TEKNIX TKG104BL User manual

User manual

Teknix Support 01759 487823

Teknix Gas & Electrical

100 cm Range Cooker

TKG104BL / TKDF104BL

User manual

2

Dear User,

Our objective is to make this product provide you with the best

output which is manufactured in our modern facilities in a careful

working environment, in compliance with total quality concept.

Therefore, we suggest you to read the user manual carefully before

using the product and, keep it permanently at your disposal.

Note: This user manual is prepared for more than one model. Some

of the features specied in the Manual may not be available in your

appliance.

All our appliances are only for domestic use, not for commercial use.

Products marked with (*) are optional.

“THIS APPLIANCE SHALL BE INSTALLED IN ACCORDANCE WITH THE

REGULA TIONS FORCE AND ONLY USED IN A WELL VENTILATED SPACE.

READ THE INSTRUCTIONS BEFORE INSTALLING OR USING THIS APPLIANCE”

“Conforms with the WEEE Regulations."

3

CONTENTS

Important Warnings 4

Introduction Of The Appliance 7

Important Warnings 8

Electrical Wiring Scheme 9

Gas Mark Table 10

Gas Hose Passage Way 10

Installation Of Your Oven 11

Technical Features Of Your Oven 12

Injector, Gas Flow And Power Table 13

Reduced Gas Flow Rate Setting For Hob Taps 15

Reduced Flame Gas Cock Adjustment 15

Removal Of The Cathedral Burner 16

Description Of Oven 16

Using The Burner Groups 17

Using Oven Section 22

Cooking Time Table 25

Timer Operation 26

Cleaning And Maintenance Of The Oven’s Door 31

Maintenance And Cleaning 32

Installation Of The Oven Door 33

Accesories 34

Using The Grill Deector Sheet 35

If Your Oven Does Not Operate 36

Environmentally-Friendly Disposal and

Package Information 36

4

IMPORTANT WARNINGS

1.WARNING: To avoid electrocution, ensure that the

electrical circuit of the product is open before replacing

the lamp.

2.WARNING:Before touching the connection terminals,

all supply circuit should be disconnected.

3.WARNING:While operating the grill, the reachable

sections can be hot. Keep the children away.

4.WARNING:Any inadvertent cooking made with fats and

oils can be dangerous and cause re.

5.WARNING:Risk of re; do not store the food materials

on the cooking surface.

6.WARNING:If the surface is cracked, unplug the device

to prevent any risk of electric shock.

7.WARNING:During usage the reachable sections can be

hot. Keep the small children away.

8.WARNING:The appliance and its reachable sections

become hot during usage.

9.The setting conditions of this appliance is

indicated on the label. (Or data tag)

10.This appliance is not connected to a combustion

product discharge system.This appliance shall be

connected and installed as per the applicable

installation legislation. Consider the requirements

related with ventilation.

5

11.Using a gas hob will release humidity and combus-

tion products in the room where it resides. Especially

during when the appliance in use, ensure that the kitch-

en is well ventilated and retain the natural ventilation

holes or install a mechanical ventilation system. (Hood

on top of the oven) Sustained usage of the appliance

may require additional ventilation. For example open-

ing a window or if available, increasing the ventilation

level of a mechanical ventilation system.

12.The reachable sections can become hot when the

grill is used. Keep the small children away.

13.WARNING:The appliance is intended for cooking only.

It must not be used for other purposes like room heating.

14.There are additional protective equipment to

prevent inadvertent touching to the oven doors. This

equipment should be installed if there are children.

15.“This appliance should be installed as per

regulations and in well-ventilated location only.

Read the instructions before installing or operating

the appliance.”

16.“Before placing the appliance check the local

conditions (gas type and gas pressure) and ensure

that the settings of the appliance is appropriate.”

17.“These instructions are applicable for countries of

which symbols are indicated on the appliance. If the

country symbol is not available on the appliance,in

order to adapt the appliance to the conditions of such

country, the technical instructions should be read.”

6

18.“Do not operate the system for more that 15

seconds. If the burner does not ignite at the end of

15 seconds stop the operation of the system and open

the section door and/or wait for at least 1 minute before

igniting the burner.

19.Do not use steam cleaners to clean the appliance.

20.Before opening the oven door clean the remnants

on it. Before closing the oven door, let it cool.

21.NEVER try to extinguish a re with water, rst

disconnect the mains supply and then using, for

example a lid or blanket, cover the re.

22.Do not use hard and abrasive cleaning agents or

hard metal scrapers to clean the oven door glass as

they may scratch and shatter the surface.

23.After placing a dish, ensure that the door is rmly

closed.

24.Unless continuous supervision is provided, the

children of age 8 or below should be kept away.

25.Pay attention for not to touch the heating elements.

26.This appliance can be used by children aged from

8 years and above and persons with reduced physical,

sensory or mental capabilities or lack of experience

and knowledge if they have been given supervision or

instruction concerning use of the appliance in a safe

way and understand the hazards involved.

27. The appliance hasn’t been designed for operation

with an external time or a separate remote control system.

7

INTRODUCTION OF THE APPLIANCE

Note: The meaning of the symbols on the control panel of device is provided below.

Not every symbol is on every model; only take notice of the symbols on your device.

1

2

3

4

6

5

7

1. Burner Plate

2. Control Panel

3. LHS Grill

4. LHS Main Oven

5. Splash Back*

6. RHS Oven

7. Lower Part

1. Auxiliary Burner

2. Rapid Burner

3. Wok Burner

4. Digital Timer*

5. LHS Gril

6. LHS Main Oven

7. RHS Oven

8. Normal Burner

9. Normal Burner

10. Auxiliary Burner

11. Rapid Burner

1 2 3 54 6 7 8 9 10 11

8

IMPORTANT WARNINGS

Electrical Connection and Security

1. Your oven requires 26 Ampere fuse according to the appliance’s power.

If necessary, installation by a qualied electrician is recommended.

2.Your oven is adjusted in compliance with 220-240V AC 50/60Hz.

electric supply. If the mains are different from this specied value, contact

your authorized service.

3. Electrical connection of the oven should only be made by the sockets

with earth system installed in compliance with the regulations. If there

is no proper socket with earth system in the place where the oven will be

installed, immediately contact a qualied electrician. Manufacturer shall

never be responsible from the damages that will arise because of the

sockets connected to the appliance with no earth system.

4. Electrical cable should not touch the hot parts of the appliance.

5. For disconnection from the supply mains having a contact separation

in all poles that provide full disconnection, must be incorporated in xed

wiring in according with the wiring rules.

Gas Connection and Security

1. Before your appliance is connected to the gas supply, ensure that

the gas category and pressure specications shown in the data plate

corresponds with your gas supply. If necessary call authorized service

for adjusting to gas category.

2. This appliance shall be installed in accordance with the regulations

in force and only used in a well ventilated space. Read the instructions

before installing or using this appliance. In the interest of safety this

appliances must be installed and / or serviced by a competent person as

stated in the gas safety regulations current editions.

3. The appliance must not be installed in a room without a window or

other controllable opening. If is installed in a room without a door which

opens directly to the outside, a permanent opening is required. The air

circulation should be 2 m³/h per kW of burners.

4. The gas connection should be performed from the right or left. For

this reason, change the hose nozzle, plug and the seals.

5. Please use exible hose for gas connection.

9

6. If you make a connection with a exible metal hose, locate a seal

between the main gas pipes.

7. The inner diameter of the exible hose, which the butane hose

nozzle is connected, should be 6 mm for the house-type gas tubes.

The inner diameter of the exible hose, which the natural hose nozzle

is connected, should be 15 mm.The hose should tightly be tted to the

hose nozzle by squeezing with a clamp. The hose should be replaced

before its last expiry date.

8. Caution! Make the oven connection to the gas inlet valve, the hose

length must be short and be sure that there is no leakage. The exible

hose used should not be longer than 125 cm for safety.

9. Re-inspect the gas connection.

10. When placing your oven to its location, ensure that it is at the

counter level. Bring it to the counter level by adjusting the feet if

necessary.

DO NOT MAKE GAS HOSE AND ELECTRICAL CABLE OF YOUR OVEN GO THROUGH

THE HEATED AREAS, ESPECIALLY THROUGH THE REAR SIDE OF THE OVEN. DO

NOT MOVE GAS CONNECTED OVEN. SINCE THE FORCING SHALL LOOSEN THE

HOSE, GAS LEAKAGE MAY OCCUR.

ELECTRICAL WIRING SCHEME

220-240V~50/60Hz

H05 VV-F 3G 4mm²

Live

Phase

Neural

Earth

10

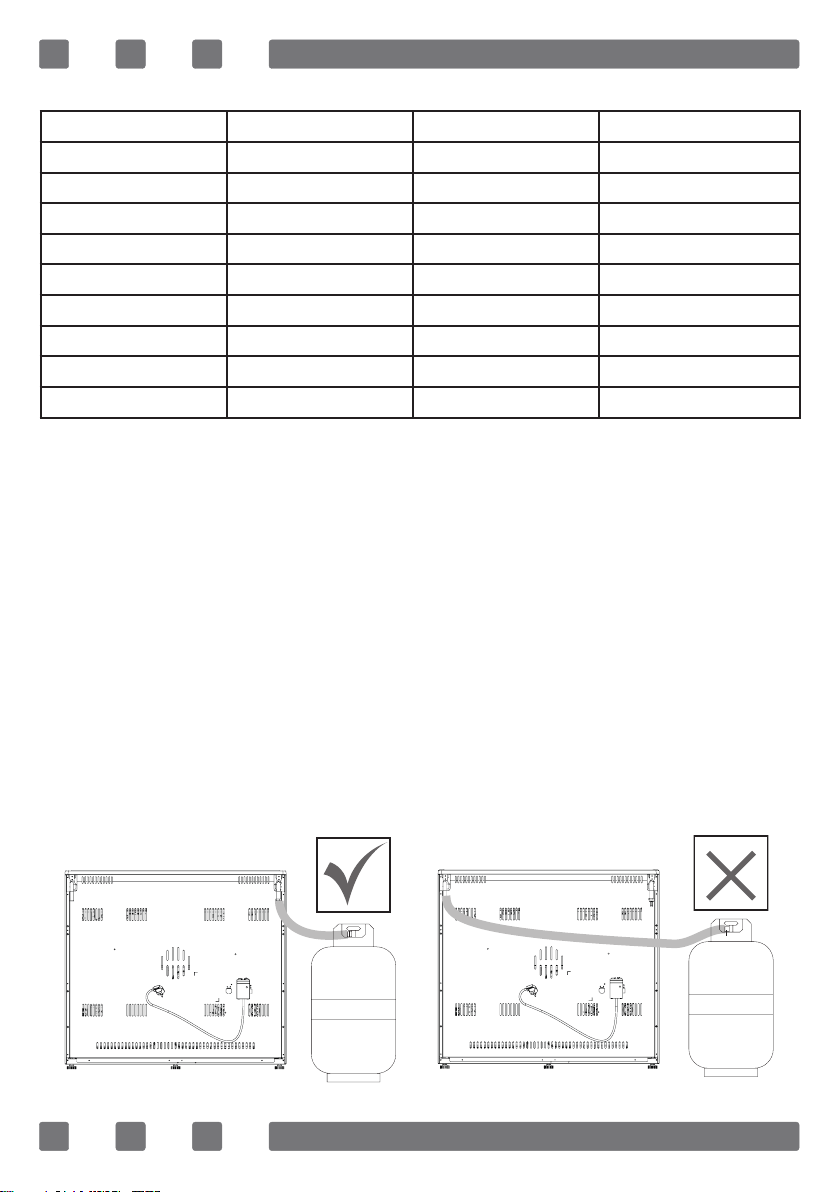

GAS MARK TABLE

Gas Mark Fahrenheit Celsius Description

1 275 140 Cool

2 300 150 ---

3 325 170 Very Moderate

4 350 180 Moderate

5 375 190 ---

6 400 200 Moderately Hot

7 425 220 Hot

8 450 230 ---

9 475 240 Very Hot

GAS HOSE PASSAGE WAY

1. Connect the appliance to the gas piping tap in shortest possible route

and in a way that ensure no gas leakage will occur.

2. In order to carry on a tightness and sealing safety check ensure that

the knobs on the control panel are closed and the gas cylindir is open.

3. While performing a gas leakage check, never use any kind of lighter,

match, cigarette or similar burning substance.

4. Apply soap bubble on the connection points. If there is any kind of

leakage then it will cause bubbling.

5. While inserting the appliance in place ensure that it is on the same

level with the worktop. If required adjust the legs inorder the make level

with the worktop.

6. Use the appliance on a level surface and in a well ventilated

environment.

Figure 1 Figure 2

11

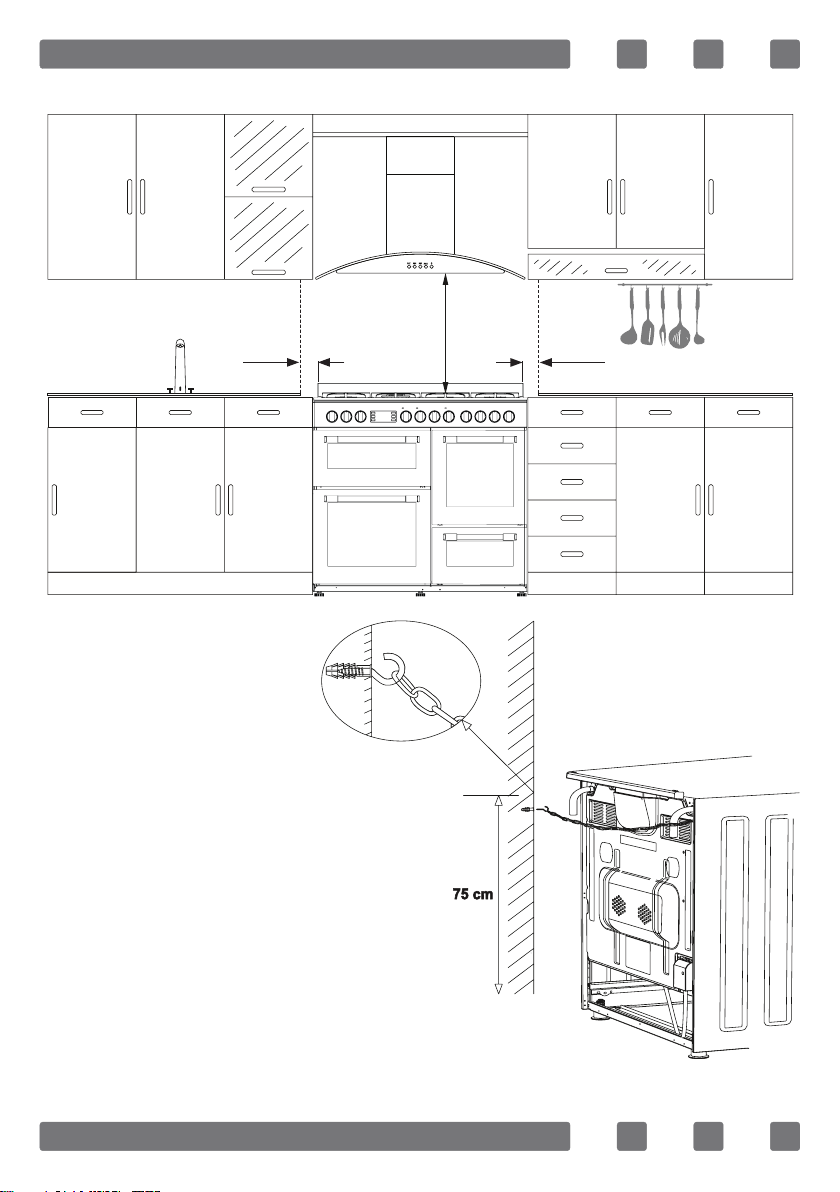

INSTALLATION OF YOUR OVEN

Chain Lashing Illustration

Before using the appliance, in order

to ensure safe use, be sure to x the

appliance to the wall using thechain

and hooked screw supplied. Ensure

that the hook is screwed into the wall

securely.

650mm min.

65mm min. 65mm min.

12

TECHNICAL FEATURES OF YOUR OVEN

Outer width 1000mm

Outer depth 600mm

Outer height 900mm

Lamp power 15-25W

Main Oven Grill Oven Top RHS Botton RHS

Bottom heating element 1200W --- 1000W 600W

Top heating element 1000W --- 800W 500W

Turbo heating element 1800W --- 1800W ---

Grill heating element --- 1400W --- ---

Supply voltage 220-240V AC 50/60Hz

Total electrical consumption

Type code MFR0/1702102E 5520W

Type code MFR0/1512122E 8320W

Total gas consumption

Type code MFR0/1701201G 20,1 kW, 1461 g/h

Type code MFR0/1512122E 10,75 kW, 782 g/h

13

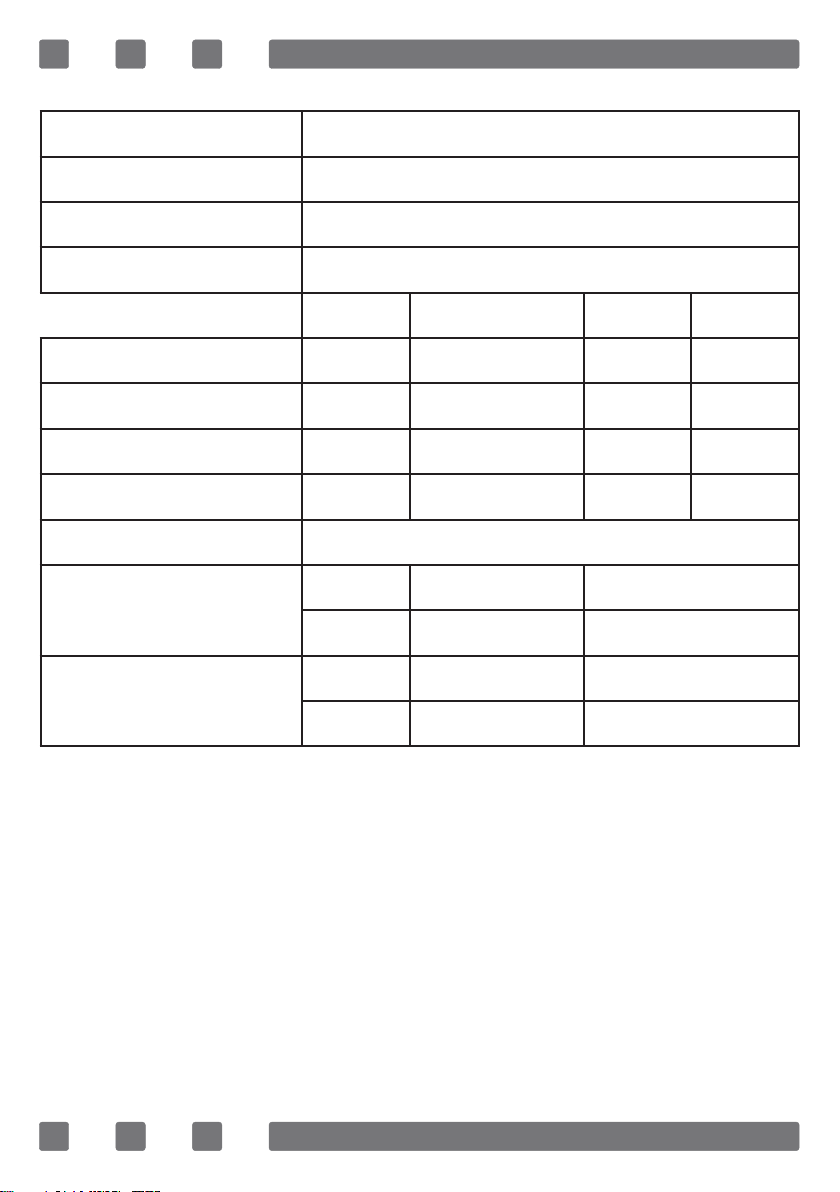

RANGE COOKER

INJECTOR, GAS FLOW And POWER TABLE

BURNER

SPECIFICATIONS

G20,20 mbar

G25,25 mbar G20,25 mbar

Gas Natural Gas Natural

Wok

Burner

Injector 1,40 mm 1,28 mm

Gas Flow 0,333 m³/h 0,333 m³/h

Power 3,50 kW 3,50 kW

Rapid

Burner

Injector 1,15 mm 1,10 mm

Gas Flow 0,276 m³/h 0,276 m³/h

Power 2,90 kW 2,90 kW

Semi-Rapid

Burner

Injector 0,97 mm 0,92 mm

Gas Flow 0,162 m³/h 0,162 m³/h

Power 1,70 kW 1,70 kW

Auxiliary

Burner

Injector 0,72 mm 0,70 mm

Gas Flow 0,96 m³/h 0,96 m³/h

Power 0,95 kW 0,95 kW

Grill

Burner

Injector 0,92 mm 0,92 mm

Gas Flow 0,144 m³/h 0,144 m³/h

Power 1,50 kW 1,50 kW

Main Oven / RHS

Burner

Injector 0,97 mm 0,97 mm

Gas Flow 0,190 m³/h 0,190 m³/h

Power 2,00 kW 2,00 kW

14

RANGE COOKER

INJECTOR, GAS FLOW And POWER TABLE

BURNER

SPECIFICATIONS

G30,28-30 mbar

G31,37 mbar G30,50 mbar G30,37 mbar

LPG LPG LPG

Wok

Burner

Injector 0,96 mm 0,76 mm 0,96 mm

Gas Flow 254 g/h 254 g/h 254 g/h

Power 3,50 kW 3,50 kW 3,50 kW

Rapid

Burner

Injector 0,85 mm 0,75 mm 0,85 mm

Gas Flow 211 g/h 211 g/h 211 g/h

Power 2,90 kW 2,90 kW 2,90 kW

Semi-Rapid

Burner

Injector 0,65 mm 0,60 mm 0,65 mm

Gas Flow 124 g/h 124 g/h 124 g/h

Power 1,70 kW 1,70 kW 1,70 kW

Auxiliary

Burner

Injector 0,50 mm 0,43 mm 0,50 mm

Gas Flow 69 g/h 69 g/h 69 g/h

Power 0,95 kW 0,95 kW 0,95 kW

Grill

Burner

Injector 0,60 mm 0,55 mm 0,60 mm

Gas Flow 109 g/h 109 g/h 109 g/h

Power 1,50 kW 1,50 kW 1,50 kW

Main Oven / RHS

Burner

Injector 0,70 mm 0,65 mm 0,70 mm

Gas Flow 131 g/h 131 g/h 131 g/h

Power 2,00 kW 2,00 kW 2,00 kW

15

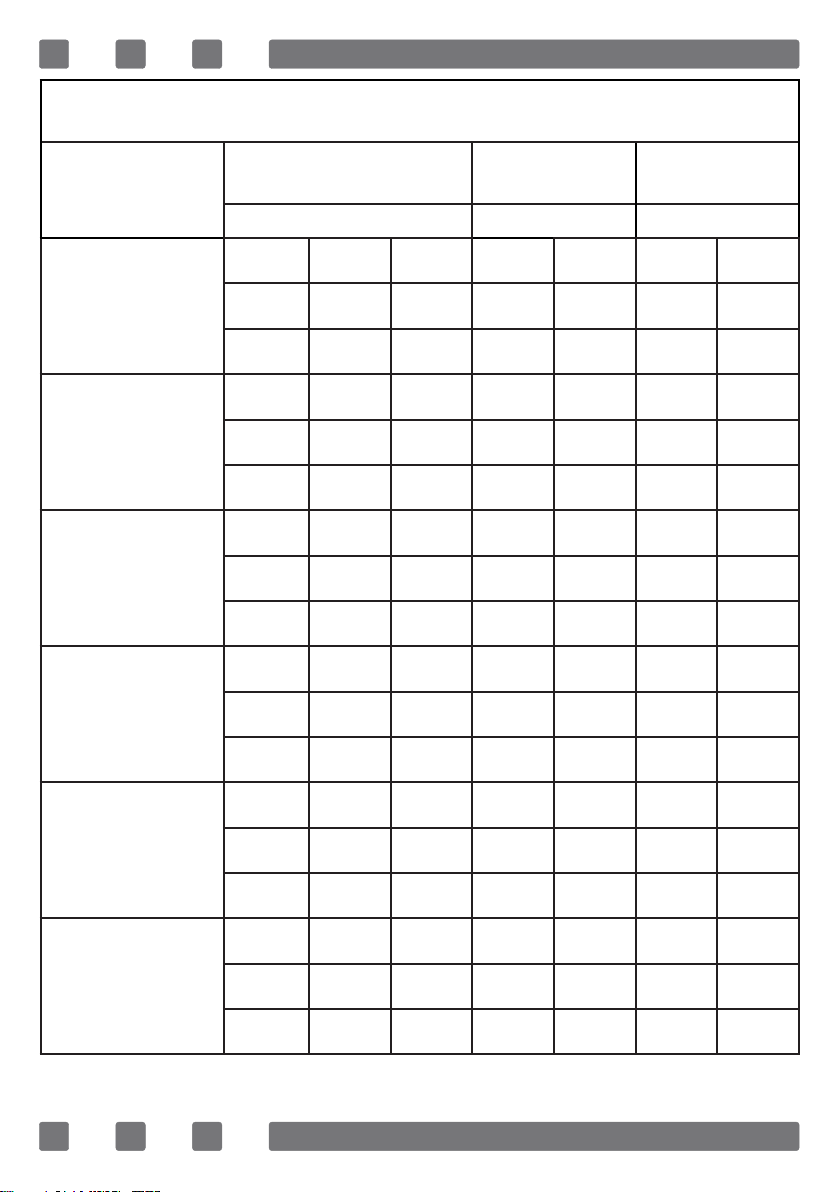

REDUCED GAS FLOW RATE SETTING FOR HOB TAPS

1. Ignite the burner that is to be adjustment

and turn the knob to the reduced position.

2. Remove the knob from the gas tap.

3. Use an appropriately sized screwdriver to

adjust the ow rate adjustment screw. For LPG

(Butane-Pro pane) turn the screw clockwise.

For the naturel gas, you should turn the screw

counter- clockwise once.

“The normal length of a straight ame in the

reduced position should be 6-7 mm.“

4. If the ame is higher then the desired

position, turn the screw clockwise. If it is

smaller turn anticolockwise.

5. For the last control, bring the burner both

to higt-ame and reduced positions and check

whether the ame is on or off.

Depending on the type of gas tap used in your appliance the adjustment

screw position may vary.

To adjust your oven acc. to the gas type, make the adjustment for re-

duced ame carefully by turning with a small screwdriver as shown below

on the screw in the middle of the gas cocks as well as nozzle changes.

(Figure 3 and 4)

REDUCED FLAME GAS COCK ADJUSTMENT

1. Please use driver with special head for removed and install nozzle

as (Figure 5).

2. Please remove nozzle (Figure 6) from burner with special nozzle

driver and install new nozzle. (Figure 7)

Figure 3

Figure 4

Figure 5

Figure 6

Figure 7

16

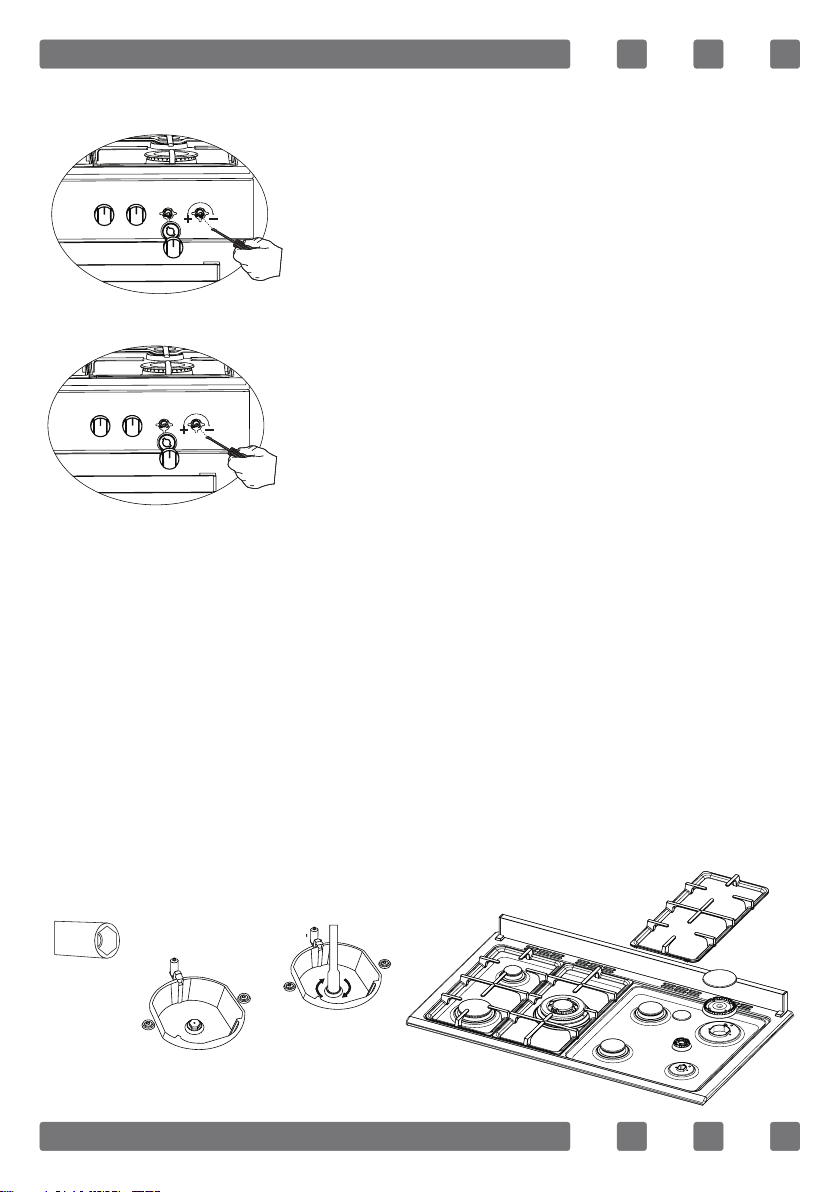

REMOVAL OF THE CATHEDRAL BURNER

The burner protection sheet is xed with two screws. As shown in

Figure 8, use a screwdriver to remove it. As shown in Figure 9, press

the spring clip in the direction of the arrow to remove the burner from

the slot. As shown in Figure 10, remove the injector in the bearing with

a socket wrench. In order to re-place the burner, apply the removal

process reversely.

DESCRIPTION OF OVEN

THERMOSTAT KNOB; In order to operate the oven, thermostat must

be adjusted to desired temperature. Your thermostat has a feature of

adjustment to 40 - 240 degree.

Figure 8 Figure 9 Figure 10

Top + Bottom heating

element Turbo heating + Fan

Bottom heating element

+ Fan

Bottom + Top heating

elements + Fan

Grill burner / Grill heating

element Top heating element

Oven burner / Bottom

heating element Flame

Ignition Lighter

17

USING THE BURNER GROUPS

1. Closed Fully open Half open

2. If your oven has ignition system from push button switch please press

and turn gas valve open position and same time press ignition button.

3. Our gas ovens top and bottom burner working system is one by one.

When you want use your preference burner, before you must make press

the tap knob and wait nearly 5-10 second. Then you can to iname through

with automatic ignition system (optional) or match. You must wait 10-15

second after iname to have press by tap knob and after you can make

allow the knob. If you can not made this operation you must try again.

4. The cocks controlling the gas cookers have special mechanism.

In order to light the cooker;

5. Always press on the switch forward and bring it to ame symbol

by turning anticlockwise (left). All of the lighters shall operate and the

cooker you controlled shall light only. Keep the switch pressed until

ignition is performed.

6. In models with security system, when ame of the cooker is extin-

guished, control valve cuts off the gas automatically. For operate the burners

with gas security system you must make press the knob and turn antilock

wise. After the ignition (with optional automatic ignition system or match)

you must wait nearly 5-10 second for gas security systems activation.

7. Do not continuously operate the igniter for more than 15 seconds.

After 15 seconds, if the burner does not ignite, then stop and if you are

trying to ignite the oven then open the door and wait a minimum of one

minute before trying again. If the burner is extinguished for of the any

reason, close the gas control valve and wait a minimum of one minute

before trying again.

8. Before operating your hob please make sure that the burner caps

are well positioned. The right placement of the burner caps are shown

as below.

Figure 11 Figure 12

18

Pot Diameter

WOK Burner 26-32cm

Big Burner 22-26cm

Normal Burner 18-22cm

Small Burner 12-18cm

Gas Connection and Safety

1. For LPG (cylinder) connection, afx

metal clamp on the hose coming from LPG

cylinder. Afx an edge of the hose on hose

inlet connector behind the appliance by

pushing to end through heating the hose

in boiled water. Afterward, bring the clamp

towards end section of the hose and tighten

it with screwdriver. The gasket and hose

inlet connector required for connection is

as the picture shown below.

NOTE: The regulator to be afxed on LPG cylinder should have 300

mmSS feature.

2. Natural gas connection should be

done by authorized service. For natural

gas connection, place gasket in the nut

at the edge of natural gas connection

hose. To install the hose on main gas

pipe, turn the nut. Complete the con-

nection by making gas leakage control.

Gas hose and electric connection of the appliance should

not pass next to hot areas such as back of the appliance.

Gas hose should be connected by making wide angle turns

against breaking possibility. Movement of appliance whose

gas connection is made may cause gas leakage.

False False False True

Main Gas Pipe

Gasket

Hose Inlet Connector

Metal Clamp

Lpg Connection Hose

Main Gas Pipe

Gasket

Nut

Natural Gas Connection Hose

19

United Kingdom Type Gas Connection:

WARNING: The gas hose must not be clamped, bent ar trapped or come

into contact with hat parts of the product. There is the risk of explosion

due to damaged gas hose.

Ventilation Of Room

The air needed for burning is received from room air and the gases

emitted are given directly in room. For safe operation of your product,

good room ventilation is a precondition. If no window or room to be

utilized for room ventilation is available, additional ventilation should

be installed. However, room has a door opening outside, it is no needed

to vent holes.

Room Size Ventilating Opening

Smaller than 5m³ min. 100cm²

Between 5m³ - 10m³ min. 50cm²

Bigger than 10m³ no need

In basement or cellar min. 65cm²

l

6 5 / r

4

F

2

1. Gasket

2. Adapter

3. Gas (safety) hose

4. Valve with 90°outlet

5. Connection piece

6. Gas supply pipe

20

Using The Hobs

1. Auxiliary Burner

2. Normal Burner

3. Rapid Burner

4. Wok Burner

Large ame symbol indicates the highest cooking power and small ame

symbol indicates the lowest cooking power. In turned off position (top),

gas is not supplied to the burners.

Gas Breaking Safety Appliance

Against putting out to be taken place as

a result of liquid overow at upper burners,

safety appliance steps in and cut gas

immediately.

Wok Burner

As it possesses double ring ame system, it gives

homogenous heat distribution at the bottom of

cooking pot at high temperature. It is ideal for

short term and high temperature cooking. When

you want to use regular cooking pot on wok burner,

it is necessary that you remove wok cooking pot

carrier from oven.

1 2 3

3 4 2 1

Figure 13

Gas shut off safety

Figure 14

This manual suits for next models

1

Table of contents

Other TEKNIX Cooker manuals

Popular Cooker manuals by other brands

Hotpoint

Hotpoint HUE 62 Instructions for installation and use

Indesit

Indesit KP9F11S-G operating instructions

Centaur

Centaur CEN-WARM1220 operating instructions

Bosch

Bosch HCE743220G instruction manual

American Range

American Range ARSCT-244 installation manual

Kuppersbusch

Kuppersbusch KEH 650.0 Instructions for use and installation instructions

Tricity Bendix

Tricity Bendix SB230 Operating and installation instructions

Nordica

Nordica CUCINOTTA Instructions for installation, use and maintenance

Midea

Midea MFS90GSS Instruction

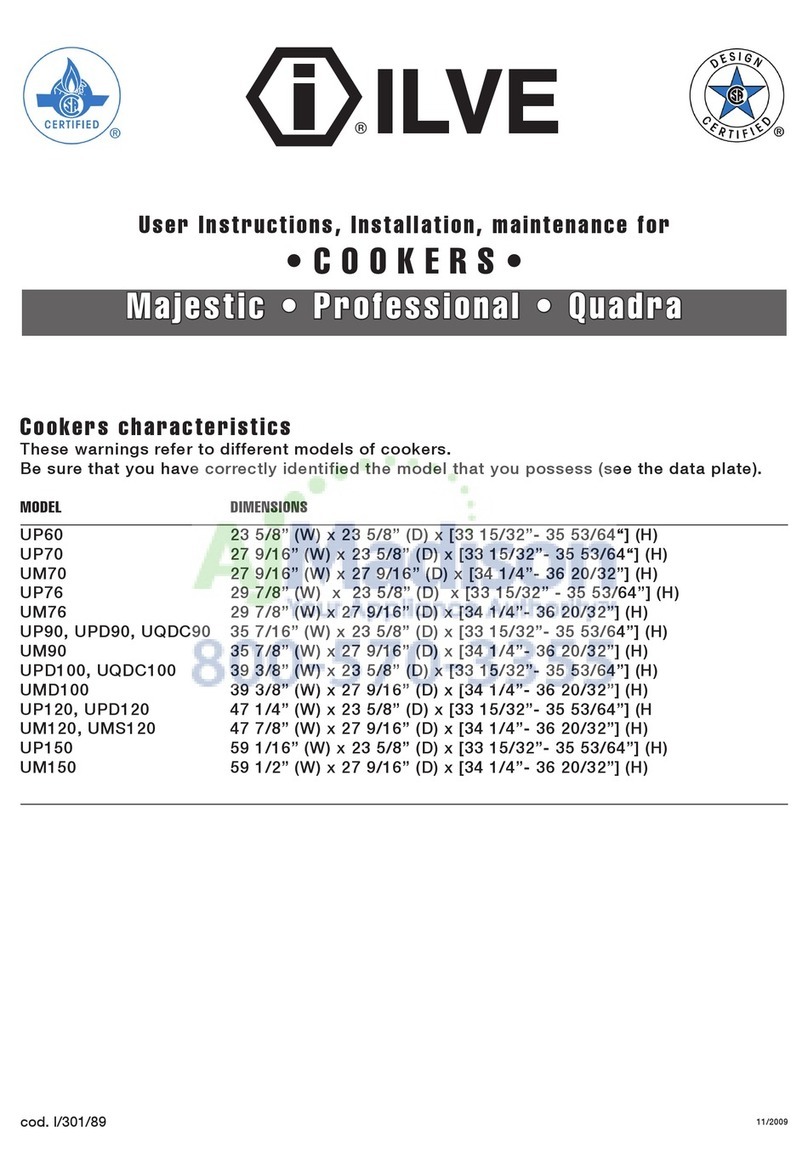

ILVE

ILVE UP60 User instructions, installation, maintenance

Creda

Creda HB49415 User instruction book

VESTEL

VESTEL VFSHI 90.60 user manual