TELEMAGNETICA 184/6KV User manual

Holiday Detector mod. 184-13-6KV

www.telemagnetica.com

Generals Mod. 184

The Holiday Detector mod. 184 is used to check the integrity of insulating coatings

applied to metallic structures.

Technical Data

- Power

60VA

- Max pulse voltage on 900pF

6kV

- Pulse duration

10 ÷ 12µs.

- Pulse repetition frequency

20 ÷ 25 Hz.

- Crest kilovoltmeter range

10 ÷ 10000V

- Measurement error

±5%

- Leak signal

Visual alarm by red lamp

Acoustic with Piezoceramic buzzer, 60dB at 2000Hz with continuous

sensitivity regulation and signal extension of 1 second

- Unit weight

25 Kg.

- Unit Dimensions

800 x 600 x 300 mm

January 2013

BR-184-13-6KV-ENG-00

Pag. 2 of 10

Holiday Detector mod. 184-13-6KV

www.telemagnetica.com

Instruction for use

a) Holiday Detector Mod. 184 has been designed for the inspection, on the

production line, of the piping insulating coating.

b) The inspection is made connecting the grounding clamp to the back

bare end of the pipe section, before the bare front of pipe reaches the

inspection point that is made by a conductive brush connected to the

hot point that feels the whole coated pipe surface, discovering any

possible leaks in coating.

c) The unit generates High Voltage pulse discharges (up to 6000V per 10

microseconds) with a repetition frequency of about 20Hz (1 pulse every

50 milliseconds). That allows to inspect the whole coating surface by

means of thin brushes, at normal pipe translation speed in the

production line, minimizing operator risks.

d) Main switch (1) connects the unit to 230Vac – 50Hz network (switched-

on green lamp (7)), activating HV output and the Crest Voltmeter (3)

allowing real time reading of effectively present pulse voltage on

insulating coating independently from the load represented by it (mostly

capacitive).

e) Change-over switch (4) allows to select the voltage range most suitable

to the kind of coating under inspection, while the potentiometer (5)

allows the voltage fine adjustment between the interval of two steps.

f) Leak presence is noticed by the intervention of the piezoelectric by an

acoustic signal and from the red lamp lighting (6); in addition the leak

signal is also available for free double change-over operation for remote

signal transmission or ausiliar operations.

g) The intervention sensitivity of acoustic piezoelectric alarm is adjusted by

the potentiometer (2), working on the achievement of the alarm

intervention just in the moment of the discharge towards leak.

During the installation of the unit, it is important to note that the

load is mostly of

capacitive kind with

a pole connected to ground, therefore, in order to avoid as useless as

undesired loads, it will be useful to connect as short as possible the hot point to the brush,

separating from the

ground or from grounded metallic structures, using the special HV

cable supplied with the unit.

January 2013 BR-184-13-6KV-ENG-00 Pag. 3 of 10

Holiday Detector mod. 184-13-6KV

www.telemagnetica.com

Safety

The unit feeded by 230Vac – 50Hz main, is used for the “on-line” inspection of different

kinds of coatings applied on metallic surfaces in the production sites.

The unit generates an output puls

e voltage of more than 6.000 V (max. value) with a

duration of some tens of microseconds and a repetition frequency of 20 ÷ 25 Hz.

Average current at max output voltage is around 200 ÷

500 microAmpere in the case of

accidental superficial contact (e.g.

. inspection brush that comes in contact with an human

body) while it can increase up to 5mA in case of sure contacts (100Ω).

The high Internal impedance of the

equivalent generator allows that operators safety is

expose to danger only if the below listed instructions are not followed:

1) Be sure that the

external ground terminal of the unit is connected to factory

grounding net, using a cable with a copper min. section of 16 sqmm

Pipe grounding cable must be connected to the same terminal.

The grounding network cable could instead be connected to the

unit internal

terminal(for equipontential reason only).

2) Make physically not accessible (to unauthorised personnel) the production zone

near the brush.

3) The operator charged to the ground cla

mp positioning must be provided with

properly insulated gloves and boots.

4) The unit cannot operate in areas classified with explosion risk.

Maintenance

Efficiency of insulators and H.V. cables used in the control system must be checked at

least on six-monthly basis.

The unit calibration is suggested at least on annually basis.

January 2013

BR-184-13-6KV-ENG-00

Pag. 4 of 10

Holiday Detector mod. 184-13-6KV

www.telemagnetica.com

Components list

P/N Description Qty

P-9059-000

Changeover switch 5922/E/1B/12/20A

(see DWG. PR-0765-004)

1

P-7263-008

Microswitch cod. NAT AZH 2041

1

P-7434-126

Main switch green M22

(see DWG. PR-0765-004)

1

P-7007-038

Green Led 230V 3W for M22 P-7434-126

1

P-7429-005

Wire potentiometer 10 k

Ω

25mm Ø

(see DWG. PR-0765-004)

1

P-7429-037

Wire potentiometer 100

Ω

10 turns Ø

(see DWG. PR- 0765-004)

1

GR-6192-012

Positive converter

1

A-9042-009

Trigger Detector

1

GR-1007-001

Dissipator group

1

GR-6200-003

Positive Crest Kilovoltmeter 10kV

(see DWG. PR- 0765-004)

1

GR-1006-004

Positive feeder group

1

GR-6194-003

HV coil group c/w high insulation cable

1

P-7422-030

Green lamp-holder

(see DWG. PR- 0765-004)

1

P-7422-029

Red lamp-holder

(see DWG. PR- 0765-004)

1

Conformity Declaration

We declare that the Holiday Detector Mod. 184 is complying with the following Standards:

EN 50081-2 (1993)

EN 50082-2 (1995)

EN 55011 (1990)

EN 61000-3-2 (1995)

EN 61000-3-3 (1995)

EN 61000-4-2 (1995)

EN 61000-4-4 (1995)

EN 61000-4-8 (1993)

ENV 50140 (1993)

ENV 50141 (1993)

ENV 50204 (1995)

Electromagnetic compatibility - Generic standard emission.

Part. 2: Industrial environment.

Electromagnetic compatibility - Generic immunity standard.

Part. 2: Industrial environment.

Limits and methods of measurement of radio disturbance characteristics of

industrial, scientific and medical (ISM) radio-frequency equipment.

Electromagnetic compatibility (EMC) – Part. 3: Limits.

Section 2: Limits for harmonic current emissions (equipment input current ≤

16 A per phase).

Electromagnetic compatibility (EMC) – Part. 3: Limits.

Section 3: Limitation of voltage fluctuations and flicker in low-voltage supply

systems for equipment with rated current ≤16 A.

Electromagnetic compatibility (EMC) – Part. 4: Testing and measurement

techniques

Section 2: Electrostatic discharge test – Basis EMC Publication.

Electromagnetic compatibility (EMC) – Part 4: Testing and measurement

techniques

Section 4: Electrical fast transient/burst immunity test – Basic EMC publication

Electromagnetic compatibility (EMC) – Part 4: Testing and measurement

techniques

Section 8: Power frequency magnetic field immunity test

Basic EMC Publication.

Electromagnetic compatibility - Basic immunity standard - Radiated radio-

frequency electromagnetic field - Immunity test.

Conducted disturbances induced by radio-frequency fields – Immunity test.

Radiated electromagnetic field from digital radio telephones - Immunity test.

As stated on the Test Report No. EMC 2999/96 and, therefore it complies with the EMC norms for the

CE marking.

January 2013 BR-184-13-6KV-ENG-00 Pag. 5 of 10

Holiday Detector mod. 184-13-6KV

www.telemagnetica.com

Attached drawings

PR-0765-004

FRONT VIEW

S-0409-006

BLOCK DIAGRAM

S-0372-001

H.V. OUTPUT WAVEFORM

S-0373-000

H.V. COIL AND TRIGGER WAVEFORMS

PR-1097-000

PIPE AND INSPECTION BRUSH CONNECTIONS

January 2013 BR-184-13-6KV-ENG-00 Pag. 6 of 10

Holiday Detector mod. 184-13-6KV

www.telemagnetica.com

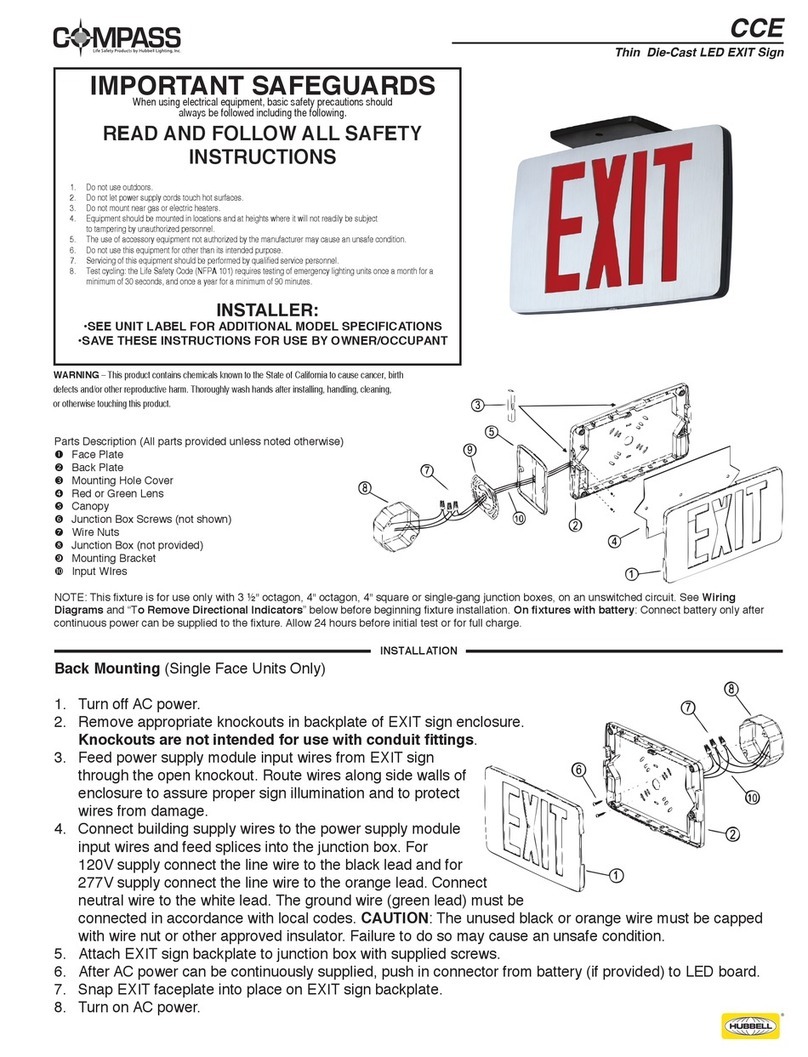

PR-0765-004 - FRONT VIEW

January 2013 BR-184-13-6KV-ENG-00 Pag. 7 of 10

Holiday Detector mod. 184-13-6KV

www.telemagnetica.com

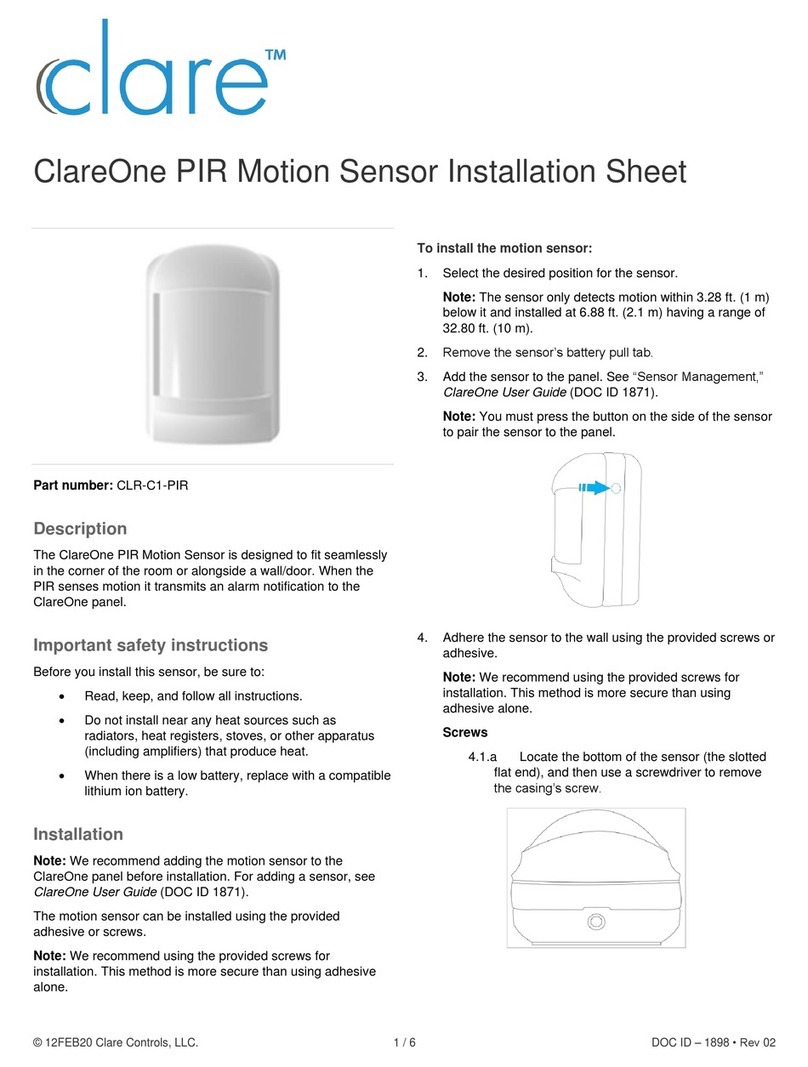

S-0409-006 - BLOCK DIAGRAM

S-0372-001-H.V. OUTPUT WAVEFORM

January 2013

BR-184-13-6KV-ENG-00

Pag. 8 of 10

Holiday Detector mod. 184-13-6KV

www.telemagnetica.com

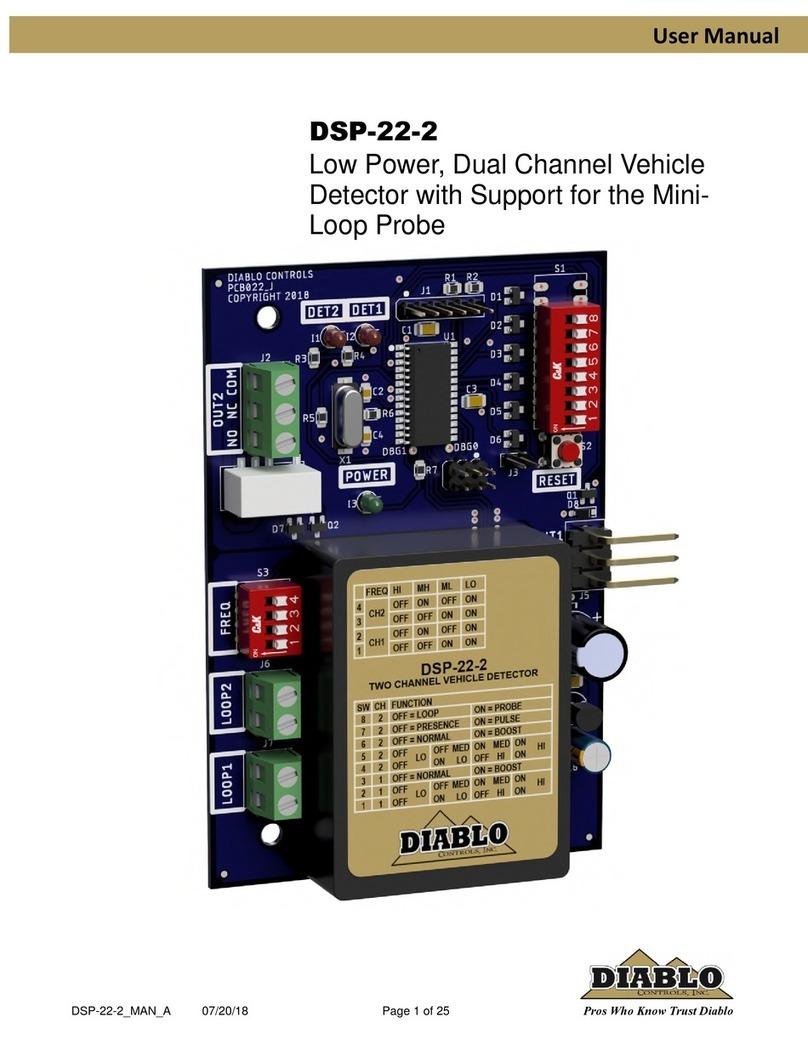

S-0373-000-H.V. COIL AND TRIGGER WAVEFORMS

January 2013 BR-184-13-6KV-ENG-00 Pag. 9 of 10

Holiday Detector mod. 184-13-6KV

www.telemagnetica.com

PR-1097-000-PIPE AND INSPECTION BRUSH CONNECTIONS

January 2013 BR-184-13-6KV-ENG-00 Pag. 10 of 10

This manual suits for next models

1

Table of contents

Popular Security Sensor manuals by other brands

Agilent Technologies

Agilent Technologies G2334A installation guide

Satel

Satel ADD-200 user manual

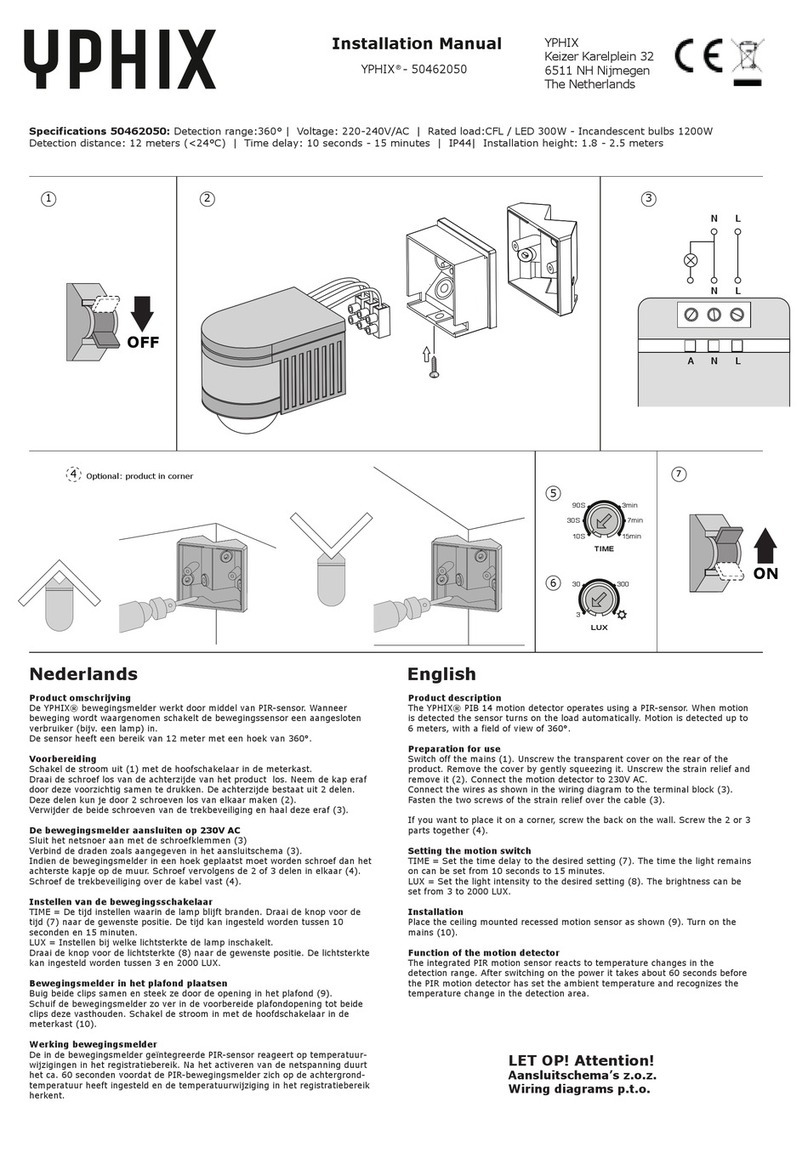

YPHIX

YPHIX 50462050 installation manual

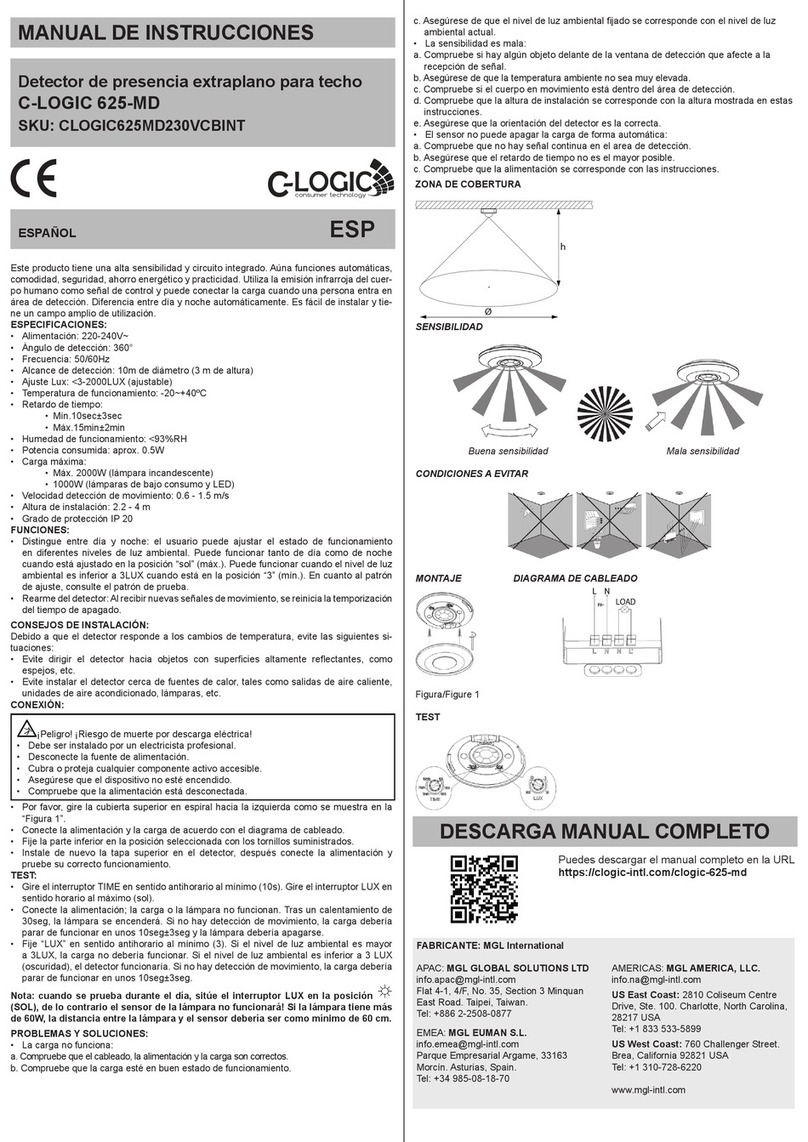

C-LOGIC

C-LOGIC 625-MD instruction manual

Bircher

Bircher Merkur 2 ES.SM Series Translation of the original instructions

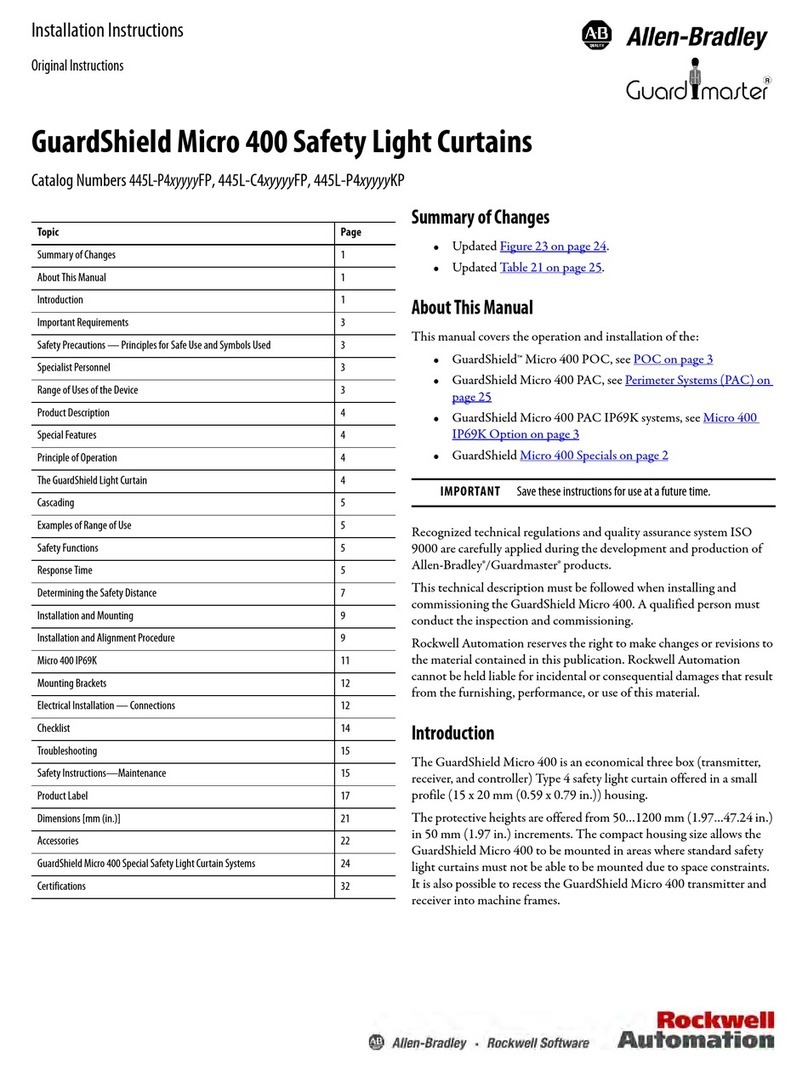

Allen-Bradley

Allen-Bradley GuardShield Micro 400 installation instructions