Teknomotor ATC41-ISO20 User manual

ATC41-ISO20 INSTRUCTION MANUAL

DOC.U.A.001.DOCX Rev.02 del 11/11/2019 2

ATC41-ISO20

INSTRUCTION

MANUAL

Practical guide to the correct use of

Automatic Tool Changer ISO20

ATC41-ISO20 INSTRUCTION MANUAL

DOC.U.A.001.DOCX Rev.02 del 11/11/2019 3

ATC41-ISO20 INSTRUCTION MANUAL

DOC.U.A.001.DOCX Rev.02 del 11/11/2019 4

This manual contains information protected by copyright. It and its attachments shall not be

photocopied or reproduced in any form, either fully or in part, without the prior written consent of

TEKNOMOTOR S.R.L.

ATC41-ISO20 INSTRUCTION MANUAL

DOC.U.A.001.DOCX Rev.02 del 11/11/2019 5

ATC41-ISO20 INSTRUCTION MANUAL

DOC.U.A.001.DOCX Rev.02 del 11/11/2019 6

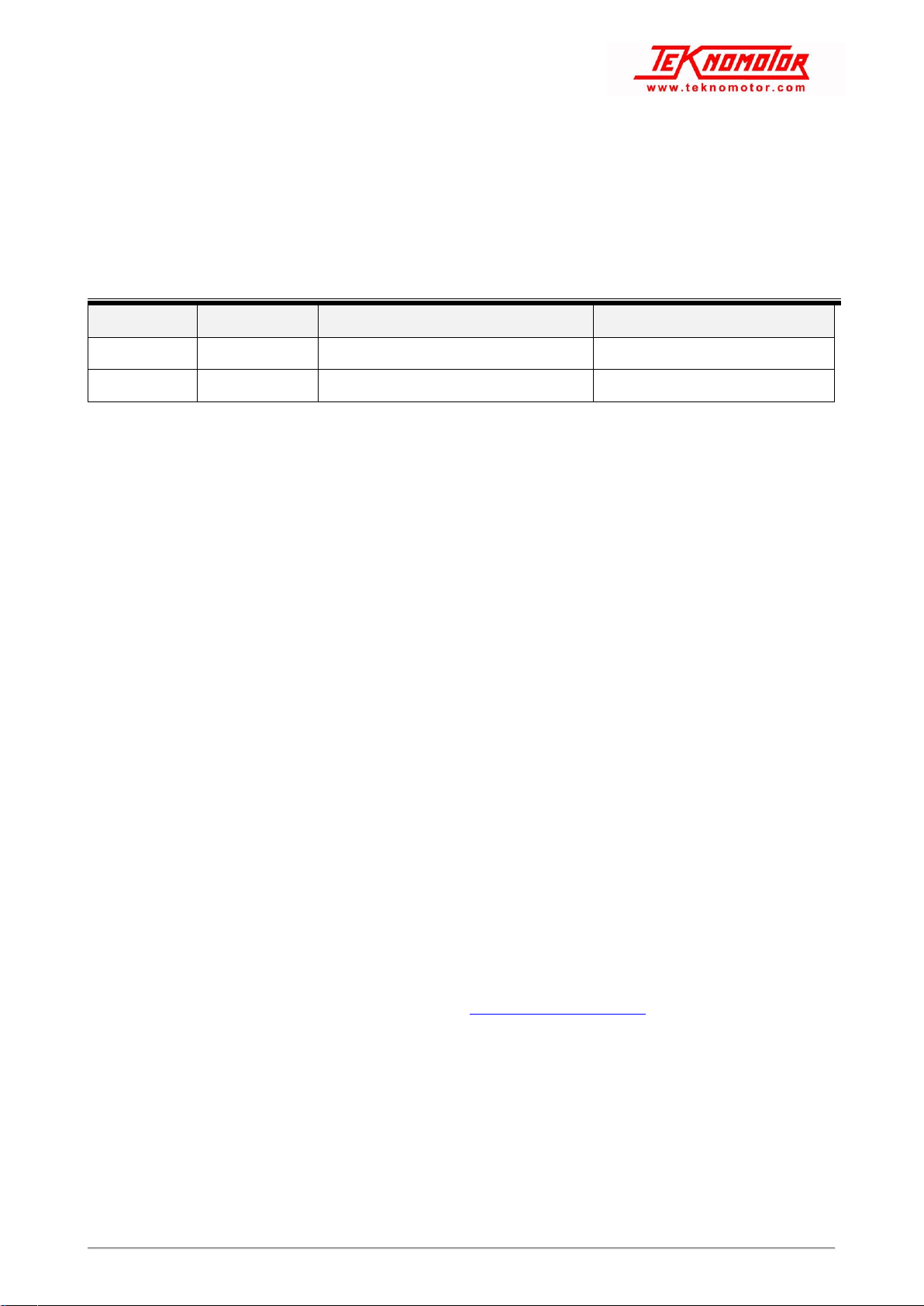

USER MANUAL REVISION TABLE:

Revision no.

Revision date

Revision description

Author

02

11/11/2019

Aggiunto render al § 8.3.1

D. Bottarel

01

21/06/2019

Aggiunto tavole

D. Bottarel

00

13/12/2018

Emissione

D. Bottarel

Technical Department of TEKNOMOTOR S.R.L. has written this user manual.

The manual addresses to installers, operators and service technicians working with TEKNOMOTOR S.R.L.

electrospindles.

TEKNOMOTOR S.R.L. supplies the manual together with its electrospindles at the last revision available.

ATTACHMENTS:

Attachments listed below are integral part of the user manual and shall be read and understood in conjunction

with to avoid missing important information:

•GENERAL VIEW DRAWINGS WITH OVERALL DIMENSIONS, PERFORMANCE DATA AND

ELECTRICAL SPECIFICATIONS

•MANUFACTURER DECLARATION OF CONFORMITY (EU)

•POWER-TORQUE SPEED DIAGRAM (IF REQUESTED BY CUSTOMER)

Listed attachments can be embedded in this user manual or constitute a separate document or data sheet.

Check that all above documents are disposable before installing, operating or maintaining TEKNOMOTOR

S.R.L. electrospindles covered by this user manual.

Ask Technical Department of TEKNOMOTOR S.R.L. tecnico@teknomotor.com for missing information or

documentation.

ATC41-ISO20 INSTRUCTION MANUAL

DOC.U.A.001.DOCX Rev.02 del 11/11/2019 7

ATC41-ISO20 INSTRUCTION MANUAL

DOC.U.A.001.DOCX Rev.02 del 11/11/2019 8

DISCLAIMER:

USE THE ELECTROSPINDLE ONLY FOR THE PURPOSE FOR WHICH

TEKNOMOTOR S.R.L. DESIGNED IT.

SAFE OPERATION DEPENDS ON THIS.

WARRANTY AND LIABILITY UNDER GENERAL SALES CONDITIONS OF

TEKNOMOTOR DEPEND ON THIS AND THEY WILL LAPSE IF THE

INSTRUCTIONS PROVIDED IN THIS USER MANUAL WILL NOT STRICTLY

APPLIED.

INSTALL THE ELECTROSPINDLES AS DESCRIBED IN THE FOLLOWING

SECTIONS OF THIS MANUAL AND ATTACHED TECHNICAL

DOCUMENTATION.

SAFE OPERATION DEPENDS ON THIS.

WARRANTY AND LIABILITY UNDER GENERAL SALES CONDITIONS OF

TEKNOMOTOR DEPEND ON THIS AND THEY WILL LAPSE IF THE

INSTRUCTIONS PROVIDED IN THIS USER MANUAL WILL NOT STRICTLY

APPLIED.

ATC41-ISO20 INSTRUCTION MANUAL

DOC.U.A.001.DOCX Rev.02 del 11/11/2019 9

ATC41-ISO20 INSTRUCTION MANUAL

DOC.U.A.001.DOCX Rev.02 del 11/11/2019 10

INDEX

USER MANUAL REVISION TABLE:...............................................................................................6

ATTACHMENTS:............................................................................................................................6

DISCLAIMER:.................................................................................................................................8

INDEX...........................................................................................................................................10

1. INTRODUCTION......................................................................................................................14

1.1. SYMBOLS AND SAFETY SIGNS USED IN THE MANUAL ........................................................... 14

1.2. PURPOSE ....................................................................................................................................... 15

2. WARNING AND SAEFTY PRECAUTIONS..............................................................................16

2.1. RISKS ASSOCIATED WITH IMPROPER USE AND HANDLING .................................................. 16

2.2. RISKS SPECIFIC TO ELECTROSPINDLE MAINTENANCE ......................................................... 17

3. GENERAL INFORMATION ......................................................................................................17

3.1. PROPER USE OF ELECTROSPINDLE.......................................................................................... 17

3.2. RANGE OF APPLICATION............................................................................................................. 18

4. TECHNICAL SPECIFICATIONS ..............................................................................................19

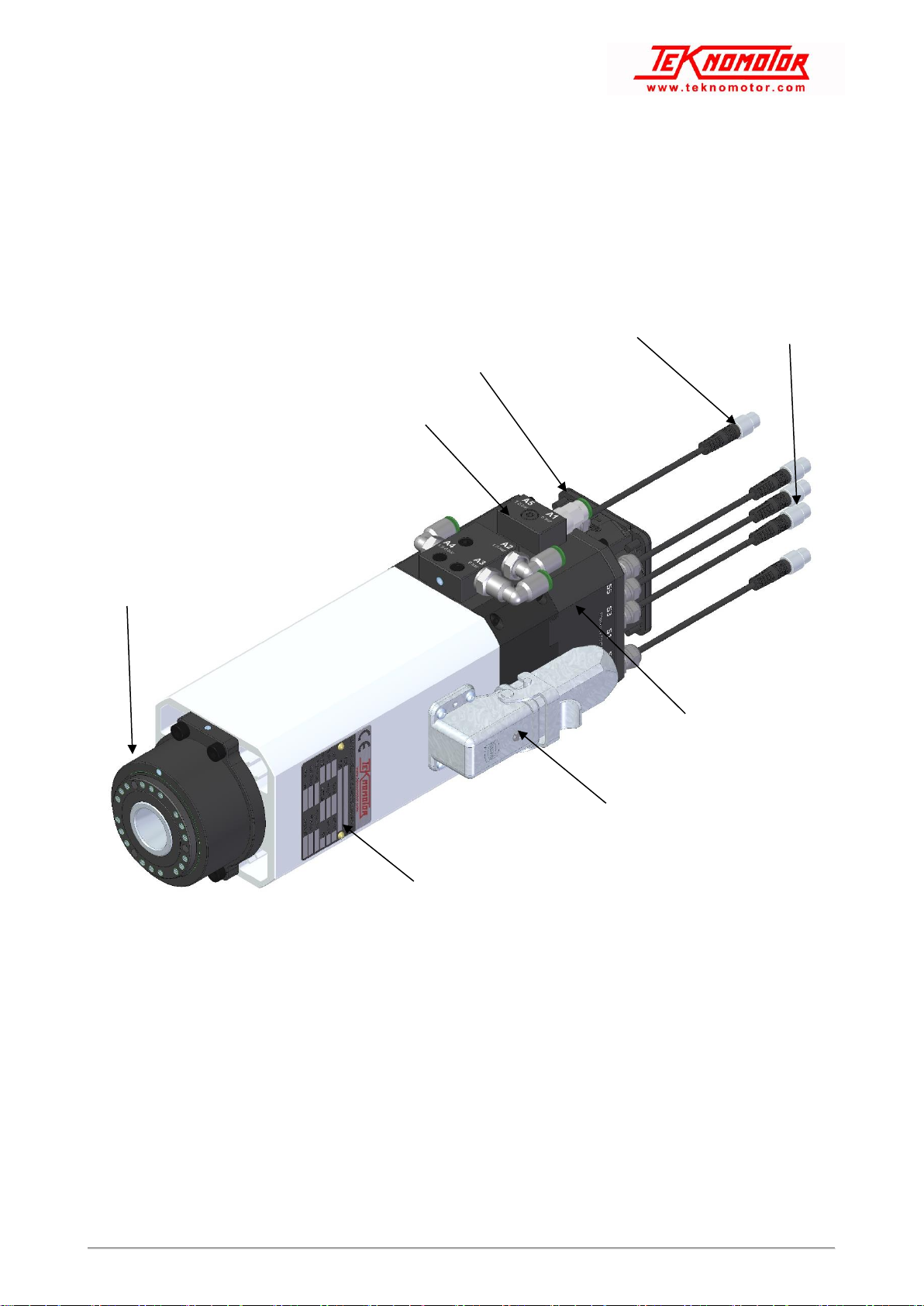

4.1. THE MAIN PARTS OF THE ELECTROSPINDLE........................................................................... 19

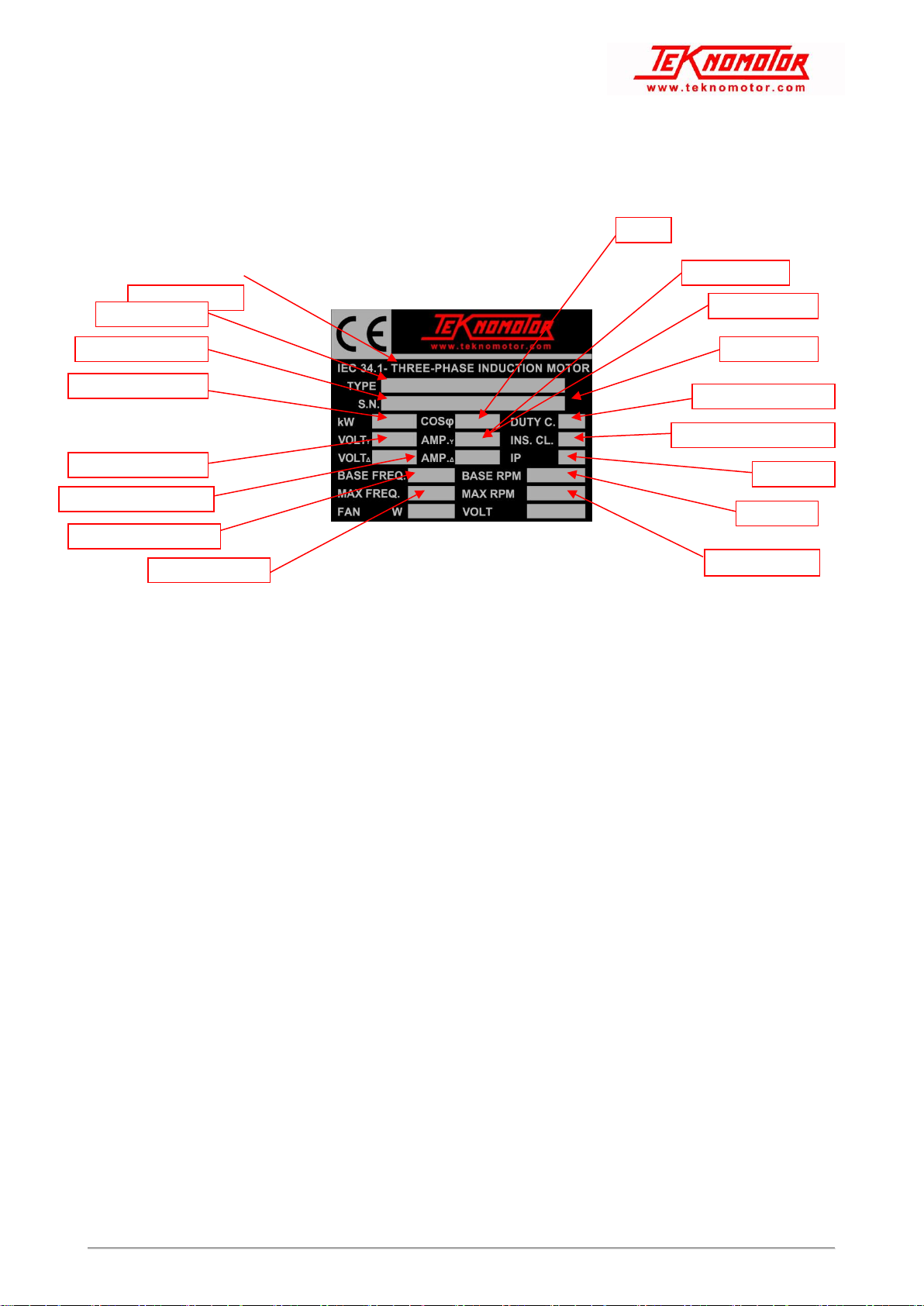

4.2. IDENTIFYNG THE MOTOR DATA FROM THE NAME PLATE...................................................... 20

4.3. GENERAL VIEWS, OVERALL DIMENSIONS AND PERFORMANCE .......................................... 20

5. TRASPORT, PACKAGING, UNPACKAGING AND STORAGE................................................21

5.1. PACKAGING AND LIFTING............................................................................................................ 21

5.2. STORAGE ....................................................................................................................................... 21

6. INSTALLATION........................................................................................................................22

6.1. CHECKING FOR DAMAGE............................................................................................................. 22

6.2. PROVISION OF ON SITE INSTALLATION EQUIPMENT.............................................................. 22

6.3. MECHANICAL CONNECTIONS ..................................................................................................... 22

6.3.1. POSITIONING OF ELECTROSPINDLE...................................................................................... 22

6.3.2. ELECTROSPINDLE RESTING SURFACE................................................................................. 22

6.3.3. TOOL CHANGE SYSTEM........................................................................................................... 23

6.3.4. FIXING ELECTROSPINDLE ....................................................................................................... 23

6.4. PNEUMATIC CONNECTION .......................................................................................................... 23

6.4.1. AIR PURITY................................................................................................................................. 23

6.4.2. PNEUMATIC CONNECTION DIAGRAM .................................................................................... 24

6.5. PNEUMATIC SPINDLE NOSE CLEANING .................................................................................... 26

6.6. NOSE PRESSURISATION.............................................................................................................. 26

6.7. ELECTRICAL CONNECTIONS....................................................................................................... 26

6.7.1. STANDARD LAYOUT OF POWER CONNECTOR..................................................................... 26

ATC41-ISO20 INSTRUCTION MANUAL

DOC.U.A.001.DOCX Rev.02 del 11/11/2019 11

6.7.2. LAYOUT OF SIGNAL CONNECTOR.......................................................................................... 27

6.8. ELECTRIC FAN............................................................................................................................... 27

7. GENERAL CHECKS AFTER INSTALLATION IN THE MACHINE AND PRIOR START-UP.....28

7.1. CHECKING ON THE ELECTROSPINDLE PRIOR TO START-UP................................................ 28

7.2. CHECKING ON THE ELECROSPINDLE AT THE TIME OF FIRST START-UP............................ 29

7.3. CHECKING ON THE ELECTROSPINDLE BEFORE RUNNING IT................................................ 29

8. OPERATION OF THE ELECTROSPINDLE .............................................................................30

8.1. CLIMATIC LIMITATIONS ................................................................................................................ 30

8.2. FORECAST AND NON FORECAST USE ...................................................................................... 30

8.3. RUNNING IN.................................................................................................................................... 30

8.4. WARMING UP................................................................................................................................. 31

8.5. TOOL-HOLDER LOCKING AND EXPULSION DEVICE................................................................. 31

8.6. TOOL-HOLDER CONE ................................................................................................................... 31

8.7. INSTALLATION OF THE PULL STUD ON THE ISO20 CONE....................................................... 31

8.8. GENERAL RACCOMANDATION FOR THE TOOL HOLDER CONES.......................................... 32

8.9. TOOL MOUNTING –TOOLHOLDER ............................................................................................. 32

8.10. TOOL MOUNTING –TOOLHOLDER WITH CONICAL SEAT FOR ER DIN 6499.................... 34

Excessive tool run-out causes premature wear of bearings. ..................................................................... 34

8.11. MAXIMUM RUN-OUT AND VIBRATION VALUES ..................................................................... 35

8.12. SPEED LIMITS............................................................................................................................ 35

8.13. WHAT TO DO IF THE TOOL IS BLOKED ON THE PIECE BEING WORKED .......................... 36

8.14. SENSORS ................................................................................................................................... 36

8.14.1. TECHNICAL CHARACTERISTICS OF THE INDUCTIVE SENSORS.................................... 36

8.14.2. STATUS MODES OF THE ELECTROSPINDLE AND CORRESPONDING OUTPUTS ........ 37

8.14.3. TRIMMING SENSORS............................................................................................................ 38

8.14.4. SENSOR S3 OUTPUT (option)............................................................................................... 39

8.14.5. THERMAL ALARM .................................................................................................................. 39

9MAINTENANCE.......................................................................................................................40

9.1. SCHEDULED MAINTENANCE AND CLEANING THE SPINDLE SHAFT TOOL HOUSING......... 41

9.1.1. CHECK THE CLEANING OF TOOL-HOLDER CONE AND CONICAL HOUSING OF THE

ELECTROSPINDLE SHAFT ...................................................................................................................... 41

9.1.2. PROTECTING THE CONICAL SEAT IN THE SPINDLE SHAFT ............................................... 42

9.1.3. CLEANING THE TOOL-HOLDER CONE.................................................................................... 42

9.1.4. CHECK THE CONNECTIONS .................................................................................................... 42

9.2. OCCASIONAL MAINTENANCE...................................................................................................... 42

10. TROUBLESHOOTING .......................................................................................................43

11. DISPOSING OF THE ELECTROSPINDLE.........................................................................43

12. USEFULL ADRESSES.......................................................................................................43

APPENDIX: ATC41 DRAWINGS AND POWER-TORQUE CURVES............................................45

ATC41-ISO20 INSTRUCTION MANUAL

DOC.U.A.001.DOCX Rev.02 del 11/11/2019 12

Figure 1 Main part of the electrospindle .......................................................................................................... 19

Figure 2 Typical Teknomotor electrospindle nameplate.................................................................................. 20

Figure 3 Air connections.................................................................................................................................. 25

Figure 4 Power supply connector.................................................................................................................... 26

Figure 5 Electrical sensor connection.............................................................................................................. 27

Figure 6 Pin number........................................................................................................................................ 27

Figure 7 Sensor plug ....................................................................................................................................... 27

Figure 8 V-f pattern.......................................................................................................................................... 28

Figure 9 Sensors cover dismounting Figure 10 Trimming sensor system............................................. 38

This manual contains information protected by copyright. It and its attachments shall not be

photocopied or reproduced in any form, either fully or in part, without the prior written consent of

TEKNOMOTOR S.R.L.

ATC41-ISO20 INSTRUCTION MANUAL

DOC.U.A.001.DOCX Rev.02 del 11/11/2019 13

ATC41-ISO20 INSTRUCTION MANUAL

DOC.U.A.001.DOCX Rev.02 del 11/11/2019 14

1.INTRODUCTION

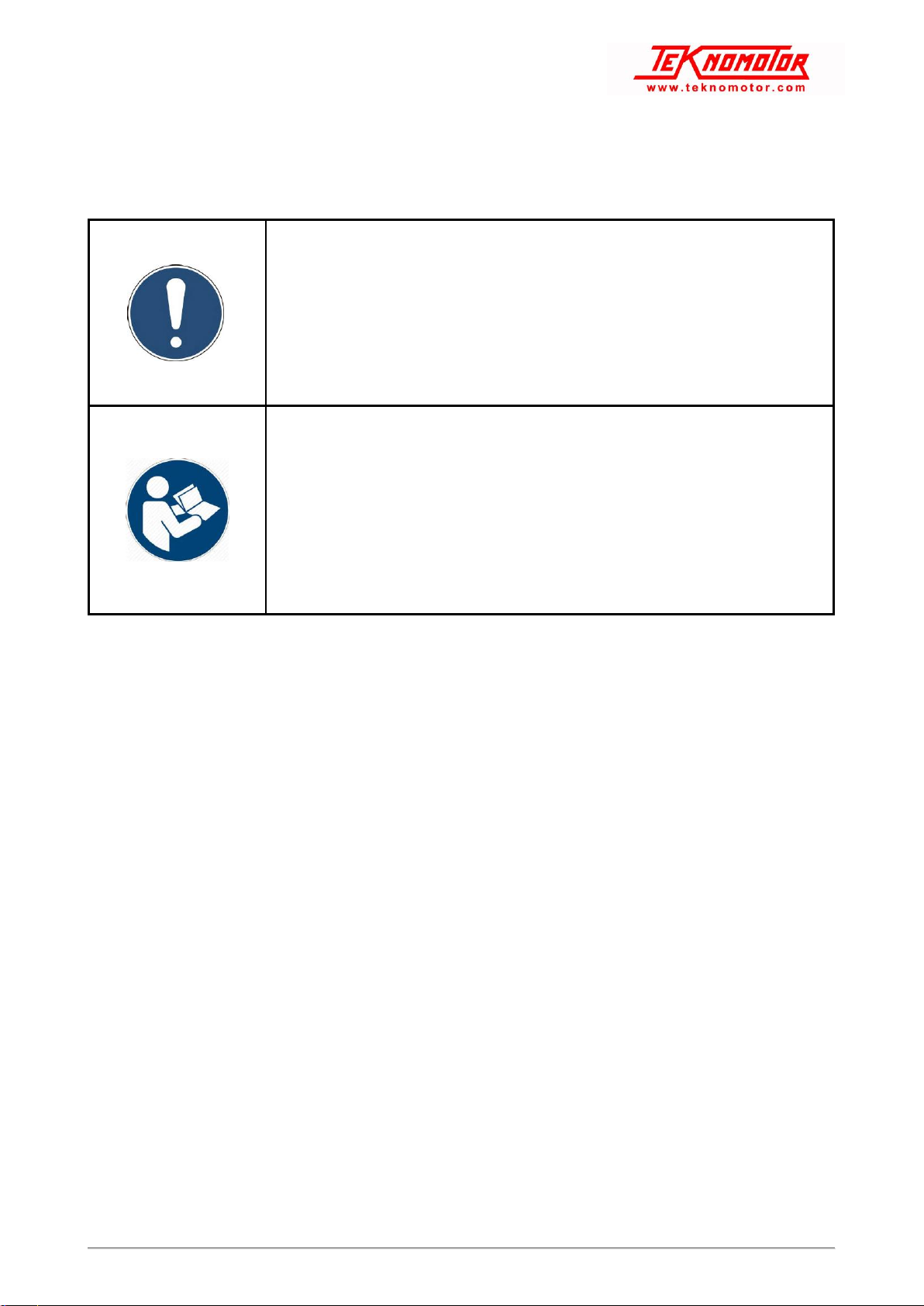

1.1. SYMBOLS AND SAFETY SIGNS USED IN THE MANUAL

This manual highlights important instructions or precautions with the following symbols and safety signs (ref.

ISO 7010):

NOTE: information highlighted by symbols and safety signs is not exhaustive and the whole manual shall be read and applied

IMPORTANT INFORMATION

GENERAL WARNING IDENTIFIED BY SUPPLEMENTARY SAFETY

INFORMATION

WARNING: SHARP ELEMENT

WARNING: FLAMMABLE MATERIAL

WARNING: ELECTRICITY

GENERAL MANDATORY ACTION IDENTIFIED BY SUPPLEMENTARY

SAFETY INFORMATION

REFER TO INSTRUCTION MANUAL BOOKLET

ATC41-ISO20 INSTRUCTION MANUAL

DOC.U.A.001.DOCX Rev.02 del 11/11/2019 15

DISCONNECT BEFORE CARRYING MAINTENANCE OR REPAIR

1.2. PURPOSE

This user manual contains important instructions and precautions and shall accompany the electrospindle at

all times since it is essential for the safe operation of the electrospindle and operators.

Safety precautions contained herein provide information necessary to ensure the safety of all persons exposed

to the residual risks associated with the electrospindle.

Instructions contained herein provide information necessary for the correct operation of the electrospindle.

Make sure that you read and fully understand all the documentation supplied with the electrospindle to avoid

incorrect operation of the unit and unnecessary risks of personal injury.

Keep this manual easily available in a suitable place near the machine-

Keep this manual safe, and ensure that all persons involved with the electrospindle know of it, fully understand

its contents and have access to it.

IMPORTERS AND DISTRIBUTORS SHALL ENSURE THAT USER MANUAL

ALWAYS ACCOMPANIES THE ELECTROSPINDLE AND THAT CONSUMER,

MACHINE MANUFACTURER AND OTHER END-USERS CAN EASILY FULLY

UNDERSTOOD IT.

USE THE ELECTROSPINDLE ONLY FOR THE PURPOSE FOR WHICH

TEKNOMOTOR S.R.L. DESIGNED IT.

SAFE OPERATION DEPENDS ON THIS.

WARRANTY AND LIABILITY UNDER GENERAL SALE CONDITIONS OF

TEKNOMOTOR DEPEND ON THIS AND THEY WILL LAPSE IF THE

INSTRUCTIONS PROVIDED IN THIS USER MANUAL WILL NOT STRICTLY

APPLIED.

INSTALL THE ELECTROSPINDLES AS DESCRIBED IN THE FOLLOWING

SECTIONS OF THIS MANUAL AND ATTACHED TECHNICAL

DOCUMENTATION.

SAFE OPERATION DEPENDS ON THIS.

WARRANTY AND LIABILITY UNDER GENERAL SALE CONDITIONS OF

TEKNOMOTOR DEPEND ON THIS AND THEY WILL LAPSE IF THE

INSTRUCTIONS PROVIDED IN THIS USER MANUAL WILL NOT STRICTLY

APPLIED.

ATC41-ISO20 INSTRUCTION MANUAL

DOC.U.A.001.DOCX Rev.02 del 11/11/2019 16

2.WARNING AND SAEFTY

PRECAUTIONS

Teknomotor S.r.l. does not and cannot know how end users will install

their electrospindles. The installer or customer must therefore perform

risk assessment specific to each installation and application.

It is also the responsibility of the installer to ensure that adequate guards are provided to prevent accidental

contact with moving parts.

The installer and the operator must also bear in mind other types of risk, particularly those associated with

foreign bodies, explosive, inflammable, toxic or high temperature gasses.

Risks associated with maintenance operations must also be guarded against. Maintenance must be performed

in conditions of maximum safety, and only with the electrospindle fully stationary and switched off.

Once the electrospindle has been installed in the way decided upon by the installer and/or customer, the

machine becomes a “finished machine” as defined for the purposes of the Machinery Directive. Overall risk

assessment must therefore be performed on the finished machine and a declaration of conformity produced

in compliance with Appendix IIA of the 98/37/CE Machinery Directive.

2.1. RISKS ASSOCIATED WITH IMPROPER USE AND HANDLING

▪Never impede the functioning of, remove, modify or in any way interfere with any safety device, guard,

or control of individual parts or of the electrospindle as a whole.

▪Never place your hands, arms, or any other part of your body near moving machinery.

▪Never push objects through the cover grill or into the electrospindle either when it is stationary or when

it is operating.

▪Do not use the electrospindle in atmospheres or environments where there is a risk of explosion.

▪Unless you are duly authorized, never attempt to repair faults or electrospindle malfunctions and never

interfere in any way with the electrospindle operation or installation.

▪On completion of servicing work for which guards, covers, or any other protections have been

removed, always make sure that they have been correctly and securely replaced and are fully

functional before re-starting the electro spindle.

▪Keep all protection and safety devices in perfect working order. Also make sure that all warning and

informative plates, labels and symbols are correctly positioned and perfectly legible.

▪When troubleshooting the electrospindle always adopt all the safety precautions listed in this manual

for the purpose of preventing injury or damage to persons and things.

▪After adjusting any mechanical part, make sure that you fully tighten all screws, bolts or ring nuts you

may have slackened or removed.

▪Before you start the electrospindle, make sure that all the safety devices are installed and perfectly

functional. Do not start the electrospindle if this is not the case, but immediately inform the person

responsible for machine safety or your direct superior.

▪Make sure that you have and use all the personal protective equipment (PPE) required by law. Do not

wear loose or hanging clothing (ties, wide sleeves, etc.).

▪Never use types of tool holder that do not correspond to the models those are specify in this manual;

this cause the risk of breakage or imperfect hook-up of the tool holder cone.

ATC41-ISO20 INSTRUCTION MANUAL

DOC.U.A.001.DOCX Rev.02 del 11/11/2019 17

2.2. RISKS SPECIFIC TO ELECTROSPINDLE MAINTENANCE

▪During all maintenance and cleaning operations, take great care if a tool is fitted. It is advisable to

remove any tool before starting cleaning or maintenance.

▪Disconnect the electrospindle from the main supply before carrying out any maintenance operations.

▪The electrospindle can still turn under the effect of inertia even after it has been switched off. Make

absolutely sure that the electrospindle is not still spinning before starting any maintenance on it.

▪Perform scheduled maintenance as specified in this manual to avoid the risk of mechanical failures

from advanced wear.

NEVER Start any maintenance before making absolutely sure the

electrospindle is stopped spinning.

NEVER Start any maintenance on the electrospindle without first

disconnecting it from the electrical power supply.

NEVER Attempt to clean the electrospindle while it is rotating.

3.GENERAL INFORMATION

3.1. PROPER USE OF ELECTROSPINDLE

Electrospindles designed by TEKNOMOTOR S.R.L. shall operate as part of a machine.

MACHINE DESIGN SHALL CONSIDER THAT FRAME OF THE MACHINE

SHALL WITHSTAND THE WEIGHT OF ELECTROSPINDLE FITTED IN AND

THE STRESSES CAUSED BY TYPE OF MACHINING TO CARRY OUT.

TEKNOMOTOR S.R.L. DESIGNED ELECTROSPINDLE FOR LOW-MEDIUM

POWER MILLING AND DRILLING OF WOOD, FIBERBOARD, PLASTICS AND

ALUMINUM (SEE TO TECHNICAL DATA OF THE SPECIFIC

ELECTROSPINDLE MODEL).

USE THE ELECTROSPINDLE ONLY FOR THE PURPOSE FOR WHICH

TEKNOMOTOR S.R.L. DESIGNED IT.

SAFE OPERATION DEPENDS ON THIS.

ELECTROSPINDLES OPERATE AT S1 DUTY CYCLE UNLESS OTHERWISE

IN TECHNICAL DOCUMENTATION OF THE SPECIFIC MODEL.

CUSTOMER SHALL CARRY OPERATION OF THE ELECTROSPINDLE

ACCORDING TO SERVICE TYPE INDICATED IN TECHNICAL

DOCUMENTATION.

ATC41-ISO20 INSTRUCTION MANUAL

DOC.U.A.001.DOCX Rev.02 del 11/11/2019 18

SERVICE TYPE S1 (standard IEC 60034-1) MEANS OPERATION AT

CONSTANT LOAD WITH A DURATION SUFFICIENT TO ENSURE THAT THE

MOTOR REACHES THERMAL EQUILIBRIUM.

3.2. RANGE OF APPLICATION

The product has been designed to carry out milling and boring operations in the field of wood and its derivates,

plastic, composite material, aluminum and light machining operations on other metals.

The quick replacement of the shaft unit complete with bearings is possible on every models, using the shaft

kit. For further information contact the Teknomotor Technical Office.

All the electrospindles have a mechanical reaction system that almost completely cancels the axial force of

the pistons on the bearing during the tool changing phase. It guarantees the long life of the front precision

bearings.

ATC41-ISO20 INSTRUCTION MANUAL

DOC.U.A.001.DOCX Rev.02 del 11/11/2019 19

4.TECHNICAL SPECIFICATIONS

4.1. THE MAIN PARTS OF THE ELECTROSPINDLE

Figure 1 Main part of the electrospindle

MOTOR NAMEPLATE

COMPRESSED AIR CONNECTORS

ELECTRIC FAN

POWER CONNECTOR

SIGNAL CONNECTOR

SENSORS CARTER

NOSE PRESSURIZATION

ELECTRIC FAN

CONNECTOR

ATC41-ISO20 INSTRUCTION MANUAL

DOC.U.A.001.DOCX Rev.02 del 11/11/2019 20

4.2. IDENTIFYNG THE MOTOR DATA FROM THE NAME PLATE

The part number (P.N. or TYPE) and the serial number (S.N.) are printed on the name plate and they are only

way to identify the electrospindle recognized by the manufacturer. For this reason they must be kept legible

throughout the unit’s working life. The place of the name plate and the disposition of data in the name plate

could be different model by model.

Figure 2 Typical Teknomotor electrospindle nameplate

4.3. GENERAL VIEWS, OVERALL DIMENSIONS AND PERFORMANCE

See attached documents. If the document is not available please contact Teknomotor technical office.

PART NUMBER

SERIAL NUMBER

MOTOR POWER [kW]

BASE VOLTAGE Y [V]

BASE VOLTAGE Δ [V]

SE

BASE FREQUENCY [Hz]

]BASE

MAX FREQUENCY [Hz]

FAN POWER [W]

CURRENT Δ [A]

CURRENT Y [A]

DUTY CYCLE

INSULATION CLASS

COSφ

INSULATION PROTECTION

BASE RPM

MAX RPM

FAN SUPPLY [V]

ATC41-ISO20 INSTRUCTION MANUAL

DOC.U.A.001.DOCX Rev.02 del 11/11/2019 21

5.TRASPORT, PACKAGING,

UNPACKAGING AND STORAGE

5.1. PACKAGING AND LIFTING

▪Lifting and moving the electrospindle can create situations of risk to persons nearby. Always follow the

instructions provided by this manual, follow all possible safety instruction for the handling of heavy

loads. Always use suitable lifting equipment. The responsibility for the safety of the people involved in

handling, moving and lifting operation is of the customer.

▪Installation and assembly work must be performed only by specialist technicians.

▪Always use great care in lifting and moving electrospindles and their components. Avoid impacts which

can damage the body or the shaft or the bearings of the electrospindle.

It is the responsibility of the customer to ensure that the lifting

equipment used is suitable for the purpose in terms of functioning and

load capacity.

Never lift the electrospindle by its fan cover. This can break, damaging

the electrospindle and possibly causing personal injury.

Never drill parts of electrospindle to attach elements useful to move

electrospindle.

Load characteristics

The load is to be considered too heavy for a single person when:

•It weights for more than 30 kg for men

•It weights for more than 20 kg for women

Do not drill the electrospindle to fit any hoisting tool.

5.2. STORAGE

If the electrospindle is to be stored for any length of time, make sure that it is protected against the elements

and in particular against damp, dust, and other forms of damage by the atmosphere or storage environment.

STORAGE TEMPERATURE: from -5°C to +55°C

NON-CONDENSING RELATIVE HUMIDITY: from 5% to 15%

The storage time of Teknomotor electrospindle is 12 months. After

this time-limit the product must be inspected by an authorized

Teknomotor service. If you need more information please contact

Teknomotor S.r.l..

Table of contents

Other Teknomotor Industrial Equipment manuals