CONTENTS

Welcome ( Indicator Note )

Safety Warning

Quick Reference

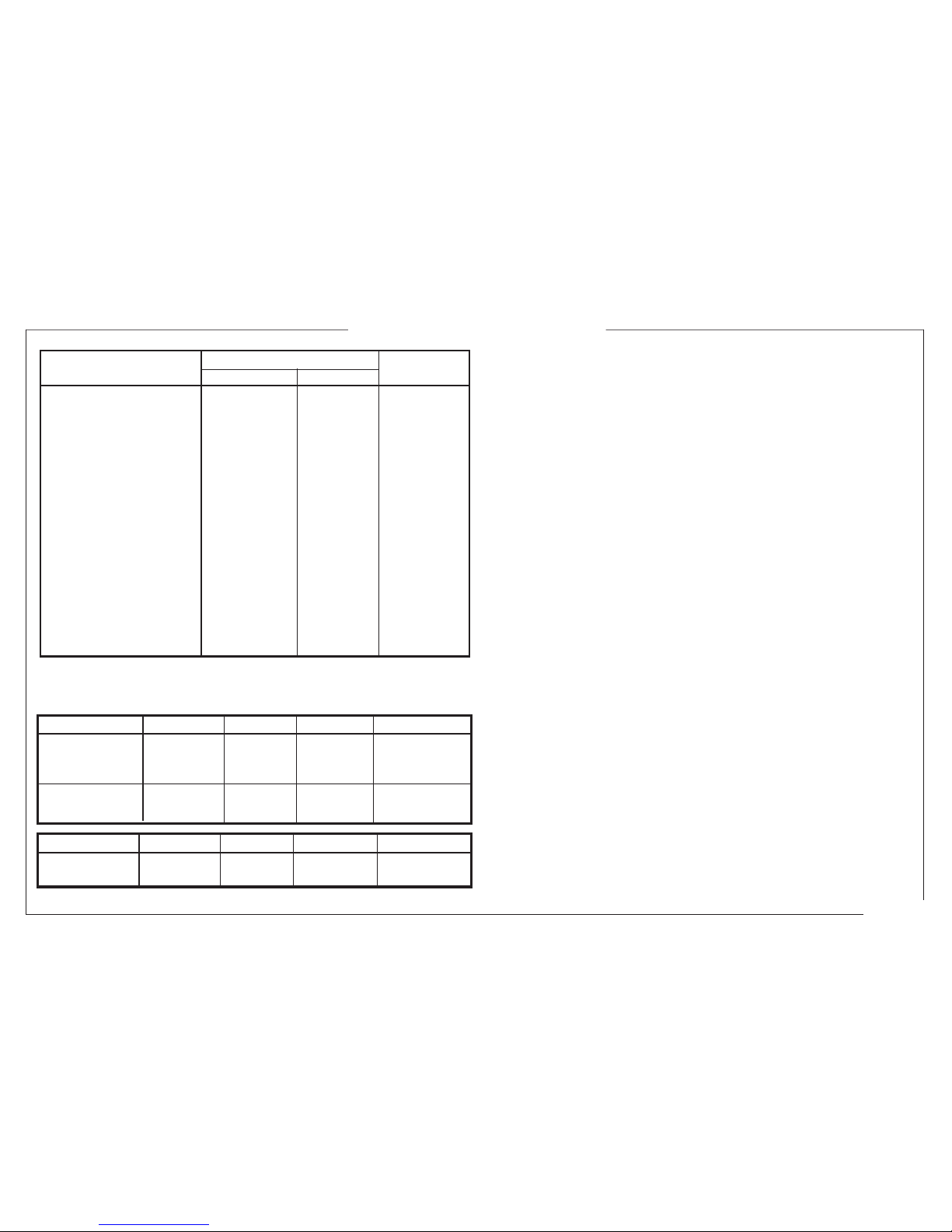

Specifications

1.0

1.1

1.2

1.3

1.4

1.4.1

1.4.2

1.4.3

1.4.4

1.4.5

PC6-IDOS Arrangement

Functions (menu 1)

Functions (menu 2)

1.5

1.6

1.6.1

1.6.3

1.6.5

1.6.6

1.6.7

1.7.1

1.7.2

1.7.3

1.7.4

1.7.5

1.7.6

1.7.7

1.7.8

1.7.9

1.7.10

1.7.11

1.7.12

1.7.13

1.7.14

1.7.15

1.7.16

1.7.17

1.7.18

1.7.19

1.8

1.9

1.10

1.11

1.12

1.13

2.0

2.1

2.2

2.3

2.4

2.5

2.6

2.10

2.12

3.0

3.1

3.2

3.3

Menu 1, Menu 2 & Menu 3

Menu 1

Menu 2

Menu 3

...................... ii

........................................... iii

iv

............................................. v

Introduction ...................................... 2

General ............................................. 2

Keypad ............................................. 2

LCD .................................................. 3

Connection Panels ( .......... 3

4 mm Sockets ............................ . 3

Quick connect coupling ........... .. 3

RS232 ..................................... .... 3

Charger ...................................... . 3

EPM ........................................... . 3

............................... 4

....................................

.................................... 6

Introduction ......................................... 10

Connections

Pressure Input .................................... 10

Voltage/Current Input ...................... 10

RS232 ................................................ 11

Battery charger ................................... 11

Voltage Output .................................. 11

Messages & Parameters

Retained parameters .... .. 12

Battery low state .............................. . 12

Tare Value .......................................... 12

Maximum/Minimum ......................... 12

Void leak test ..................................... 12

Switch Off .......................................... 12

Auto Switch Off .................................. 12

Pressure Overload ............................ 12

Low Battery Detect ............................ 12

Pressure Switch State Change .......... 12

Printer Busy ........................................ 12

Outside User Set Alarm Value ........... 12

Display Hold ...................................... 12

Connection Fault ............................... 13

Short Detected .................................. 13

Voltage / Current Overscale .............. 13

RS232 Output Format ....................... 13

Alarm Flag ......................................... 13

Symbols ............................................. 13

Units ................................................... 15

Max,Min,Switch,Temp.,

Tare .................................................... 15

V / mA ................................................. 15

Leak Test ............................................ 17

File (logged files) ................................ 18

Alarm Settings - High / Low ............... 21

V / mA (Measure mode)............................ 22

V-Out, Display light, Port ................... 26

Resolution ........................................... 26

Event ................................................... 26

Log ..................................................... 27

Zero .................................................... 30

Port

Power_Off ........................................... 31

Span ................................................... 33

History (overload, zero/span, ...)........... 35

Language .................................... 35

Units ................................................... 35

..........................

Unit, Leak ....................................... 38

V / mA ............................................ 39

File ................................................. 40

High & Low .................................... 41

V / mA (measure) ........................... 42

V / mA (source) .............................. 43

V-out, Display light ....... 48

Resolution, Event, RS232 ............. 48

Log ................................................ 49

Date&Time, Language, Zero, Port,

Power_Off ...................................... 50

Span .............................................. 51

History ............................................ 52

Language ........................................ 53

Units ................................................ 54

(Keys, Activating functions, Exit,

Menu selection, Data Entry, Tare) ............................

Maintenance

Functions (menu 3)

1.6.2

1.6.4

2.7

2.8

2.9

................................................ vi

Front/Rear)

........

..........

........

........

........

.................................... 8

......................................... 10

.

EPM ..................................................... 10

Switch Test........................................... 11

.

.

.................... 12

.................. ....

.

Date&Time,% 15

.

V / mA (Source mode)...............................23

..

.

RS232 ................................................. 29

Date & Time ....................................... 30

Language ............................................. 30

....................................................... 31

.

.........

..

.................

........

5

37

1.7

2.11

Description 1

Operating Instructions 9

How to Select Functions (Menu 1) 14

Set-menu (menu 2) 20

Cal-menu (menu 3) 32

Flowcharts 36

Appendices 55

Index 62

1External Pressure Module (EPM) 55

2

3

Calibration Procedures......................... 58

Panel Mount Dimensions...................... 60

Page i

K0354, Iss. 1