SS02 - ANN-NNN - USER MANUAL

Space Scan Series

Photoelectric measurement light curtains

Website: www.telcosensors.com

Warning

1.26 Part Number: L40-0666220750

This product is not a safety system and must not be used as such.

It is not designed for personnel safety applications, and must not be used

as a stand alone personnel safety system.

January 2015

edition

Made in Denmark Telco A/S reserves the right to make changes without prior notice

Page 1 of 4

tel

!

EN

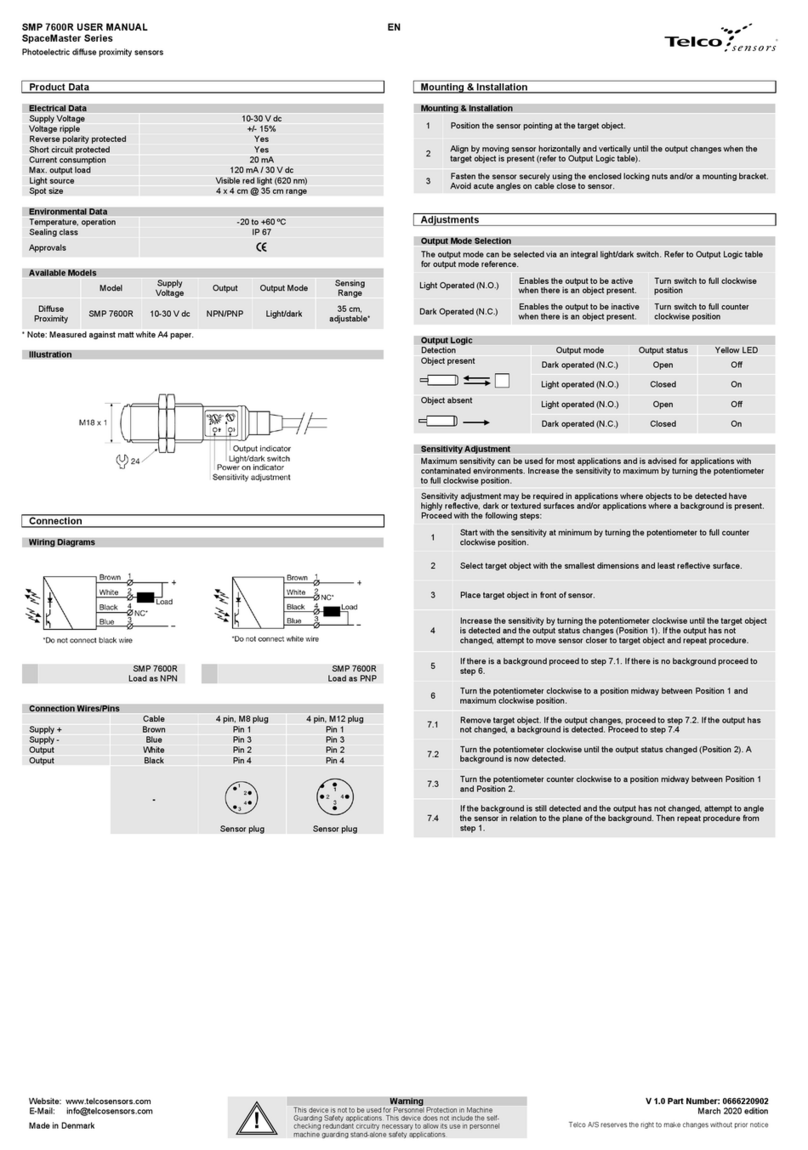

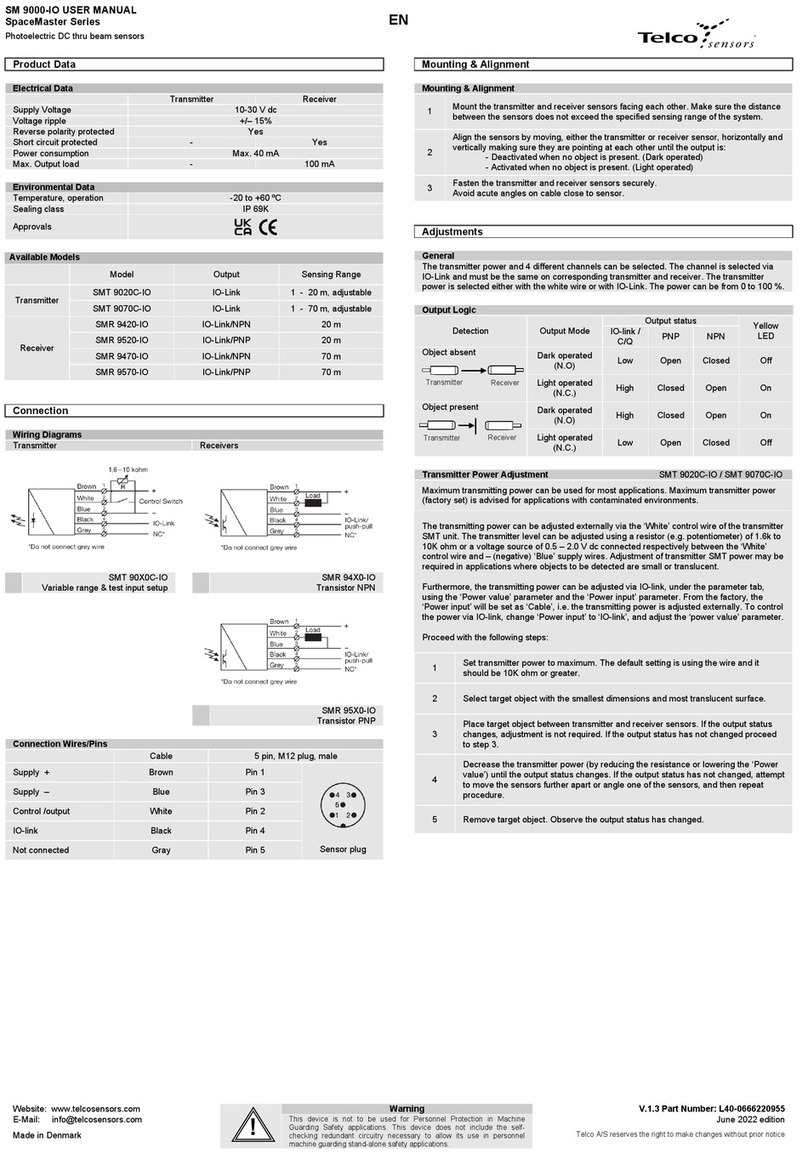

Product Data

Electrical Data

SST (Transmitter)

SSR (Receiver)

Supply voltage

18

30 V dc

Max. Voltage ripple

15 % (within supply range)

Current consumption

100 mA (RMS)

75

mA

Reverse polarity protected

Yes

Short circuit protected

Yes

Environmental Data

Light immunity @5º incidence

> 100.000 lux

Temperature, operation

-30 to + 60 ºC

Sealing class

IP 67

Marking

Available Models

Model

Beam spacing

Sensing Range

Transmitter

SST 01-10-xxx-xxx-05-H-1D1-0.5-J5 5 mm

10 mSST 01-10-xxx-xxx-10-H-1D1-0.5-J5 10 mm

SST 01-10-xxx-xxx-20-H-1D1-0.5-J5 20 mm

Receiver

SSR 02-10-xxx-xxx-05-H-ANN-NNN-0.5-J12 5 mm

0.5 m — 10 mSSR 02-10-xxx-xxx-10-H-ANN-NNN-0.5-J12 10 mm

SSR 02-10-xxx-xxx-20-H-ANN-NNN-0.5-J12 20 mm

Connection

Wiring Diagram ANN-NNN

5 pin, M12 8 pin, M12

SST 5 pole M12 male connecto

SSR 8

pole M12 male connecto

Wiring diagram

ANN-NNN

Installation & Adjustments

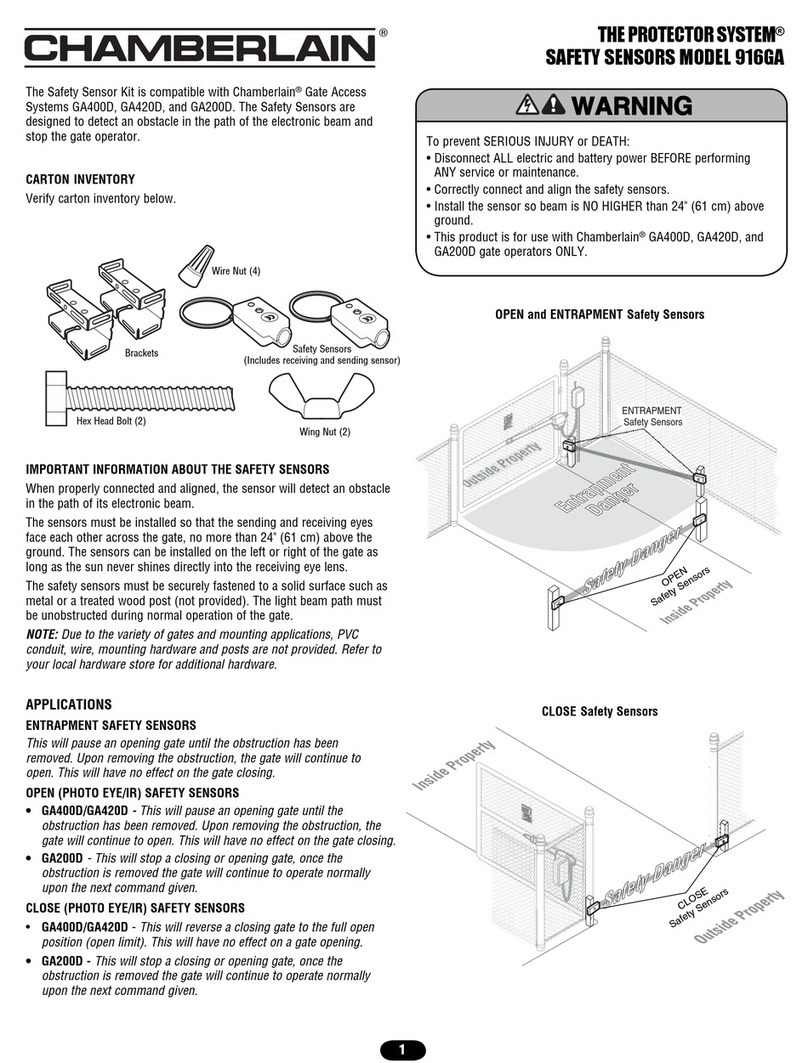

Installation

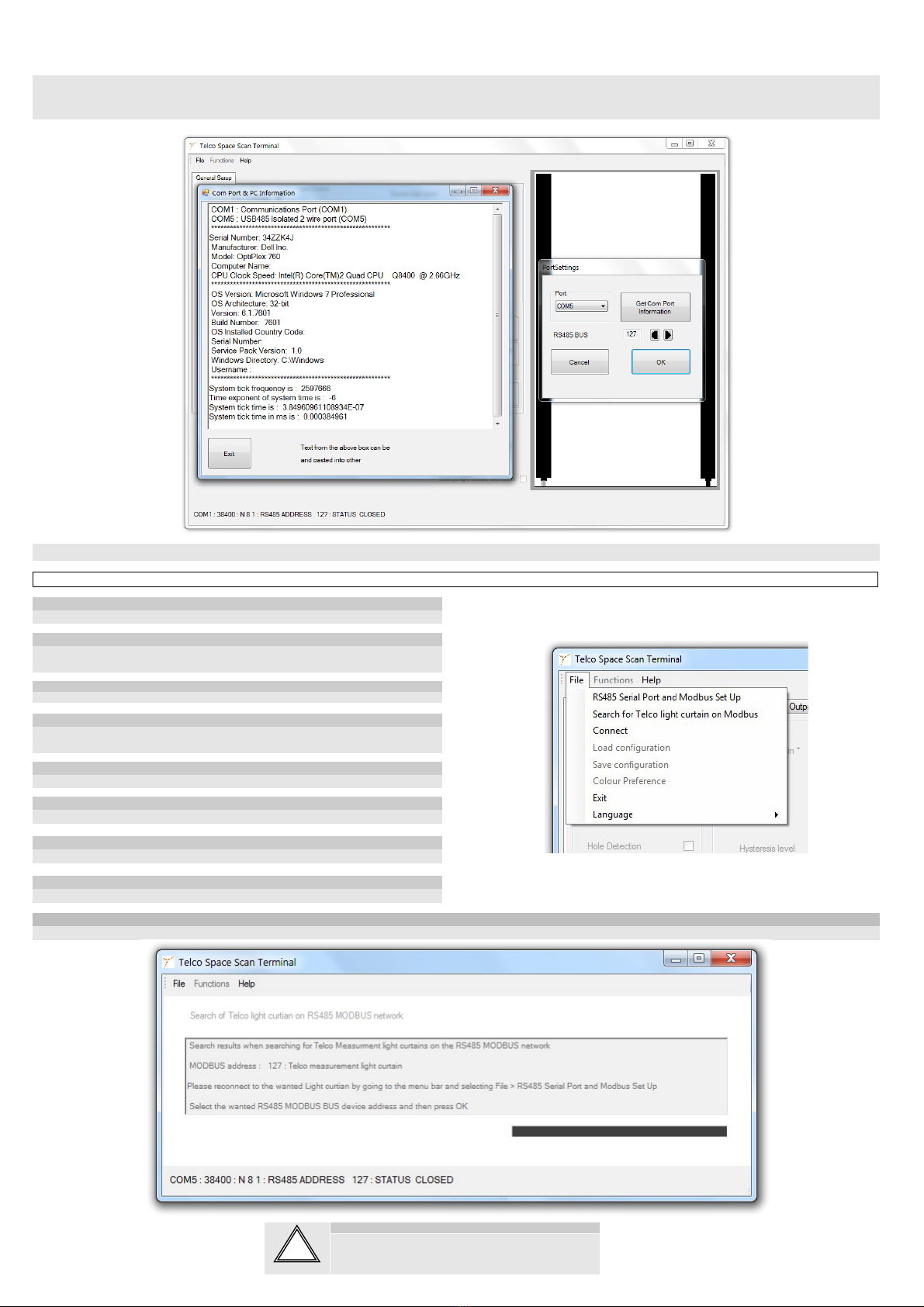

The light curtain is configured by the PC program ‘Telco Space Scan Terminal’, described in

the following pages. Before using it, check the power supply complies with electrical data.

1 Mount the transmitter (SST) and receiver (SSR) facing each other and correctly aligned.

2

Wire the sensor according to the wiring diagram.

Notice that the pin 2 on the SSR and the pin 3 on SST (blue wires) must be connected

together to a common GND ( — ).

Make sure the SSR output load does not exceed 100 mA.

3 Check for correct wiring before turning power on.

4 When the power on indicator (green LED) on SSR and SST is on, the system is

operating.

5 The position of the receiver and transmitter must not be changed after power-up. The

light curtain is only intended for static applications.

SST Test Input

The transmitter SST can be externally disabled and enabled via the black control wire for test

purposes. When the transmitter is disabled the action of the receiver corresponds to breaking

all beams.

Indicators

SSR Red LED Status indicator

SSR Yellow LED Detection Indicator

SSR & SST Green LED Power on indicator

Troubleshooting

Probable Reason

Corrective Action

1. Symptom: Status indicator (Red LED) on SSR is constant on.

SST has no power. Check supply and supply cable to the SST

SST & SSR white, grey and blue wires are

not connected correctly. Connect the wires.

2. Symptom: Output indicator (Yellow LED) on SSR is flashing.

Severe electrical interference. Separate SSR and SST supply cable from high

voltage cables.

Severe ambient light. Swap position of SSR and SST.

Cross talk from another light curtain or

photo sensor Swap position of SSR and SST.

Cross talk from a nearby HF strip light Swap position of SSR and SST or remove the

strip light.

3. Symptom: Digital outputs do not response when IR beams are obstructed.

One or more beams are blocked or the

rails are out of sensing range.

Remove obstruction or reduce the distance

between the rails.

The test input on SST is activated Remove SST pin 4 (black wire) from ground.

Outputs are not configured for simple

detection of obstructions

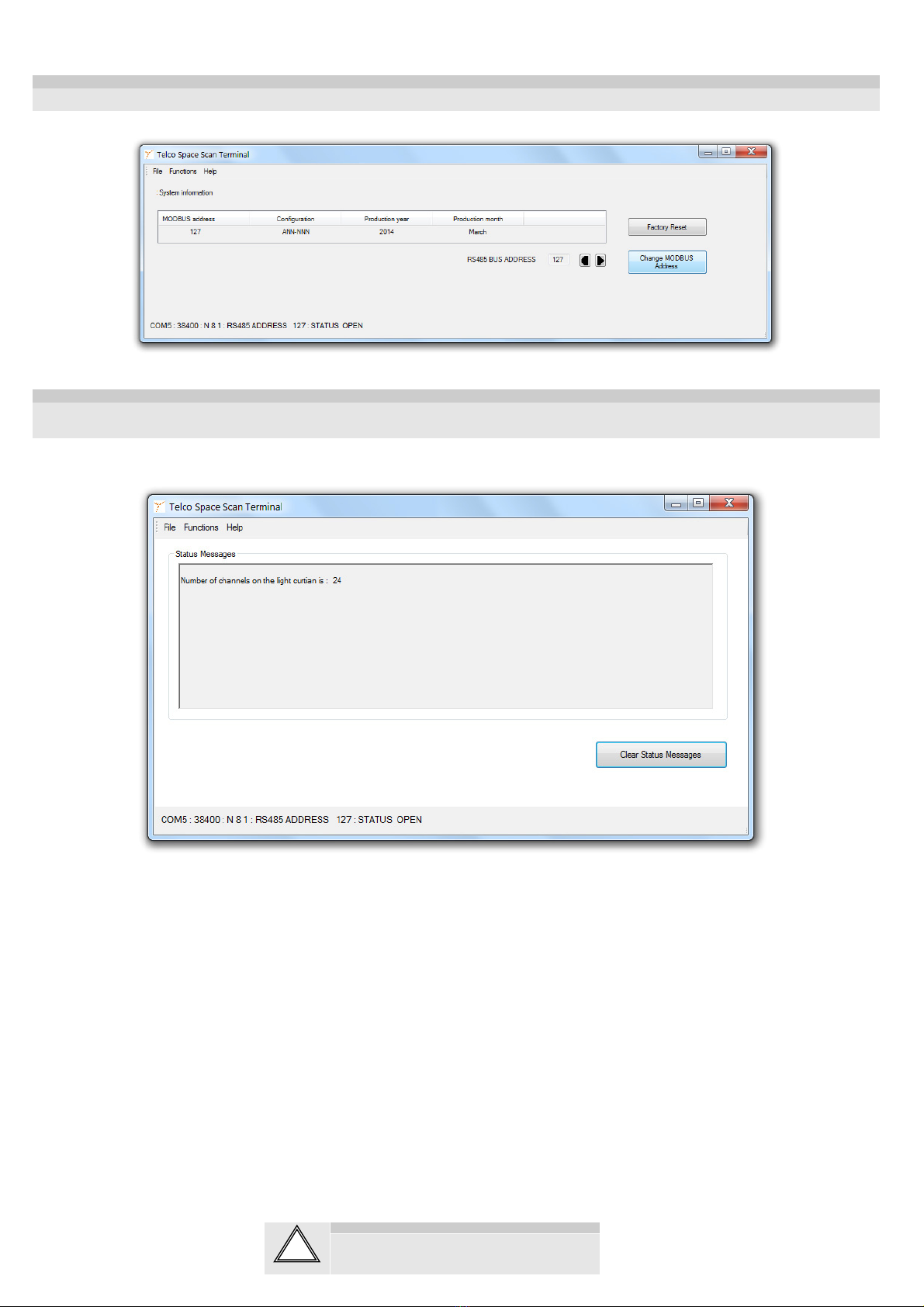

If needed factory reset the SSR using the

System Information page in the PC program

‘Telco Space Scan Terminal’

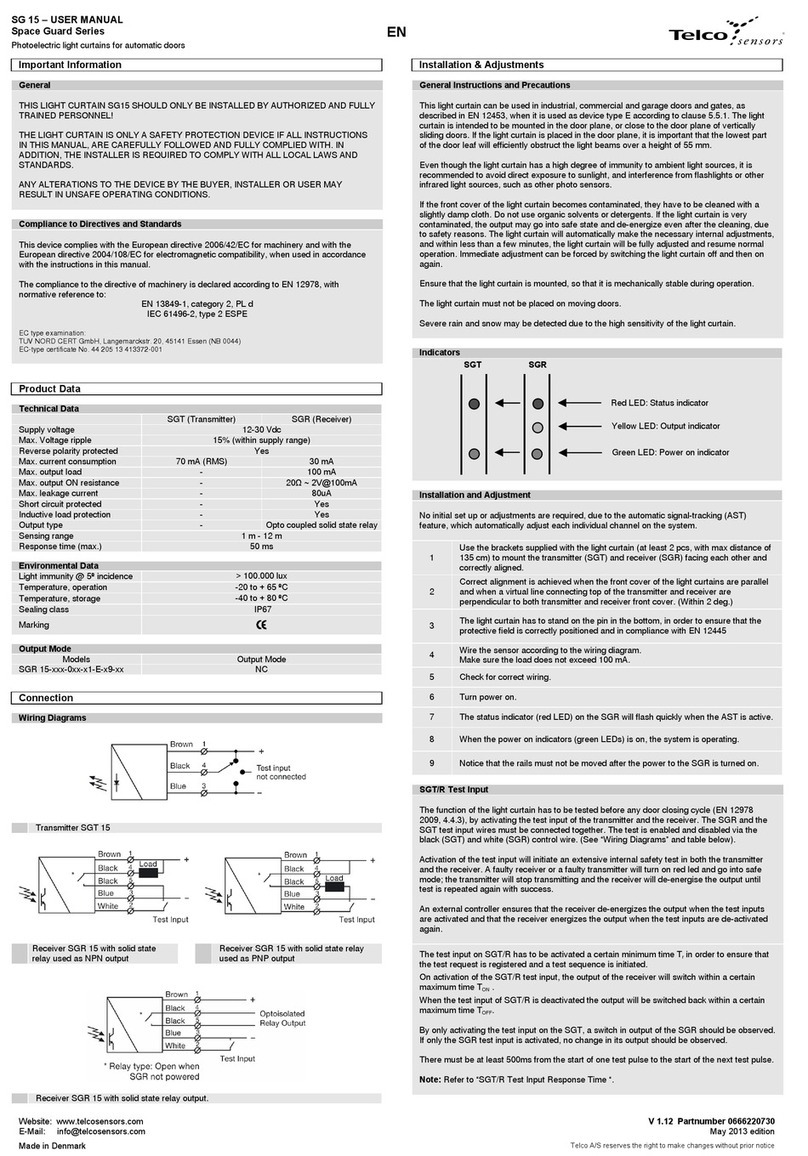

SSR02 and PC connection

To setup or adjust a SS02 it is required to use the Telco Space Scan Terminal software together with an RS485 data link.

Transmitter Model Black wire

connected to ( - )

Black wire

not connected

Black wire

connected to ( + )

SST 01-10-xxx-xxx-xx-H-1D1-0.5-J5 not transmitting transmitting transmitting