USER MANUAL, original instructions

SpaceMaster SM 3000/CAT2 Series

Photoelectric DC thru beam sensors

Website: www.telcosensors.com

E-Mail: info@telcosensors.com

Telco A/S reserves the right to make changes without prior notice

tel

15% (within supply range)

Reverse polarity protected

Light immunity @ 0Oincidence

Approvals

Transmitter SMT 3010C/CAT2 - -

10 m

Receiver

SMR 3010/CAT2 NPN

SMR 3210/CAT2 PNP

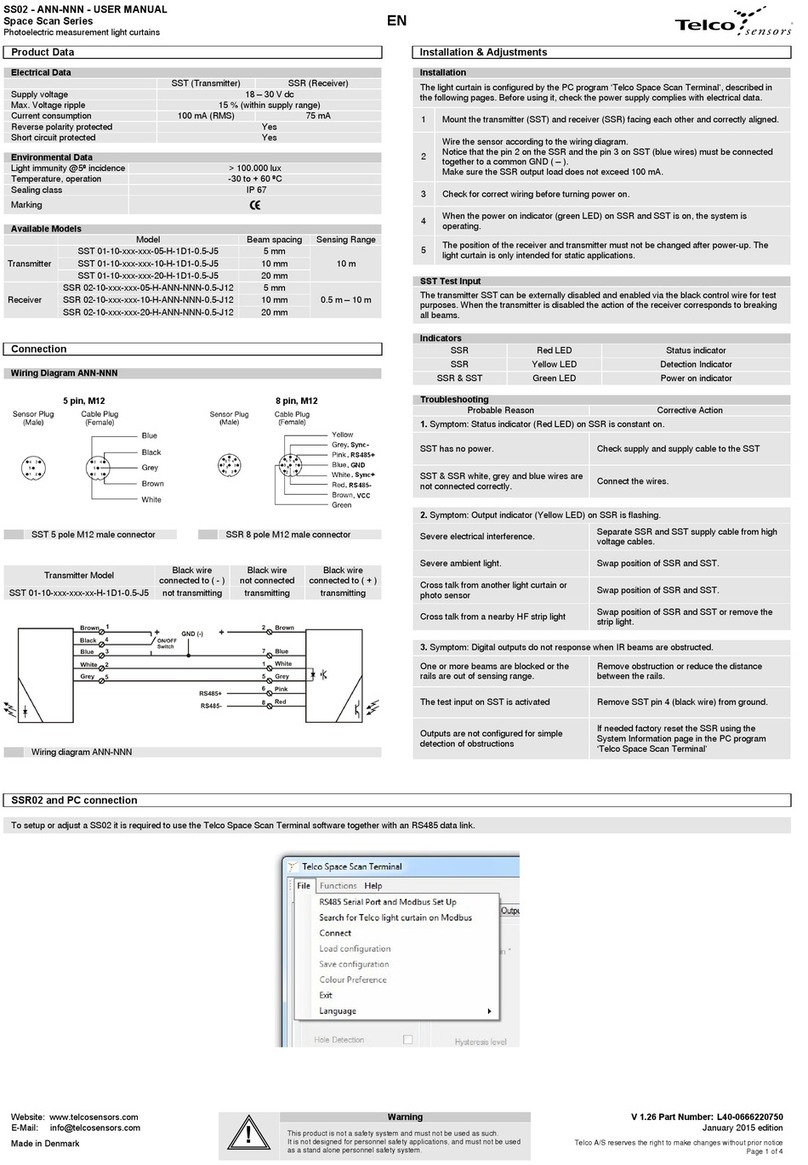

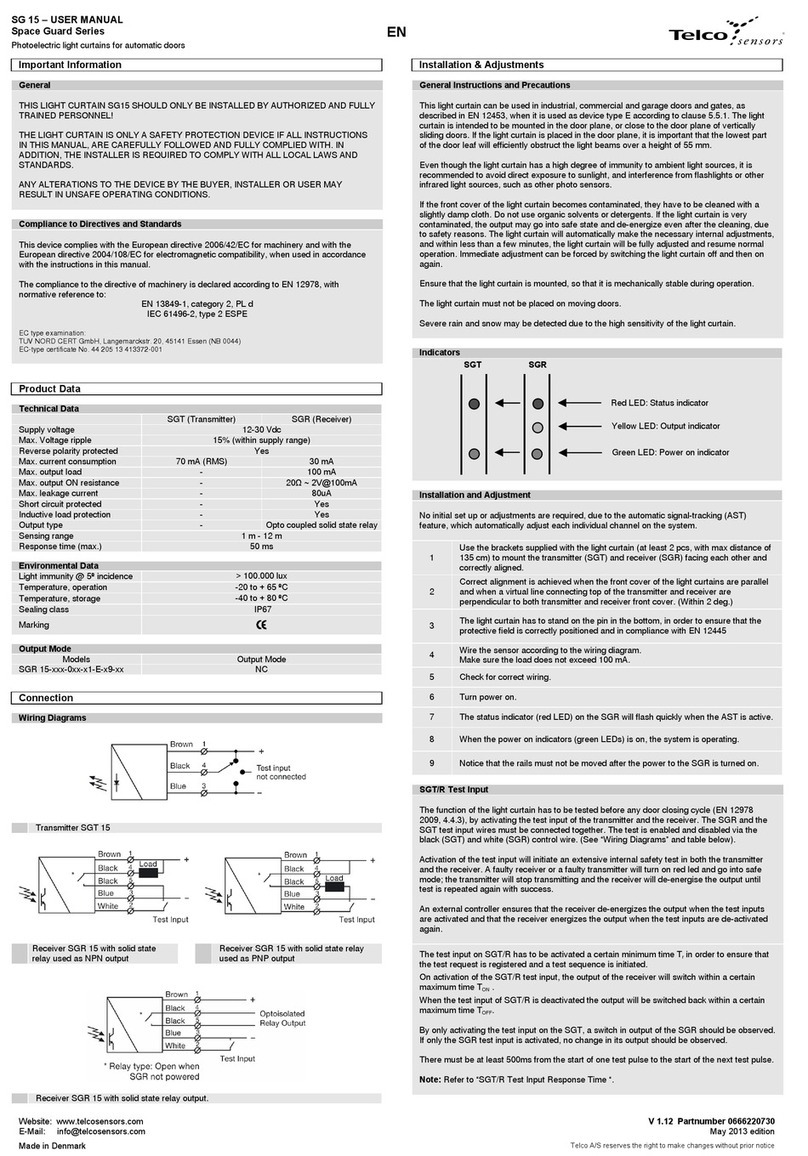

General Instructions and Precautions

This light curtain can be used in industrial, commercial and garage doors and gates, as

described in EN 12453, when it is used as device type E according to clause 5.5.1.

Even though the sensor has a high degree of immunity to ambient light sources, it is

recommended to avoid direct exposure to sunlight, and interference from flashlights or other

infrared light sources, such as other photo sensors.

If the front cover of the sensor becomes contaminated, it has to be cleaned with a slightly

damp cloth. Do not use organic solvents or detergents. If the light curtain is very contaminated,

the output may go into safe state and de-energize even after the cleaning, due to safety

reasons.

Ensure that the sensor is mounted, so that it is mechanically stable during operation.

Severe rain and snow may be detected due to the high sensitivity of the light curtain.

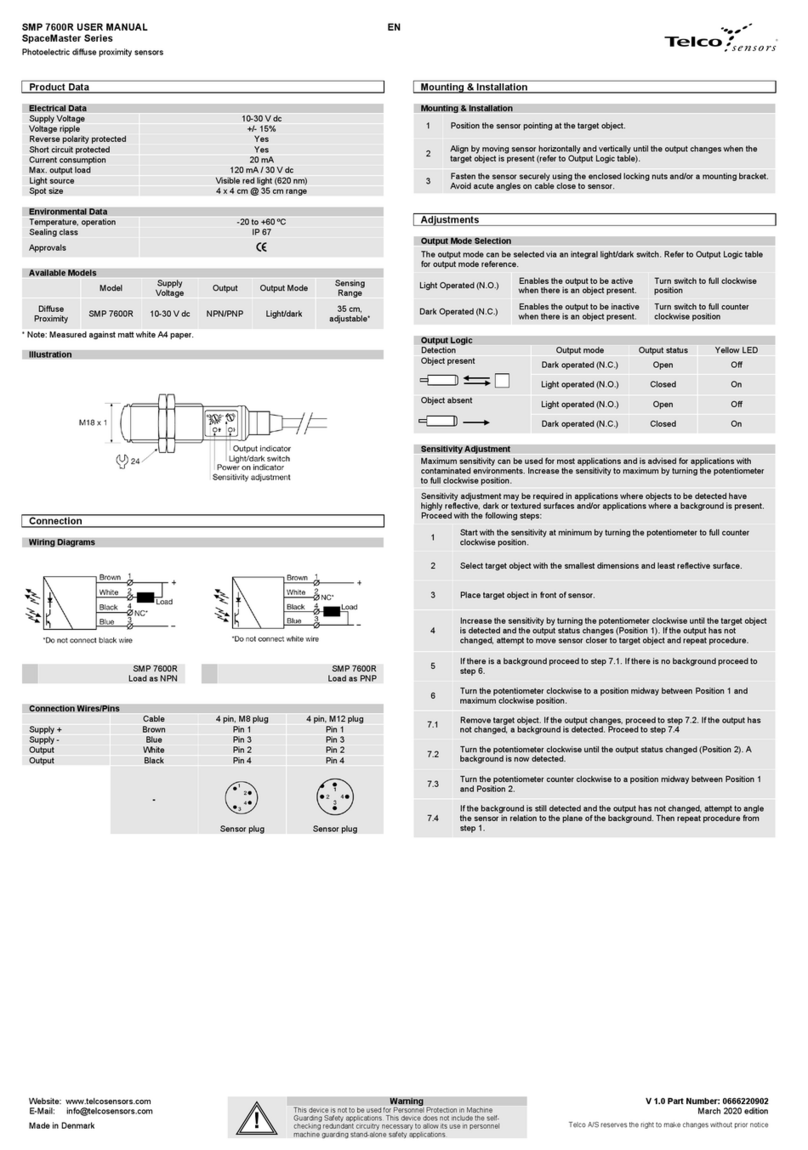

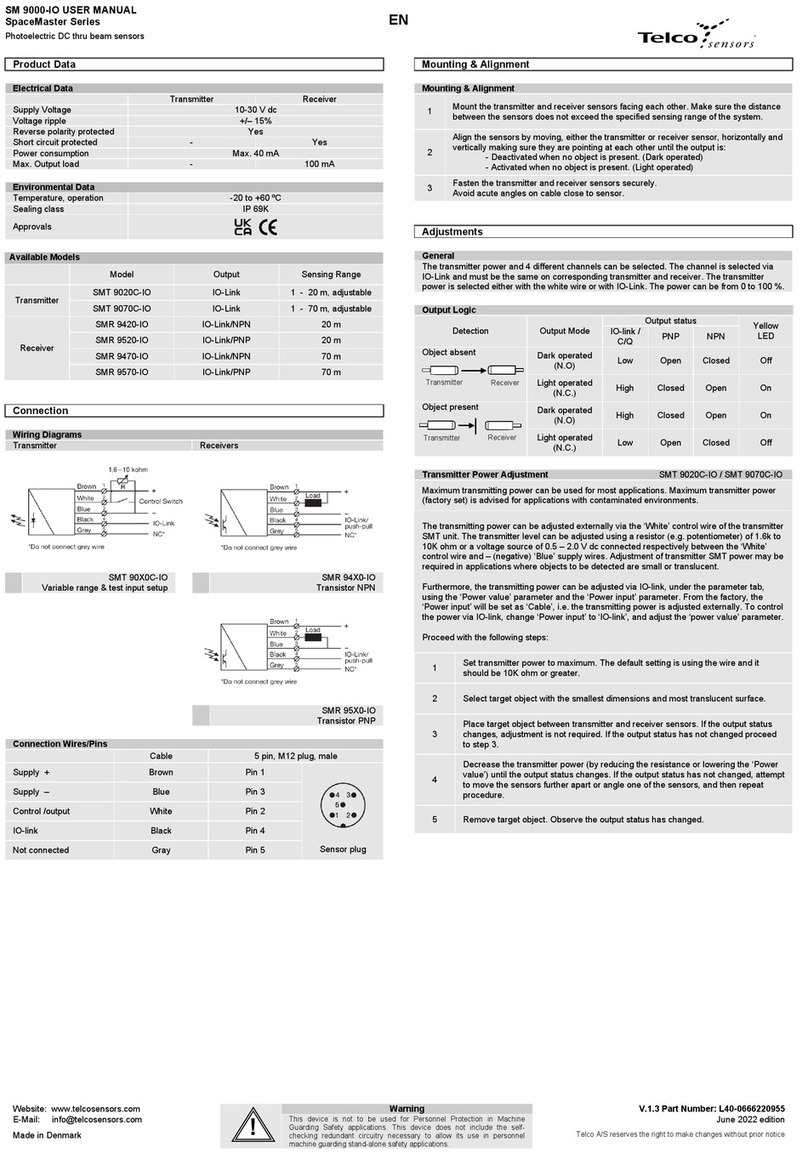

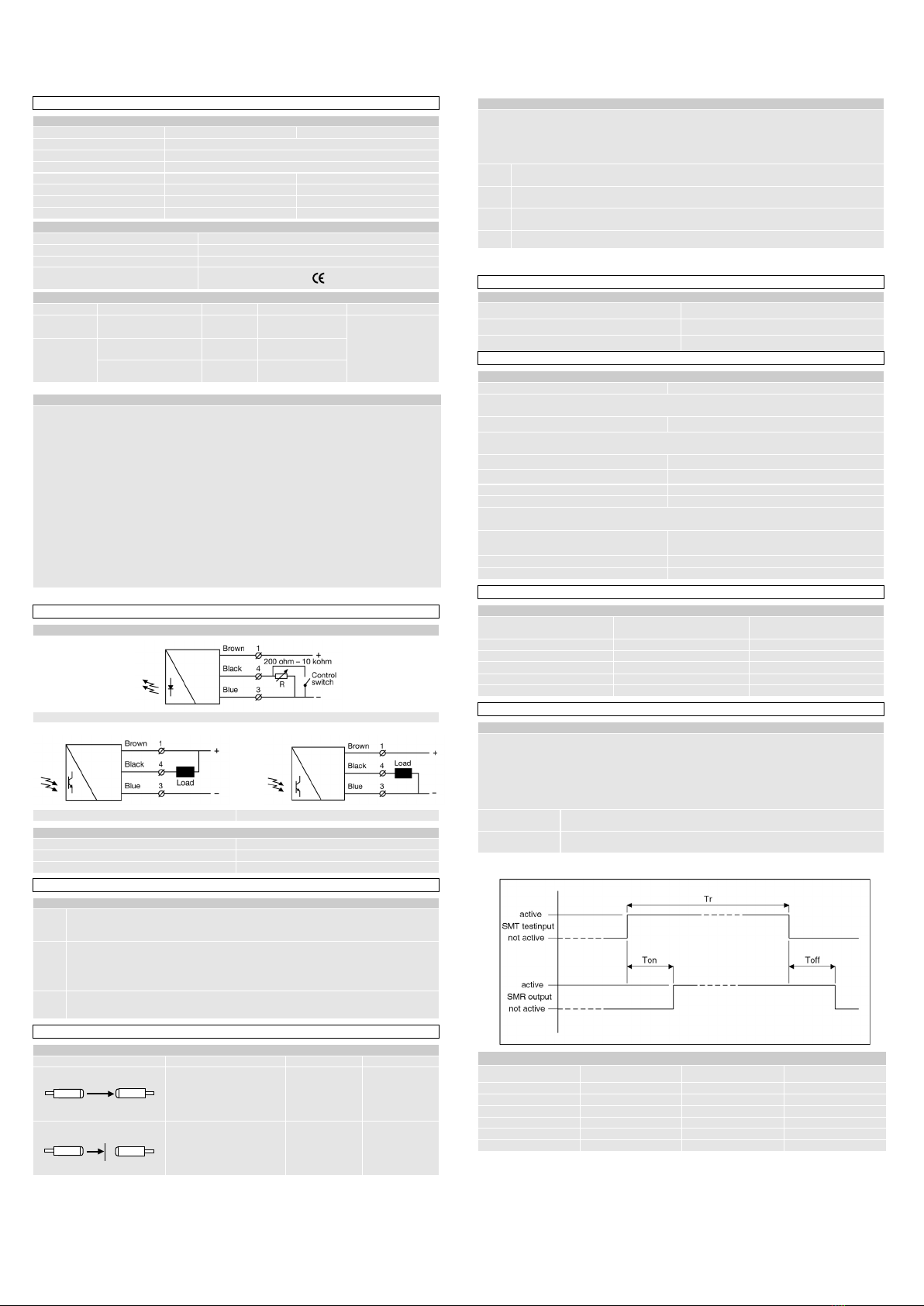

SMT 3000 Variable range and test input

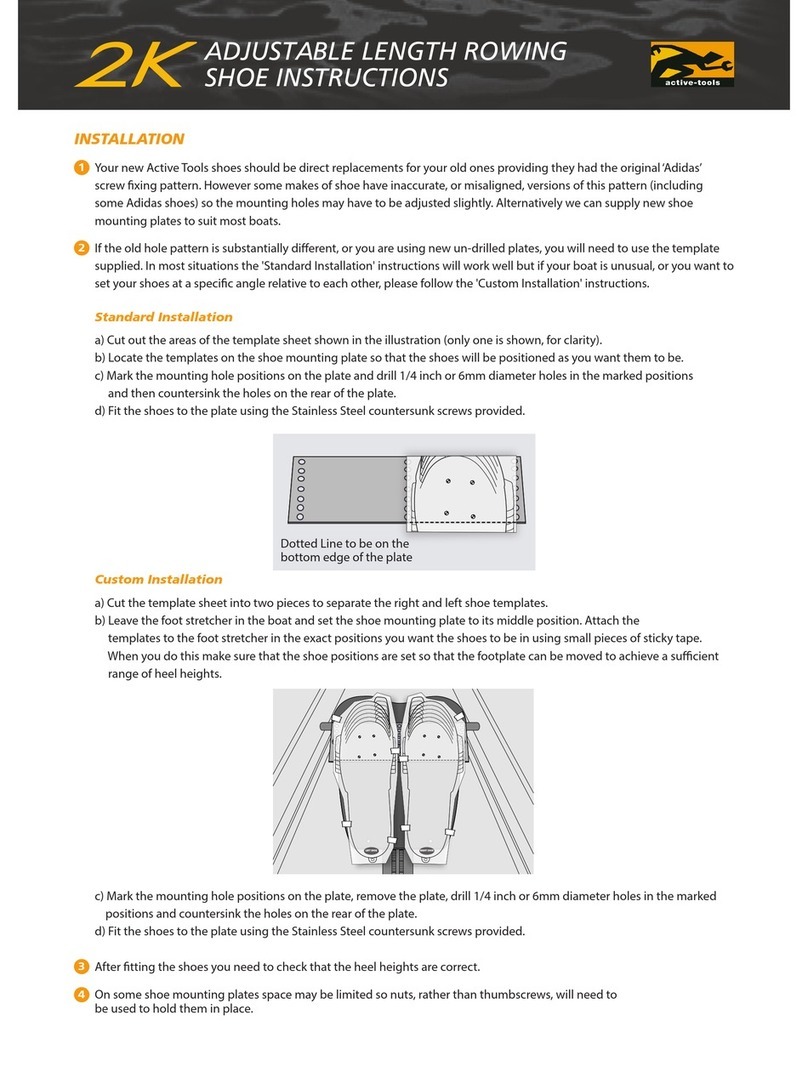

1 Mount the transmitter and receiver sensors facing each other. Make sure the distance

between the sensors does not exceed the specified sensing range of the system.

2

Align the sensors by turning, either the transmitter or receiver sensor, horizontally and

vertically until the output is:

- Deactivated when no object is present. (Dark operated)

- Activated when no object is present. (Light operated)

3 Fasten the transmitter and receiver sensors securely.

Avoid acute angles on cable close to sensor.

Light operated (N.C.) Closed On

Light operated (N.C.) Open Off

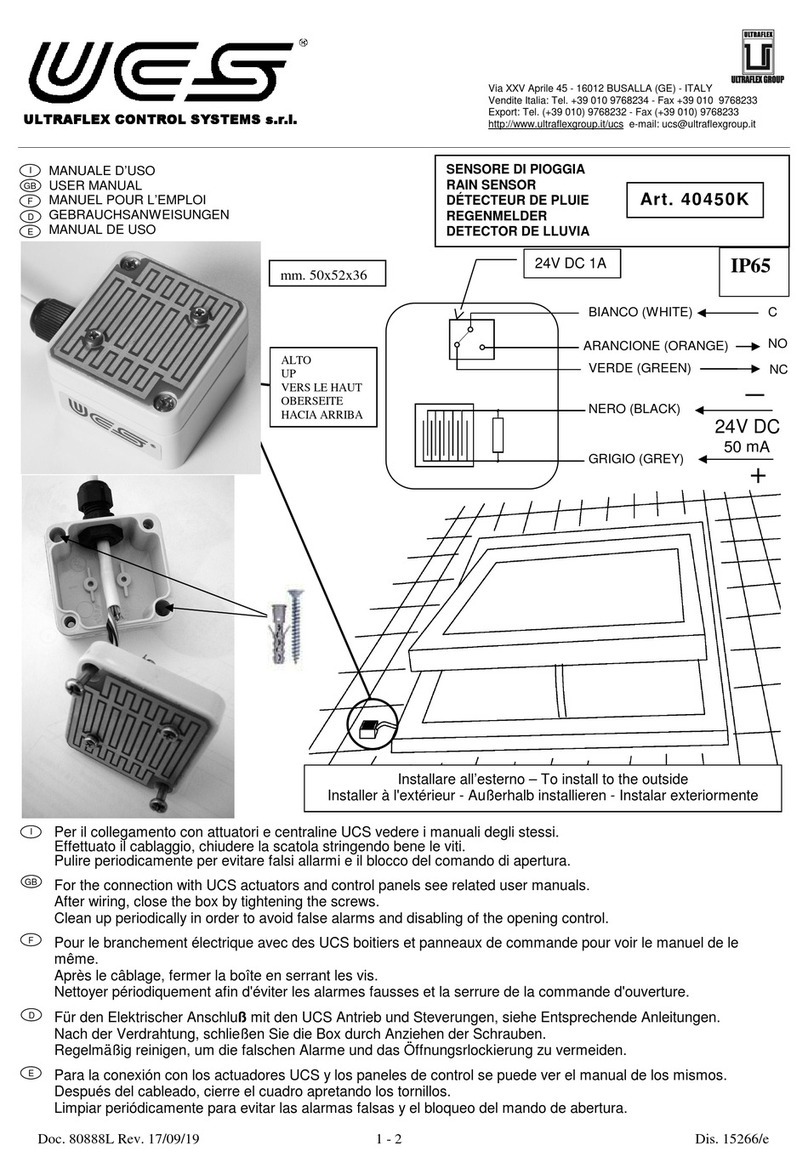

Transmitter power adjustment

The transmitting power can be adjusted externally via the wires of the transmitter sensor.

Adjust using a resistor (e.g. a potentiometer) of 200 ohm to 10k ohm or a voltage source of 1-

4 V dc connected respectively between control and – supply (ground) wires. Adjustment of the

transmitter power may be required in applications where objects to be detected are small or

translucent. Proceed with the following steps:

1 Select target object with the smallest dimension and most translucent surface.

2

Place target object between transmitter and receiver sensors. If the output is activated,

adjustment is not required. If the output is not activated proceed to step 3.

3

Decrease the transmitter power (by decreasing the resistance) until the output is

activated.

4 Remove target object. Observe the output deactivates.

Note: If the test input is not to be used (not safety application), it is recommended to connect the

control wire to + (positive) supply wire.

Green LED on transmitter Power on indicator

Yellow LED on receiver Indicates closed output

1. Symptom: Power indicator (Green LED) on SMT is off.

Check supply and cable to the SGT

2. Symptom: Output indicator (Yellow LED) on SMR does not correspond to a beam break

Check supply and cable to the SMR

TX is not emitting, green LED off

Check supply and cable to the SMT

The sensors are misaligned

3. Symptom: Output indicator (Yellow LED) on SMR is flickering

Severe electrical interference

Remove SMR and SMT supply cable from high

voltage cables

Change position of SMT and SMR

Cross talk from another light transmitter

Change position of SMT and SMR

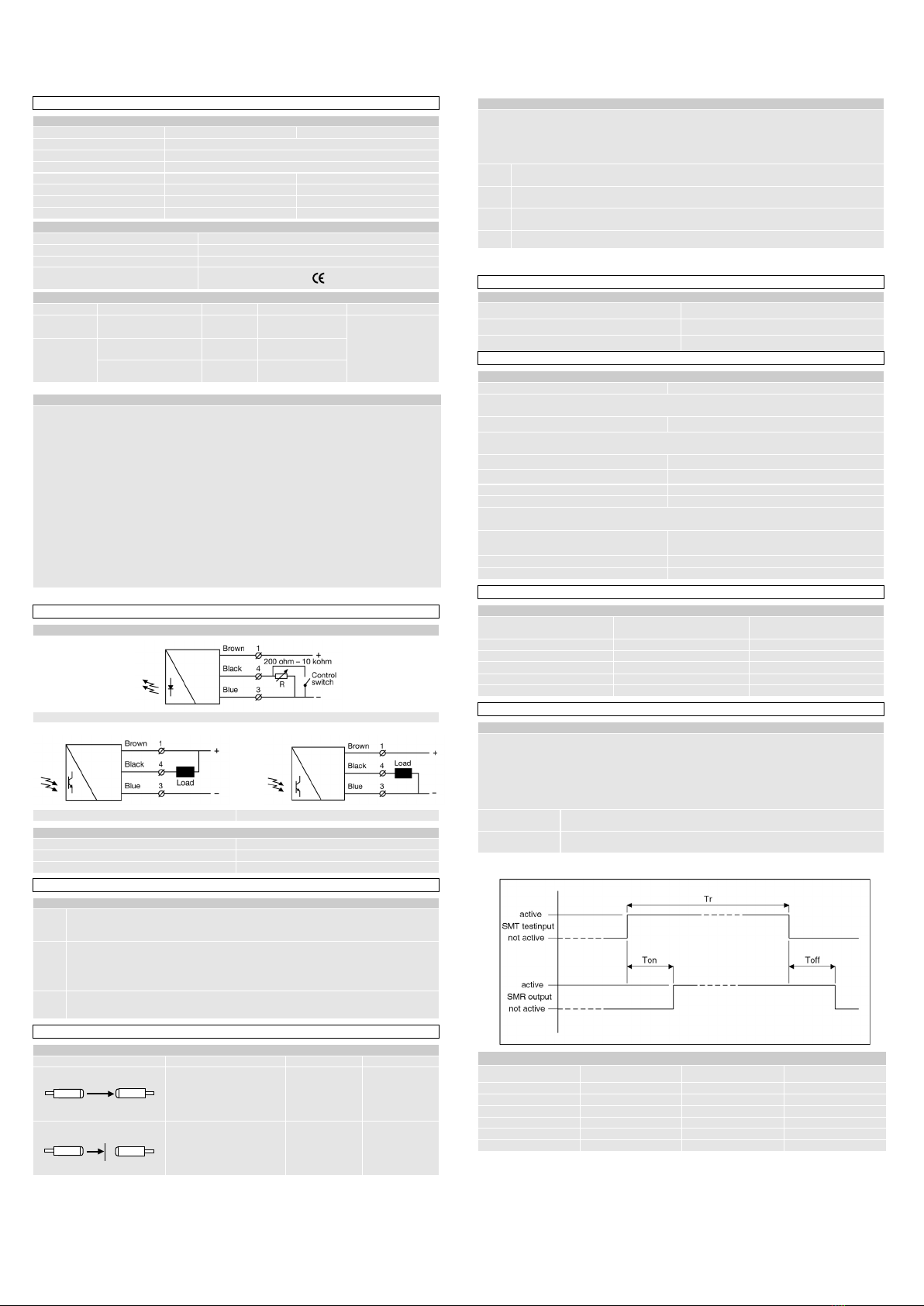

SMR Output Response Time (typical)

Range Ton (beam break) Toff (beam make)

If the sensor is used as a safety device in accordance with EN12978, the function of the

sensor pair has to be tested periodically, at the latest at one of the end positions of the

door leaf. (EN12978:2003+A1:2009: 4.4.3).

During the test the transmitter is disabled by connecting the control wire to – supply

(ground). The control system has to check that the receiver de-energises the output (NC

system). The control wire of the transmitter is hereafter disconnected or connected to +,

and it is checked that the receiver re-energises the output.

Enable transmitter Open (off) control switch, a resistor over 10k ohm, or voltage over 4 V dc

Disable transmitter

Close (on) control switch, a resistor below 200 ohm, or voltage below 0,7 V dc

Note: If the test input is not to be used (not safety application), it is recommended to connect the

control wire to + (positive) supply wire.

SMT test input reaction time (typical)

Range Ton (beam break) Toff (beam make) Tr (min.)