Page 16

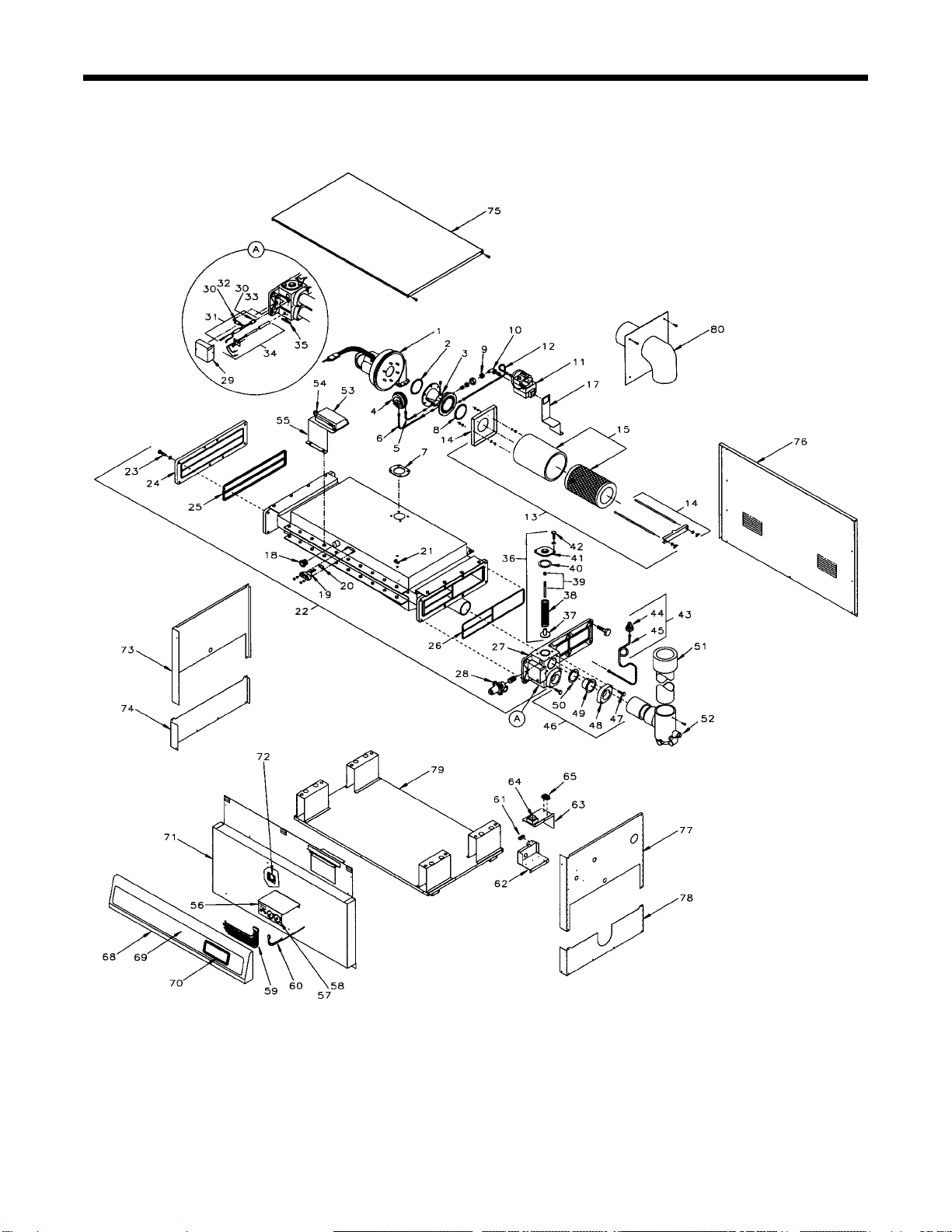

Item Description Part Number

22. Burner/Heat Exchanger Assy................... R0204200

23. Bolt/Washer Set, Header ......................... R0205900

24. Header, Return......................................... R0202200

25. Gasket, Return Header............................ R0201200

26. Gasket, In/Out Header..............................R0201100

27. Header, In/Out ......................................... R0202600

28. Pressure Relief Pressure ......................... R0200000

29. Cover, High Limits ................................... R0201700

30. Retainer, High Limits ............................... R0207800

31. Harness Assembly, High Limits............... R0208000

32. High Limit, 150°F..................................... R0023000

33. High Limit, 135°F..................................... R0022700

34. Sensor Assy., Temperature...................... R0208100

35. Drain Cock/Plug Kit ................................. R0010500

36. Flow Control Assembly............................ R0208200

37. Disc, Flow Control ....................................R0011500

38. Spring, Compression, Green................... R0202000

39. Rod/Nut Set, Flow control ....................... R0206100

40. Gasket, Flow Control ................................R0011400

41. Cap, Flow Control.....................................10557400

42. Bolt/Washer Set, Flow Cntrl Cap ............ R0206000

43. Water Pressure Switch Assy. .................. R0200300

44. Water Pressure Switch ............................ R0095100

45. Siphon Loop, Water Press. Sw................ R0208300

46. Flange Assembly ..................................... R0055000

47. Bolt/Washer Set, Flange...........................R0211200

48. Flange, 2 Inches ....................................... 10573500

49. Sleeve, Flange , 2 Inches .........................S0078200

50. Gasket, 1-1/2 Inches Pipe Adapter ..........S0078100

51. Vent Stack Assembly............................... R0203100

52. Vent Adapter Assembly ........................... R0202800

53. Ignition Control ........................................ R0202900

54. Fusible Link.............................................. R0012200

55. Bracket, Ignition Control .......................... R0209100

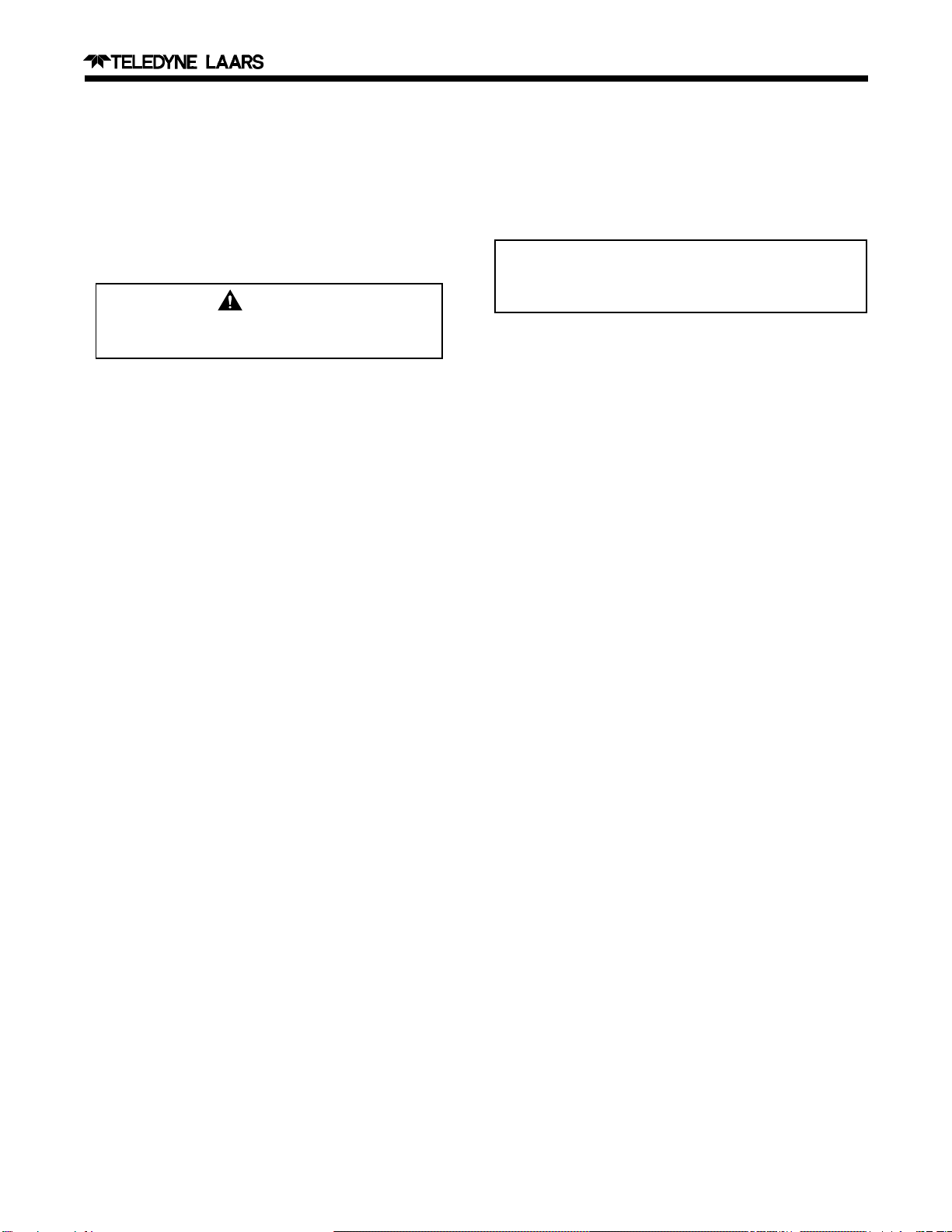

56. Temperature Control Assembly ................R0211300

57. Knob/Temp-Lok Set ..................................R0211400

58. Label, Temperature Control ......................R0211600

59. 8-Pin Harness Assembly ......................... R0212300

60. 3-Pin Harness Assembly ......................... R0212400

61. Lug, Neutral ..............................................E0106800

62. Junction Box, Bottom .............................. R0209500

63. Junction Box, Top .................................... R0209600

64. Transformer, 120/24 VAC ........................ R0200800

65. Terminal Strip Assembly.......................... R0209700

66. Fuse Assembly ........................................ R0212600

67. Fuse, 1 1/4 Amp. ..................................... R0021300

68. Panel, Upper Front .................................. R0205100

69. Label, Upper Front Panel ........................ R0209800

70. Bezel, Temperature Control ..................... R0209900

71. Panel, Lower Front .................................. R0210000

72. Glass, Sight ..............................................F0038700

73. Panel, Upper Left Side............................. R0210100

74. Panel, Lower Left Side............................. R0210200

75. Panel, Top ................................................ R0210300

76. Panel, Rear .............................................. R0210400

77. Panel, Upper Right Side .......................... R0210500

78. Panel, Lower Right Side .......................... R0210700

79. Base Assembly ........................................ R0210800

80. Vent Termination* ..................................... 10685600

*Required for Indoor Installations

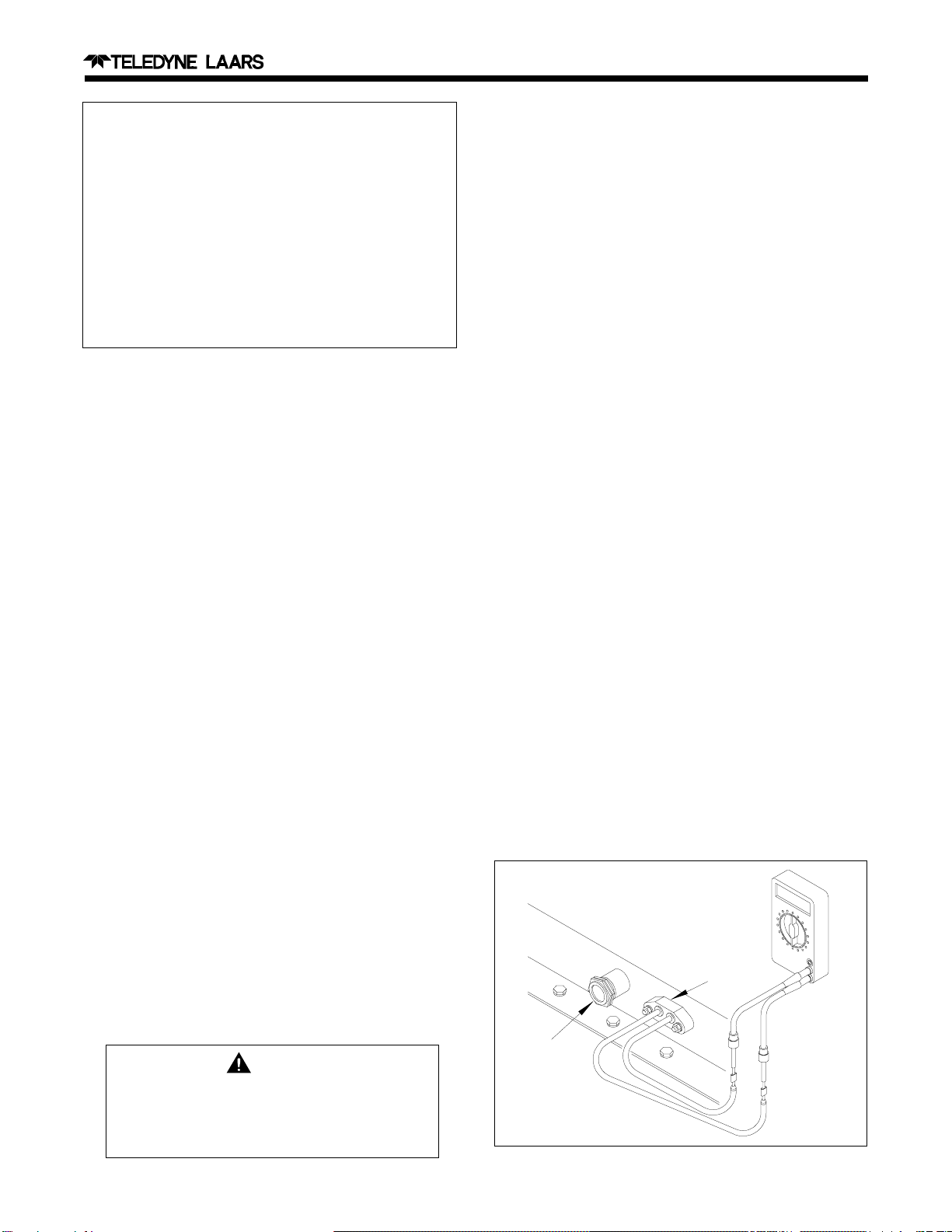

Figure 16. Igniter Installation

After eliminating all possible problems with the

fuel supply and igniter, replace the ignition control.

SECTION 5.

Parts List for Hi-E EPH 300

5A. General Information

To order or purchase parts for the Teledyne Laars

Hi-E EPH 300 pool and spa heater, contact your nearest

Teledyne Laars dealer or distributor. If they cannot

supply you with what you need, contact Customer

Service, Teledyne Laars, 6000 Condor Drive, Moorpark,

CA 93021, telephone (805) 529-2000.

5B. Parts List

Item Description Part Number

1. Fan, Combustion ..................................... R0204700

2. O-Ring, Venturi ........................................ R0205400

3. Venturi...................................................... R0015700

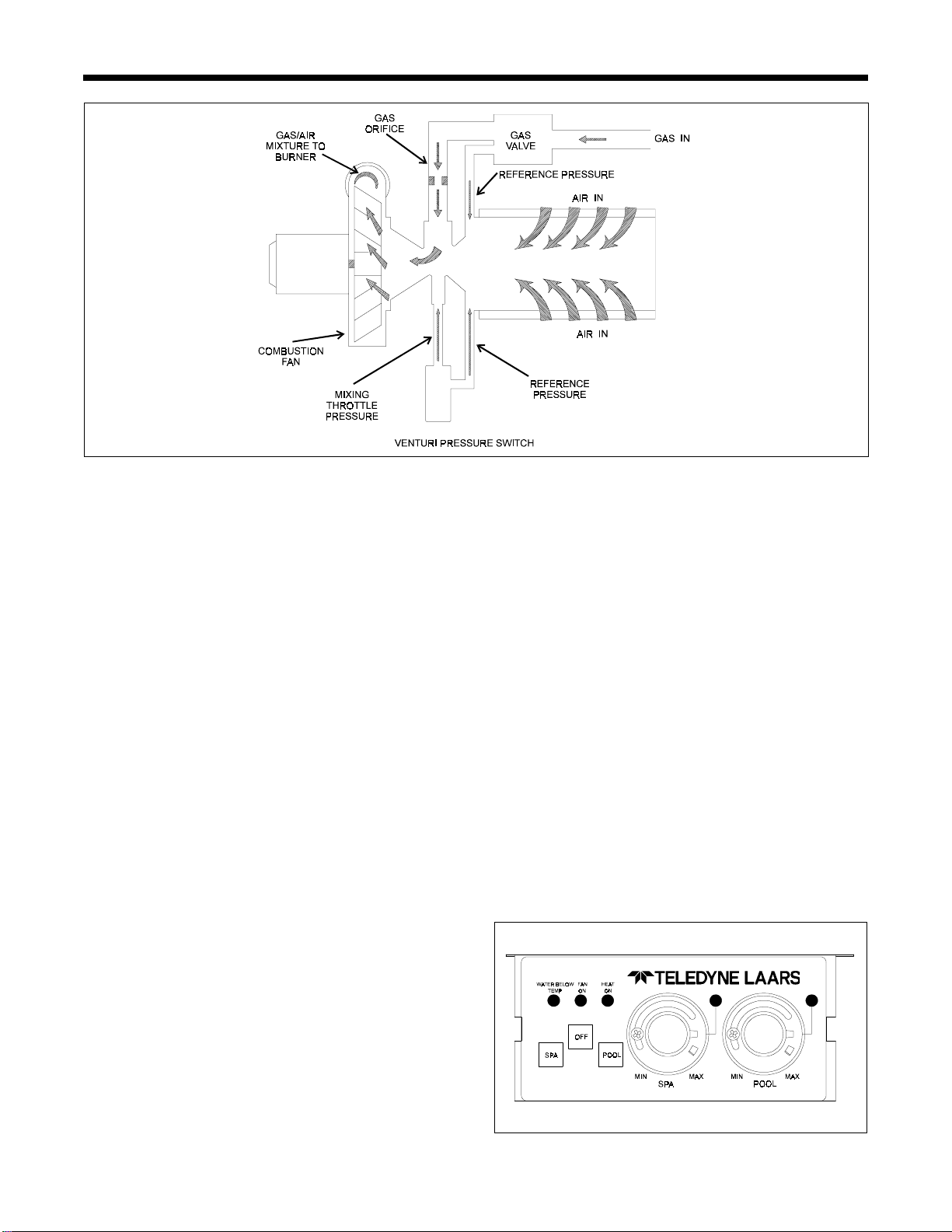

4. Venturi Pressure Switch........................... R0203300

5. Tube, Venturi Press. Sw., Throat............. R0202300

6. Tube, Venturi Press. Sw., Filter ............... R0202500

7. Gasket, Combustion Fan......................... R0205500

8. Plug, Pressure Test Point ........................ R0204800

9. Nipple, Gas Orifice .................................. R0205600

10. Orifice

Natural Gas ............................................. R0205700

LP Gas ..................................................... R0205800

11. Valve, Gas ............................................... R0200100

12. Tube, Venturi Press. Sw., Valve............... R0202500

13. Filter Assembly ........................................ R0204500

14. Filter Support, Kit..................................... R0206200

15. Filter, Air................................................... R0201800

16. Harness, Combustion Fan....................... R0206700

17. Bracket, Gas Valve .................................. R0210900

18. View Port Nipple ...................................... R0201500

19. Igniter Assembly ...................................... R0016400

20. Gasket, Igniter ......................................... R0205300

21. Connector, Wire........................................E0092000