SG 15 – USER MANUAL

Space Guard Series

Photoelectric light curtains for automatic doors

Website: www.telcosensors.com

1.12 Partnumber 0666220730

May 2013 edition

Made in Denmark Telco A/S reserves the right to make changes without prior notice

tel

EN

Important Information

General

THIS LIGHT CURTAIN SG15 SHOULD ONLY BE INSTALLED BY AUTHORIZED AND FULLY

TRAINED PERSONNEL!

THE LIGHT CURTAIN IS ONLY A SAFETY PROTECTION DEVICE IF ALL INSTRUCTIONS

IN THIS MANUAL, ARE CAREFULLY FOLLOWED AND FULLY COMPLIED WITH. IN

ADDITION, THE INSTALLER IS REQUIRED TO COMPLY WITH ALL LOCAL LAWS AND

STANDARDS.

ANY ALTERATIONS TO THE DEVICE BY THE BUYER, INSTALLER OR USER MAY

RESULT IN UNSAFE OPERATING CONDITIONS.

Compliance to Directives and Standards

This device complies with the European directive 2006/42/EC for machinery and with the

European directive 2004/108/EC for electromagnetic compatibility, when used in accordance

with the instructions in this manual.

The compliance to the directive of machinery is declared according to EN 12978, with

normative reference to:

EN 13849-1, category 2, PL d

IEC 61496-2, type 2 ESPE

EC type examination:

TUV NORD CERT GmbH, Langemarckstr. 20, 45141 Essen (NB 0044)

EC-type certificate No. 44 205 13 413372-001

Product Data

Technical Data

SGT (Transmitter)

SGR (Receiver)

Supply voltage

12-30

Vdc

Max.

Voltage ripple

15% (within supply range)

Reverse polarity protected

Yes

Max. current consumption

70

mA

(RMS)

30

mA

Max. output load

-

100 mA

Max. output ON resistance

-

20Ω~ 2V@100mA

Max.

leakage current

-

80uA

Short circuit protected

-

Yes

Inductive load protection

-

Yes

Output type

-

Opto coupled solid state relay

Sensing range 1 m

-

12 m

Response time (max.)

50 ms

Environmental Data

Light immunity @ 5º incidence > 100.000 lux

Temperature, operation -20 to + 65 ºC

Temperature, storage -40 to + 80 ºC

Sealing class IP67

Marking

Out

ut Mode

Models

Out

ut Mode

SGR 15-xxx-0xx-x1-E-x9-xx

NC

Connection

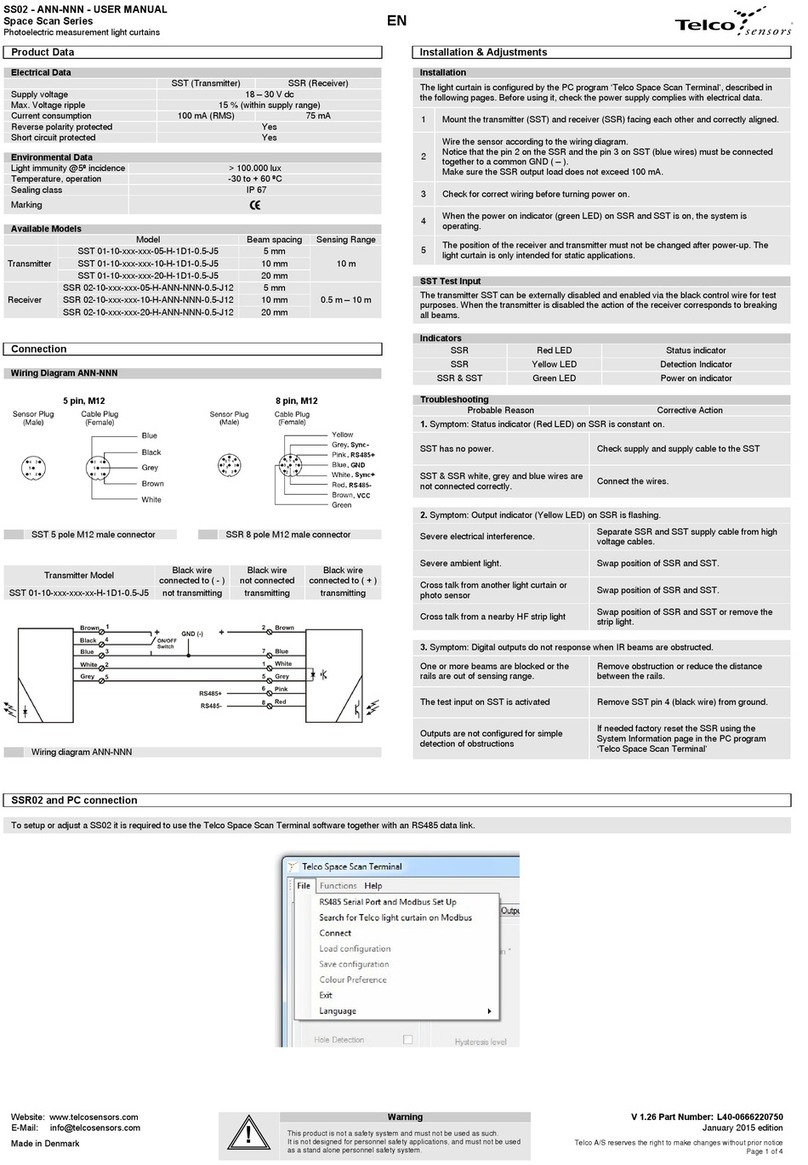

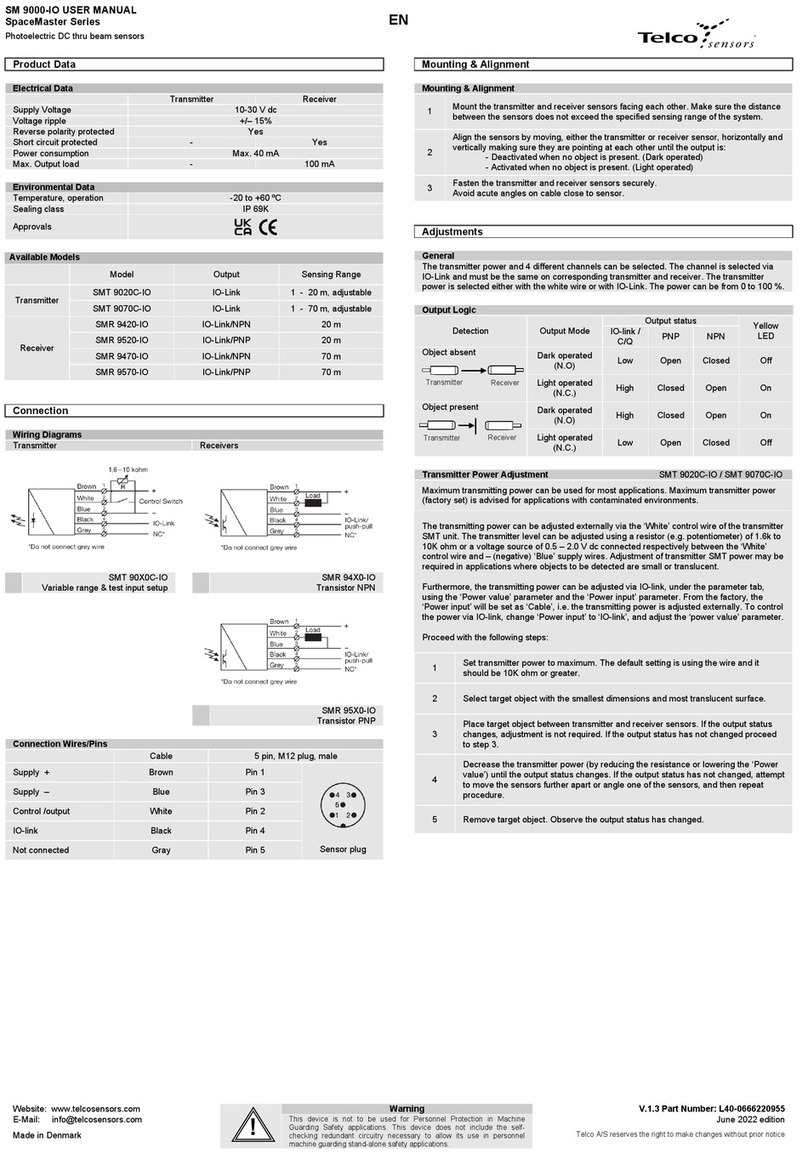

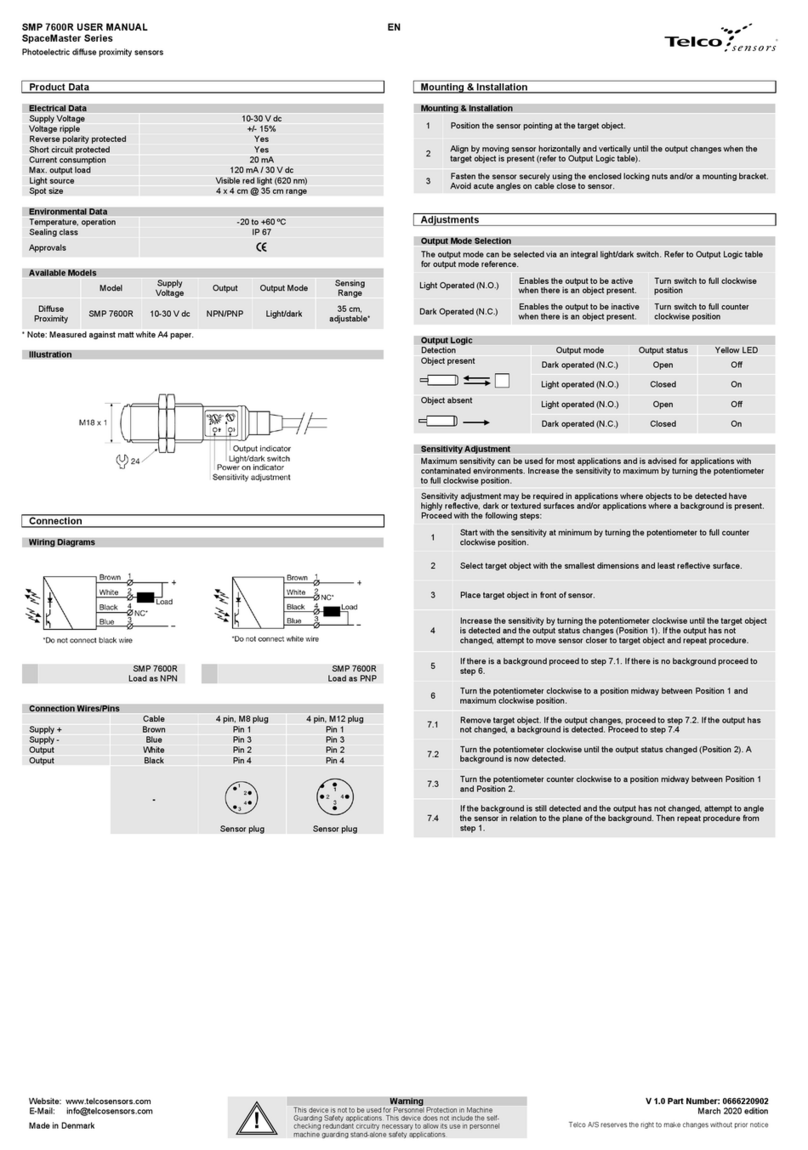

Wiring Diagrams

Transmitter SGT 15

Receiver SGR 15

with solid state

relay used as NPN output

Receiver SGR 15

with solid state relay

used as PNP output

Receiver SGR 15 with solid state relay output.

Installation & Adjustments

General Instructions and Precautions

This light curtain can be used in industrial, commercial and garage doors and gates, as

described in EN 12453, when it is used as device type E according to clause 5.5.1. The light

curtain is intended to be mounted in the door plane, or close to the door plane of vertically

sliding doors. If the light curtain is placed in the door plane, it is important that the lowest part

of the door leaf will efficiently obstruct the light beams over a height of 55 mm.

Even though the light curtain has a high degree of immunity to ambient light sources, it is

recommended to avoid direct exposure to sunlight, and interference from flashlights or other

infrared light sources, such as other photo sensors.

If the front cover of the light curtain becomes contaminated, they have to be cleaned with a

slightly damp cloth. Do not use organic solvents or detergents. If the light curtain is very

contaminated, the output may go into safe state and de-energize even after the cleaning, due

to safety reasons. The light curtain will automatically make the necessary internal adjustments,

and within less than a few minutes, the light curtain will be fully adjusted and resume normal

operation. Immediate adjustment can be forced by switching the light curtain off and then on

again.

Ensure that the light curtain is mounted, so that it is mechanically stable during operation.

The light curtain must not be placed on moving doors.

Severe rain and snow may be detected due to the high sensitivity of the light curtain.

Indicators

Installation and Adjustment

No initial set up or adjustments are required, due to the automatic signal-tracking (AST)

feature, which automatically adjust each individual channel on the system.

1

Use the brackets supplied with the light curtain (at least 2 pcs, with max distance of

135 cm) to mount the transmitter (SGT) and receiver (SGR) facing each other and

correctly aligned.

2

Correct alignment is achieved when the front cover of the light curtains are parallel

and when a virtual line connecting top of the transmitter and receiver are

perpendicular to both transmitter and receiver front cover. (Within 2 deg.)

3 The light curtain has to stand on the pin in the bottom, in order to ensure that the

protective field is correctly positioned and in compliance with EN 12445

4 Wire the sensor according to the wiring diagram.

Make sure the load does not exceed 100 mA.

5 Check for correct wiring.

6 Turn power on.

7 The status indicator (red LED) on the SGR will flash quickly when the AST is active.

8 When the power on indicators (green LEDs) is on, the system is operating.

9 Notice that the rails must not be moved after the power to the SGR is turned on.

SGT/R Test Input

The function of the light curtain has to be tested before any door closing cycle (EN 12978

2009, 4.4.3), by activating the test input of the transmitter and the receiver. The SGR and the

SGT test input wires must be connected together. The test is enabled and disabled via the

black (SGT) and white (SGR) control wire. (See “Wiring Diagrams” and table below).

Activation of the test input will initiate an extensive internal safety test in both the transmitter

and the receiver. A faulty receiver or a faulty transmitter will turn on red led and go into safe

mode; the transmitter will stop transmitting and the receiver will de-energise the output until

test is repeated again with success.

An external controller ensures that the receiver de-energizes the output when the test inputs

are activated and that the receiver energizes the output when the test inputs are de-activated

again.

The test input on SGT/R has to be activated a certain minimum time Trin order to ensure that

the test request is registered and a test sequence is initiated.

On activation of the SGT/R test input, the output of the receiver will switch within a certain

maximum time TON .

When the test input of SGT/R is deactivated the output will be switched back within a certain

maximum time TOFF.

By only activating the test input on the SGT, a switch in output of the SGR should be observed.

If only the SGR test input is activated, no change in its output should be observed.

There must be at least 500ms from the start of one test pulse to the start of the next test pulse.

Note: Refer to “SGT/R Test Input Response Time “.

Red LED: Status

indicato

SGT SG

Yellow LED: Out

ut indicato

Green LED: Power on indicato