DM-20-08K10 and DM-20-05K10 Detector User’s Manual 3

Teledyne DALSA 03-032-20109-03

Contents

1. System Precautions and Safety _____________________________________________________________________4

2. The Argus Detector _____________________________________________________________________________6

Detector Highlights............................................................................................................................................................6

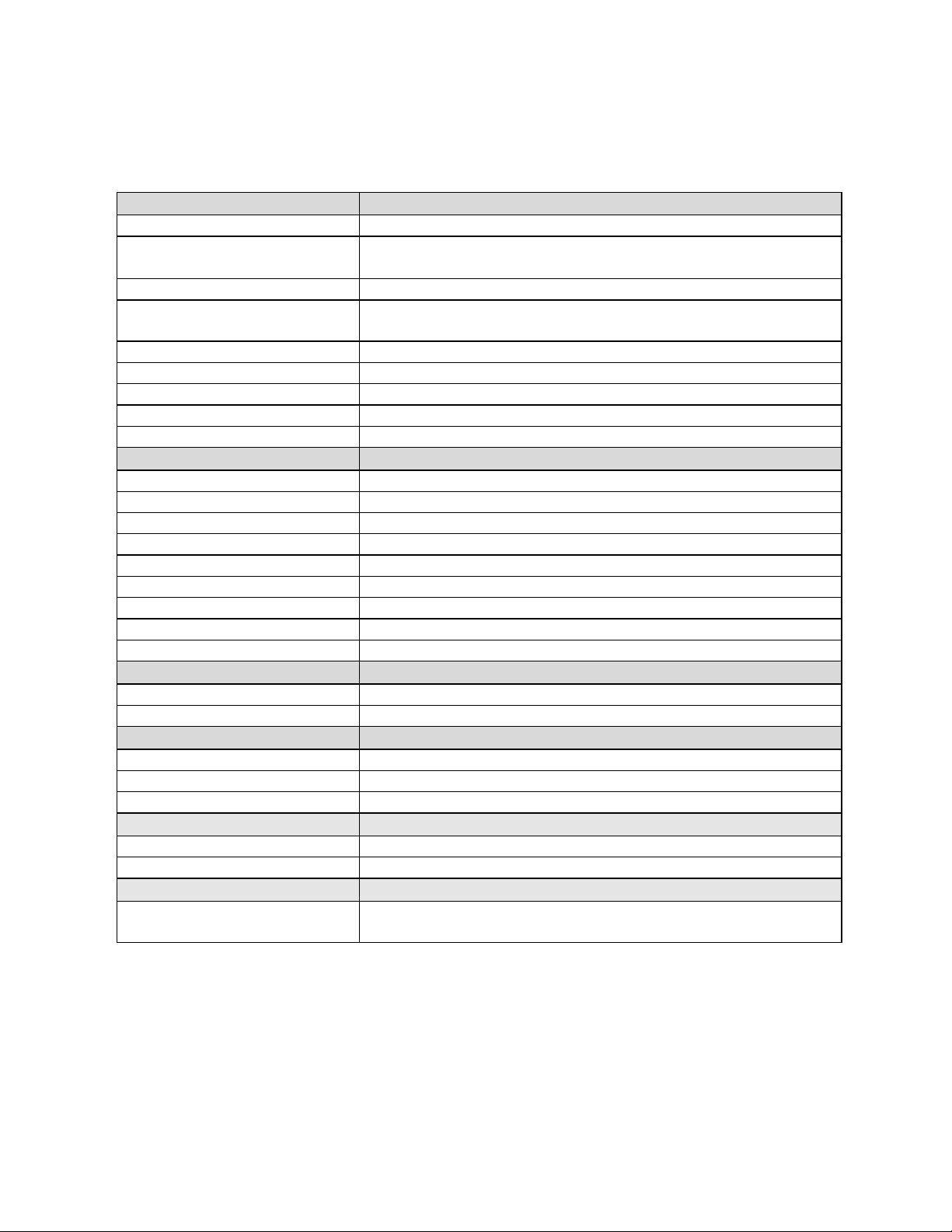

Detector Performance Specifications .................................................................................................................................8

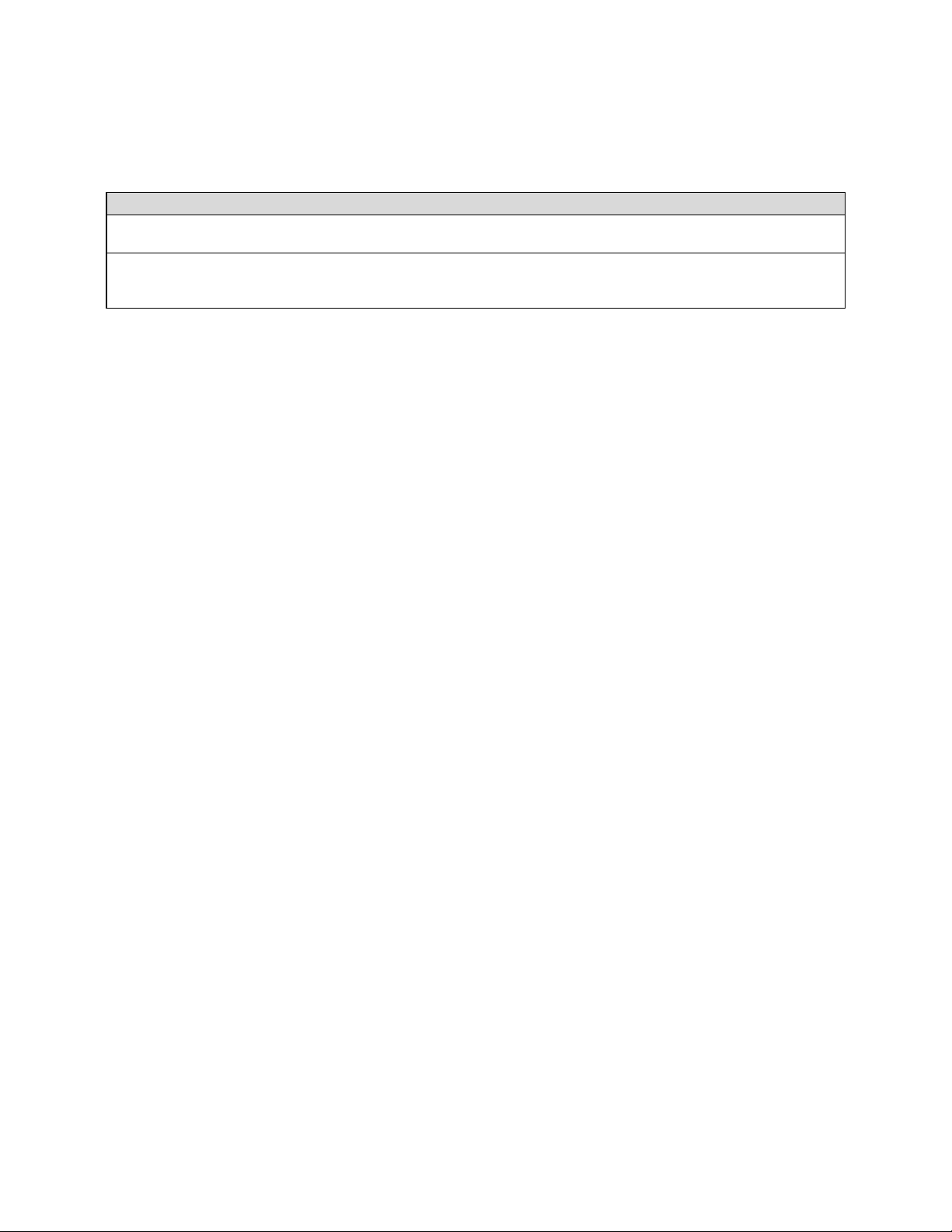

Certifications ......................................................................................................................................................................10

Mechanicals........................................................................................................................................................................11

3. Software and Hardware Setup______________________________________________________________________13

Setup Steps: Overview.......................................................................................................................................................13

Step 1. Detector Mounting.................................................................................................................................................14

Step 2. Ethernet Network Card: Install and Configure......................................................................................................15

Step 3. Connect Power, Ethernet, and Trigger Cables .......................................................................................................17

Step 4. Establish Communication with the Detector ..........................................................................................................21

Step 5. Detector Settings and Test Patterns.......................................................................................................................22

4. Detector Operation _____________________________________________________________________________24

Saving and Restoring Detector Settings ............................................................................................................................24

Binning ..............................................................................................................................................................................25

Imaging Modes and Timing...............................................................................................................................................27

Image Retrieval .................................................................................................................................................................33

Gain and Offset Adjustment ..............................................................................................................................................33

Noise vs. Gain....................................................................................................................................................................35

Detector Memory ...............................................................................................................................................................36

Line Rate ...........................................................................................................................................................................36

Exposure Time ...................................................................................................................................................................36

Image Height.....................................................................................................................................................................36

Verify Temperature and Voltage .......................................................................................................................................37

I / O Opto-couplers ............................................................................................................................................................37

Appendix A: All Commands _________________________________________________________________________39

Appendix B: Web GUI Interface ______________________________________________________________________42

Introduction .......................................................................................................................................................................42

Web GUI Access..................................................................................................................................................................45

Acquisition and Control .....................................................................................................................................................50

Firmware upgrade using the Web GUI..............................................................................................................................53

Appendix C: API Overview __________________________________________________________________________55

Appendix D: Enable and Use Telnet ___________________________________________________________________56

Appendix E: IP Address Information ___________________________________________________________________60

Appendix F: Troubleshooting ________________________________________________________________________61

Image Quality....................................................................................................................................................................63

Common Solutions.............................................................................................................................................................66

Specific Questions and Answers .........................................................................................................................................67

Revision History _________________________________________________________________________________69

Index ________________________________________________________________________________________70