TEL AFA 1000 User manual

1

AFA 1000

FUME HOOD ALARMS

Operating and Instruction Manual

Model AFA1000 / 1

• Digital display

• 1 Output relay

• 3 Input relays

• Com port

Used for alarm indication and monitoring on

Fume Hoods

1/MK3/FH/USPSU

250804

2

Table of contents :-

Section

Description

Page

1

Operator display panel 3

2

Connection details

4

3

General description – overview

5 to 8

4

Installation

8

5

Start-up / Calibration

9 to 11

6

Monitor configuration

11

7

Events – actions

12 to 15

8

Dimensions

16 to 17

9

In-line sensor installation

18 to 19

10

Wiring diagram

20

11

Spares

21

12

Limitation of Warranty and Liability

22

13

Contact us

22

3

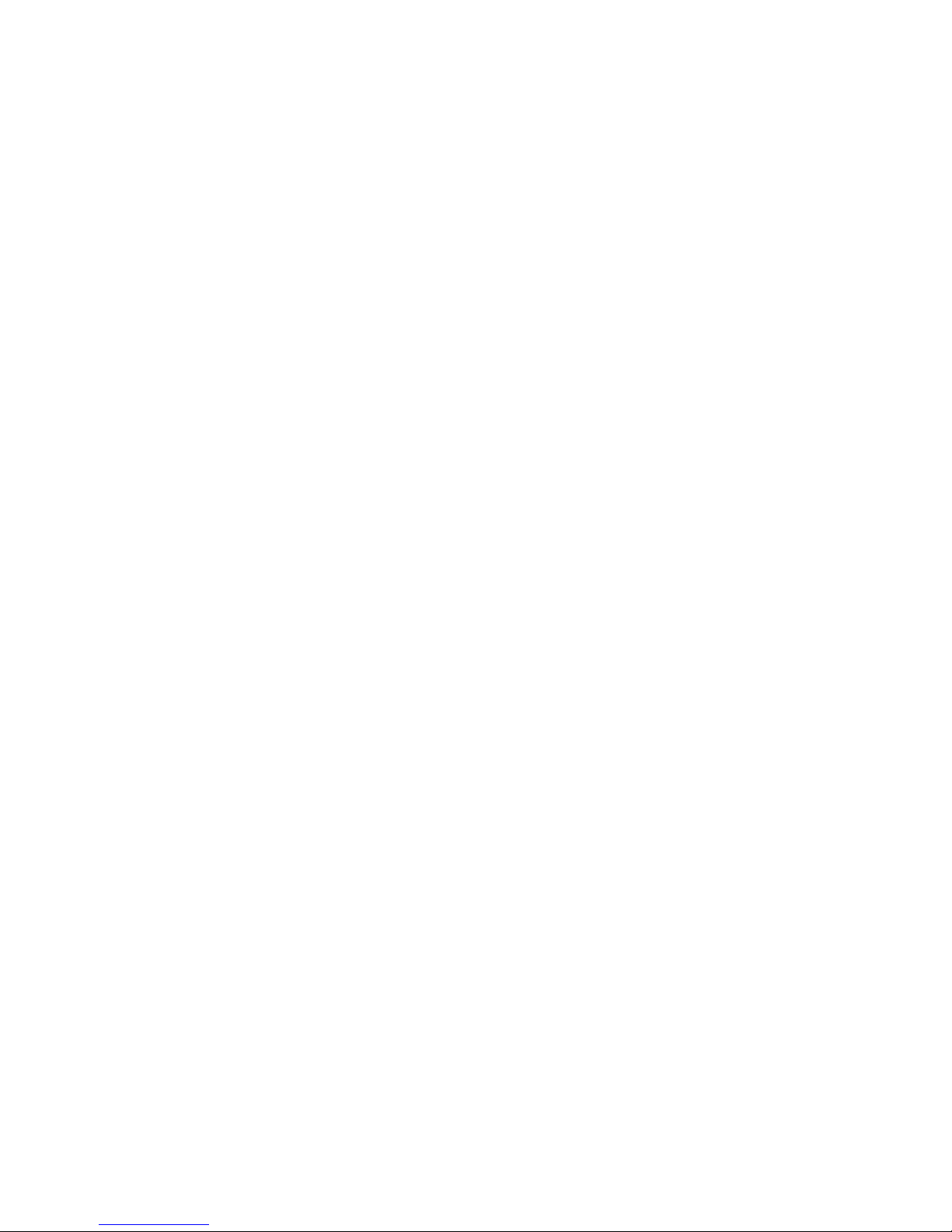

Velocity Bar Graph or

Alarm Time Line

Velocity display fpm or m/sec

LED indicators

Function and up/down buttons

for Menu Configuration and

Calibration.

ENTER – also used as

Mute button for audible alarm

1.0 Operator Display Panel

4

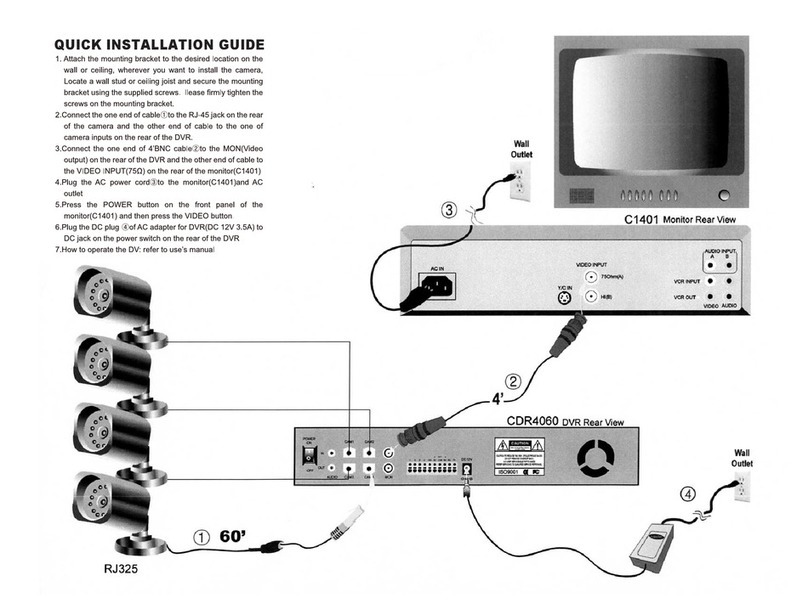

120V

PSU

120V / 15V DC

Plug – in power adapter for

120V socket

Power requirement - 110mA

@ 120v AC Supply

Flying lead with plug

connection for PCB

15 V DC

Flying lead with RJ11

plug connection for PCB

and SM6 airflow sensor

12V DC

Sash High

Proximity switch

( Optional )

SM6 or Inline

Airflow Sensor

OUTPUT

RELAY

R1

SENSOR

SOCKET

15V DC

POWER

SUPPLY

INPUT

REFER TO

INSTALLATION

INSTRUCTIONS

BEFORE

CONNECTING

MADE IN ENGLAND

www.tel-uk.com

TEL

INPUT 3

Blu

Blk

Brn

AFA 1000 USA

Sash High

Micro - switch

( Optional )

IDC

14-way

Connector

for remote

Interface Box

( Optional )

INPUT 2

INPUT 1

RS 232

Com Port

Notes :-

Inputs 1 2 & 3 are volt free inputs. (Max line resistance 4.7K ohms) (Short circuit current 5mA DC)

Relay output R1 is a power limited volt free contact. Contact rating 30VAC / 42VDC Max

Primary power requirement - 110mA @ 120VAC ( 3A Fused supply recommended ).

2.0 Connection details

s/w

+

-

5

3.0 General Description

All systems comprise of the following components :-

1 – In-line Airflow Sensor,

1 – AFA1000 Alarm unit,

1 – AC power supply

If the Sash Alarm System option is included there will also be a sash micro switch

or proximity switch.

Operator Features --- the alarm has the following operator features :-

Digital Display

The digital display is a back-lit, full graphic unit with a visual display of approx

2.2" x 1.18 ". The display operates through the software allowing the generation

of figures, wording and Icons.

The display shows the fume hood face velocity in m/sec or fpm when enabled

or the alternative with no velocity reading but showing LOW AIR / NORMAL as

continuous display.

All of the above are configurable via the alarm key pad.

An ‘ event time line ’ segmented into 20 x 3 minute segments will scroll across

the display ( when enabled) .This takes the form of a graphical ‘ blip’ that will

progress from the right hand side to the left hand side – representing events that

have occurred during the past hour. On the standard alarm this will be limited to

airflow alarms but other alarms are available.

The alternative to the event time line is a dynamic ‘ bar graph ’ representing the

face velocity

The display shows a Horn icon ( with line through it ) when the audible alarm is in

the Muted condition

Sash High – will be displayed when the Sash alarm is enabled and the sash

is raised above the max safe working opening.

This display will alternate on/off with the velocity reading.

Ext Alarm – will be displayed when the external alarm input is activated ( when

enabled )

This display will alternate on/off with the velocity reading

Low Air - will be displayed if the airflow is less than the Low air alarm point.

This display will alternate on/off with the velocity reading

6

High Air - will be displayed if the airflow is more than the High air alarm point.

This display will alternate on/off with the velocity reading

Set-back - will be displayed if the night set-back function is activated ( when

enabled )

This display will alternate on/off with the velocity reading

Disabled - will be displayed if the alarm disable function is activated ( when

enabled )

This display will alternate on/off with the velocity reading

LED Indicators ---- the alarm unit has three LED indicators :-

Red -- Low

Amber -- Caution

Green -- Normal

Audible Alarm sounder -- the alarm has an audible alarm sounder with local or

remote Mute facility

Enter --- the alarm has an Enter button -- this is multi-functional as follows :-

Press Enter momentarily when alarm is sounding will mute the alarm.

The horn can be permanently disabled using the configuration menu.

When this option is selected the Horn Icon with the word OFF will

permanently appear on the display.

Press Enter for 5 secs will gain access to Calibration and

Configuration menus ( both menus password protected )

+ / - -- the alarm has + / - buttons that can be used to scroll through the

calibration and configuration menu or to select options or values

7

External Connections -- the alarm unit has the following connection points :-

Input 1 --- volt free relay input configurable for normally closed or normally

open relays

This input can be configured as :-

Alarm disable

Night set-back

External alarm

Sash High

High / Low

Input 2 --- volt free relay input configurable for normally closed or normally

open relays

This input can be configured as :-

Alarm disable

Night set-back

External alarm

Sash High

High / Low

Input 3 --- volt free relay input configurable for normally closed or normally open

relays

This input can be configured as :-

Alarm disable

Night set-back

External alarm

Sash High

High / Low

Output 1 --- volt free relay output configurable as normally closed or normally

open relay .

Com Port --- for communications to building computer system ( BMS)

Power supply --- low voltage DC power supply

Airflow Sensor --- connection socket for the face velocity airflow sensor.

8

4.0 Installation

Follow the instructions below for installing the unit. :-

1. Fit the alarm to the Fume Hood using the cut-out details provided with the

unit --- see page 16 to 17

2. Fit the airflow sensor to the Fume Hood using the cut out and installation

details provided --- see page 18

3. Connect the ‘telephone style’ airflow sensor plug-in cable to the sensor

and the back of the alarm unit --- see typical connection diagram on page

19 & 20

4. Plug in the power adapter to a 120V AC power socket and connect the

power supply connector to the alarm unit --- see typical connection

diagram on page 19 & 20

5.0 Start up / Calibration

1. Power up the alarm and it then performs a self test on the display and all

indicators etc ( approx 5 sec ) , then wait at least 30 secs while the sensor

temperature stabilizes.

2. If the alarm has not been calibrated it will display ‘ Requires setup ’ –

press ENTER to continue and in the Main Menu use the +/- buttons on the

alarm face to select ‘ SETUP ‘ and then press the ENTER button.

3. To calibrate the alarm it is necessary to use a pre-calibrated anemometer

which can be used to give an accurate measurement of the actual face

velocity of the hood at two sample values. The lower value is taken with

the sash at the normal working height and is ‘captured’ by the alarm.

9

A higher value is taken with the sash partially closed and this is also

‘captured’ by the alarm. From these two known points the alarm will track

the face velocity over the whole range of the hood face velocities.

Before starting the calibration of the alarm please read the ‘Calibration

Notes ‘ below.

When you are ready to start the calibration proceed as follows :-

a. In the Setup Menu select ‘CALIBRATION’ and press the ENTER

button

b. At this stage you will be requested to enter the PASSWORD. Use

the +/- buttons to select the individual digits in turn and press

ENTER for each digit.

If the password is correct the unit will go to the Calibration mode. If

the password is not correct you will be requested to try again --- on

the third wrong password entry the calibration menu will lock out for

10 mins

NOTE:- If you enter the Calibration Menu by accident :-

press the + & - buttons at the same time to escape back to the

Main Menu

c. When in the calibration mode follow the instructions on the display

screen to carry out the calibration of the unit. See ‘Calibration

Notes’ below for hints on successful calibration.

d. When the calibration is complete the unit will return to the Main

Menu.

e. From the Main Menu use the +/- buttons on the alarm face select ‘

RUN ’ and then press the ENTER button.

The unit will now function and display the measured Fume Hood face

velocity

Note:- To re-enter the Menu functions press and hold the ENTER button until

the Main Menu appears on the display

10

5.1 Calibration Notes :-

1. When using a standard Fume Hoods with Vertical Sliding sashes open

the sash to the normal max safe working height for the Low Air sample.

2. For the Higher Air sample close the sash to approx 50% of the opening

used for the Lower Air sample. If the Higher air sample value is too close

to the Lower Air sample the alarm will detect this and ask you to repeat

with a higher value. To do this close the sash a little more and repeat the

sample. Avoid closing the sash below 4 ins.

A difference of at least 50 fpm or more between the high and low velocity

points will create the best accuracy over the whole operating range.

3. The face velocity readings on the open sash may vary at different points

on the measuring grid by up to 20fpm. This is quite acceptable in terms of

the fume hood performance so long as no individual point is below the

designated Low Air alarm point .The figure entered for the calibration point

can be taken as the average value of all the measuring grid readings or

could be taken as the individual lowest point on the grid. For most fume

hoods this low point is on the bottom row in the centre and is a convenient

position to measure and for future reference when checking the alarm

during annual maintenance.

4. Take time when measuring the face velocities for the calibration procedure

to allow for the velocities across the open sash to stabilize. If the velocities

are changing or are turbulent during the sampling period the alarm will

detect this and ask you to repeat the sample.

5. When using a Fume Hood with Horizontal Sliding sashes open the

sashes to the normal max safe working opening for the Low Air sample.

When calibrating or re-calibrating the alarm it is important to ensure that the ‘Vent

kit’ is connected to the In-line airflow sensor on the fume hood. If the vent kit is

not connected the sensor will not ‘see’ a change in the airflow during the

calibration procedure. If this occurs the alarm will detect this an bring up a

warning on the display asking you to ‘check the sensor’

If the sensor cable is not connected the alarm will display SENSOR ERROR and

you will not be able to proceed with the calibration.

11

6.0 Monitor Configuration

The configuration of the various functions and the calibration of the alarm face

velocity display is menu driven. Access to the Calibration and Configure menu

will be via separate passwords (4 digit numbers ). The numbers are factory set to

0000 and 0000 . These numbers can be changed via the pushbuttons and

display from the Setup Menu.

NOTE:- If you enter the Configure or Password Menu by accident :- press

the + & - buttons at the same time to escape back to the Main Menu

The menus and sub–menus are in ‘ plain language ’ and incorporate brief

instructions where appropriate.

See ‘ Menu Block Diagrams ‘ for a step by step view of the menu structure

12

7.0 Events / actions

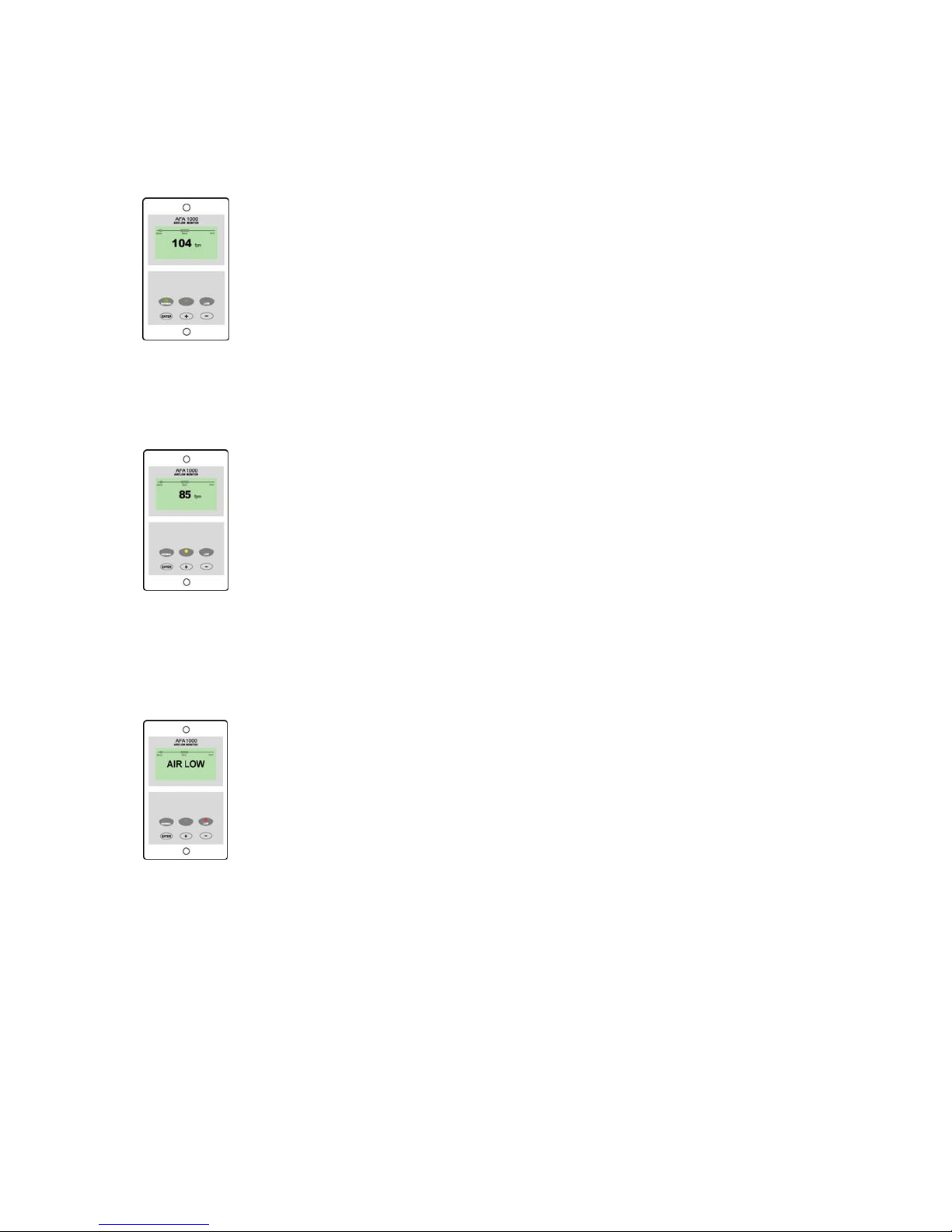

Normal airflow

• Meter reading above warning level ( e.g. > 90fpm )

• Green LED on

Warning airflow

• Meter reads between warning level and air fail level ( e.g. > 80fpm and

< 90fpm )

• Amber LED on

Low airflow

• Meter reads below alarm level for longer than the warning to low air delay

time

• LOW AIR toggles on / off with display

• Red LED on ( Flashing )

• Audible alarm sounds -- can be muted via Enter pushbutton

• Low air relay operates ( if configured )

Reset : -- when airflow rises 4fpm above Low air level for longer than the low air

to warning air delay time the Low air alarm resets automatically

13

High airflow

If configured :-

• High Air toggles on / off with display

• Audible alarm sounds – can be muted via Enter pushbutton)

Sash High

• When the input configured as Sash High is activated

• Amber LED on

• Sash High – toggles on / off with velocity display

• Audible alarm sounds

• Audible can be muted via Enter pushbutton -- this silences the alarm and

initiates a repeat timer ( if configured ). After the delay time the alarm re-

sounds ( and can be re-muted). During this time the Amber LED flashes on /

off.

• Sash High relay operates ( if configured )

Reset when Sash lowered to safe position and input de-activated.

14

High / Low

• When input configured as High/Low is activated

• Display Icon shows High or Low

• High / Low relay operates ( if configured )

This function is designed for two speed fan operation or two position damper

operation switched via a micro switch or proximity switch activated at a given

position on the sash.

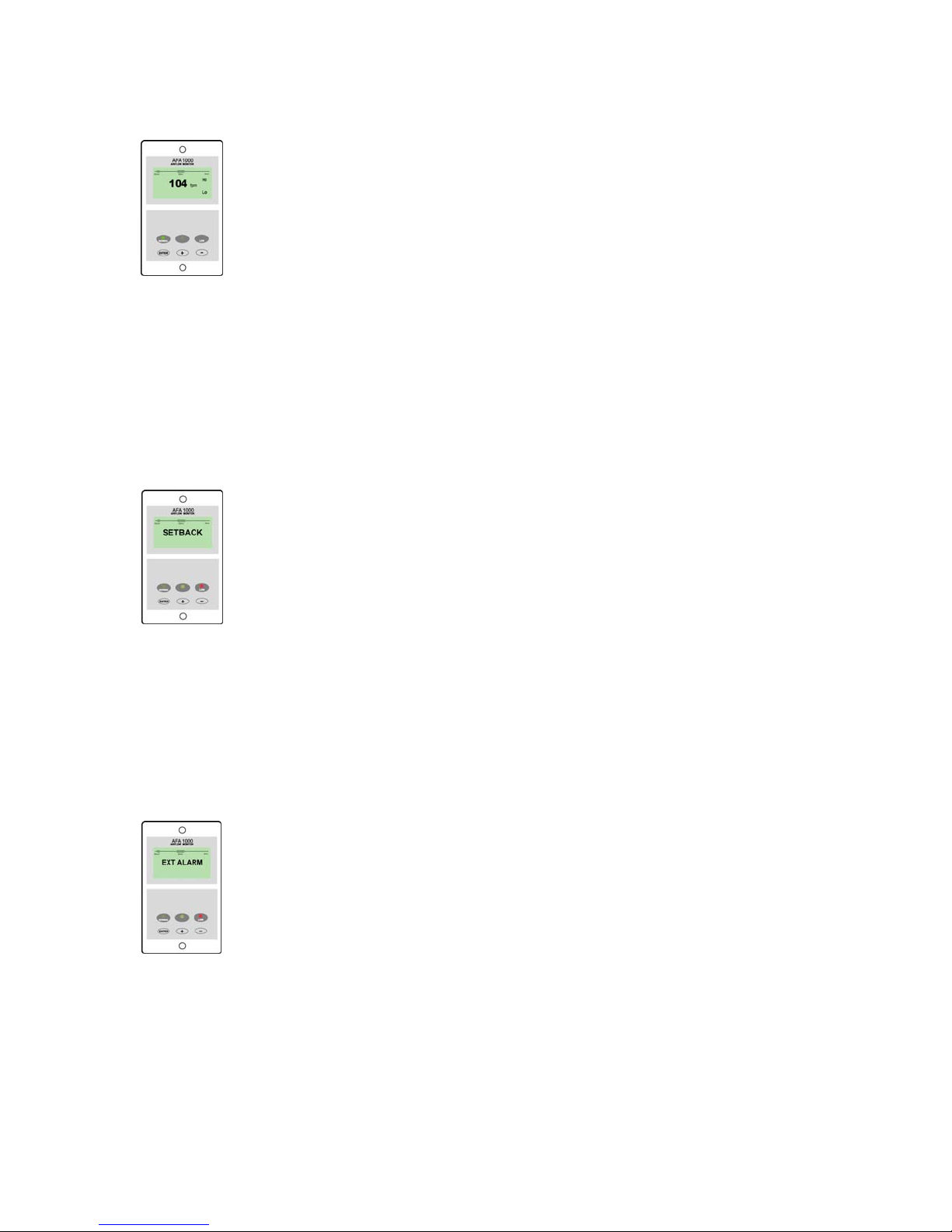

Night set-back

• When input configured as Night set-back is activated

• Night set-back Icon is displayed

• Red LED on ( Flashing)

• Reduced Low air alarm ( if configured )

• Audible alarm muted

• Mute Icon shown on display

External alarm

• When input configured as External alarm is activated

• Red LED on ( Flashing) – ( if configured )

• Ext Alarm toggles on /off with display -- ( if configured )

• Audible alarm sounds – can be muted via Enter pushbutton

• External alarm relay operates ( if configured)

15

Alarm disable

• When input configured as Alarm disable is activated

• Alarm disabled is displayed

• Red LED on ( Flashing)

• Audible alarm muted

• Mute Icon shown on display

Audible alarm Mute

• When the audible alarm is muted via the Enter button - an Icon ( horn with

forward slash) is shown on the display.

16

8.0 Dimensions

3.19″

(81mm)

5.2 ″

(132mm)

Alarm Panel

Dimensions

Panel Cutout

Dimensions

3.00″x 2.00″

4.37 ″

(111mm)

R1

15V

T

EL

s1

IDC

2

3

232

1.14

″

(29mm)

1.14

″

(29mm)

2.91

″

(74mm)

1.89 ″

(48mm) 0.75 ″

(19mm) 0.38 ″

(9.75mm)

Front

View Rear

View Side

View

1.59

″

(40.5mm) 1.59

″

(40.5mm)

2 x Fixing Holes

for 2 x No. 6

Self tapping screws provided

3.00″

(76.2mm)

2.00

″

(50.8mm)

4.37

″

(111mm)

17

Airflow Alarm

Vent Tube Hole

Airflow Alarm

Vent Tube Hole

Concept or Pioneer

Fume Hood

SafeAire

Fume

Hood

18

9.0 In – line Airflow Sensor Installation

The in-line sensor kit comprises of the following components

Select the correct length of Hose to suit the installation .

The Cross Hatch Washer is fixed inside of the female coupling.

19

It is very important to position the In-line airflow sensor in the correct position to

give long term stable reading of the face velocity. Please read the

INSTALLATION NOTES below and if in doubt contact us for further advice.

INSTALLATION NOTES :-

1. The In-line sensor must be positioned where it can " see " the room pressure

of the laboratory.

1” Threaded coupling should be mounted through a 1" hole in the front face

of the side wall post. Cross hatch washer is pre- fitted between Hose & female

coupling.

1” Elbow should be mounted through a 1" hole in the inner lining side wall.

The ideal position for this elbow is 4" back from the sash glass and 4"

higher than the normal sash opening height through the inner side wall.

2 The sensor should not be mounted in a position where it is subject to drafts

from the laboratory air input or ventilation system.

20

10.0 Typical Wiring Diagram --- (Alarm only)

120V

PSU

120V / 15V DC

Plug – in power adapter for

120V socket

Power requirement –

110mA @ 120v AC Supply

Flying lead with plug

connection for PCB

15 V DC

Flying lead with RJ11

plug connection for PCB

and SM6 airflow sensor

12V DC

Sash High

Proximity switch

( Optional )

SM6 or Inline

Airflow Sensor

OUTPUT

RELAY

R1

SENSOR

SOCKET

15V DC

POWER

SUPPLY

INPUT

REFER TO

INSTALLATION

INSTRUCTIONS

BEFORE

CONNECTING

MADE IN ENGLAND

www.tel-uk.com

TEL

INPUT 3

Blu

Blk

Brn

AFA 1000 USA

Sash High

Micro - switch

( Optional )

IDC

14-way

Connector

for remote

Interface Box

( Optional )

INPUT 2

INPUT 1

RS 232

Com Port s/w

+

-

Table of contents

Other TEL Security System manuals