Tek-Trol TEK-DP 1670A User manual

Table of contents

Other Tek-Trol Measuring Instrument manuals

Tek-Trol

Tek-Trol TEK-DP 1610D User manual

Tek-Trol

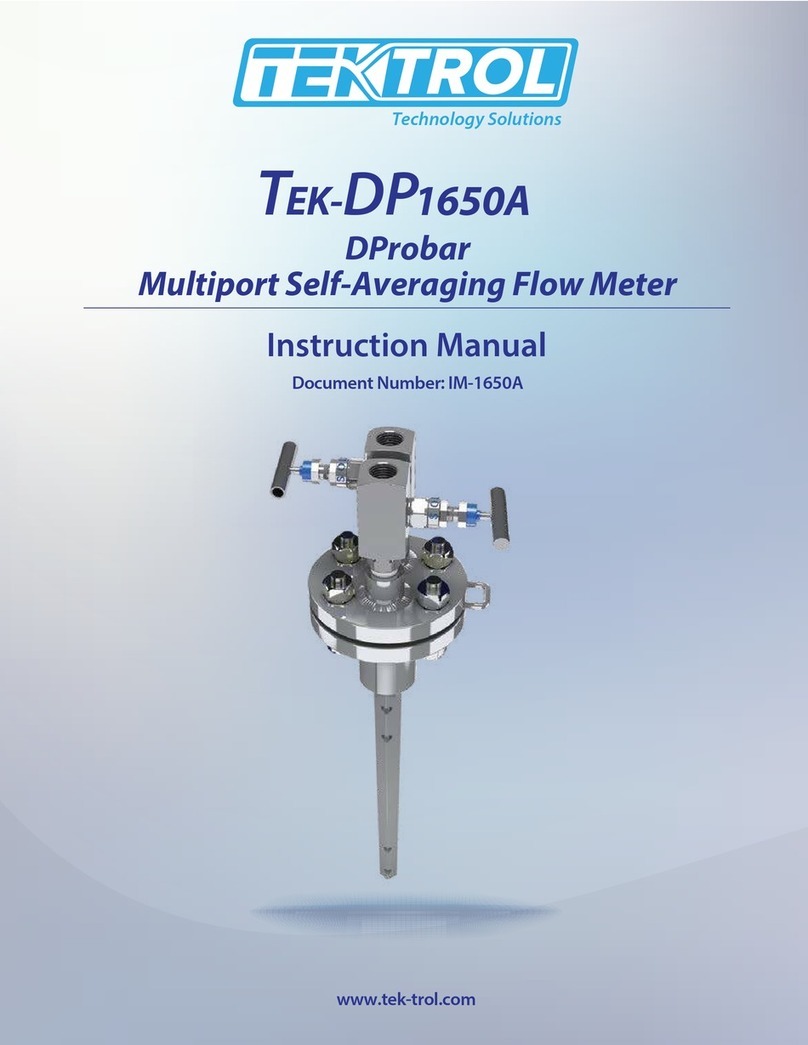

Tek-Trol TEK-DP1650A User manual

Tek-Trol

Tek-Trol Tek-Flux 1400A User manual

Tek-Trol

Tek-Trol TEK-VOR 1300C User manual

Tek-Trol

Tek-Trol TEK-VOR 1300C User manual

Tek-Trol

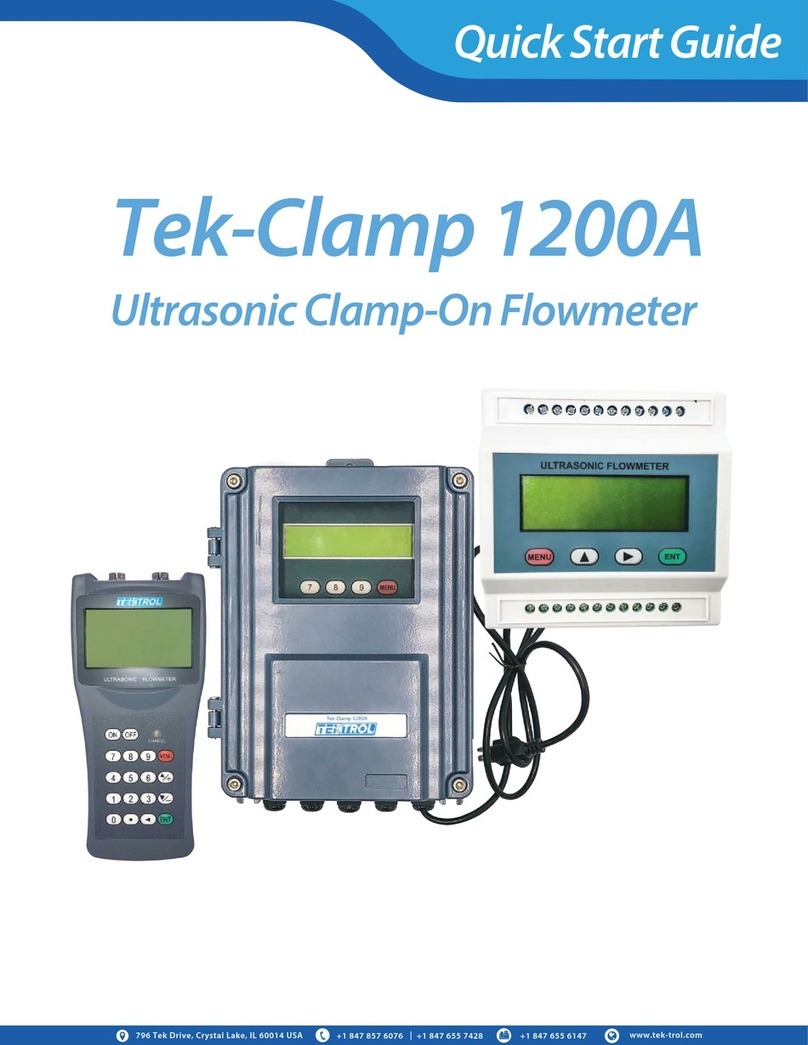

Tek-Trol TEK-C LAMP 1200A-100H User manual

Tek-Trol

Tek-Trol Tek-Clamp1200A-100H User manual

Tek-Trol

Tek-Trol TEK-LCD 7800A-0L1 User manual

Tek-Trol

Tek-Trol TEK-COR 1100A User manual

Tek-Trol

Tek-Trol Tek-Flux 1400C User manual

Tek-Trol

Tek-Trol TEK-CLAMP 1200A-100H User manual

Tek-Trol

Tek-Trol Tek-Bar 3110B User manual

Tek-Trol

Tek-Trol Tek-LCD 7805B User manual

Tek-Trol

Tek-Trol Tek-Clamp 1200A User manual

Tek-Trol

Tek-Trol Tek-Clamp 1200A User manual

Tek-Trol

Tek-Trol Tek-Flux 1400A User manual

Tek-Trol

Tek-Trol Tek-Batch 7900B User manual

Tek-Trol

Tek-Trol TEK-DP1620A User manual

Popular Measuring Instrument manuals by other brands

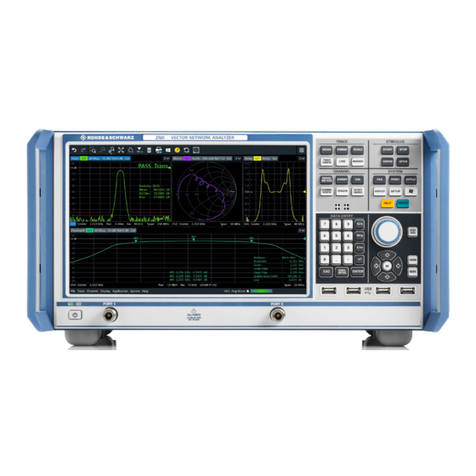

Rohde & Schwarz

Rohde & Schwarz R&S ZNB user manual

POWERSIDE

POWERSIDE PQube 3 installation manual

Instantel

Instantel 716A0401 Operator's manual

Kingst

Kingst LA1016 user guide

Vanguard Instruments Company

Vanguard Instruments Company ATO-400P operating instructions

Chauvin Arnoux

Chauvin Arnoux PAC 20 user manual

PCB Piezotronics

PCB Piezotronics 3503A1160KG/-0002 Installation and operating manual

Kingwell

Kingwell 600 Series Instructions for use

LOMVUM

LOMVUM LV Series user guide

Savant

Savant SmartEnergy SEM-1024 Quick reference guide

CMT ORANGE TOOLS

CMT ORANGE TOOLS DHG-001 quick guide

Hinds Instruments

Hinds Instruments EXICOR 150AT user manual