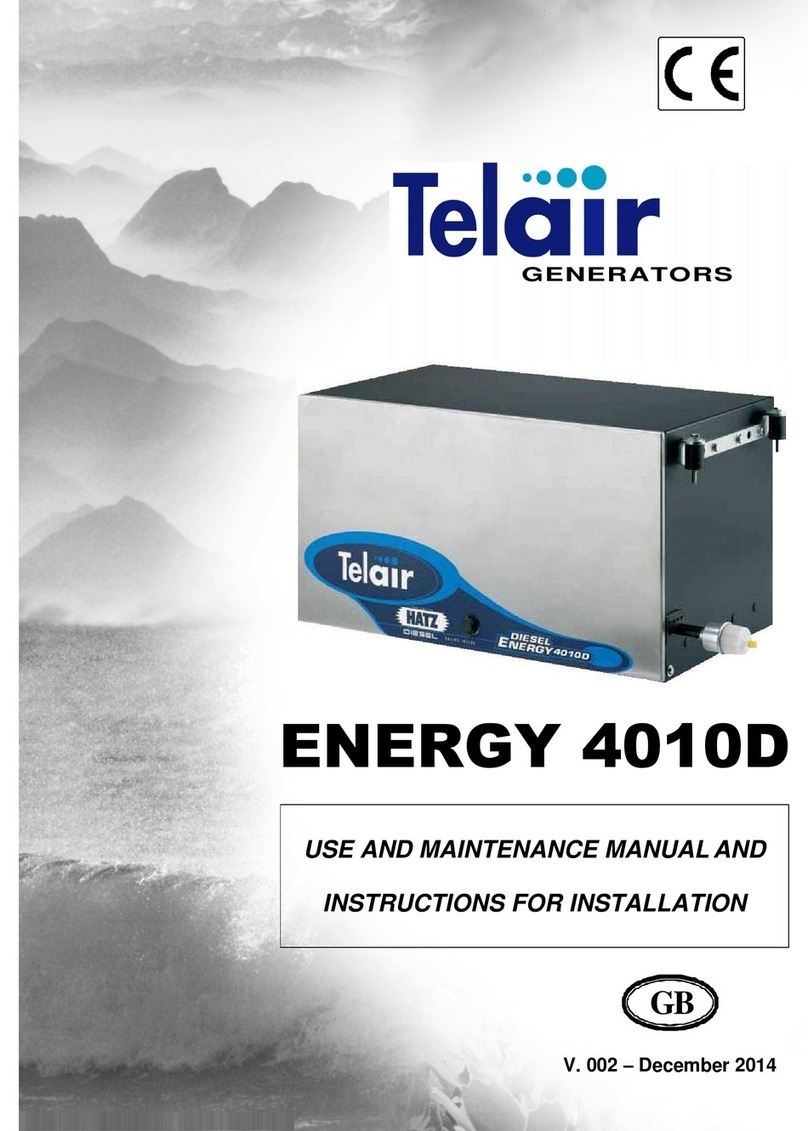

Telair ENERGY 4010B Operation instructions

Energy 4010 B Vers. 022

1

GB

INDEX

USER'S OPERATING INSTRUCTION

AND INSTALLATION MANUAL

GB

ENERGY 4010B

v. 001

–

Februar

y

2011

GENERATORS

Energy 4010 B Vers. 001

GB

2

INDEX

1 FOREWORD ..................................................................................................................................... 5

1.1 Purpose and scope of this manual ............................................................................................. 5

1.2 Symbols and Definitions ............................................................................................................. 5

1.3 General Information .................................................................................................................... 5

2 GENERATING SET IDENTIFICATION DATA................................................................................... 6

2.1 Components (Fig. 1) ................................................................................................................... 6

2.2 Identification plate (Fig. 2) .......................................................................................................... 6

2.3 Overall dimensions ..................................................................................................................... 6

2.4 Technical specifications.............................................................................................................. 7

3 SHIPPING, HANDLING, STORAGE .................................................................................................7

3.1 Storage ....................................................................................................................................... 7

3.2 Weight......................................................................................................................................... 7

3.3 Handling...................................................................................................................................... 8

4 INSTALLATION ................................................................................................................................. 8

4.1 Preliminary information ............................................................................................................... 8

4.2 Instructions for fastening the generating set............................................................................... 8

4.2.1 Hanging assembly ………..….…………………………………………………………………..8

4.2.2 Floor fastening …..………….……..…………..…………………………………………………9

4.3 Wiring connection instructions .................................................................................................. 10

4.4 Battery connection .................................................................................................................... 10

4.5 Electric Load connection........................................................................................................... 11

4.6 Auxiliary electric cable connection............................................................................................ 12

4.7 Electronic control panel connection .......................................................................................... 12

4.8 Auxiliary (optional) fuel pump connection .................................................................................12

4.9 (Optional) tank installation instructions ..................................................................................... 13

4.10 Fuel reserve............................................................................................................................ 14

4.11 Battery charger ....................................................................................................................... 14

4.11.1 Auxiliary Battery Charger ................................................................................................. 14

4.12 Connecting an additional silencer........................................................................................... 15

4.13 Connecting an External Network Relay .................................................................................. 16

5 OPERATING INSTRUCTIONS........................................................................................................ 16

5.1 Machine safety.......................................................................................................................... 16

6 USING THE GENERATING SET ....................................................................................................17

6.1 Starting up the generating set................................................................................................... 17

6.2 Turning the generating sets off ................................................................................................. 18

6.3 Information on not recommended uses .................................................................................... 18

6.4 Useful tips ................................................................................................................................. 18

6.5 Control and alarm functions (Fig. 24) ....................................................................................... 18

6.6 Control panel alarm causes and resetting ................................................................................ 18

6.7 Automatic Version (optional). ………………………………………………………………………20

6.8 MANUAL operation .………………………………………………………………………………….20

6.9 AUTOMATIC OPERATION…………………………………………………………………………..20

7 MAINTENANCE INSTRUCTIONS................................................................................................... 21

7.1 Service check list ...................................................................................................................... 21

7.2 Maintenance not requiring specialised personnel..................................................................... 21

7.3 Checking the engine oil level .................................................................................................... 21

Vers. 001 Energy 4010 B

G

B

3

7.4 Maintenance operations to be carried out by qualified personnel............................................. 22

7.4.1 Engine oil replacement ...................................................................................................... 22

7.4.2 Air filter maintenance ......................................................................................................... 22

7.4.3 Spark plug maintenance .................................................................................................... 22

7.4.4 Voltage adjustment ............................................................................................................ 22

8 ROUTINE MAINTENANCE SCHEDULE ......................................................................................... 23

9 PROLONGED INACTIVITY ............................................................................................................. 24

10 DISMANTLING .............................................................................................................................. 24

11 RECOMMENDED FIRE-FIGHTING EQUIPMENT ........................................................................ 24

GENERAL WARRANTY TERMS ......................................................................................................... 25

WIRING DIAGRAM ENERGY 4010 B .................................................................................................. 26

DRAWING FOR SPARE PARTS LIST ENERGY 4010 B .................................................................... 28

When the generator remains idle for at least three weeks, old unleaded

petrol sediments could build up inside the carburettor. These sediments

can seriously damage the engine and it is therefore COMPULSORY that

the carburettor be completely emptied prior to a long period of non-use:

do this by turning off the fuel tap and running the generator set until it

stops.

It is also essential that you never use old unleaded petrol, as it can

undergo chemical modifications and seriously damage the engine.

Failure to observe these instructions automatically renders the

WARRANTY NULL AND VOID.

Energy 4010 B Vers. 001

G

B

4

Via E. Majorana , 49 48022 Lugo (RA) ITALY

"CE" COMPLIANCE STATEMENT

Under Machine Directive 89/392/ EEC, attachment II A

We hereby represent that the generating set - the data concerning which are specified below - has been

designed and built to correspond to the essential safety and health requirements laid down by the European

Directive on Machine Safety.

This statement shall no longer be valid if any changes are introduced in the machine without our written

approval.

Machine: GENERATOR-SET

Model: ENERGY 4010 B

Serial number: ………………………...

Reference Directive:

Machine Directive (89/392/ EEC) version 91/31/ EEC

Low Voltage Directive (73/23/ EEC)

Electro-magnetic Compatibility (89/336\ CEE) version 93/31/ EEC

Harmonised standards applied, in particular: EN 292-1; EN 292-2; EN 60204-1

DATE ........07/12/2010..........

THE PRESIDENT

Vers. 001 Energy 4010 B

G

B

5

1 FOREWORD

Refer carefully to this

manual before performing any operation on

the power generator set.

1.1 Purpose and scope of this manual

This manual has been drawn up by the

Manufacturer in order to provide basic

information and instructions for performing every

operation for servicing and using the generating

set in a proper and safe manner.

It is an integral part of the generating set

equipment, must be kept with care throughout

the life of the same, and must be protected

against any agent which could damage it.

It must follow the generating set if this is installed

on a new vehicle, or if its ownership changes

hands.

The information in this manual is addressed to

the personnel in charge of installing the

generating set, and to all those involved in its

maintenance and use.

This manual sets out the purpose the machine

was designed for, and contains all the

information required to guarantee that it is used

in a safe and proper manner.

Constant compliance with the instructions laid

down here will guarantee the safety of the user,

operating economy and longer life of the

machine.

To facilitate reference, this manual has been

subdivided into chapters specifying the main

notions contained therein; for quick consultation,

refer to the table of contents.

The most important parts of the text are in bold

letters and preceded by symbols described here

below.

It is strongly recommended that you read the

contents of this manual and the reference

documents carefully; doing so is essential to the

correct long-term performance and reliability of

the generator set and the prevention of injury

and/or damage.

Note: The information contained in this

publication was correct at the time it went to

print, but may be modified without advance

notice.

1.2 Symbols and Definitions

"Graphic safety symbols” have been employed in

this booklet to identify different levels of danger

or important information.

This means that you must

pay attention to avoid serious consequences

which might lead to serious accidents or damage

the health of the operators.

This means a potentially

hazardous situation which could lead to

accidents or damage to property.

This calls the user’s attention

to a potentially dangerous situation which could

cause malfunction or damage the machine.

The drawings are only provided by way of

example.

Even though the machine you actually have may

differ from the illustrations contained in this

manual, safety and information about the same

are guaranteed.

The manufacturer, as part of his policy of

constant product development and updating,

may introduce changes without giving any notice.

1.3 General Information

The ENERGY generating set has been designed

for installation on vehicles. It can deliver power at

a voltage of 230 VAC 50 Hz.

The ENERGY 4010 B models must be fed lead-

free petrol.

In order to achieve a low noise level, the

ENERGY series generating sets are provided

with internally insulated sound-proofing cases.

They can be accessed easily in order to perform

maintenance work, and are provided with a

remote control panel which can be installed

inside the vehicle.

The generating sets can be connected to the

tank of the vehicle as long as the fuel type is

compatible. Otherwise, install a special tank

which can be supplied as an option.

Energy 4010 B Vers. 001

G

B

6

2 GENERATING SET IDENTIFICATION

DATA

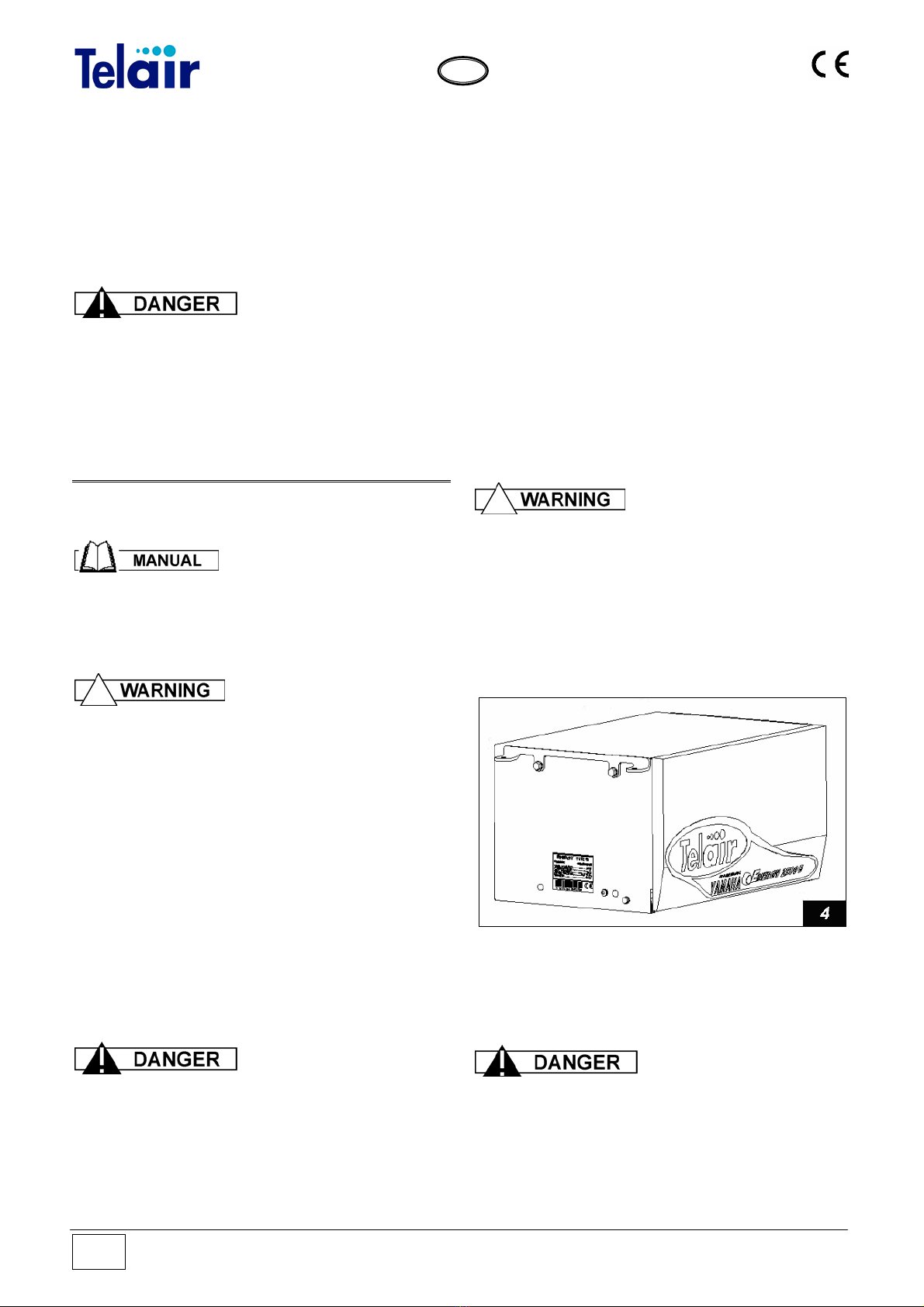

2.1 Components (Fig. 1)

1 Sound-proofing casing

2 Supporting brackets

3 Access door

4 Access door closure

5 Technical features sticker

6 Anti-vibration support

7 Anchoring bracket

8 Electronic control panel

9 Gas pipe and cable outlet block

10 Sliding surface locking screw

11 Fuel pipe

12 Sliding surface all out locking screw

2.2 Identification plate (Fig. 2)

1 Generating set model

2 Model code number

3 Serial number

4 Date of manufacture

5 Power factor

6 Frequency

7 Maximum electric power

8 Maximum current

9 Rated voltage 230V AC

10 Current delivered at 12V/DC

11 Weight

12 Bar code

2.3 Overall dimensions

Figure 3 shows the dimensions of the generating

sets.

Vers. 001 Energy 4010 B

G

B

7

2.4 Technical specifications

ENERGY

ENGINE 4010 B

Type Single cylinder, 4 stroke petrol, overhead valves, air cooling

Engine Yamaha MZ 250

Displacement cm3 251

Bore x Stroke mm 70 x 57

Max Fuel Consumption 2,0 l/h

Fuel supply Lead-free petrol

Ignition system Electronic

Spark plug BPR4ES

Oil sump capacity litres 1,0

Speed governor Automatic with centrifugal weights

ALTERNATOR 4010 B

Type

Synchronous, single phase, self-adjusting,

two poles, brushless

Max power kW 3,8

Continuous power kW 3,3

Voltage/ Frequency V/Hz 230 / 50

Continuous current output A / Vdc 10 / 12

Rotor insulation class H

Stator insulation class F

Cooling

Centrifugal fan

GENERATOR 4010 B

Overall weight kg 82

Dimensions (L X W X H) mm 665 x 465 x 345

Starting

Electrical / Manual

Fuel pump Negative pressure fuel pump

Noise level 60 dBA - 7 mt

Operation Hours h 7

3 SHIPPING, HANDLING, STORAGE

3.1 Storage

The generating set is protected during transport

by suitable carton packaging and a wooden

base. It must be stored horizontally, in a covered,

dry and ventilated area.

Do not turn the package

upside down. The correct position is the one

shown by the symbol printed on the package

( ).

3.2 Weight

Total weight including packing:

ENERGY 4010 B: 82 kg

Energy 4010 B Vers. 001

G

B

8

3.3 Handling

The generating sets, complete with their

packaging, can be handled using common lifting

and transport vehicles.

The boxes are provided with spacers in order to

allow for the introduction of pallet truck forks.

During lifting and

transport, comply with accident prevention

and safety regulations. Use lifting and

transport equipment with a capacity greater

than the load to be lifted.

4 INSTALLATION

4.1 Preliminary information

Before installing the

generator set, it is absolutely necessary to

read these instructions to prevent any

installation errors.

The generator must be

installed so as to prevent water seeping

directly into the alternator through the air

inlets; it must therefore be protected.

Incorrect installation of generating sets can

cause irreparable damage to the equipment

and endanger the safety of users.

Should the generating sets be installed not in

compliance with the instructions in this manual,

the Manufacturer shall not be held responsible

for malfunctioning or for the safety of the

generating set, by the terms of the Italian Law

Decree D.M. 89/392/EEC. The Manufacturer

shall also not be liable for any injury or damage

to people or property.

Installation must be

performed by qualified and adequately

trained personnel only.

4.2 Instructions for fastening the generating

set

The ENERGY 4010B generating sets are

provided with anchoring brackets with extra

vibration dampers (Fig. 4, Ref. 1) and a fuel filter

to be fitted along the generator feeding pipe. The

brackets allow for hanging and floor assembly.

This kind of assembly provides the following

advantages: less room taken up, quick

installation, easy access for routine and

unscheduled maintenance.

Make sure that there is enough room around the

hood of the generating set to let cooling air

through; also leave 10 cm free room between the

hood and the surrounding parts.

Should the generating set air intake be behind a

wheel of the vehicle, care should be taken to

prevent water from being sprayed into the

generating set by the wheel when raining.

Ensure that, when the door

is open, the engine sliding surface can be

taken out (Fig. 12).

4.2.1 Hanging assembly

The generator, when sticking out of the package,

is preset for hanging assembly, as shown in fig.

12.

The package also contains 4 vibration-damping

cylinders (fig. 5 ref.1) and 2 brackets for hanging

assembly (fig. 5 ref. 2).

The vibration-damping

cylinders must imperatively be fitted as

shown in fig. 5. They must be pressed, and

NOT extended (as shown in fig. 6) by the

generator weight.

Vers. 001 Energy 4010 B

G

B

9

4.2.2 Floor fastening

The package contains a drilling jig, which allows

the generator bearing surface to be prepared

quickly, fig. 7.

Place a spongy, heat-

resistant gasket around the outlet opening of

the exhaust pipe. The gasket height must

reach the bottom of the generator and has the

purpose of preventing hot air from spreading

inside the generator compartment.

The brackets of the generator must be moved in

order to fasten the Energy 4010B on the bearing

surface.

On both sides, remove the hole plugs (fig. 8 ref.

1) and screw out the screws (fig. 8 ref. 2) in order

to remove the bracket (fig. 8 ref. 3).

Place the bracket (fig. 9 ref. 3) on the 4 holes

which were previously covered by the plugs

using the same screws (fig. 9 ref. 2) and apply

the hole plugs (fig. 9 ref. 1) in the seats which

previously housed the screws.

Energy 4010 B Vers. 001

G

B

10

The generator can now be located on the

previously drilled surface (fig.7) using the suitable

vibration-damping cylinders (fig. 10 ref. 1) and

spacers (fig. 10 rif.2)

4.3 Wiring connection instructions

By using the special key to open the lock,

remove the front door.

Then remove the bottom surface locking screws

(Fig. 11 Ref. 2) on both sides.

Take out the bottom surface with the engine all

the way to the mechanical stop (Fig. 12).

If you wish to completely remove the engine

surface, screw out the locking screws (Fig. 11

Ref. 3), too.

4.4 Battery connection

To start up the generating set, connection to the

battery of the vehicle must be provided using a

sheathed power cable up to current standards,

with the cross-section shown in Table 1.

To this end, the generating set is provided with

two special terminals (Fig.13 Ref.2) used to

connect the positive and negative poles of the

battery.

Connect the cable of the positive pole (red cable)

to the terminal already having a red cable and

the cable of the negative pole (black pole) to the

terminal already having a black cable. The cable

of the negative pole must be of the same cross-

section as the positive cable, and must be

connected both to the negative pole of the

battery and to the vehicle chassis.

Make sure there is good contact; remove any

paint or rust from the contact surface, and protect

the connection by applying grease.

The capacity of the battery to be used for starting

up must not be less than 100 A/h.

The soundproofing box is equipped with two

cable outlets used to let through the battery

connection cables (Fig. 11 Ref. 1).

The cable presser block is used to prevent water

seeping into the power generating set.

Vers. 001 Energy 4010 B

G

B

11

Always fit a 100 A fuse

onto the positive cable connecting the

generating set to the positive pole of the

battery.

4.5 Electric Load connection

To connect loads to the power generating set,

use a three-pole cable up to the applicable

standards in force. The correct cross section is

shown in Table 1. Table 1

Model Sect. mm2

line 230 V Cable leng.

Lgth < 6 m Cable leng

Lgth. > 6 m

4010B 4 10 16

LINE

CONNECTION 230 V BATTERY

CONNECTION

For connection to the 230V input line, the

generating set is equipped with a special terminal

strip (Fig.13 Ref.1) to which the cables must be

connected.

Use the special cable outlet (Fig.11 Ref.1) to

prevent water seeping into the generating set.

Although the generating set is equipped with a

special internal thermal cut-out to cut power

delivery in the event of overload or short circuits

(Fig.13 Ref.5), it is advisable to install (in the

vehicle control panel) a thermomagnetic cut-out

switch, suitably set to stop power delivery to the

various users when current absorption exceeds

16,5 Amp for ENERGY 4010 B

If the generating set thermal cut-out switch has

been operated, press the button (Fig. 7 Ref. 5) to

restore closed circuit and power delivery

conditions.

Carefully check the

position of the line connection for picking up

230 Volt current. Wrong connection could

damage the generating set irreparably or

create dangerous short circuits.

Energy 4010 B Vers. 001

G

B

12

4.6 Auxiliary electric cable connection

All 3 auxiliary cables to connect are equipped

with a polarized connector.

One cable is necessary for generator operation,

while the other 2 are optional cables.

•Cable from the generating set to the control

panel (mandatory). It is included in the

standard supply and is 5 metres long. Check

that its length is sufficient to cover the chosen

rout between the generating set and the

control panel. Optional cables in longer sizes

are also available.

After leading the cable through the cable

outlet block (Fig.11 Ref.1) connect the white

connector to the fixed connector (Fig.13 Ref.

9) provided inside the generating set,

checking that the plugging direction is correct.

•Cable from the generating set to the auxiliary

fuel pump and fuel tank reserve (optional).

From the three-pole connector (Fig.13 Ref.8)

it is possible to take two cables to supply

electric input to an auxiliary fuel pump; also

see paragraph 4.8.

From the same connector (Fig.13 Ref.8) it is

also possible to take the signal for tank fuel

warning; also see paragraph 4.10.

•Cable from the generating set to the auxiliary

battery charger (optional). From the bipolar

connector (Fig.13 Ref.6) it is possible to

derive supply for an RCB battery charge

regulator via two 4 mm2cables; also see

paragraph 4.11.1.

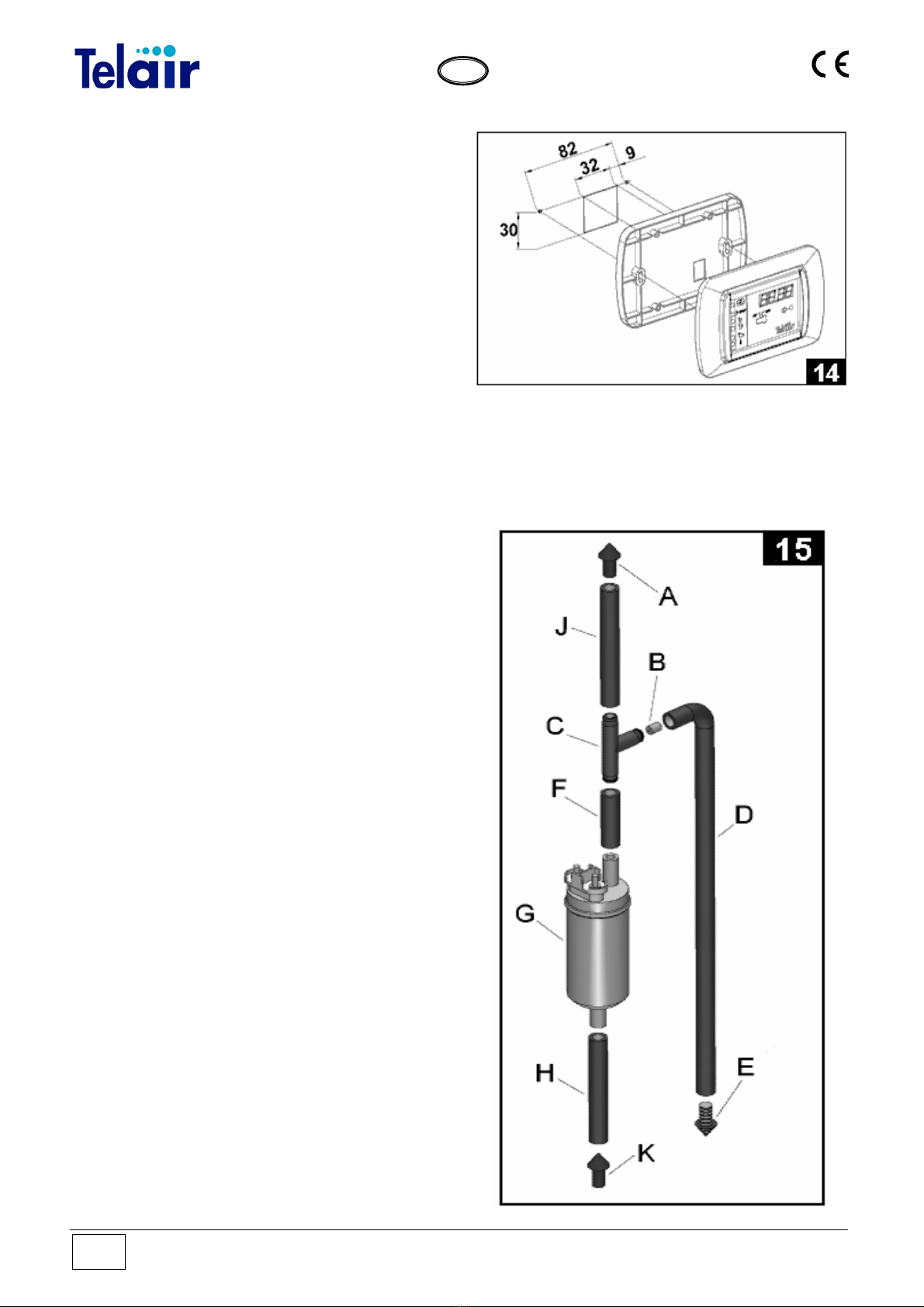

4.7 Electronic control panel connection

Choose your required position for the control

panel inside the vehicle and drill a 30 x 32 mm

rectangular hole. After letting out of the hole the

connecting cable coming from the generating set

(paragraph 4.6) connect the cable black

connector on the back of the electronic control

panel. Fix the electronic control panel (Fig.14) by

using 3 x 20 mm self-tapping screws, making

sure that the rear part does not interfere with

other surfaces. Apply light pressure to fix the

plastic frame, until the anchoring tabs click in.

4.8 Auxiliary (optional) fuel pump connection

If the distance that fuel must cover between the

fuel tank and the generating set is too long or the

tank is installed at a lower level than the

generating set, the fuel pump installed inside the

generating set may find it difficult to take fuel in

from the tank by suction. In this case, an auxiliary

optional fuel pump (code 00507) should be

installed as close as possible to the tank for easy

priming.

Vers. 001 Energy 4010 B

G

B

13

As is shown in the figure, fuel coming from a tank

K fitting is taken in by suction by the pump Gvia

a hose Hand then fed to the joint Cvia the hose

F.

The amount of fuel necessary for generating set

operation will be fed through the hose J to the

generator unit A; while any excess fuel will return

to the tank via the return fitting E.

Inside the joint C, a flow rate reducer B should be

installed consisting in a fit-in cylinder with a 2.5

mm ID. Each pipe coupling must be secured with

a special clamp.

On the generating set front is a three-pole

connector (Fig.13 Ref.8). Checking the wiring

diagram, identify the two auxiliary fuel pump

control poles (+12 and GND ). Two cables with

minimum cross sections of 1 sq.mm must be

connected to those two Faston terminals with

special connectors to reach the auxiliary pump

poles. (Fig.15 Ref. G)

4.9 (Optional) tank installation instructions

The fuel tank installation position (Fig. 10) must

be chosen so as to ensure that the fuel hose

length is reduced to a minimum.

Also ensure that the hose cross-section is not

reduced due to choking, bending or crushing. We

advise the install the tank at the same height as

the generating set; in any case, the installation

height difference should never exceed 20 cm

(Fig. 16).

Should it not be possible to observe the

maximum permitted level difference

requirements, an electric fuel pump can be

installed (available as an optional part, code

00507) which can easily overcome over 1 metre

level differences between the fuel tank and the

generating set.

See paragraph 4.8

Do not install the fuel

tank next to sources of heat; the tank should

be protected from the risk of outside water

seeping.

Carry out the fuel tank-to-generating set

connection by using a rubber hose (Fig.16 Ref.

2) suitable for unleaded fuel with an ID of 5 mm

interposing a fuel filter (Fig.16 Ref. 1).

The tank requires an outlet and a special hose is

connected to the special hose connector to this

end (Fig.16 Ref.3). Make sure that the outlet

hose path is upwards (Fig.16 Ref.4) and straight-

lined without any elbows.

Dealers can supply two different fuel tank models

to meet any installation requirements.

•For standard vehicle installation, use the

optional tank code 05472 (Fig.16 Ref.8) with a

capacity of 15 litres; the filler (Fig.16 Ref.5) is

supplied complete with a closing plug. (Fig.16

Ref. 6)

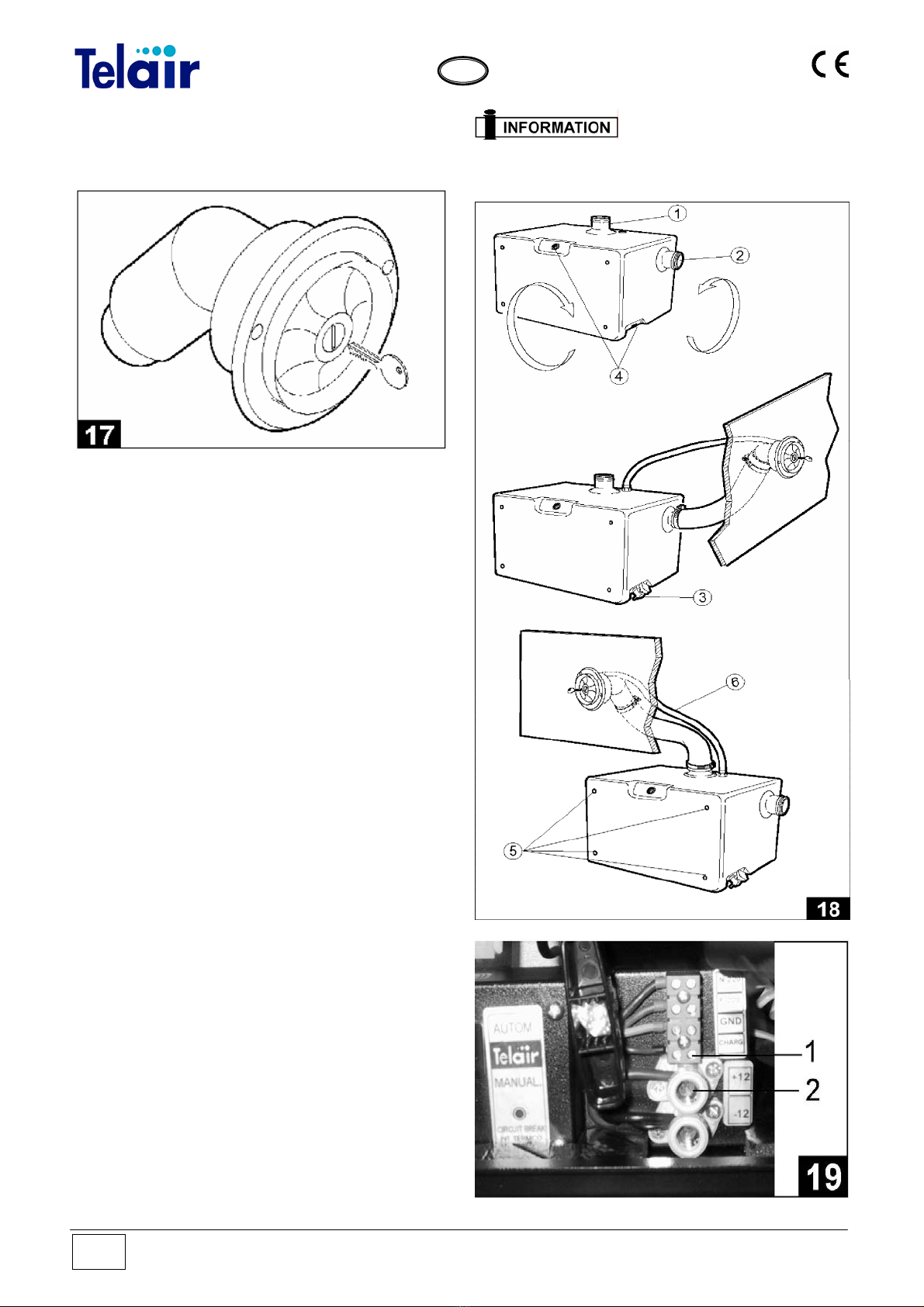

•The optional tank code 05466 (Fig. 18)

with a capacity of 15 litres has been designed for

installation at different positions to make the most

of the available vehicle space and to enable filler

(Fig. 17) connection at two different locations

(Fig.18 Ref. 1 and 2). This enables the installer to

choose the most suitable solution each time

according to the type of installation.

The fuel cut-off tap (Fig. 18 Ref. 3) can also be

screwed onto two different threaded pipe fittings

(Fig.18 Ref. 4) according to different installation

positions.

Energy 4010 B Vers. 001

G

B

14

For tank anchoring to the vehicle, special

threaded inserts (Fig.18 Ref. 5 ) and (Fig.16 Ref.

7) should be used according to requirements.

4.10 Fuel reserve

Both fuel tank models are provided with a tap

with fuel warning (Fig.18 Ref.3). To electrically

connect this component, ground the wire

screwed on the tap body then connect the other

tap wire to the special three-pole connector

Faston terminal via an electric lead (Fig.13 Ref.

8); to identify the correct Faston terminal, check

the wiring diagram.

The fuel reserve available in both tanks is

approximately 4 litres.

A special fuel warning light (Fig.30 Ref.8) will

light up to show that the fuel level inside the tank

has gone below the safe reserve level.

4.11 Battery charger

ENERGY 4010B generating sets are equipped

with a battery charger which can deliver current

of approximately 10 Amp at 12 V. It can be used

to recharge the generating set start-up battery.

To obtain this function, use a 2,5 mm2cross-

section cable to connect the terminal identified by

CHARG (Fig.19 Ref. 1) to the positive pole (red

cable) of the generating set (Fig. 19 Ref. 2)

possible to use the 12 Volt alternating current

output provided on the bipolar connector shown

in Fig. 13 Ref. 6 .

4.11.1 Auxiliary Battery Charger

If you wish to recharge a different battery or do

not wish to use the CHARG terminal, it is To

these two Faston terminals, 4 sq.mm cross-

section cables should be connected to obtain

interfacing to an optional RCB regulator (code

05424) as shown in Fig. 20.

The generating set will not

autonomously recharge the battery used for

starting-up unless this is connected to a

battery charger.

Energy 4010 B Vers. 022

15

G

B

The generating set will not

autonomously recharge the battery used for

starting-up unless this is connected to a

battery charger.

4.12 Connecting an additional silencer

To further reduce the generating set operating

noise, an (optional) additional silencer can be

installed externally.

The additional silencer kit code 03991 consists

of:

•A silencer code 01761 (Fig.21 Ref.1).

•Two metre long section of flexible steel tubing

code 00705 (Fig.21 Ref.2).

•Two connection fastening clamps code 01655

(Fig.21 Ref.3).

•Two rubber suspenders cod. 02,440 (Fig. 21

Ref 4).

To connect the silencer to the generating set, first

of all remove the door (Fig.22 Ref.2) by using the

special key (Fig.22 Ref.1) and the muffler guard

(Fig.22 Ref.3).

Energy 4010 B Vers. 001

G

B

16

Then put the hose code. 00,705 (Fig. 21 Ref 2)

Lock the output of the exhaust pipe with clamp

code. 01,655 (Fig. 21 Ref 3).

Attach the hose (Fig. 21 Ref 2) to the terminal

input side of the muffler (Fig. 21 Ref 1) using the

other band that came on (Fig. 21 Ref 3).

Install the muffler 01761 using the appropriate

rubber suspenders.

Do not use silencers not

supplied by TELAIR Silencers that have not

been specially sized may damage the motor.

4.13 Connecting an External Network Relay

An (optional) relay or change-over switch code

05423 (Fig.28) should be fitted to the vehicle

wiring system. Its purpose is to insulate the

generating set when the vehicle is connected to

an external electric input network.

Connect the relay (Fig.29) according to the

following instructions:

•Connect the two wires of the 230 V line of the

generating set to the PINS 1 - 3.

•Connect the user line to the PINS 7 - 9.

•Connect the outside line to the PINS 6 – 4.

•Jumper the PINS 4 – A.

•Jumper the PINS 6 – B.

•Connect all the grounding cables together

Electric connections to

the generating set should be carried out by

skilled electricians only.

5 OPERATING INSTRUCTIONS

The generating set is

delivered without engine oil.

Use detergent oil for multigrade 4-stroke

petrol engines, having SAE viscosity suitable

for the operating climate (see table and

detailed indications on the user and

maintenance manual of the engine).

ENERGY series generators consist of petrol

internal combustion engines connected to an

alternator that can produce both alternating and

direct electrical current. The generating sets are

assembled inside a steel plate casing, insulated

and sound-proofed using special sound

absorbing materials.

Fuel is fed to the internal combustion engine via

a pump fitted to the generating set as part of the

standard supply.

5.1 Machine safety

The generating sets come with perfectly sealed

casings, so there is no danger of contact with any

moving or high temperature parts or with live

cables.

The doors open with a lock and key. The keys

must not be left within the reach of children or

inexperienced persons.

The generating sets

must only and exclusively be used with their

doors shut.

Remove any flammable substance (for

example: petrol, paints, solvents, etc.) from

near the generating sets.

Vers. 001 Energy 4010 B

G

B

17

Make sure that any hot parts of the

generating sets are not in contact with any

flammable material.

Never fill up the fuel tank while the engine is

running.

Never touch the generating sets or the wiring

connections with wet hands.

Never replace the fuses or the cut-out

switches with others having higher

amperage.

Should any electrical part need checking, this

must only be done with the engine turned off

and by specialised personnel.

The generating sets have been built in

compliance with the safety standards listed in the

EEC statement of compliance.

6 USING THE GENERATING SET

6.1 Starting up the generating set

The generating sets are provided with an

electronic remote control panel which allows you

to perform starting up / turning off operations and

to check their running conditions.

The panel controls are:

1 ON/OFF switch

2 Display unit

3 High temperature indicator

4 Engine minimum oil level indicator

5 Startup failed

6 Generator running (flashing)

7 Engine oil change indicator

8 Fuel warning light

9 Display time changeover switch

10 Reset

Set the startup switch (Fig.30 Ref.1) to its “ON”

position. The message “WAIT” will be displayed

for 8 seconds. After this time, the electronic

control panel will start the first automatic

procedure for starting up the generating set. If

the engine starts up at the end of this phase, the

“generator running” indicator light (Fig.30 Ref.6)

will start to flash.

Should the engine not start up, this automatic

procedure will be repeated up to 4 times.

If, at the end of a complete cycle, the engine has

not yet started up, the “startup failed” indicator

(Fig.30 Ref.5) will light up to signify that the

generating set has failed to start up.

If the “startup failed” indicator (Fig.30 Ref.5) light

only stays lit, you can repeat the procedure

several times. If the generating set has not

started up after several attempts, contact the

manufacturer’s After-sales service. Should the

battery be flat, you can start the generating set

by hand, using the handle of the engine coil

winding (Fig.31 Ref.1) after setting the selector

switch to "ON" (Fig.31 Ref. 2) and the electronic

control panel to "ON". Once you have started up

the engine manually, put the selector switch back

to "0FF" (Fig.31 Ref. 2). The start-up battery

should never be disconnected, as there would be

no input to the electronic control panel which

would prevent the generating set from working.

Energy 4010 B Vers. 001

G

B

18

6.2 Turning the generating sets off

To stop the generating set, set the switch 1 to its

"OFF" position (Fig.31 Ref.1).

The generating set is

provided with an internal combustion engine,

therefore, the fuel used is highly flammable.

The exhaust gases are conveyed under the

casing; their temperature, inevitably, is quite

high, even though they are mixed with

cooling air.

Do not touch the casing areas near the

exhaust, and do not put your hands or any

objects inside the casing.

6.3 Information on not recommended uses

These generating sets

must be installed and used by qualified and

authorised personnel only, according to the

manufacturer’s instructions. These

generating sets must only and exclusively be

used to produce electrical power on vehicles

provided with an electrical system built to

standards and according to the quantity of

power delivered.

6.3 Useful tips

To make the best use of the generating sets,

remember that even minor overloads - if they last

long enough - will operate the thermal cut-out

switches (Fig.31 Ref.3).

During the running-in period, do not subject the

new engine to loads exceeding 70% of the rated

load, at least for the first 50 running hours.

6.5 Control and alarm functions (Fig. 30)

2 Display: when the generating set has started

up, the total running hours will be displayed.

Press the key provided below the control panel

display unit (Fig.30 Ref.9) to display the number

of generating set operation hours since the latest

engine oil change.

3 High temperature indicator: this warning light

will light up when the temperature of the

generating set goes over its safety value; the

engine will stop at the same time.

4 Engine oil minimum level indicator: this

warning light will light up to indicate that oil in the

engine has gone below the minimum level. A

safety system will kill the engine automatically to

prevent failures.

5 Engine startup failed: this warning light will

light up to indicate that the generating set has not

started up, after all four start-up attempts.

7 Change oil: this warning light will light up when

the engine has reached 100 running hours since

the latest oil change. Every time the oil is

changed, the After-sales service staff must reset

the timer to zero.

8 Fuel warning: this warning light will light up

when the fuel level inside the extra tank has gone

below its reserve level (about 4 litres)

9 Display time changeover switch: press this

switch to display the running hours since the

latest engine oil change.

10 Reset: When the display shows characters

without any apparent logic, the panel needs to be

reinitialised. Press the Reset key (Fig.30 Ref. 10)

and, holding it down, switch on the panel. When

4 zeroes (0000) are displayed, the panel has

been reinitialised.

6.6 Control panel alarm causes and resetting

During generating set use, alarm signals may be

displayed referring to engine oil checks. After

Vers. 001 Energy 4010 B

G

B

19

checking the engine oil, the control panel must

be reset in the following way:

Alarm: the red ‘service’ light is flashing.

Cause: 50 hours have elapsed since the latest

engine oil change and oil level should be

checked.

How to reset the alarm: press the partial

counter key (Fig.30 Ref.9) and while holding it

down, turn the panel on and release the push-

button when the unit has started up

Alarm: the red ‘service’ light is lit.

Cause: 100 hours have elapsed since the latest

engine oil change and engine oil should be

changed.

How to reset the alarm: turn on the panel and

wait for the generating set to start. Now press the

button hidden under the small hole in the bottom

left corner (Fig.30 Ref.10) and release it

immediately thereafter.

Wait a couple of minutes before turning the

generating set off.

In certain situations, the data contained in the

microprocessor inside the panel may be altered.

This may be because the battery is very low, or

because the cables used to connect the battery

to the set have too small cross-sections. Altered

processor data may prevent the generating set

from running. In order to restore the generating

set operating efficiency, proceed as follows:

Alarm: the display unit shows random

characters.

Cause: malfunctioning due to low voltage during

start-up (low battery, cable cross-section too

small). Reinitialise the panel.

How to reset the control panel: press the

button (Fig.30 Ref. 10) and while holding it down,

turn on the control panel. Only release the push-

button when 4 zeros (0000) are displayed. The

panel has been reinitialised.

6.7 Automatic Version (optional)

If you wish the start-up batteries to be recharged

automatically in the En 4010 B generating sets, it

is possible to install the ASP (optional) automatic

control panel (fig.32) instead of the manual

control panel.

The elements making it up are:

1 ON/OFF switch for the start-up and switch-off

function

2 Display

3 High temperature indicator

4 Minimum oil level indicator

5 Start-up failed indicator

6 Generator running indicator (flashing)

7 Maintenance request indicator

8 Fuel reserve indicator

9 Hour or voltmetric changeover switch button

10 Reset

11 Battery charged indicator

12 Automatic function indicator

13 AUTO/MAN switch for the automatic or

manual function

6.7 MANUAL operation

See section 7.3

6.9 AUTOMATIC operation

Turn the AUTO/MAN switch (Fig.32 Ref.13) to

the AUTO position and set the start-up switch

(Fig. 25 Ref. 1) to ON position.

The automatic function indicator (Fig.32 Ref.12)

will light up. If the battery which supplies the

generating set has a voltage of more than 11.5

Volts, the battery charged indicator (Fig.32 Ref.

11) will light up.

When the voltage at the ends of the 12V DC

terminals of the generating set is lower than 11.5

Volts, the battery charged light indicator (Fig.32

Ref.11) will go off and the generating set will

begin the start-up procedure (similar to that of the

manual operation).

During the operation in automatic mode, the

display (Fig.32 Ref.2) will show the total running

hours of the generating set. Press the hour or

voltmetric changeover switch button (Fig.32

Ref.9) to display the voltage at the ends of the

12V DC terminals, i.e. at the ends of the battery.

Energy 4010 B Vers. 001

G

B

20

When the battery is charged, and anyway after at

least 15 minutes’ running, the battery charged

hours indicator (Fig.32 Ref.11) will light up and

the electronic control panel will turn off the

generating set.

Setting the switch to the

automatic position after turning the control panel

on sets the generating set in stand-by mode and

does NOT activate the automatic function.

Remember that the time which is taken by

the generating set in automatic mode to

recharge the battery may vary according to

the battery status, the amount of connected

batteries and the season temperature.

Generally, the lower the temperature the less

the time required to charge the battery.

Applying any load higher

than the energy just then available in the

battery will prevent the generating set from

turning on due to insufficient voltage.

7 MAINTENANCE INSTRUCTIONS

Only use original spare

parts. Using poorer quality spare parts may

damage your generating set.

Routine checks and adjustments are of the

essence in preserving a high level of

performance. Routine maintenance also

ensures long generating set life.

Before performing any

check or maintenance operation on the

generating set, turn the selector switch (Fig.

31 Ref.2) to the position 1 “manual” in order

to avoid accidentally starting up the

generating set.

7.1 Service check list

See table at the bottom of page 25.

7.2 Maintenance not requiring specialised

personnel

To perform this kind of service, it will be

necessary to open the generating set door. The

following precautions must therefore be taken:

1 The generating set must not be in operation,

and all its parts must be cold

2 Let the generating set cool off.

3 Turn the selector switch to the position "ON"

(manual) (Fig.31 Ref.2)

N.B. Remember to switch the selector switch

to "OFF" (automatic) after completing the

required checks.

7.3 Checking the engine oil level

•Unscrew the engine oil filler cap and clean the

dipstick (Fig.33 Ref.1).

•Put the dipstick back in without screwing.

•Take the dipstick out again, and make sure

that the engine oil level is between the two

(min and max) notches. Should the oil level be

below the minimum notch, restore the oil level

using the recommended type of engine oil

(refer to the engine user and maintenance

manual).

•Put the dipstick and filler cap back on and

screw tightly.

Do not fill to exceed the

maximum level, as this could cause

malfunctioning of the fuel pump and hence of

the generating set.

All engine oil level

checking operations must be performed with

the generating set in a perfectly horizontal

position.

Table of contents

Other Telair Inverter manuals