow meter pulse rate tag, or

an Auto Calibration procedure can be

activated to determine flow meter pulses

based on a known volume of fluid.

Figure 4-5: Flow Meter Pulses

650

650650

650

1 2 3 4 5 6 7 8 9 10

11

12

P

RO

Manual Entry

Locate the factory-calibrated flow meter pulse

rate tag on the flow meter. If this varies from

the default value (it usually does) of the

console, use the Plus or Minus keys to modify

the value.

In some cases, larger flow meters with small

calibration numbers will include decimals for

greater accuracy. To add a decimal to the

calibration number, press the Auto/Man key.

844-AB Sprayer control 9

Software 4.03

Automatic Calibration

To complete an automatic calibration of the

flow meter, press the Plus and Minus keys

simultaneously. This will clear the existing

value and initiate the calibration procedure.

“CAL” will be displayed in the screen. This

indicates that the controller is ready to

begin the calibration process.

Figure 4-6: Calibration Procedure

CAL

CALCAL

CAL

0

00

0

1 2 3 4 5 6 7 8 9 10

11

12

P

RO

Engage the sprayer pump. Turn the boom

sections “On” and begin spraying a known

volume of fluid (e.g. 100 gallons/400 liters). As

the known amount is sprayed, the console will

count the pulses. After the known volume has

been sprayed, turn the Master Switch “Off” to

stop counting pulses.

Figure 4-7: Calibration Procedure (Continued)

cal

calcal

cal

3

33

3

777

777777

777

1 2 3 4 5 6 7 8 9 10

11

12

P

RO

Press the Program key. The console will ask

for the volume that was sprayed. Use the Plus

or Minus keys to adjust the value to match the

volume sprayed in gallons (liters).

Figure 4-8: Calibration Procedure (Continued)

vol

volvol

vol

378

378378

378

1 2 3 4 5 6 7 8 9 10

11

12

P

RO

Press the Program key to return to the Setup

mode. The new flow meter calibration number

will be displayed. To accept the value

displayed, press the Program key again. To

repeat the calibration procedure, repeat the

previous steps.

Figure 4-9: Calibration Procedure (Continued)

615

615615

615

1 2 3 4 5 6 7 8 9 10

11

12

P

RO

Pressure Transducer Low Pressure

Calibration (P Ref)

The Pressure Transducer Low Pressure

Calibration step is used to calibrate the “0”

pressure setting of the

pressure transducer. The pressure transducer

used with the 844-AB uses a 4-20 mA reading

(4.0 mA represents 0 pressure).

844-AB Sprayer control 10

Software 4.03

Figure 4-10: Pressure Transducer Low

Pressure Calibration

4.0

4.04.0

4.0

p

pp

p

ref

refref

ref

1 2 3 4 5 6 7 8 9 10

11

12

P

RO

Make sure the sprayer pump is turned “Off”

and there is no pressure in the system. Press

and release the Plus and Minus keys

simultaneously to activate the auto-calibration

feature. The message “ME S” will be

displayed. A count of “0” through “9” will

appear on the lower right portion of the

screen.

Figure 4-11: Pressure Transducer Low

Pressure Calibration (Continued)

3.9

3.93.9

3.9

160

160160

160

mes

mesmes

mes

9

99

9

1 2 3 4 5 6 7 8 9 10

11

12

P

RO

Once the display finishes counting, a number

close to 4.0 (+/- 0.2) should be displayed. The

low pressure value of the transducer is

calibrated. Press the Program key to advance

to the next step.

Figure 4-12: Pressure Transducer Low

Pressure Calibration (Continued)

3.9

3.93.9

3.9

p

pp

p

ref

refref

ref

1 2 3 4 5 6 7 8 9 10

11

12

P

RO

NOTE:

If a pressure transducer is not installed on

the system, skip this step by pressing the

Program key. Leave the default value at

“4.0”.

Pressure Transducer Maximum Rating

(P HI)

The Pressure Transducer Maximum Rating

establishes the maximum rating of the

pressure transducer. This number can be

found stamped on the pressure transducer. If

the transducer has a maximum rating of 145

psi (10 bar in SI mode) and the number is

shown on the display, advance to the next

step by pressing the Program key. If the

maximum rating is 363 psi

(25 bar in SI mode), use the Plus or Minus

keys to change the value. Press the Program

key to advance to the next step.

Figure 4-13: Pressure Transducer Maximum

Rating

145

145145

145

p

pp

p

hi

hihi

hi

9

99

9

1 2 3 4 5 6 7 8 9 10

11

12

P

RO

844-AB Sprayer control 11

Software 4.03

NOTE:

If a pressure transducer is not installed on

the system, skip this step by pressing the

Program key. Leave the default value at

“145 PSI/10 Bar”.

Speed Sensor Calibration

NOTE:

During Speed Calibration, the 844-AB will

automatically sense whether a Wheel

Speed or Radar Speed Sensor is being

used.

Proximity/Magnetic Pulses

The speed sensor must be calibrated in order

to provide the proper speed and area

readings. The value is determined by the

number of pulses generated by the speed

sensor in 300 feet (100 meters), or by

manually entering the number.

Figure 4-14: Proximity/Magnet Pulses

50

5050

50

1 2 3 4 5 6 7 8 9 10

11

12

P

RO

Automatic Calibration:

To automatically calibrate the speed sensor,

mark a distance of exactly 300 feet (100

meters). Press the Plus and Minus keys

simultaneously to clear the contents of the

display and activate auto calibration mode.

“CAL” will be displayed on the lower right

of the screen.

Figure 4-15: Speed Sensor Automatic

Calibration

cal

calcal

cal

1 2 3 4 5 6 7 8 9 10

11

12

P

RO

Drive toward the initial point of the of

designated 300 feet (100 meters). At the

starting location, press the Plus key once to

begin the calibration process. Continue driving

the course. The 844-AB will count the pulses

as the sprayer moves. The speed at which the

vehicle travels is not important. As the ending

point is reached, press the Plus key again.

The console will display the speed calibration

number.

NOTES:

The auto speed calibration process should

take place in a field-like environment with

the sprayer tank at least half full.

It is recommended to repeat the automatic

speed calibration process at least twice

and use an average of the speed

calibration numbers.

Figure 4-16: Speed Sensor Automatic

Calibration (Continued)

157

157157

157

1 2 3 4 5 6 7 8 9 10

11

12

P

RO

cal

calcal

cal

844-AB Sprayer control 12

Software 4.03

NOTE:

Once the automatic speed calibration

process has been activated, no other

functions will operate until the console

receives speed pulses for calibration. To

deactivate automatic calibration mode,

press the Plus key twice.

During the automatic calibration process,

the 844-AB will automatically sense

whether a proximity/magnetic or radar

ground speed sensor is installed. If a

manual entry is preferred, refer to MANUAL

CALCULATION.

Manual Calculation:

To manually calculate the proper value for

Wheel Speed Sensor pulses, the

circumference of the wheel to which the

sensor is mounted must be known. It can be

measured by marking the tire and measuring

the distance covered as the mark makes one

full revolution. Once the number is known, use

the following formula:

The result can be entered instead of using the

automatic calibration method. Use the Plus or

Minus keys to adjust the value. Press the

Program key to save the value and advance to

the next program step.

Radar Speed Pulses

AUTOMATIC CALIBRATION:

To automatically calibrate the radar speed

sensor, mark a distance of exactly 300 feet

(100 meters). Press the Plus and Minus keys

simultaneously to clear the contents of the

display and to activate auto calibration mode.

Once auto calibration mode is activated,

“RAD” will be displayed on the lower left of the

screen.

Figure 4-17: Radar Speed Sensor Automatic

Calibration

rad

radrad

rad

118

118118

118

1 2 3 4 5 6 7 8 9 10

11

12

P

RO

cal

calcal

cal

Drive toward the initial point of the of

designated 300 feet (100 meters). At the

starting location, press the Plus key once to

begin the calibration process.

Continue driving the course. The 844-AB will

count the pulses as the sprayer moves. The

speed at which the vehicle travels is not

important. As the ending point is reached,

press the Plus key again. The console will

display the radar speed calibration number.

NOTES:

The radar speed calibration process

should take place in a field-like

environment with the sprayer tank at least

half full.

It is recommended to repeat the radar

speed calibration process at least twice

and use an average of the speed

calibration numbers.

MANUAL CALCULATION:

It is not possible to manually calculate the

calibration value of a radar. However, the

value can be entered manually if it is known

from a prior calibration. To manually enter the

radar calibration value, press the Auto/Man

key to enter Radar mode. Once radar

calibration mode is activated, “RAD” will be

displayed on the lower left of the screen. Use

the Plus or Minus keys to adjust the value.

Press the Program key to save the value and

advance to the next program step.

844-AB Sprayer control 13

Software 4.03

Simulated Ground Speed

Simulated ground speed allows the console

and sprayer to be tested (and actually spray

water) without physically moving the sprayer.

This can and should be tested prior to any

spraying activity.

The 844-AB has a low and high simulated

ground speed. This allows the operator to

switch between the two to simulate a speed

change and ensure the console is regulating

properly during the sprayer checkout.

Figure 4-18: Simulated Ground Speed

spd

spdspd

spd

sim

simsim

sim

6.0

6.0 6.0

6.0

lo

lolo

lo

1 2 3 4 5 6 7 8 9 10

11

12

P

RO

spd

spdspd

spd

sim

simsim

sim

6.0

6.0 6.0

6.0

high

highhigh

high

1

2

3

4

5 6 7 8 9

10

11

12

P

RO

To enter simulated speeds, determine

whether the low or high simulated speed is

displayed on the console. Change from low to

high by pressing the Auto/ Man key. Use the

Plus or Minus keys to adjust the values. Press

the Auto/Man key to switch to the other setting

(either low or high) and adjust the value with

the Plus or Minus keys. Once both values are

entered, press the Program key to advance to

the next step.

The console will display the simulated speed

upon exiting System Setup mode. The

simulated speed will remain on the Operation

mode display until the console receives actual

speed pulses. While in Operation mode, with

the Master Switch in the “On” position, press

the Program and Minus keys for low simulated

speed; press the Program and Plus keys for

high simulated speed.

NOTE:

The simulated speed feature will be

deactivated once the sprayer begins

moving and the 844-AB receives actual

speed pulses. If a radar speed sensor is

being used, disconnect the radar

connection from the main console. Any

movement can disable the simulated

speed test due to the sensitivity of the

speed sensor.

844-AB Sprayer control 14

Software 4.03

Reference Flow Rate Per Section

AB MODE

The flow rate for each section of the sprayer

must be input into the 844-AB console so that

the necessary adjustments can be made

when boom sections are shut off. The console

is programmed to treat the left and right boom

sections as symmetrical; therefore the console

treats the flow rate for the lower left section

(L1) identically to the flow rate of the lower

right section (R1). The flow rate entered for

level 1 will serve as reference flow for L1

and/or R1.

Figure 4-19: AB Flow Rate Illustration

HC MODE

The flow rate for a single nozzle must be input

into the 844-AB console so that the necessary

adjustments can be made when boom

sections are shut off. If several different

nozzles are mounted to spray on a face, they

should be considered as ONE nozzle and the

total flow should be programmed.

Figure 4-20: HC Flow Rate Illustration

844-AB Sprayer control 15

Software 4.03

Up to twelve preset flow configurations can be

entered into the 844-AB. The presets are

represented by the numbers “1-12” at the

bottom of the display. The arrow symbol

indicates which preset is being programmed.

Select which preset flow configuration to

program. Use the Plus or Minus keys to toggle

through the twelve presets. Press the

Auto/Man key to enter into the selected

preset.

Figure 4-21: Preset Selection

SEL

SELSEL

SEL

conf

confconf

conf

1

2

3

4

5 6 7 8 9

10

11

12

P

RO

Press the Program key to advance to the next

program step in System Setup mode. It is not

necessary to program all twelve presets

unless they are to be used. Program the

number of presets required. Press the

Program key again to continue in System

Setup mode.

Reference Pressure

Before entering the reference flow, determine

the pressure at which the flow will be

referenced. Use the Plus or Minus keys to

adjust the value of the pressure (PSI or Bar)

to be used as flow reference. The pressure

selected to reference flow is not critical (any

pressure can be used). Select a pressure that

is close to normal operating pressure or select

a pressure from the flow rate chart for the

nozzles being used. After the reference

pressure has been selected, press the

Auto/Man key to advance to the reference

flow for preset #1.

Figure 4-22: Reference Pressure

ref

refref

ref

10

1010

10.

..

.0

00

0

1

2

3

4

5 6 7 8 9

10

11

12

P

RO

bar

barbar

bar

Reference Flow

Calculate (add) the flow rates at the

referenced pressure from all nozzles on level

1 (left or right should be the same). Enter the

total flow rate in gallons/min (liters/min) for

level 1. Use the Plus or Minus keys to adjust

the value.

Figure 4-23: Reference Flow (Level One

Entry)

1.36

1.361.36

1.36

10

1010

10.

..

.0

00

0

1

2

3

4

5 6 7 8 9

10

11

12

P

RO

bar

barbar

bar

-

--

- 1

1 1

1-

--

-

lpm

lpmlpm

lpm

Once flow entry is complete for level 1, press

the Auto/Man key to proceed with level 2.

Calculate (add) the flow rates at the

referenced pressure from all the nozzles on

level 2 (left or right should be the same). Enter

the total flow rate in gallons/min (liters/min) for

level 2. Use the Plus or Minus keys to adjust

the value.

844-AB Sprayer control 16

Software 4.03

Figure 4-24: Reference Flow (Level 2 Entry)

0.85

0.850.85

0.85

10

1010

10.

..

.0

00

0

1

2

3

4

5 6 7 8 9

10

11

12

P

RO

bar

barbar

bar

-

--

- 1

1 1

1-

--

-

lpm

lpmlpm

lpm

Press the Auto/Man key to advance to the

Select Configuration display. Use the Plus or

Minus keys to advance to another preset flow

configuration, if necessary. Follow the

previous steps for programming the reference

pressure and reference flow for presets 2-12.

Once programming is complete for all presets,

press the Program key to advance to the next

programming step.

Figure 4-25: Reference Flow (Select

Configuration Display)

SEL

SELSEL

SEL

conf

confconf

conf

1

2

3

4

5 6 7 8 9

10

11

12

P

RO

Regulating Valve Response Time

Operating conditions may require a higher or

lower response speed for the regulating valve.

To change the response time number, use the

Plus or Minus keys to increase or decrease

the number. Any number between 0.0 and 9.9

may be selected (0=Slow; 9=Fast). The

default value is 9.5. The first digit establishes

the speed for coarse adjustments (when

relatively far from the target rate). The second

digit establishes the speed for the fine

adjustment (when relatively close to the target

rate). If the regulating valve is plumbed in a

bypass line, the valve speed number of 9.5

works well for most applications.

Figure 4-27: Regulating Valve Actuating

Factor

9.

9.9.

9.

5

55

5

reg

regreg

reg

1

2

3

4

5 6 7 8 9

10

11

12

P

RO

Act

ActAct

Act

If the regulating valve is plumbed in the

throttling position (supply line), start with a

valve speed of 3.0 and adjust the number

according to application requirements.

Adjusting agitation volumes can often assist

the regulating valve operation. Press the

Program key to accept the entry and advance

to the next step.

NOTE:

The speed value can be adjusted to

optimize system performance. If the valve

tends to “search” for the programmed

application rate by cycling the pressure up

and down continuously, reduce the

number until the “searching” is minimal or

eliminated. A higher number will increase

the valve response speed and increase the

rate of adjustment.

844-AB Sprayer control 17

Software 4.03

Pressure Regulating Mode

Pressure Regulating mode directs the 844-AB

to the location of the regulating valve

plumbing. Once established, this value should

not change unless the regulating valve is

physically moved to a new plumbing location.

For additional information about plumbing,

refer to the Plumbing and Installation manual

supplied with this kit.

The default value of bypass “BYP ” indicates

that the pressure regulating valve is plumbed

in a bypass line. If no changes are necessary,

press the Program key to accept the value

and advance to the next step.

Figure 4-27: Pressure Regulating Mode

(Bypass Mode)

byp

bypbyp

byp

1

2

3

4

5 6 7 8 9

10

11

12

P

RO

NOTE:

Once the bypass mode is selected and the

console is set to “manual” mode, the

pressure regulating valve should close

when the Plus key is pressed and open

when the Minus key is pressed.

If the pressure regulating valve has been

plumbed into in a supply line to the booms, it

is considered a “throttling position”. Use the

Plus or Minus keys to change the displayed

value to “THR” (throttling mode). By doing this,

the polarity that the console uses to control

the regulating valve will be reversed.

Figure 4-28: Pressure Regulating Mode

(Throttling Mode)

thr

thrthr

thr

1

2

3

4

5 6 7 8 9

10

11

12

P

RO

NOTE:

Once the throttling mode is selected and

the console is set to “manual” mode, the

pressure regulating valve should open

when the Plus key is pressed and close

when the Minus key is pressed.

Press the Program key to accept the entry

and advance to the next step.

Minimum Pressure Setting

The Minimum Pressure Setting establishes

the minimum pressure the sprayer will

regulate. When the vehicle slows down, the

control system will sometimes regulate the

pressure so low that it falls below the

manufacturer’s recommended pressure for

the spray tip. It may also reduce system flow

to the point where the flow meter will stall.

To avoid these situations, the 844-AB can be

programmed to avoid regulating below the

pressure established with this setting. If the

default setting of 10 PSI (0.7 bar) is used, the

pressure will not fall below 10 PSI (0.7 bar)

while spraying in automatic mode.

Use the Plus or Minus keys to adjust the

value.

Press the Program key to advance to the next

program step.

844-AB Sprayer control 18

Software 4.03

Figure 4-29: Minimum Pressure Setting

0.6

0.60.6

0.6

1

2

3

4

5 6 7 8 9

10

11

12

P

RO

bar

barbar

bar

min

minmin

min

prs

prsprs

prs

Density (Liquid Specific Gravity)

The default value of “1.00” corresponds with

the specific gravity of water and is correct for

most pesticide applications. Some spray

solutions, such as fertilizer, have different

densities. If such a material is being used, a

new value should replace the default. The

following chart will help determine the density

of other solutions.

Figure 4-30: Density Display

1. 8

1. 81. 8

1. 8

D

1

2

3

4

5 6 7 8 9

10

11

12

P

RO

Figure 4-31: Density Settings

Use the Plus or Minus keys to change the

value.

Press the Plus and Minus keys simultaneously

to clear the value to “0”. Press the Program

key to accept the value and advance to the

next step.

If the solution is not identified on the chart

(above), the Specific Gravity can be

calculated as follows:

NOTES:

Water weighs 8.34 lbs/gallon or 1 Kg/L.

To activate the specific gravity number

while in the Application Setup Mode, press

the Auto/ Man key so “D” is displayed on

the top of the screen. All calculations will

use the specific gravity entered during this

step. To remove the “D” press the

Auto/Man key again. Once the “D” is not

displayed, all calculations will use the

specific gravity of water (1.00) regardless

of whether another density was

programmed or not. Refer to Application

Setup mode for additional information.

844-AB Sprayer control 19

Software 4.03

Communications

If the 844-AB has been upgraded and is

communications compatible, a variety of

communications options can be entered.

Choices available include the default of no

communications “no com”, contractor printing

”cnt prt ” , user printing “usr prt ”, global

positioning system communications capability

“gps”, downloading to a pc ‘on-the-go’

capability “log” , or PC link “pc” (not used).

Figure 4-32: Communications Settings

com

comcom

com

1

2

3

4

5 6 7 8 9

10

11

12

P

RO

no

no no

no

If the 844-AB has not been upgraded with the

communication package, no change is

required. If a change is necessary, press the

Plus or Minus keys to select the type of

communication used. Press the Program key

to accept the value and advance to the

beginning of System Setup mode.

Press and hold the Program key for three

seconds to exit System Setup mode. Changes

will be saved to the console’s memory.

NOTE:

The 844-AB console will not automatically

power down during System Setup mode.

The system must be exited by holding the

Program key for three seconds. A loss of

power to the controller during System

Setup mode will erase all changes not

previously saved to system memory.

Table of contents

Other TeeJet Controllers manuals