tefen MixRite TF10 User manual

TEFEN Advanced Plastic Solutions.

TEFEN

1

Edition 01.12

10034

English

p.1-17

Espaniol

p.18-28

TEFEN

Propotional Injector

Pompe à Dosage Proportionnel

Pompa proporzionale

®

10032

Edition 6.11

Injetor Proporcional

Proportionale Injektorpumpe

www.tefenplastic.com E-mail: info@tefenplastic.com

User Manuel

Bedienungsanleitung Manual do usuario

Manuel Utilisateur Manuale d’Uso

Manual del Usuario

English Espan Français Italiano Russian Portuguese Deutsch

Recommended:

120 mesh water filter prior to the MixRite injector

p.2 - 1 0 p. 1 1 - 1 0p. 2 - 3 0 p. 31-39 p. 40-46 p. 47-55 p. 56-63

9

TEFEN

Propotional Injector

Pompe à Dosage Proportionnel

Pompa proporzionale

®

10032

Edition 6.11

Injetor Proporcional

Proportionale Injektorpumpe

www.tefenplastic.com E-mail: info@tefenplastic.com

User Manuel

Bedienungsanleitung Manual do usuario

Manuel Utilisateur Manuale d’Uso

Manual del Usuario

English Espan Français Italiano Russian Portuguese Deutsch

Recommended:

120 mesh water filter prior to the MixRite injector

p. 2 - 1 0 p. 1 1 -1 0p. 2 - 3 0 p. 31-39 p. 40-46 p. 47-55 p. 56-63

9

TEFEN Advanced Plastic Solutions.

TEFEN

2

TEFEN

Tefen MixRite TF 10 Fertilizer and Chemicals Injector

Congratulations on your purchase of one of Tefen’s high quality products.

To get the best results from the MixRite TF-10 Proportioning Dosing Injector it is important to

spend a few minutes

reading carefully the explanations and recommendations in this user’s manual.

Operating princip

The proportioning dosing injector is fitted on the water line. The flows of water passing through the

injector activate it and cause the pumping of liquid fertilizer (or other additive) and inject it in a

relative quantity into the water line.

The MixRite TF 10 technical working range:

The flow rate of water passing through the injector is between 0.5 and 10 m³/Hr. (2 - 45 GPM).

The water pressure is between 1 and 8 bar (14.7 and 120 PSI).

The water and air temperatures are not less than 4°C and not more than 40°C (39°F - 104°F).

Head loss: Low flow 0.1 Bar – High flow 0.9 Bar.

Max deviation injection rate +/- 10%.

Before using, an initial calibration should be done, in order to assure accurate match with the

injector printed scale.

The flow rate of the fertilizer and chemicals can be adjusted relative to the flow rate of the water in

the range of:

0.1% to 1%

0.2% to 2%

0.5% to 5%

Installing the Injector

Check that Injector package contains the following items:

* One proportioning dosing injector to which are attached

Two compression fittings (Plasson) for a 50 mm PE pipe.

* One flexible suction tube to which is attached a flat seal

And a filter.

* 2 stand brackets.

* One User’s manual.

* 4 legs (optional)

To fit to wall – connect one of the brackets to the

wall by inserting 4 screws in the Bracket.

To install the stand – insert the brackets into the body grooves at the bottom and press up until

they fit in place. Place the legs in the holes and press until they well locked.

TEFEN Advanced Plastic Solutions.

TEFEN

3

Connection of the suction tube

Insert the flat seal into the nut of the coupling on the end of the tube (1). Thread and tighten the

nut to the inlet valve on the bottom of the injector. Make sure that the nut is threaded and tighten

properly (2,3).

Connection of the Injector to a 1.5”threaded line

Note the direction of the water flow. Place the injector so that the arrow stamped on the body of

the injector and the red arrow on central sticker point in the direction of the water flow. Connect

the injector using the plastic couplings.

Connection of the Injector to a 50 mm. polyethylene line

Note the direction of the water flow. Place the injector so that the arrow stamped on the body of

the injector and the red arrow point in the direction of the water flow. Make sure that the ends of

the entry pipe and the exit pipe are cut straight and that the end is in the shape of a rounded cone.

The distance between the entry end and the exit ends should be about 25 cm (9.8").

Remove the 50 mm nut from the injector and the white

ring and slide them onto the pipe at a short distance

from the end. Check that accessory seal 50 and that

the sealing 50 fixture closes the unit from outside (1).

Insert the pipe into the entry opening or exit opening

in accordance with the direction indicated and push it

so that the pipe penetrates passes the seal and stops

at the end of the track.

To facilitate the penetration of the pipe spread a little

silicone grease on the end of the tube before

inserting it. Push the white ring in until it reaches the

thread (2). Close the nut and tighten securely.

In the same way connect the injector to the other pipe.

TEFEN Advanced Plastic Solutions.

TEFEN

4

Water with high particle content

(ex.: 120 mesh - 130 microns depending on your water quality) water filter must

be installed prior to the injector (see accessories), if a filter is not installed

Abrasive substances will cause the injector to deteriorate prematurely.

Installing the injector on an irrigation line

It is recommended to fit a main valve (1) at the beginning of the line as well as a backflow

prevention valve (3). On a drinking water line, according to local regulations, it is obligatory to

install a backflow prevention valve to prevent entry of chemicals into the drinking water. Then as

shown in the din the diagram the following have to be installed: A pressure reducer (4) to

protect the injector from excess pressure, a filter (2) of at least 120 mesh (130 micron), a valve

(6) before entry to the injector, vacuum valve (7) to prevent siphoning when the injector is not

operating, and valves to the feed lines have then to be installed. It is advisable to add a bypass

pipe through which the water can flow to irrigation without fertilizer or when it is required to

dismantle the injector.

Installation of the injector on a bypass line

It is necessary to fit the proportional dosing injector to a bypass line when irrigation with a flow

rate higher than the maximum recommended for the injector. The bypass enables only part of the

water flow to pass through the bypass and activate the injector, while the reminder passes through

the main line. Using the choke valve (7) on the main line, the flow of water passing through the

main is regulated so that the rest of the flow passes through the bypass and activates the injector.

The metering must be calculated in accordance with the flow rate passing through both lines.

It is necessary to fit a main valve (1) at the beginning of the line and after it a backflow

prevention valve (3), pressure reducer (4), a water filter (2) of at least 120 mesh (130 micron)

, a T connection (A) for diversion from the main line to the bypass, a valve on the bypass before

the inlet to the proportioning dosing injector, a valve after the outlet from the injector (9) on the

bypass and a T-connector for the return to the main line (B). A choke valve, preferably an angled

valve, should be fitted on the main line between the bypass. An anti vacuum valve (8) should be

fitted together with valves for the branch lines after the return connection from the bypass.

TEFEN Advanced Plastic Solutions.

TEFEN

5

Installation of two injectors in parallel

When the water flow rate in the irrigation line is higher than the maximum nominal flow rate of the

injector, the water may be divided between two injectors. If the 2 injectors are used for pumping the

same type of fertilizer, the scale should be adjusted in an identical manner to the same level of

metering. Two different additives may be metered at different levels. The metering in each unit must

be calculated separately for each flow rate passing through each of the two injectors.

It is necessary to fit a main valve (1) at the beginning of the water line and after it, a backflow

prevention valve (3), a pressure reducer (4), a filter (2) with at least 120 mash (130 micron). a T-

junction (5) is then fitted from the main line into 2 lines. To each of these lines are fitted a regulation

valve (6), the injector and non-return valve (7) immediately after the injector and a connection back

to the main line (8). Care must be taken to ensure that both branches are exactly the same length.

TEFEN Advanced Plastic Solutions.

TEFEN

6

Connection to the Fertilizer Tank

Connect the suction tube to the fertilizer tank (preferably about 5cm (2") above the bottom). The

liquid fertilizer must be passed through a filter with at least a 120 mesh (130 micron).

If the fertilizer is drawn from an open tank, a heavy weight should be placed at the end of the

suction tube that will keep the opening of the suction tube inside the additive liquid and prevent

the tube from floating and failing outside the tank. Make sure that the level of the fertilizer is

always below the injector. Otherwise uncontrolled flow of the fertilizer may occur.

When connecting to a large fertilizer tank use a valve that is not affected by the fertilizer and an

N.C. valve to prevent the siphon effect. The valve will only open when there is water pressure

irrigation line.

Adjustment of Metering

On the metering cylinder there is a scale indicating the percentage of additives. When the entry

valve is closed and there is no water pressure in the injector, turn the adjustment control nut and

set its upper edge on the percentage required. Turning it counterclockwise increases the amount of

fertilizer metered. Turning it clockwise decreases the amount of fertilizer metered. The actual

fertilizer metering rate should be checked. If necessary, adjust by increasing or decreasing the

adjustment control nut.

TEFEN Advanced Plastic Solutions.

TEFEN

7

Manual On/Off Control

In models with manual on/off control the suction can be controlled while water flows through the

injector. To inject the additive, flick the handle to it's 'on' position ('on' face up), to stop injection of

additive flick the handle to it's 'off' position ('off' face up).

Hydraulic On/Off Control

In models with a hydraulic on/off control the suction can be controlled while the water continues to

flow through the injector, using a connection to the control tubes that are controlled by irrigation

computer by means of electric valves.

TEFEN Advanced Plastic Solutions.

TEFEN

8

Routine Maintenance

Regularly clean the water filter at the injector inlet and the fertilizer suction filter.

If its planned not to operate the injector for a long period, operate the injector for a few minutes

with the metering tube immersed in a tank with clean water to remove fertilizer residues from the

injector preventing them solidifying in the injector.

If there is fear of frost and the temperature falling below 4°C (39°F) empty the water from the

injector. To do this, close the entry and exit valves securely. Open and dismantle the 3/4" record

that connects the suction pipe. Press the suction check valve using a finger or a thin rod, allowing

all the water that has collected in the injector to drain out while pressing the air release valve at

the top of the injector.

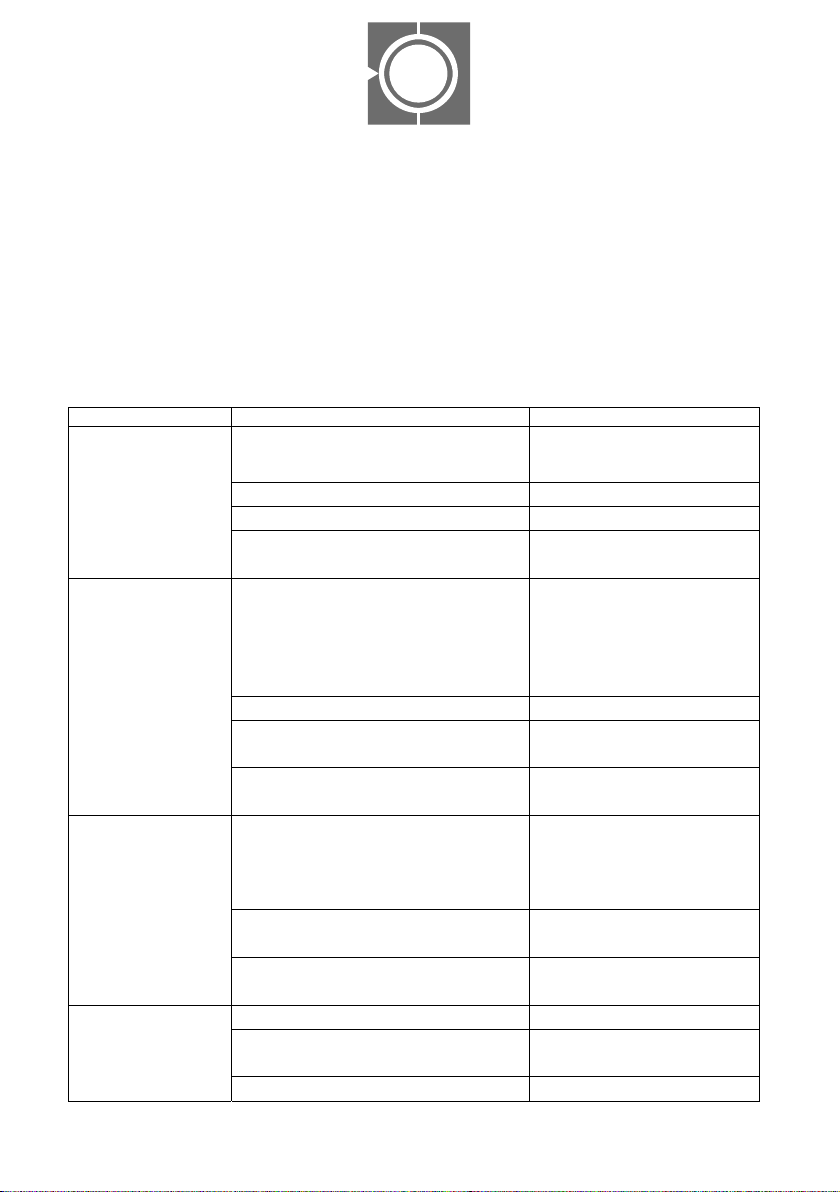

Troubleshooting Guide

Problem Check Solution

The injector is fitted with the arrows in the

opposite direction to the water flow.

Fit The injector with the arrows in

the direction of the water flow.

The inlet and outlet valves are closed. Open the valves

The inlet filter is blocked. Clean the filter.

The injector does not

work

There is no water flow at the appropriate

pressure.

Open the main valve.

There is no water flow at the appropriate

pressure. Open the main valve. Open the nut

locking the motor cover, remove the motor

cover, and remove the mechanism. Check if

the motor seals are defective.

Replace the motor seals.

Check if the springs are broken. Replace the springs.

Check if the seals above the valves are

defective or have been displaced.

Replace the seals.

The injector has

stopped working

Check if one of the parts of the mechanism

is broken.

Replace the broken part.

The leak is from the connection between the

body and the cover.

Open and remove the motor

cover, replace the seal, fit the

cover, and thoroughly tighten the

cover locking nut.

The leak is from the connection of the

suction tube.

Remove the suction tube, replace

the defective seal and reconnect.

There is a leak from

the injector.

The leak is from the non-return valve. Dismantle the non-return valve

and replace the defective seal.

The suction filter is blocked. Clean the filter.

Dismantle the injector unit and check if the

suction seal is defective.

Replace the suction seal.

There is no suction.

The non-return valve is defective. Replace the non-return valve.

TEFEN Advanced Plastic Solutions.

TEFEN

9

For advice, technical support and purchase of spare parts, Contact the authorized sales

representative in your area.

LIMITED WARRANTY

Tefen Manufacture & Marketing Plastic Products 1990 Ltd. will replace all parts shown to be

defective in material or workmanship during a period of twelve months from the date of purchase

by the original purchaser.

To obtain warranty replacement of a part, the MixRite must be returned with original proof of

purchase receipt to the manufacturer or authorized distributor and thereafter recognized as

defective after examination by the technical services of the manufacturer or distributor.

The MixRite must be flushed of any chemical and sent to the manufacturer or distributor prepaid,

but will be returned free of charge once repairs are made if found to be covered by the warranty.

Any repairs made under warranty will not extend the initial warranty period.

This warranty only covers circumstances where the part has failed due to defects caused by the

manufacturing process. This warranty is invalid if the defects are found to be due to the product's

misuse, inappropriate use of tools, lack of maintenance or defective installation or environmental

accidents or corrosion by foreign bodies and liquids found within or in proximity to the MixRite.

The seals and "O" rings are not covered under warranty, nor is damage to the MixRite caused by

water impurities such as sand. A filter (200 Mesh) must be used in front of the unit for the warranty

to be valid.

Tefen Manufacture & Marketing Plastic Products 1990 Ltd. declines any responsibility if the MixRite

is not used in compliance with the operating instructions and tolerances as indicated herein.

This warranty gives you specific legal rights and you may also have other rights which vary from

state to state. But any implied warranty or merchantability or fitness for a particular purpose

applicable to this product is limited in duration to the time period of this written warranty or any

implied warranty.

There is no warranty express or implied relating in any way to products used in conjunction with

Tefen Manufacture & Marketing Plastic Products 1990 Ltd.

The manufacturer or authorized distributor shall not be liable for incidental or consequential

damage, such as any economic loss, resulting from breach of this written warranty or any implied

warranty.

There are no warranties, express or implied, which will extend beyond those described above.

TEFEN Advanced Plastic Solutions.

TEFEN

10

1% TF10

105

TF10 - BSPT / NPT

TEFEN Advanced Plastic Solutions.

TEFEN

11

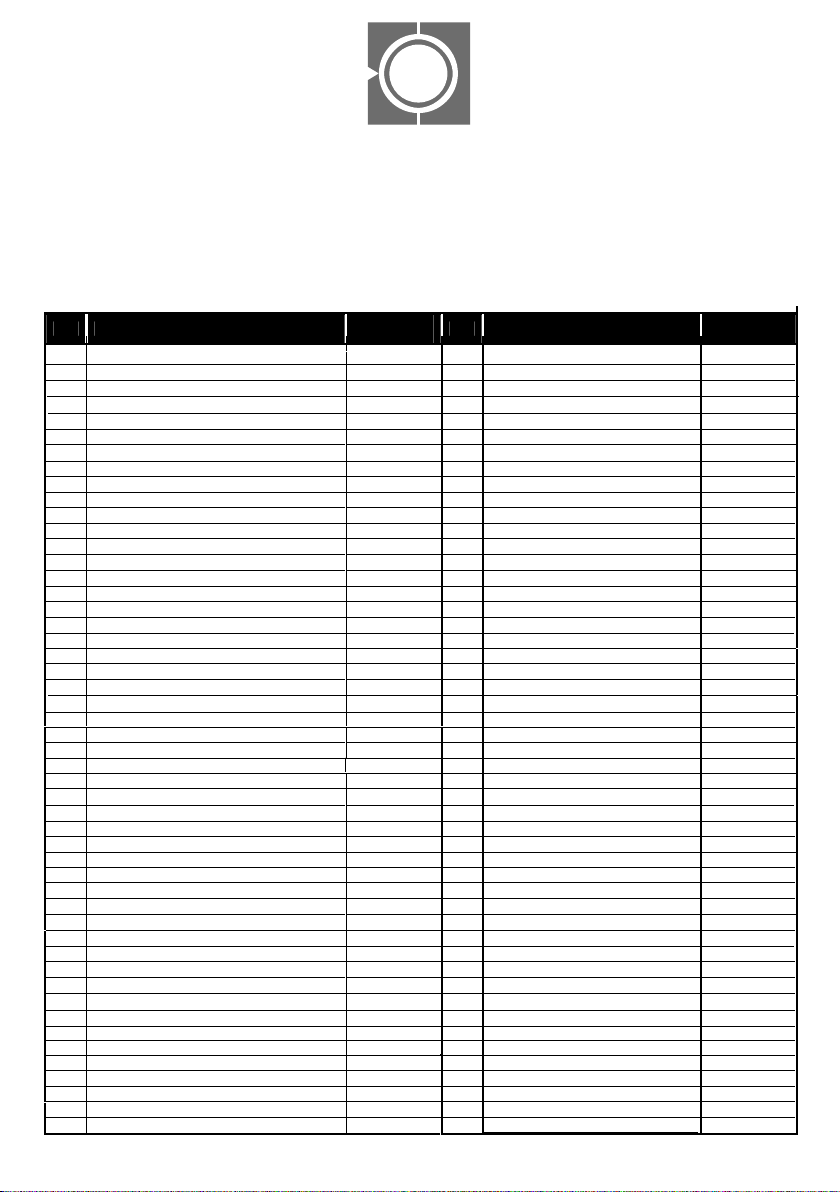

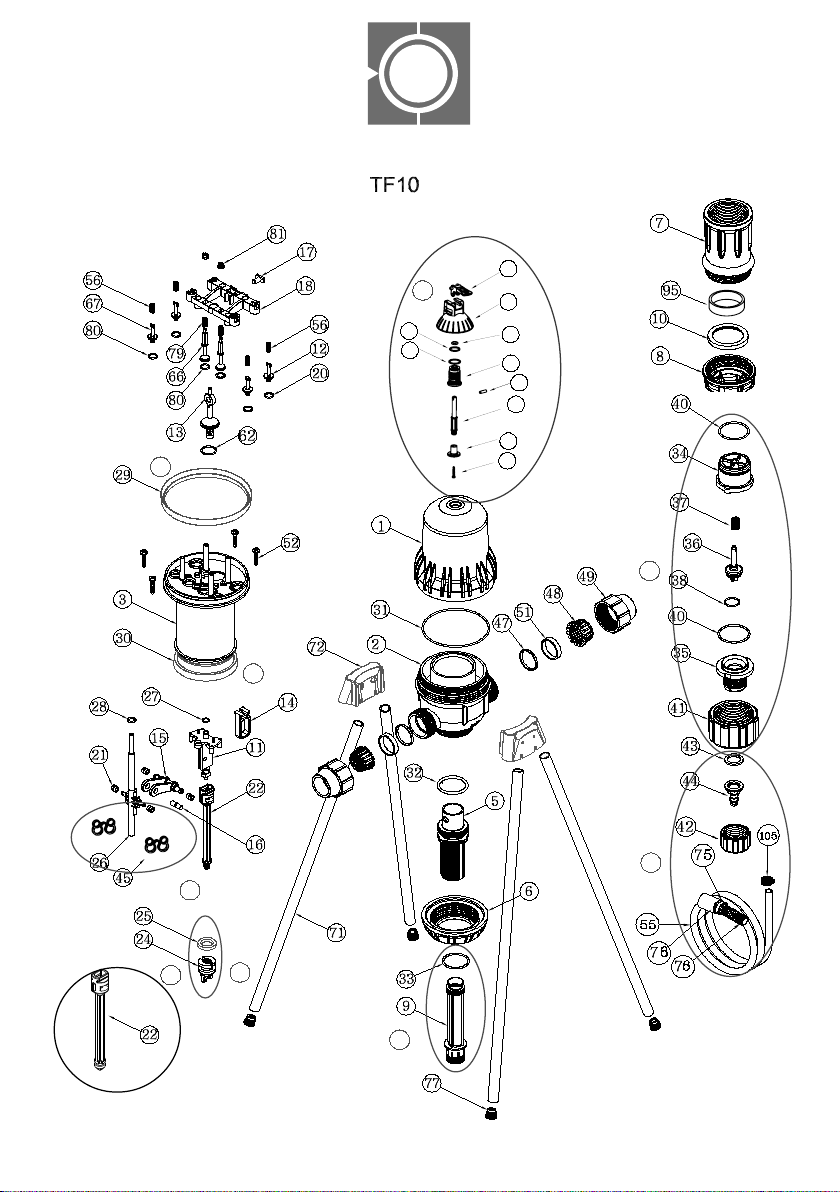

COMPONENT

CODE

COMPONENT NAMENo.

COMPONENT

CODE

COMPONENT NAMENo.

PISTON CHECK VALVE36

TF 10 COVER

1

SPRING FOR CHECK VALVE HSTY372

O RING 2-206 PO38

PISTON TF3 39

O RING 30*3 PO40CYLINDER SUPPORT5

CHECK VALVE NUT41CYLINDER SUPPORT NUT6

NUT 3/4"HOLE 2042ADJUSTMENT NUT7

WASHER FOR SWIVEL 3/4"

43LATCH NUT8

RECORD BODY 19X3/4"44CYLINDER 1% MIXRITE TF 10

9

CYLINDER 2% MIXRITE TF 109

CYLINDER 5% MIXRITE TF 109

45

10

INSIDE BASE11

EXIT VALVE 312

CENTRAL VALVE 313

14

15

16

EJOTE SCREW WN-141252

BRIDGE PIN17

53

BRIDGE18

SUCTION TUBE 19mm55

19

AIR RELEASE58

O RING 2-11220

21

PISTON BAR22

23

SUCTION PISTON 2% MIXRITE TF 10

24

SUCTION PISTON 5% MIXRITE TF 10

24

O RING 20X364

SUCTION SEAL 1% MIXRITE TF 10

25

SUCTION SEAL 2% MIXRITE TF 10

25

SUCTION SEAL 5% MIXRITE TF 10

25

OPERATION ROD26

EASEL LEG TF71

"O" Ring 12X2

27

72

28

UPPER PISTON SEAL29

LOWER PISTON SEAL30

75

O RING 2-36231

76

O RING 2-33432

EASEL LEG PLUG D. 2277

O RING FOR 1%,2% MODEL

33

78

CHECK VALVE SLEEVE34

CHECK VALVE LID35

65

80 O RING 2-111

81 V7 INNER VALVE LOCKER

LARGE

79 INNER VALVE SPRING

66 INNER VALVE TF10

67 SMALL EXIT VALVE

56 LARGE EX. VALVE SPRING

2%,5%

CYLINDER SUPPORT SPACER

BODY 11/2" BSP

TOGGLE BEARING

TOGGLE FRAME

TOGGLE

TOGGLE PIN

35101011301

35102091302

35103013103

35104013304

35105011806

35107011807

35108011808

35109016109

35110016109

35111016109

35117013110

35112010211

35119011112

35113011113

35113011114

35116011115

35113011116

35113011117

35106013118

35121011121

35122013122

35118021124

35118051124

38000032022

35102024225

35002024225

35114011126

35123012229

35124012230

36030162284

36030622100

36030120033

35016003858

38000004171

10

35125011872

35028001181

38000001151

38021129280

37005852002

38023622231

38023342232

36023242233

36030675102

36030101101

38028110529

38022060284

38003033246

37245581200

32454759122

38000001152

36030001955

38000001150

38002032264

35120011166

35119011167

38001003277

37005821110

HOSE COVER 19 MM 36030111935

SUCTION FILTER 30

FILTER WEIGHT 38002000107

33 O RING 39X4 FOR 5% MODEL

10

PISTON BAR 1% TF10

22

TF10

TF10

TF10

TF10

TF10

TF10

TF10

TF10

TF10

TF10

TF10

TF10

TF10

TF10

TF10

TF10 BRACKET

54 11/2" FEMALE PIPE COUPLING 38050107015

35122013124 O RING 2-116 38021169292

59 SPRING 5 38060000059

60 AIR RELEASER SCREW 36030284360

61 "O" RING 2-107 38060210761

62 NUT 3/4" 38000007389

63 ADAPTOR 3/4" 35000003863

38003942233

2

2

105 SST CLIP SCREW 38013322102

PLASTIC SPRING 1 TF 10 35126108249

46

BODY 11/2" NPT 35102081302

MixRite TF10, 0.1-1% ,Air Releaser , 28090100000 / 28080100000

MixRite TF10, 0.2-2% ,Air Releaser , 28090200000 / 28080200000

MixRite TF10, 1 -5% , Air Releaser , 28090500000 / 28080500000

BSP NPT

SPACER FOR CYLINDER 5% 35117053195

95

95 SPACER FOR CYLINDER 2% 35117023196

36030013036

TEFEN Advanced Plastic Solutions.

TEFEN

12

50 MM

Manual On/Off

82

83

84

85

86

88

87

89

90

91

88

92

TEFEN Advanced Plastic Solutions.

TEFEN

13

COMPONENT

CODE

COMPONENT NAMENo.

COMPONENT

CODE

COMPONENT NAMENo.

TF 10 COVER

1

2

PISTON TF3

4

CYLINDER SUPPORT5

CYLINDER SUPPORT NUT6

NUT 3/4"HOLE 20

42

ADJUSTMENT NUT7

WASHER FOR SWIVEL 3/4"43

LATCH NUT8

RECORD BODY 19X3/4"

44

CYLINDER 1% MIXRITE TF 10

9

CYLINDER 2% MIXRITE TF 109

CYLINDER 5% MIXRITE TF 109

PLASTIC SPRING 1 TF 10

45

10

INSIDE BASE11

EXIT VALVE12

CENTRAL VALVE13

14

15

16

EJOTE SCREW WN-141252

BRIDGE PIN17

53

BRIDGE18

SUCTION TUBE 19 mm55

19

O RING 2-11220

21

PISTON BAR22

61

23

SUCTION PISTON 2% MIXRITE TF 10

24

SUCTION PISTON 5% MIXRITE TF 10

24

64

SUCTION SEAL 1% MIXRITE TF 10

25

SUCTION SEAL 2% MIXRITE TF 10

25

SUCTION SEAL 5% MIXRITE TF 10

25

OPERATION ROD26

EASEL LEG TF71

"O" Ring 12X2

27

72

28

UPPER PISTON SEAL29

LOWER PISTON SEAL30

75

O RING 2-36231

76

O RING 2-33432

EASEL LEG PLUG D. 22

77

O RING FOR 1%,2% MODEL

33

78

CHECK VALVE SLEEVE34

CHECK VALVE LID35

65

LARGE

79 INNER VALVE SPRING

66 INNER VALVE TF10

67 SMALL EXIT VALVE

56 LARGE EX. VALVE SPRING

2%,5%

CYLINDER SUPPORT SPACER

BODY 50 mm

TOGGLE BEARING

TOGGLE FRAME

TOGGLE

TOGGLE PIN

35101011301

351P2011302

35103013103

35104013304

35105011806

35107011807

35108011808

35109016109

35110016109

35111016109

35117013110

35112010211

35119011112

35113011113

35113011114

35116011115

35113011116

35113011117

35106013118

35121011121

35122013122

35118021124

35118051124

38000032022

35102024225

35002024225

35114011126

35123012229

35124012230

36030120033

38000004171

10

35125011872

38000001151

38021129280

37005852002

38023622231

38023342232

36023242233

36030675102

36030101101

37245581200

32454759122

51

38000001152

36030001955

38000001150

35120011166

35119011167

38001003277

37005821110

HOSE COVER 19 MM 36030111935

SUCTION FILTER 30 36030013036

FILTER WEIGHT 38002000107

33 O RING 39X4 FOR 5% MODEL

10

PISTON BAR 1% TF10

22

TF10

TF10

TF10

TF10

TF10

TF10

TF10

TF10

TF10

TF10

TF10

TF10

TF10

TF10

TF10

54

35122013124

38003942233

105 SST CLIP SCREW 38013321202

60

TF10

TF10

35028001181

80 O RING 2-111

EASEL BRIDGE TF10

63

PISTON CHECK VALVE36

SPRING FOR CHECK VALVE HSTY

37

36030162284

38028110529

O RING 2-206 PO38 38022060284

39

O RING 30*3 PO40

CHECK VALVE NUT41 36030622100

38003033246

82

83

84

85

86

87

88

89

90

91

81 V7 INNER VALVE LOCKER

ON/OFF HANDLE FOR TF 35305011285

COVER FOR ONOFF TF 35303011258

PIN 35308011286

O RING 9*3 38000932246

BAR FOR TF5 HANDLE ON/OFF

35308011288

O RING 20*3 38002032264

O RING 2-116 38021169292

ADAPTOR 3/4" ONOFF TF 35301011287

EJOTE SCREW WN-1412 4*25 38000042565

ON/OFF DISC FOR TF10 35302101290

35126108249

46

47

48

49

SEAL 50 MM TF10 38000504247

50 MM LOCK RING TF10 38000505148

50 MM NUT TF10 38000504249

SEAL HOLDER TF10 35117013151

MixRite TF 10 , 1-5% , ON/OFF,

MixRite TF 10, 0.1-1.0%, ON/OFF, 50 mm, 28100110000

MixRite TF 10, 0.2-2.0%, ON/OFF, 50 mm, 28100210000

50 mm, 28100510000

92 STAINLESS STEEL DISC 38060351641

SPACER FOR CYLINDER 5% 3511705319595

95 SPACER FOR CYLINDER 2% 35117023196

TEFEN Advanced Plastic Solutions.

TEFEN

14

A

A

A

E

D

F

C

1% TF10

G

82

83

84

85

86

88

87

89

90

91

H

TEFEN Advanced Plastic Solutions.

TEFEN

15

TF 10 -KITS

C SUCTION TUBE KIT 36000000028

35100000016

H MANUAL ON/OFF KIT

TEFEN Advanced Plastic Solutions.

TEFEN

16

A

A

A

E

D

F

C

1% TF10

G

82

83

84

85

86

88

87

89

90

91

CL

TEFEN Advanced Plastic Solutions.

TEFEN

17

TF 10 CL - KITS

C SUCTION TUBE KIT 36000000028

35100000053

COMPLETE ENGINE CL

TEFEN Advanced Plastic Solutions.

TEFEN

18

MixRite TF 10

Manual del Usuario

Edición 01-12

TEFEN Advanced Plastic Solutions.

TEFEN

19

Inyector de Fertilizante y Productos Químicos Tefen MixRite TF 10

Lo felicitamos por haber adquirido uno de los excelentes productos de Tefen.

Es muy importante que dedique algunos minutos a la lectura, en forma cuidadosa, de

las explicaciones y recomendaciones que contiene este Manual del Usuario para

obtener los mejores resultados del inyector de dosificación proporcional MixRite TF-10.

Principios operativos

El inyector de dosificación proporcional se conecta a la línea de agua. El flujo de agua

que pasa a través del inyector lo activa y provoca el bombeo del líquido fertilizante (u

otro aditivo) y lo inyecta en una cantidad proporcional en la línea de agua.

El MixRite TF 10 tiene el siguiente rango de trabajo:

El caudal que pasa a través del inyector debe estar entre 0,5 y 10 m3/h (2 – 45 GPM).

La presión de agua debe estar entre 1 y 8 bar (14,7 y 120 PSI).

Las temperaturas del agua y del aire no deben ser inferiores a 4°C y tampoco

superiores a 40°C (39 °F – 104°F).

Pérdida de carga: caudal bajo 0,1 bar – caudal alto 0,9 bar

Máxima desviación de la tasa de inyección: +/- 10%

Antes de usarlo, se debe realizar una calibración inicial a los efectos de asegurar una

coincidencia precisa con la escala impresa en el inyector.

El caudal de fertilizante y de productos químicos puede ser ajustado en forma

proporcional al caudal de agua en el siguiente rango:

0,1% a 1%

0,2% a 2%

0,5% a 5%

Instalación del inyector

Verifique que el paquete del inyector contenga los siguientes

ítems:

Un inyector de dosificación proporcional al que están fijados dos

conectores de compresión (Plasson) para una tubería de PE de 50

mm.

Un tubo de succión flexible al que está fijado un sello plano y un

filtro.

2 soportes de pie.

Un Manual del Usuario.

4 patas (opcional)

Para amurarlo a la pared – fije uno de los soportes a la pared insertando los 4 tornillos

en el soporte.

Para instalar el pie - inserte los soportes en las ranuras del cuerpo en la parte inferior

y presione hasta que entren en su lugar. Coloque las patas en los agujeros y presione

hasta que estén bien trabadas.

TEFEN Advanced Plastic Solutions.

TEFEN

20

.

Conexión del tubo de succión

Inserte el sello plano en la tuerca del acoplamiento en el extremo del tubo (1).

Enrosque y ajuste la tuerca a la válvula de entrada ubicada en la parte inferior del

inyector. Asegúrese de que la tuerca esté bien enroscada y debidamente ajustada

(2,3).

Conexión del inyector a una línea roscada de 1,5”

Tenga en cuenta la dirección del flujo de agua. Arme el inyector de forma tal que la

flecha que está estampada en su cuerpo y la flecha roja en la etiqueta central apunten

en la dirección del flujo de agua. Conecte el inyector usando los acoplamientos

plásticos.

Conexión del inyector a una línea de polietileno de 50 mm

Tenga en cuenta la dirección del flujo de agua. Arme el inyector de forma tal que la

flecha que está estampada en su cuerpo y la flecha roja apunten en la dirección del

flujo de agua. Asegúrese de que los extremos de la tubería de entrada y salida estén

cortados en forma recta y que el extremo tenga una forma de cono redondeado. La

distancia entre el extremo de entrada y el de salida debe ser de 25 cm (9,8”).

Retire la tuerca de 50 mm y el anillo blanco del

inyector, y deslícelos por fuera de la tubería hasta

llegar a una corta distancia de su extremo. Verifique

que el accesorio sello 50 y que el sellado de

sujeción 50 cierren la unidad desde afuera (1).

Inserte la tubería en la abertura de entrada o de

salida de acuerdo con la dirección indicada y

empuje con fuerza de modo tal que la tubería

penetre y el sello pase y se detenga al final de su

recorrido.

Para facilitar la penetración de la tubería aplique un

poco de grasa siliconada en el extremo del tubo

antes de insertarla. Empuje el anillo blanco hasta

que alcance la rosca (2). Coloque la tuerca y

ajústela con firmeza. De la misma forma conecte el

inyector a la otra tubería.

Table of contents

Languages:

Other tefen Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

IKA

IKA C-MAG HS4 operating instructions

Esco

Esco ETS-Lindgren GTEM! 5411 installation manual

Pentair

Pentair SMART UV EU18-U Installation and user guide

Lafayette Instrument

Lafayette Instrument 63040A user manual

Hardy Diagnostics

Hardy Diagnostics QuickSlide HemaPRO quick start guide

MRC

MRC LOM-150-UV Operation manual