TeeJet 845-AB User manual

REFERENCE GUIDE

1

98-01611-EN R0

POWER

Power On the Console

To power on the console:

1. Press and release the PROGRAMME button.

The console will initially display the software version at the top of

the screen and the serial number of the console at the bottom of the

screen. After approximately 3 seconds, the console will enter the

work screen.

Power O the Console

To power off the console:

1. While pressing and holding the MINUS button, press and

release the PROGRAMME button.

2. Release the MINUS button.

The console will save new information (area and volume counters)

to memory before it powers down. Pressing any key during the

power off count down will cancel the shut off function.

Automatic Shutdown

With the Master Switch in the “OFF” position, the console will

automatically shut down after 10 minutes of no inputs (or at the time

specied in the Automatic Shutdown Time setting in the OEM Setup

Mode).

APPLICATION MODE

The 845-AB gives the possibility of working in two different ways

to t the application. Therefore, the console should be set up and

consequent programming and working features will be dependant

of the chosen mode.

Airblast Mode

This mode is designed to work with Airblast sprayers, mostly

spraying on two sides (left and right) with the possibility to switch

on or off sections in the height. The working width is dened by

the distance between two rows of trees. This mode is called AB

(airblast).

Figure 1: Airblast (AB) principle

-2-L

-1-L

-2-R

-1-R

Working Width

High Clearance / Vineyard Mode

This mode is designed to work with vineyard sprayers that are

spraying horizontally. Several rows are covered and sections can

be switched on or off to adapt the working width. Each section

covers a number of faces. The working width is dened by the

number of faces and the row width.

One or more nozzles can be spraying each face. If all nozzles

spraying on a face are not equal, they should be considered

as a unique nozzle and the total ow has to be set up in the

conguration menu. But all faces have to be sprayed equally. This

mode is called HC (high clearance / vineyard).

Figure 2: High Clearance / Vineyard (HC) principle

Section 1 Section 2 Section 3

3 Faces 4 Faces 3 Faces

Face

Working Width

Row Width

845-AB SPRAYER

QUICK START GUIDE

298-01611-EN R0

REFERENCE GUIDE

Selecting a Mode

Application Mode is set by the Machine Type option on the OEM

Setup Menu. OEM setup mode contains the options that customize

the controller to the sprayer or sprayer components. These include

calibration steps and parameters that will never change once

programmed.

ADVISORY! OEM setup parameters (except Machine Type) should

not be changed unless advised by TeeJet Technologies or an

authorized dealer.

Enter OEM Setup Mode

To enter the OEM setup mode both the 845-AB console and Master

Switch must be off.

Press and hold the PLUS key and MINUS key

simultaneously while pressing the PROGRAMME key one time.

Wait for the display to show “Program menu OEM.”

While continuing to press and hold the PLUS key and

MINUS key simultaneously, press the PROGRAMME key

3 times within 3 seconds to conrm menu access.

Exit OEM Setup Mode

To exit the OEM setup mode the Master Switch must be off.

Press and hold the PROGRAMME key for 3 seconds.

The inputs are stored, and the console will enter the Operation

Screen.

For information on all OEM options, see 845-AB OEM Reference

Guide 98-01612.

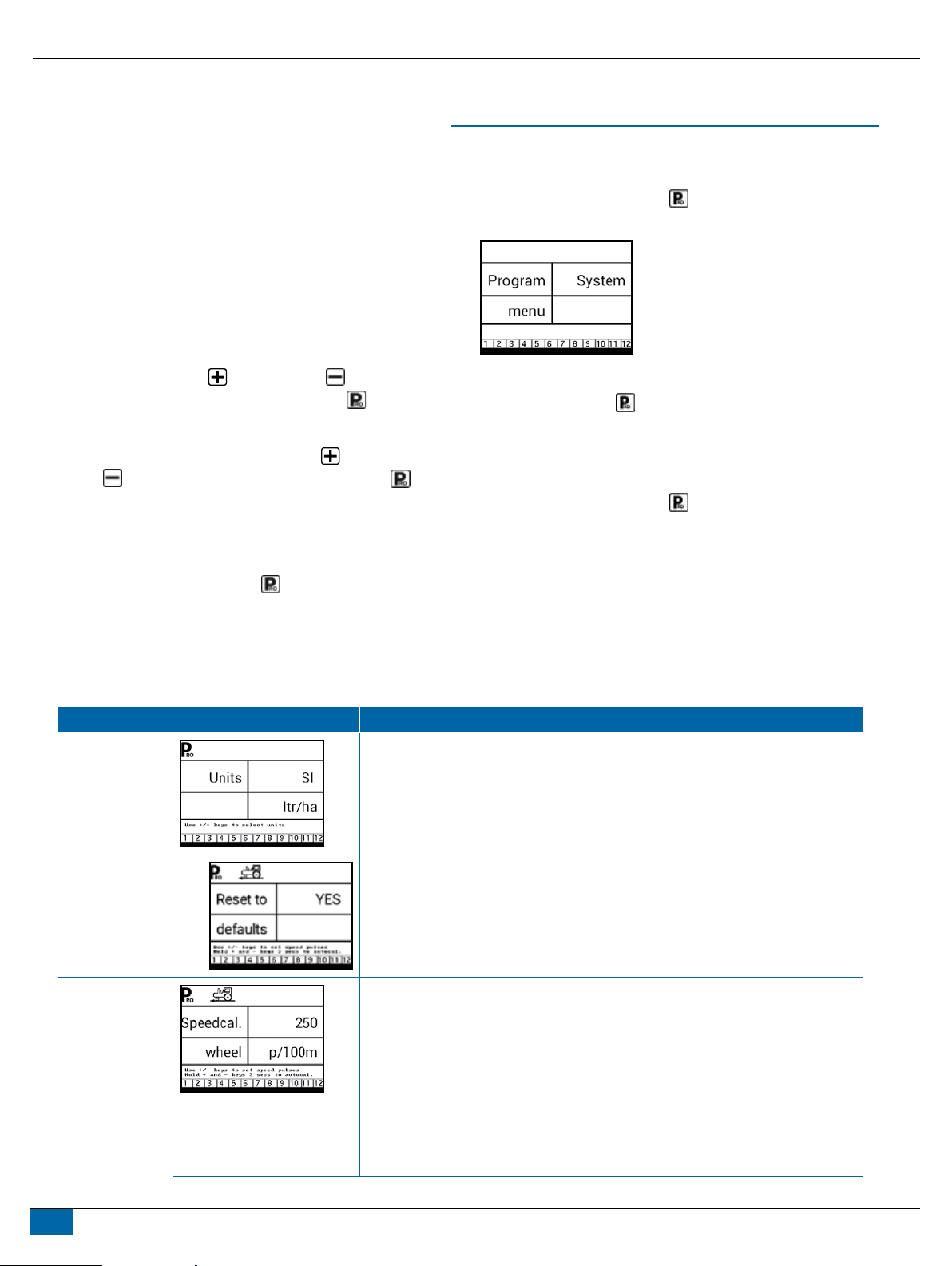

SYSTEM SETUP MODE

Enter the System Setup Mode

The Master Switch must be off.

Press and hold the PROGRAMME button until the Program

System Menu screen appears (approximately 3 seconds).

Advance to the Next Option

Press the PROGRAMME button to advance the system to the

next Program step. After the nal setup option is complete, the

console will return to the initial setup option.

Exit the System Setup Mode

Press and hold the PROGRAMME button for 3 seconds.

The inputs are stored, and the console will exit the setup mode.

Step Display Description Default

Units Select the units for operation.

Options include: US, SI.

US

Restore Defaults If the units of measurement are changed, default values for all

settings must be restored.

XYes – Units WILL be changed, and value WILL be reset.

XNo – units will NOT be changed, and value will NOT be

reset.

Yes

Speed Sensor

Calibration

Set number of Pulses per 300 feet/100 metres.

While it is difcult to give an accurate starting value for a wheel

speed sensor, radar (or simulated radar as with GPS speed)

sources usually having a starting value. Make sure the source is

set to “rad”.

100 metres

WTeeJet GPS Speed Sensor – default calibration number is 1300.

WMatrix Pro GS consoles – default calibration number is 914.

WMatrix 430 – default calibration number is 1000.

3

www.teejet.com

TEEJET TECHNOLOGIES

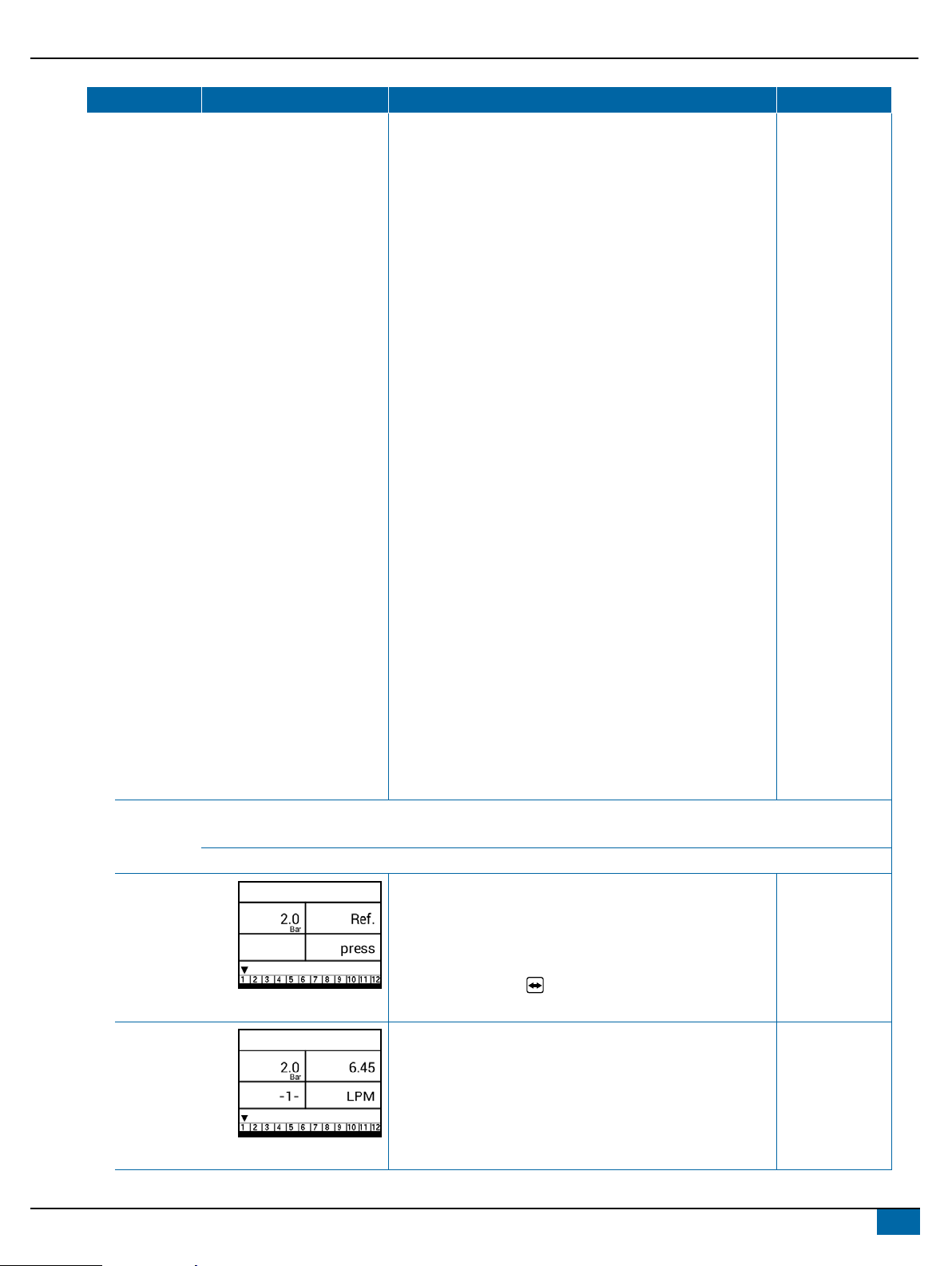

Step Display Description Default

Distance

Counter

The Distance Counter step is not a calibration step. It is a help

function that can be used to measure a distance in feet/metres

such as to conrm Automatic Speed Calibration. No value can

be entered here.

0 m

Pressure Sensor

Installed

Select if a pressure sensor is installed.

If a ow sensor is not installed, this step is automatically set to

“Yes” and cannot be changed.

Yes

Pressure

Sensor->

Zero Pressure

Reference

This step is available if “Pressure Sensor Installed” is set to

“Yes”.

The Zero Pressure Reference is used to calibrate the zero

pressure setting of the pressure sensor installed on the system.

4.0 mA

Pressure

Sensor->

Maximum

Pressure Rating

This step is only available if “Pressure Sensor Installed” is set to

“Yes”.

The Maximum Pressure Rating is used to establish the

maximum rating of the pressure sensor in the system. This

number can be found stamped on the pressure sensor itself.

10.0 bar

Minimum

Pressure

Below the Minimum Pressure value, regulation is stopped,

except when using lane spraying (GLM or LKM).

0.6 bar

Flow Meter

Installed1

Select if a ow meter is installed. Yes

Flow Meter->

Flow Meter

Calibration

This step is only available if “Flow Meter Installed” is set to

“Yes”.

Sets the number of pulses per litre.

Pressing the AUTO/MAN button will switch between normal

value and decimal value (/10).

650 pulses per

litre

Most ow meters have a tag on the sensor cable which contains the proper ow

meter calibration number and units used, whether pulses per gallon, pulses per litre,

pulses per 10 gallons, etc.

XTeeJet 801 ow meter has a calibration number of 82.

XTeeJet 802 ow meter has a calibration number of 21.

1 If a pressure sensor is not installed this step is automatically set to “Yes” and cannot be changed. If no, skip the next 2 steps.

498-01611-EN R0

REFERENCE GUIDE

Step Display Description Default

Flow Meter->

Flow Sensor

Minimum Flow

Capacity

This step is only available if “Flow Meter Installed” is set to “Yes”

and the console is programmed for use with a pressure sensor.

Set the minimum ow capacity for the installed ow sensor.

Below the minimum ow capacity, regulation will switch to

pressure mode. When ow capacity once again reaches an

acceptable level for the ow meter to regulate, the console

automatically switches back to ow based regulation.

10.0 l/ min

Regulation Mode This step is only available when both a Flow Meter and a

Pressure Sensor are installed. This step is automatically set to

“Flow” and cannot be changed if lane spraying is selected (GLM

or LKM).

Selecting a regulation mode will determine which sensor is used

as the primary mode for regulation.

Flow

Number of

Sections

Select the number of sections. The number of sections must

match the physical number of sections on the sprayer.

NOTE: In HC mode, 1 to 13 sections can be selected. In AB

mode, 2 to 10 can be selected in steps of 2.

4 sections

Congure up to twelve ow presets. The ow presets are

represented by the numbers 1 through 12 at the bottom of

the display. The arrow symbol indicates which preset is being

congured.

Press the AUTO/MAN button to proceed to the next setting

for the selected ow preset.

1

5

www.teejet.com

TEEJET TECHNOLOGIES

Step Display Description Default

AB Mode – The ow rate for each section of the sprayer

must be input into the 845-AB console so that the necessary

adjustments can be made when boom sections are shut off. The

console is programmed to treat the left and right boom sections

as symmetrical; therefore the console treats the ow rate for

the lower left section (L1) identically to the ow rate of the lower

right section (R1). The ow rate entered for section 1 will serve

as reference ow for L1 and/or R1.

HC Mode – The ow rate for a single nozzle must be input

into the 845-AB console so that the necessary adjustments

can be made when boom sections are shut off. If several

different nozzles are mounted to spray on a face, they should

be considered as ONE nozzle and the total ow should be

programmed.

NOTE: In AB mode, the reference flow is the total flow at

reference pressure of all nozzles on the given section

number on one side of the sprayer. The console is

programmed to treat the left and right boom sections as

symmetrical. Therefore, the console treats the flow rate

for the lower left section (L1) identically to the flow rate

of the lower right section (R1). The flow rate entered

for section 1 will serve as reference flow for L1 and/

or R1. The flow rate entered for section 2 will serve as

reference flow for L2 and R2 and so on.

In HC mode there is only one setting per preset. The

reference flow in this case represents the flow for one

single nozzle at the reference pressure. If several

different nozzles are mounted to spray on each face,

they should be considered as ONE nozzle and the total

flow should be programmed. All faces on the sprayer

must have the same nozzle configuration.

Flow Presets

Conguration

Flow Presets

Conguration->

Reference

Pressure

Conguration

This step is only available if a “Flow Presets Conguration” is

active.

The display will show the reference pressure for the current ow

preset selected.

Press the AUTO/MAN button to proceed into the settings for

the selected ow preset.

2.0 bar

Flow Presets

Conguration->

Reference Flow

Conguration

This step is only available if a “Flow Presets Conguration” is

active.

Calculate (add) the ow rates at the referenced pressure from

all nozzles on the current preset section (left or right should be

the same).

Enter the total ow rate for the current ow preset selected.

6.45 l/min

698-01611-EN R0

REFERENCE GUIDE

Step Display Description Default

Density Establishes the weight per volume setting based on the type of

fertilizer being used.

Water = 1.00. The density value equals

Weight of the Solution ÷ Weight of Water.

1.00

Regulation Valve

Type

Instructs the console where the regulating valve is plumbed into

the system.

Options include: Throttle, Bypass and PWM

Bypass

Regulation

Speed Factor

Coarse

adjustment

Fine

adjustment

9.5

The rst digit sets the speed for the coarse adjustment in

relation to a large percentage outside of the target application

rate.

The second digit sets the speed for the ne tune adjustment

in relation to a small percentage close to the target application

rate.

Coarse: 9

Fine: 5

XIf plumbed in a bypass mode, the Regulation Speed Factor of 9.5 works very

well in most applications.

XIf plumbed in a throttling mode, start with a Regulation Speed Factor of 5.5

and adjust the number according to your application requirements. Low ow

situations will require a slower response time.

Section Valve

Type

The Section Valve Type distinguishes the type of On/Off boom

control valves installed on the machine.

2-way

Tank Size Sets the maximum tank size. 1000 litres

Minimum Tank

Level

Sets the tank level at which an alarm will trigger.

Setting this value to 0 will disable the tank alarm.

100 litres

Communication

Mode

The Communications step allows for the selection of the type of

communications (if any) used.

None

7

www.teejet.com

TEEJET TECHNOLOGIES

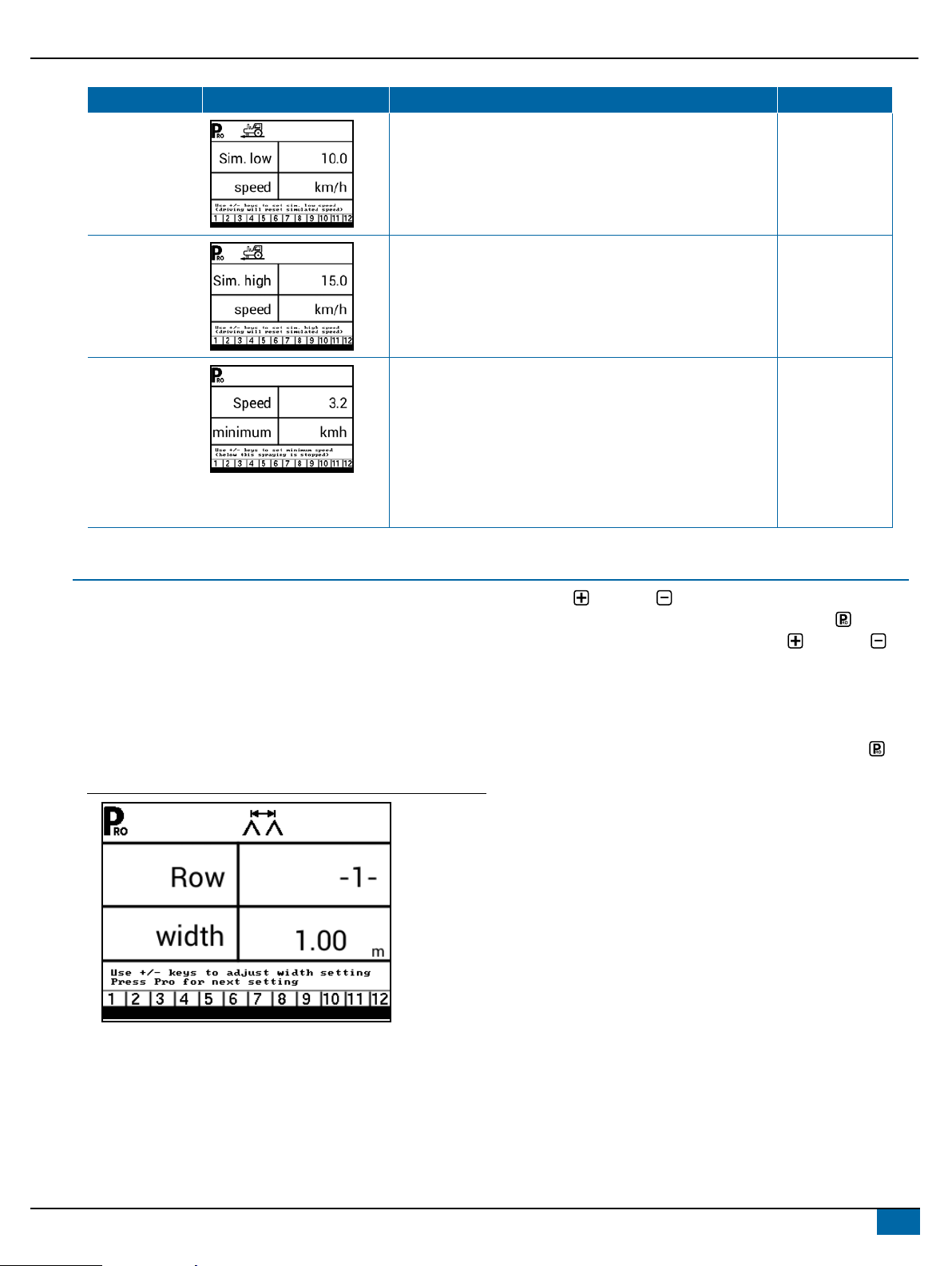

Step Display Description Default

Simulated

Ground Speed –

Low Speed

Set simulated low speed. 10.0 km/h

Simulated

Ground Speed –

High Speed

Set simulated high speed. 15.0 km/h

Minimum Speed Set the minimum speed at which the console automatically

shuts the boom sections off to eliminate an operator function

when slowing to stop or turn around. There will be no spraying

below this speed.

When the sprayer speed exceeds the established Auto Master

Off Speed, the boom sections turn back on.

Set this value to “0” to disable.

3.0 km/h

SWATH WIDTH

The 844-AB can be programmed with up to 6 swath widths. This

allows the operator to easily change from one swath to another

during application. (This is essential when spraying orchards that

have varying swath widths.)

To enter swath width presets mode, press and hold the GREEN

button for 3 seconds. The swath width setting screen for preset

number 1 will be displayed. The swath width is displayed on the

lower right of the console (measured in metres for SI [metric] units).

Figure 3: Entering swath width presets

Use the Plus and Minus keys to adjust the value for the rst

swath preset. Press the GREEN button or the Programme key

to advance to the next swath preset. Use the Plus and Minus

keys to adjust the swath value. Continue this process through the six

possible presets. If all six presets are not required, enter values only

for the necessary number of presets. All others should be set to “0”.

Values set to “0” will not be available for selection. Once the presets

have been entered, press the GREEN button or the Programme

key to return to the Operations mode.

898-01611-EN R0

REFERENCE GUIDE

Selecting a Swath Width Preset

Once the swath widths are programmed, select the swath width to

be used by pressing the GREEN button during Operations mode.

The console will display which swath preset is being used. If the

preset displayed is correct, press the Programme key to return to

Operations mode.

Figure 4: Swath width selection

Should a different swath preset be desired, press the GREEN button

again to advance to the next swath selection. Continue to press the

GREEN button until the appropriate swath preset is displayed. Press

the Programme key to select the preset and return to Operations

mode.

NOTE: Only presets that contain a width setting > 0 can be selected.

Pressing the green button will advance to the next preset

that has a width setting greater than 0.

APPLICATION SETUP MODE

The Application Setup Mode is used to set up application specic

parameters.

Enter the Application Setup Mode

The Master Switch must be off.

Press and release the PROGRAMME button once so the

Program User Menu screen appears. Press and release the

PROGRAMME button again within 3 seconds to enter the setting

options.

Advance to the Next Option

Press the PROGRAMME button to advance the system to the

next Program step. After the nal setup option is complete, the

console return to the initial setup option.

Exit the System Setup Mode

Press and hold the PROGRAMME button for 3 seconds.

The inputs are stored, and the console will exit the setup mode.

Activate Density Factor

At any time in Application Setup Mode, pressing the AUTO/MAN

button will toggle the density symbol (‘D’) on or off. When the density

symbol is on, the density value (set in System Setup mode) will be

used in the regulation algorithms. If the density symbol is off, the

density factor will not be used.

9

www.teejet.com

TEEJET TECHNOLOGIES

Step

AB Application Mode

Display

HC Application Mode

Display Description Defaults

Flow Preset

Selection

Sets which ow preset will be used. 1

Nozzles Per

Face

Sets the number of nozzles per face

(only available in HC Application

Mode).

3

Target

Application Rate

Sets the target application rate. AB 800 l/ha

HC 120 l/ha

Known Pressure

Value

The console will calculate the speed for

the selected pressure, Tip/Nozzle type

and target rate.

XIf the indicated speed is too high,

a set of smaller Tips/Nozzles is

required.

XIf the indicated speed is too low,

a set of larger Tips/Nozzles is

required.

2.0 bar

Known Speed

Calculation

The console will calculate what the

pressure must be to maintain the target

application rate at the entered speed.

No defaul

value

10 98-01611-EN R0

REFERENCE GUIDE

OPERATION FEATURES

Feature and Display Description

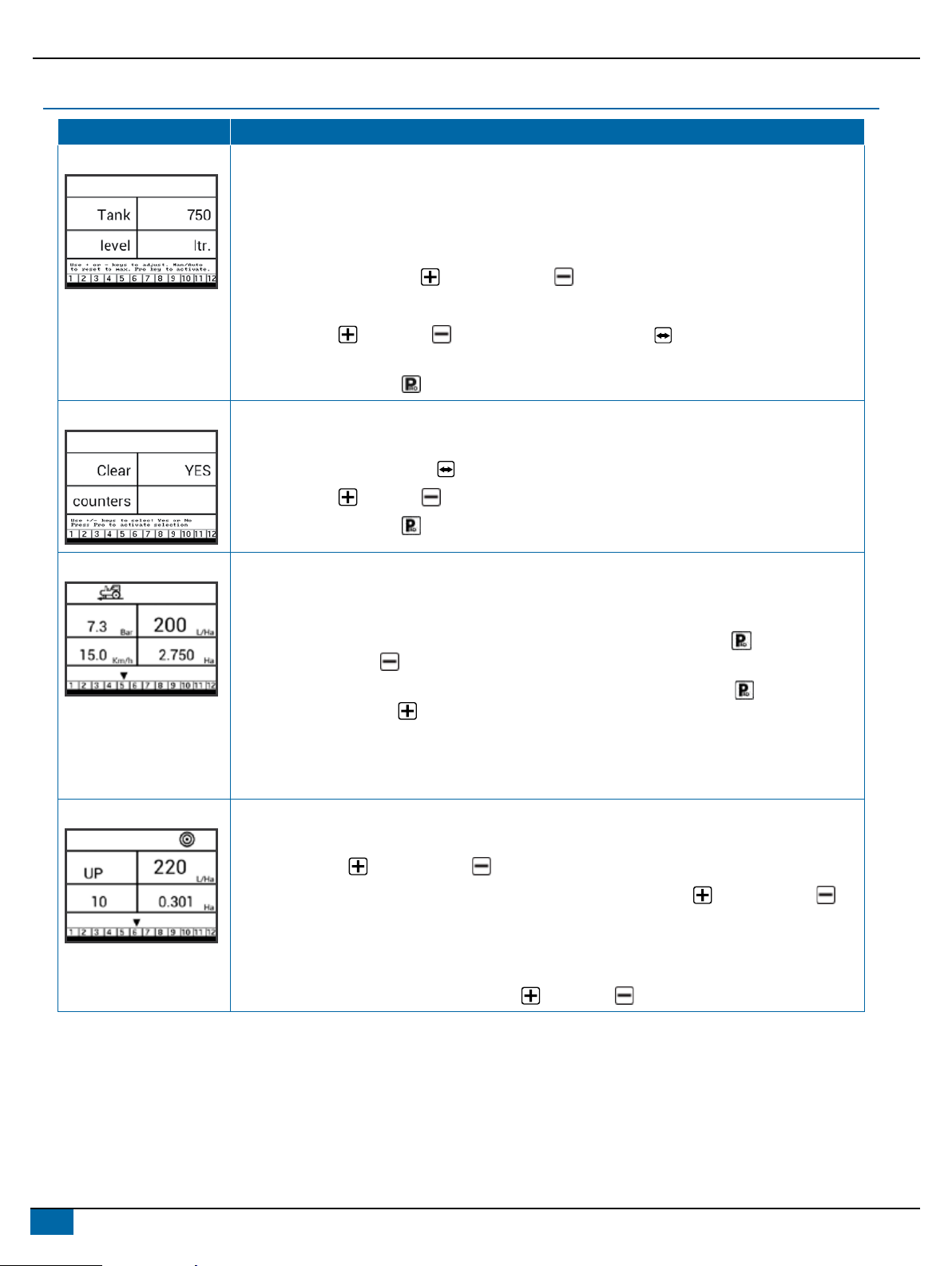

Tank Level Used to show and/or set the actual content level in the tank. This level will decrease by the amount being

sprayed. If the minimum tank level has been set to a value greater than zero and the actual level becomes

less than the minimum level, a tank alarm will be triggered. Setting minimum tank level to zero will disable

tank alarm function.

View Tank Level – Start from the work screen with the Master Switch “OFF”.

1. Press and release the PLUS button and MINUS button simultaneously.

Adjust Tank Level – Start from the work screen with the Master Switch “OFF”.

2. Use the PLUS and MINUS buttons. Or Press the MAN/AUTO button to reset tank level to

maximum.

3. Press the PROGRAMME button to conrm the selection and exit to normal work screen.

Clear Counters Used to reset the total area, total volume and total distance counters to zero.

Start from the work screen with the Master Switch “OFF”.

1. Press and hold the MAN/AUTO button for 3 seconds.

2. Use the PLUS or MINUS buttons to select “YES”.

3. Press the PROGRAMME button to conrm the selection and exit to normal work screen.

Simulated Speed Allows the verication of console functions and the sprayer without actually moving the sprayer.

Activate the Simulated Speed – While on the work screen without the machine in motion and the Master

Switch in the “On” position:

XActivate Low Simulated Speed – While pressing and holding the PROGRAMME button, press and

release the MINUS button.

XActivate High Simulated Speed – While pressing and holding the PROGRAMME button, press

and release the PLUS button.

Deactivate Simulated Speed – Once the sprayer begins moving and the console receives actual speed

pulses, simulated ground speed is deactivated. Simulated speed will also be deactivated if the console is

powered off.

Boost Function Used to increase or decrease the application rate by increments of 10%.

Increase/Decrease Target Application Rate

1. Press the PLUS button or MINUS button.

2. Within 3 seconds (while the boost activation period is active), use the PLUS button or MINUS

button, to increase or decrease the rate in steps of 10%.

After the activation period, the display will revert to normal, but if the rate has been changed, the target

symbol will stay visible and ashing.

Reset Target Application Rate – Press the PLUS and MINUS buttons simultaneously.

11

www.teejet.com

TEEJET TECHNOLOGIES

Feature and Display Description

Manual/Automatic

Regulation Mode

In manual mode, automatic rate regulation is stopped completely.

XPressing the PLUS button simply moves the regulating valve to increase the ow (or increase the

PWM duty cycle) as long as the button is pressed.

XPressing the MINUS button gives the opposite action.

The valve (or the PWM duty cycle) stays in the position it had when the PLUS or

MINUS button was released. The application rate value shown on the screen is the actual rate for the

given speed. Since automatic regulation is stopped, it will appear that the rate value changes when the

speed is changed.

ALARM SYSTEM

A number of sensor alarms have been included in the 845-AB software. The alarm system is only active with Master on. All audible alarm

signals can be cancelled by pressing any button. All alarms are reset when Master is switched off.

Alarm Name Display Description Audible Alarm Type

Rate Alarm Too high difference between target and

actual rate.

High Priority (3 short beeps, repeated

every second)

No Speed Alarm If speed is zero with master on, then no

speed alarm is triggered and spraying is

stopped.

Medium Priority (2 short beeps, repeated

every second)

No Flow Alarm If no ow pulses are received with master

on and ow meter installed, a no ow

alarm is triggered.

Medium Priority (2 short beeps, repeated

every second).

No Pressure

Alarm

If no pressure is measured with master

on and pressure sensor installed, a no

pressure alarm is triggered.

Medium Priority (2 short beeps, repeated

every second).

Low Pressure

Alarm

If pressure drops below minimum value

with master on, a low-pressure alarm is

triggered.

Medium Priority (2 short beeps, repeated

every second).

98-01611-EN A4LT R0 English-International

© TeeJet Technologies 2023

REFERENCE GUIDE

www.teejet.com

Alarm Name Display Description Audible Alarm Type

Low Speed

Alarm

If speed drops below minimum value with

master on, a low-speed alarm is triggered

and spraying is stopped.

Medium Priority (2 short beeps, repeated

every second).

Pressure

Difference

Warning

With ow based regulation, the controller

(if pressure sensor installed) will compare

the actual measured pressure with the

calculated pressure (based on ow and

nozzle type).

No audible alarm.

Flow Difference

Warning

With pressure based regulation, the

controller (if ow meter installed) will

compare the actual measured ow with

the calculated ow (based on pressure

and nozzle type).

No audible alarm.

Tank Level Alarm Current tank level drops below tank

minimum.

Low Priority (1 short beep, repeat every

second).

Table of contents