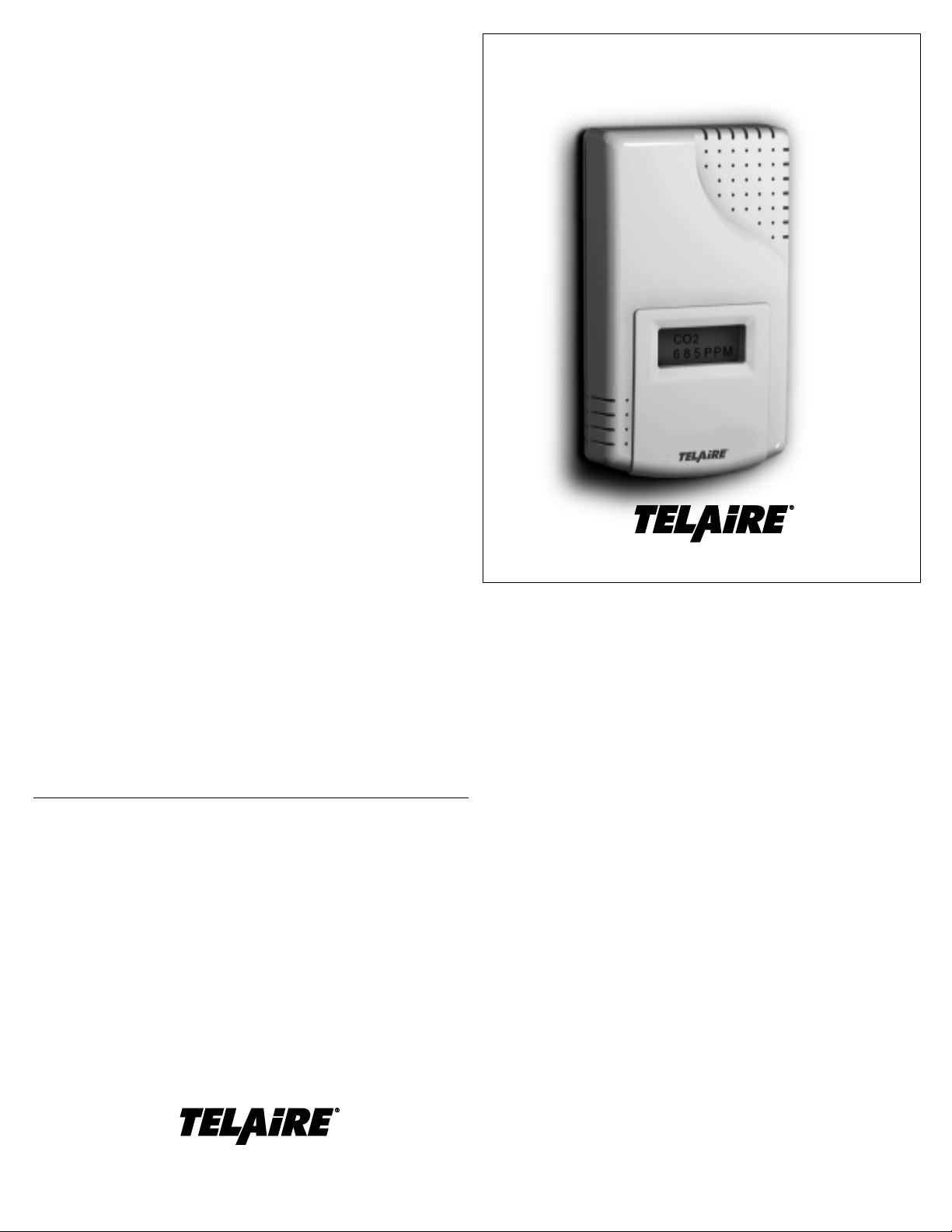

Telaire Ventostat 8000 Series User manual

clear

mode

enter clear

mode

enter

Installing the Sensor

Basic Installation of the Mounting Plate and Sensor

1. 2-3.

4. 5. 6.

1. Prepare for installation by using the mounting holes configured for US or

European junction boxes.

2. Use the mounting plate as a template to mark mounting holes.

3. Secure the Mounting Plate to the wall or junction box and make necessary

wire connections.

4. Mount the Controller on the base by aligning the top clips and then securing

to the bottom clips. A “snap” sound will indicate that the sensor is secure.

The sensor will now have power. A 2 minute warm-up will take place. After 2

minutes, the sensor will stabilize and display the “Normal Mode” (current

CO2readings).

5. At this point one of nine preset programs or one custom channel can be

selected for operation. Refer to “8. Configuring the Sensor.”

6. Finish installation by sliding the cover over the menu keys and secure with

the supplied screw.

Sensor Settings

Sensors with display can be adjusted via keypad and display or the UIP

Software program (model 2072). Sensor without display will need the program

to make any adjustments.

Altitude:

All Telaire 8000 series products are calibrated at sea level. As altitude

increases, the density of the air around us slightly decreases. This natural

phenomenon affects the accuracy of all gas sensors and introduces an error

of approximately -3% of the reading per 1,000 ft of elevation. Much of the

urbanized world is at an elevation of less than 1000 ft meaning that altitude

has very little effect on the reading and no adjustment is necessary. However,

users in locations significantly higher than sea level such as Denver, Colorado

may want to consider adjusting for elevation based on altitude to have the most

accurate reading. The altitude setting can be adjusted on the unit in 500 ft

increments.

ABC Logic™ Self Calibration System:

All Telaire 8000 series sensors are factory set with the ABC Logic™ (ABC =

Automatic Background Calibration) (formerly called TEMA) Self Calibration

feature ON. This feature allows the sensor to continually recalibrate itself

when the indoor concentrations drop to outside levels while the building is

unoccupied. Generally a building must be regularly unoccupied (with the

exception of cleaning or maintenance staff) for 4 hours or more for this self-

calibration system to operate properly. Under these conditions, ABC Logic™

should maintain sensor calibration over the lifetime of the sensor. The ABC

Logic™ should be turned OFF where a building is continuously occupied 24

hours per day, or where there could be significant sources of non-occupant

related CO2such as greenhouses, breweries and other industrial and food

processing applications.

Standard Sensor Settings Available Via the Keypad (Display Units

Only) or PC Based UIP Interface (All Units).

Typeof

Equipment

Interfacew/Standard

BuildingControlSystem

Interfacew/Standard

BuildingControlSystem

Interfacew/Standard

BuildingControlSystem

Economizer(Hvac)

Economizer(Hvac)

Economizer(Hvac)

Economizer(Hvac)

Health&Safety

Parking/AirIntakes/

LoadingDocks

Type

of

Output

Proportional

Proportional

Exponential

Proportional

Proportional

Exponential

Exponential

Proportional

Proportional

Ventilation

Rate

(cfm/

Person

Any

Any

Any

15

20

15

20

NA

NA

Analog

Output

0-10V

4-20mA

2-10V,

7-20mA

0-10V

4-20mA

0-10V

4-20mA

0-10V

4-20mA

0-10V

4-20mA

0-10V

4-20mA

0-10V

4-20mA

0-10V

4-20mA

CO2

Control

Range

(ppm)

0-2000

0-2000

0-2000

0-1100

0-900

0-1100

0-900

0-9999

0-2000

Optional

Relay

Setpoint

(ppm)

1000

1000

1100

1100

900

1100

900

5000

700

Relay

Hysteresis

(ppm)

50

50

50

50

50

50

50

500

50

Setting

No

1

2

3

4

5

6

7

8

9

Sensor Setting

The standard factory settings are the typical settings used when a CO2

sensor is connected to a building control system. If the installation is

somewhat unique or specialized, the user can customize certain characteris-

tics of the sensor. For example, non-factory settings may be applicable when

the sensor is being connected to equipment that has a fixed input range (e.g

actuators used with economizer systems).

Outlined below are the adjustable parameters of the sensor and the factory

setting. In addition to these adjustable features, the programming interface

allows for a fast and simple adjustment of sensor calibration.

8000 Series Adjustment Parameters and Factory Settings

Range

0-10,000Ft

On/Off

1to 9

0-10,000

4-20mA/0-10V

SelectOne

0-10,000PPM

0-10,000PPM

FactorySetting

0Ft

On

1

0-2,000

4-20mA/0-10V

Proportional

1000PPM

50PPM

Adjustment

AltitudeAboveSeaLevel

ABCLogic™

SelectStandardSetting

CustomizeSetting

PPMRange

OutputRange

Proportional/

ExponentialOutput

RelaySetpoint

RelayHysteresis

Standard Pre-Programmed Settings:

There are 9 Standard settings that can easily be selected using the keypad

(display units only) or the PC based UIP Program. The chart below describes

each of the settings. The definitions for some of the terms used in the chart

are described in more detail as part of the custom settings section to follow.

Settings 1, 2 and 3 are applicable for automated or computerized building

control systems.

Settings 4 to 7 are specifically designed for operation with economizer controls

and actuators where a 0-10 VDC signal will provide 0-100% outside air modula-

tion. These control settings provide different modulation ranges depending on the

target cfm-per-person ventilation rate desired. As described below the exponential

setting is best used in applications that have large volumes of air and people

such as auditoriums, gyms and large conference areas.

Setting 8 is intended for use in applications related to occupational health and

safety where users may want to measure concentrations in relation to the

5000 ppm 8 hour exposure levels established by OSHA (Occupation Safety

and Health Administration).

Setting 9 is intended for use in parking garages where CO2can be used as an

indicator of the presence of combustion fumes. As part of most types of

combustion, CO2is generated at a rate that is 50 times or more of other more

harmful contaminants. This is particularly the case with the extensive use of

catalytic converters that tend to remove most of the carbon monoxide from

vehicle exhaust. The 700 ppm setting should maintain levels of other exhaust

contaminants well below levels of concern.

Custom Settings:

In addition to the 9 standard settings programmed into the 8000 series, users

can also custom program the sensor for their own application. Outlined below

is a brief description of each of the adjustable custom settings:

62332-007 09/08/2004

Specifications

Method

Dual Beam Absorption Infrared

Diffusion sample method

Performance

Measurement Range

0-2000 ppm factory default

Adjustable to 10,000 ppm with UIP

Software

Accuracy

@60-90°F (15-32°C)

±50 ppm or 5% whichever is greater

(7% for levels over 1500 ppm)

@32-122°F (0-50°C)

±100 ppm or 7% whichever is greater

Elevation (Pressure) Correction

Add 0.13% of reading per mm Hg

decrease from 760 mm Hg (On-board

correction, user set with UIP

software), preset at sea level

Response Time 0-90%

<1 minute

Warm-Up Time @ 25oC

<2 minutes

Operating Conditions

0 – 50oC (32-120oF)

0 – 95% RH, non-condensing

Storage Temperature

-40 – 70oC

Agency Certification

FCC Part 15 Class B / CE

Plastic Case - UL94-5V Rated

Input/Output

Power

18-30 VAC RMS, 50/60 Hz -half-wave

rectified

18-42 VDC polarity protected

1.75 VA maximum average power

2.75 VA peak power

Analog Output

0-10 VDC (100 Ohms output

impedance)

4-20 mA (RLmax = 500 Ohms)

Both outputs available simultaneously

Relay Output

Normally Open and Normally Closed

(wire either way), gold bifurcated, 2A

max. @ 24VAC. Adjustable setpoint

(with UIP software kit), factory set at

1000 ppm, 50 ppm hysteresis

Wiring

18-28 AWG stranded copper wire

only. 2 wires each for power, analog

output, relay

Digital I/O

RS-232 interface for use with optional

PC software and cable in UIP kit

2072

Warranty/Other

Warranty

18 months parts and labor

Calibration

5-year calibration guarantee

Adjusting Sensor (Display Units Only)

Button Features [CLEAR] - Resets Menu

- Returns to Normal Mode

[MODE] - Toggles to Next Menu Item

[ENTER] - Press to Lock Menu

[UP/DOWN] - Increase/Decrease Selection Value

Altitude Correction and ABC LogicTM (On/Off):

1. After 2 minute warm-up period, press [CLEAR] + [MODE] and hold (at least

5 seconds) until the sensor enters the edit mode.

2. The first menu will be the Altitude correction. The adjustments will increase/

decrease in 500 ft. increments. To do this use the UP/DOWN Rocker Button

to adjust to the proper altitude.

3. Press ENTER to lock in value then press MODE to proceed to ABC LogicTM.

4. Use the UP/DOWN Rocker Button to switch to ON or OFF.

5. Press ENTER to lock in value then press MODE to proceed to Normal Mode.

Note: It is recommended that the ABC LogicTM feature be left ON for the best

sensor operation.

Selecting a Pre-Programmed Setting:

The pre-programmed settings shown in Table 3 are factory set and cannot be

changed. These settings can be selected from the Standard Settings

(STDSET) menu. The Altitude and ABC Logic™ features can be changed

without entering the Standard Settings (STDSET) menu.

1. After 2 minute warm-up period, press CLEAR + MODE and hold (at least 5

seconds) until the sensor enters the edit mode.

2. Press MODE 2 times. You will enter the STDSET menu.

3. Use the UP/DOWN Rocker Button to select the desired pre-programmed

number. Refer to “Configuring the Sensor” for the appropriate setting number.

4. Press ENTER to lock in selection then press MODE to return to Normal Mode.

For Non-Standard (Custom) Settings:

The non-standard (custom) settings can be changed at any time after the

sensor is powered up. The 7 variables are: PPM Range, Scale (proportional or

exponential), Output (V or mA), Output Range V, Output Range mA, Relay

Setpoint, and Relay Hysterisis. The Altitude and ABC Logic™ features can be

changed without entering into the Non-Standard (NONSTD) menu.

1. After 2 minute warm-up period, press [CLEAR] + [MODE] and hold (at least

5 seconds) until the sensor enters the edit mode.

2. Press [MODE] 2 times. You will enter the STDSET menu.

3. Use the [UP/DOWN] Rocker Button to toggle to the NONSTD menu.

4. Press [MODE] to move through the variables. Use the [UP/DOWN] button

to toggle to desired setting.

5. Press [ENTER] to lock in the selection then press [MODE] to continue to

the next variable.

Dual Channel CO2Ventilation Controller

Ventostat®8000 Series

Warranty

6860 Cortona Drive, Suite B - Goleta, California 93117

P- 805-685-4000 F- 805-685-0015 www.telaire.com

Telaire seeks to present reliable information concerning the composition, properties and use of its

products, however; (1)All advice concerning selection and use of any product is provided at no

charge and with no warranty. (2) No warranty is made hereby. Products described herein are

warranted to conform to Telaire specifications only at the time of sale. All sales are subject to

Telaire standard terms and conditions, which are reproduced on the reverse side of each invoice.

All warranties of merchantability and fitness of purpose are disclaimed and remedy for any breach

of warranty is limited to replacement of the defective product. (3) Telaire assumes no responsibil-

ity for any patent liability arising from the use of any product in a process, manner or formula not

designed by Telaire. ©Copyright 1999-2004

62332-007 09/08/2004

6860 Cortona Drive, Suite B - Goleta, California, 93117

P- 805-685-4000 F- 805-685-0015

NOTICE!

Use of cellular telephones or radio transceivers within two (2) feet of the

sensor during calibration process could cause sensor interference, calibration

errors and affect sensor accuracy. Please refrain from using these devices

during sensor calibration.

Other Telaire Controllers manuals