Teknion interpret WWSSC Operating and maintenance instructions

Single - Sided Complete Frame (WWSSC),

Wire Gap Worksurface (WWWRW)

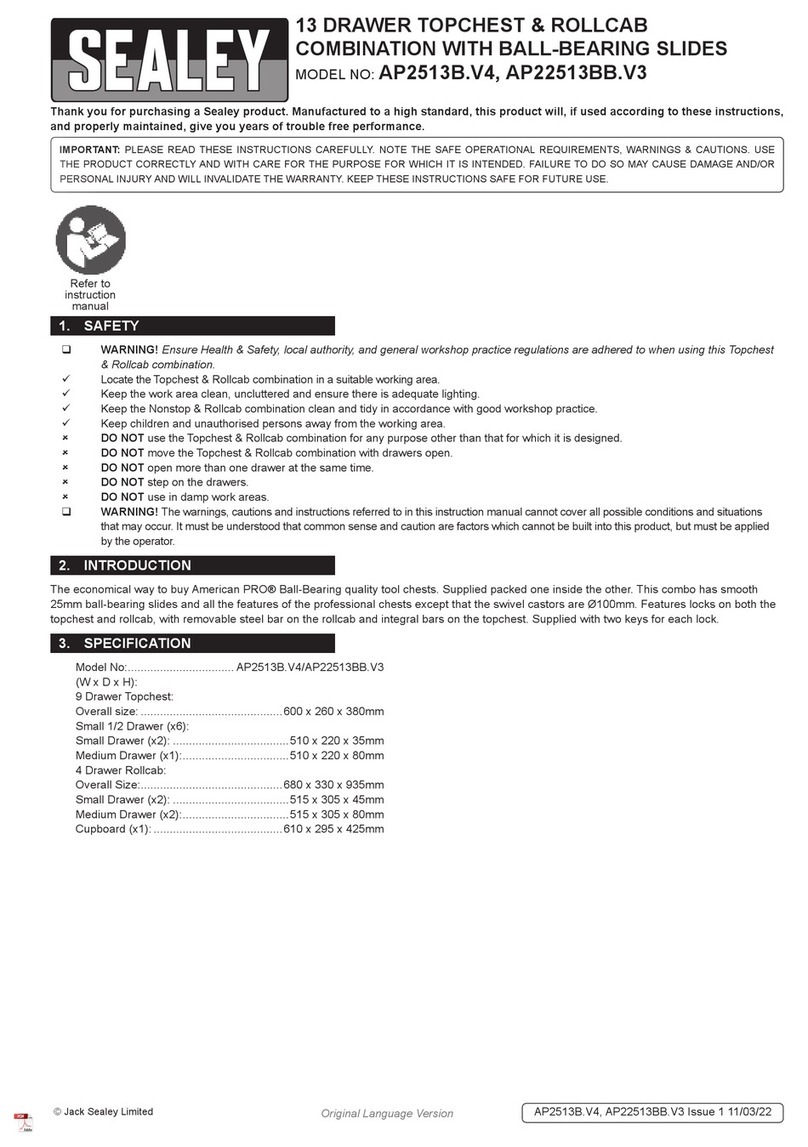

Part and Product Identification

Section:

Description: Page No:

Date:

Rev. No: 4

COMPLETE FRAME AND WIRE GAP WORKSURFACE - SINGLE SIDED

FRAMES, SUPPORTS AND WORKSURFACES

Aug 2017 1 of 12

INT_009

interpret

Installation Guides

A

G

F

H

Angled Leg Frame shown

I

J

C1

E

M

Wire Gap Worksurface

(WWWRW) x1

O

A-End Leg, Angle

Single Sided

(N02-3700) x1

Left & 1 Right

D-1/4-20x3-1/2 Flat Head

Machine Quad

(E01-0771) x2

E-Front Standoff

(B02-0658) xqty varies

F-Return Center Rail

Assembly

(N02-2150) x1

H-Modesty, Single Sided

(C05-7238) x1

O-Gable Corner Bracket

L/R

(X05-0273) x2

I-Infill Bottom Bracket

(A16-0947) x2

K-1/4-20 UNC x0.500"

2A, Cross Square

Socket, Truss Head,

Machine Steel, Zinc

(E01-0110) x8

or x12

N-#10x0.875 Quad Pan

Washer

(E07-0077) x 6

or x12

L-#8118x1/2 Cross

Square Comb, Self

(E07-0012) x2

M-Worksurface Support

Bracket

(N09-4134) x2

or x4

B-End Leg, Straight

Single Sided

(N02-3698) x1

Left & 1 Right

G-Return Center Rail Cap

(N02-2151) x2

J-Infill Bottom Bracket

Cover

(A25-0389) x2

Q-5/16-18 x 3/8 Hex Nut

1/2A/F .190 Thick

(E03-0551) x6

or x8

P-5/16-18x3/8 Button

Head, Hex Socket

(E01-0798) x6

or x10

R-Interpret Drilling

Template

(A16-1623) x1

OR

C2-5/16-18x2.5 Socket Head

Cap Screw

(E01-0756) x8

C3-5/16-18 Hex Nut 1/2 A/F

.265 Thick

(E01-0755) x8

C1-Transverse Beam

Assembly

(N02-3688) x1

Leveler Cover is

located inside Leg,

assembled and

secured in place

with tape.

Section:

Description: Page No:

Date:

REMOVE NUTS AND SCREWS

Aug 2017 2 of 12

INT_009

COMPLETE FRAME AND WIRE GAP WORKSURFACE - SINGLE SIDED

FRAMES, SUPPORTS AND WORKSURFACES

interpret

Installation Guides

STEP 1: Remove Screw and Nut from Clamp as shown on illustration.STEP 1: Remove Screw and Nut from Clamp as shown on illustration.

Do Not Remove

C2

C3

C1

C3

C2

C1

End Gable Connection

Mid Gable Connection

Section:

Description: Page No:

Date:

RELOCATE CLAMP

Aug 2017 3 of 12

INT_009

COMPLETE FRAME AND WIRE GAP WORKSURFACE - SINGLE SIDED

FRAMES, SUPPORTS AND WORKSURFACES

interpret

Installation Guides

STEP 2: Remove Clamp.

Clamps at End Gable Location

Clamps at Mid Gable Location

Clamp to be removed and repositioned to

End Gable Postion

Clamps at End Gable Location

Refer to highlighted holes to

fasten Clamps for End Gable

Position.

C3

C2

Section:

Description: Page No:

Date:

CONNECT END GABLES AND TRANSVERSE BEAM SECURE WITH FASTENERS

INT_009

4 of 12

Aug 2017

COMPLETE FRAME AND WIRE GAP WORKSURFACE - SINGLE SIDED

FRAMES, SUPPORTS AND WORKSURFACES

interpret

Installation Guides

STEP 4 : Fasten together using Socket Cap Screw and Nuts. Level and square the whole

assembly.

STEP 3: Bring End Gables and Central Transverse Beam Assembly together. Line up the

middle set of holes on the End Gable Cross Beams with Clamp Brackets holes.

Position End Gables

with holes facing inward.

C2

C3

A1

End Gable Connection

Section:

Description: Page No:

Date:

REMOVE SCREWS FROM THE GABLE FASTEN GABLE CORNER BRACKETS

INT_009

5 of 12

Aug 2017

COMPLETE FRAME AND WIRE GAP WORKSURFACE - SINGLE SIDED

FRAMES, SUPPORTS AND WORKSURFACES

interpret

Installation Guides

STEP 6: Using the same screws install two Gable Corner Brackets.STEP 5: Remove two screws from both gables as shown.

M

Section:

Description: Page No:

Date:

RAIL ASSEMBLY SLIDING NUTS INTO POSITION

INT_009

6 of 12

Aug 2017

COMPLETE FRAME AND WIRE GAP WORKSURFACE - SINGLE SIDED

FRAMES, SUPPORTS AND WORKSURFACES

interpret

Installation Guides

STEP 8: Slide Nuts inside the channel to line them up with holes in both Gable Corner

Brackets. Place remaining Nuts in approximate position for future installation.

STEP 7: Insert Hex Nuts into Rail underside channel. There should be one Nut for each Gable

Corner Bracket and two for each Worksurface Support Bracket.. Install Rail Cap both sides of

the Rail. Rotate set screws to secure Caps in place.

G

F

Q

O

Q

Section:

Description: Page No:

Date:

INSTALL RAIL ASSEMBLY TO THE FRAME ATTACH MODESTY

INT_009

7 of 12

Aug 2017

COMPLETE FRAME AND WIRE GAP WORKSURFACE - SINGLE SIDED

FRAMES, SUPPORTS AND WORKSURFACES

interpret

Installation Guides

STEP 10: Fasten Modesty Panel to Corner Brackets. Make it loose connection.STEP 9: Line up the Rail with Nuts and holes in the Gable Corner Brackets align. Fasten with

Screws. Don't tighten.

P

FH

Underside View

K

Do not tighten!

Section:

Description: Page No:

Date:

PREPARATION FOR ATTACH MODESTY TO LEG ATTACH INFILL BOTTOM BRACKET TO MODESTY

INT_009

8 of 12

Aug 2017

COMPLETE FRAME AND WIRE GAP WORKSURFACE - SINGLE SIDED

FRAMES, SUPPORTS AND WORKSURFACES

interpret

Installation Guides

STEP 12: Fasten Infill Bottom Brackets to the Modesty. Use pilot holes for location.STEP 11: Align Drilling Template with the bottom of Modesty and push it against the Leg.

Mark the location to be drill as shown. Push Modesty out of the way and drill the marked

location.

NOTE: Please mark another pilot hole if End Gable is specified.

Underside VIew

K

I

ALIGN

NOTE: Make sure to position

Drilling Template as shown.

Please mark another pilot hole if

End Gable is specified.

Modesty End Gable

(Optional)

R

Section:

Description: Page No:

Date:

FASTEN MODESTY TO LEGS SUPPORT BRACKET ALIGNEMENT

INT_009

9 of 12

Aug 2017

COMPLETE FRAME AND WIRE GAP WORKSURFACE - SINGLE SIDED

FRAMES, SUPPORTS AND WORKSURFACES

interpret

Installation Guides

STEP 14: Line up each Worksurface Support Bracket with sets of inserts on the Modesty. Push

the top of Modesty for easier access to the Rail channel. Adjust Nuts inside channel to align

with Bracket holes.

C

L

J

M

Push the top of

the Modesty for

an easieraccess

L

Q

STEP 13: Fasten Infill Bottom Brackets to back legs using predrilled holes. Slide Bracket Cover

on the top of them.

Section:

Description: Page No:

Date:

FRAMES, SUPPORTS AND WORKSURFACES FRAMES, SUPPORTS AND WORKSURFACES

INT_009

10 of 12

Aug 2017

COMPLETE FRAME AND WIRE GAP WORKSURFACE - SINGLE SIDED

FRAMES, SUPPORTS AND WORKSURFACES

interpret

Installation Guides

STEP 15. After Bracket is placed in the space between Rail and Modest, with holes aligned with

Nuts, secure it with Screws provided. Continue with remaining Brackets. Tighten Corner

Bracket to Rail screws.

P

Underside View

K

STEP 16: Move Modesty back to it's original location. Fasten Brackets to the Modesty.

Move Modesty back

to original location

Tighten Screws!

Section:

Description: Page No:

Date:

LEVEL INSTALL LEVELER COVERS AND SPACER

INT_009

11 of 12

Aug 2017

COMPLETE FRAME AND WIRE GAP WORKSURFACE - SINGLE SIDED

FRAMES, SUPPORTS AND WORKSURFACES

interpret

Installation Guides

STEP 18: Lock each leveler and remove tape so Leveler Cover can slide down.STEP 17: Level and square. Tighten screws and bolts.

E

Tighten

Section:

Description: Page No:

Date:

LOWER WORKSURFACE ON THE FRAME FASTEN

INT_009

12 of 12

Aug 2017

COMPLETE FRAME AND WIRE GAP WORKSURFACE - SINGLE SIDED

FRAMES, SUPPORTS AND WORKSURFACES

interpret

Installation Guides

STEP 20: Fasten with screws provided. Inside set of inserts are to be used for Complete Frame.

The second set is for Mid Gable connection.

STEP 19: Line up holes in Clamp Brackets and inserts underneath of Worksurface. Place

Worksurface on the top of the frame.

Underside View

Top View

D

N

This manual suits for next models

1

Popular Tools Storage manuals by other brands

Holzmann

Holzmann WB210 Assembly instruction

Husky

Husky H27CH5TR4BGK Use and care guide

DIVERSIFIED WOODCRAFTS

DIVERSIFIED WOODCRAFTS SHAIN GSB-6024 Assembly instruction

Grizzly

Grizzly H7725 instructions

Husky

Husky HOTC4412BN1S Use and care guide

Seville Classics

Seville Classics UltraDurable SHE15390B manual