South Bend, Indiana USA | networketi.com FPT-130 INSTALLATION MANUAL | PART NO. 25165 REV F

2

Odeur ou fumée anormale

En cas de fumée ou de brûlure ou d’odeur anormale,

coupez immédiatement l’alimentation de l’unité en

fermant le disjoncteur protégeant l’unité.

Electrical Shock / Fire Hazard

Any installation involving electric heater wiring must

EH JURXQGHG WR HDUWK WR SURWHFW DJDLQVW VKRFN DQG ƓUH

hazard. Suitable ground fault detection and interrupting

V\VWHPVPXVWDOZD\VEHLQXVHWRUHGXFHVKRFNDQGƓUH

hazard and to protect equipment.

Electric wiring to heating elements must be installed

in accordance with National Electrical Code (NEC)/

Canadian Electrical Code requirements, as well as all

other local and applicable electrical codes and any third-

party standards. This product is intended for commercial

and industrial applications. Follow the installation

instructions contained in this manual and those provided

by the heater manufacturer. Size the circuit breaker

appropriately for the expected load and inrush current.

The maximum rated current for the FPT 130 is 30 amps

with resistive load.

Heater loads and their controls should not share a circuit

branch with other types of equipment. A shared circuit

may result in electromagnetic interference that can affect

system operation. Make certain that the heater shield is

properly grounded. Failure to do so may result in damage

WRWKHHTXLSPHQWRUƓUH

Following installation and prior to beginning system

operation, refer to and perform the Post-Installation Test

described in this manual.

Risque de choc électrique / d’incendie

Toute installation impliquant un câblage de chauffage

électrique doit être mise à la terre pour se protéger

contre les chocs et les risques d’incendie. Des systèmes

appropriés de détection et d’interruption des défauts à la

terre doivent toujours être utilisés pour réduire les risques

de choc et d’incendie et protéger l’équipement.

Le câblage électrique des éléments chauffants doit être

installé conformément aux exigences du Code national

de l’électricité (NEC) / du Code canadien de l’électricité,

ainsi qu’à tous les autres codes électriques locaux et

applicables et à toute norme tierce. Ce produit est

destiné aux applications commerciales et industrielles.

Suivez les instructions d’installation contenues dans ce

manuel et celles fournies par le fabricant de l’appareil

de chauffage. Dimensionnez le disjoncteur en fonction

de la charge et du courant d’appel attendus. Le courant

nominal maximum pour le FPT 130 est de 30 ampères

avec une charge résistive.

Les charges de chauffage et leurs commandes ne doivent

pas partager une branche de circuit avec d’autres types

d’équipement. Un circuit partagé peut entraîner des

interférences électromagnétiques qui peuvent affecter

opération Système. Assurez-vous que le blindage du

radiateur est correctement mis à la terre. Ne pas le

faire peut endommager l’équipement ou provoquer un

incendie.

Après l’installation et avant de commencer le

fonctionnement du système, reportez-vous et effectuez le

test de post-installation décrit dans ce manuel.

ITEMS INCLUDED

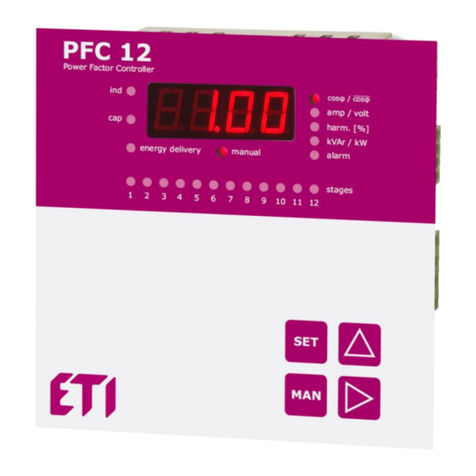

QTY. P/N DESCRIPTION

1 25169 TRACON MODEL FPT 130 Single-Point

Freeze Protection Heat–Trace Control

1 25076 Temperature Sensor

1 25298 FPT 130 Installation Sheet

- 25165 TRACON MODEL FPT-130 Installation

& Operation Manual (this document)

Available online at:

networketi.com/product-manuals

OVERVIEW

The TRACON FPT-130 Heat–Trace Control is a

microprocessor–based heat–trace control thermostat.

Ideal uses include freeze protection, and other

temperature monitoring and control applications.

The FPT-130 and its heater load can be powered with

an available line voltage source of 100 – 277 V ac. The

Heat Tracin

Sales Mt. Air

, MD

410

795-2223 www.heattracin

sales.com

Heat Tracin

Sales Mt. Air

, MD

410

795-2223 www.heattracin

sales.com