Telemark Cryogenics CRYO-CHILLER User manual

MICROPROCESSOR BASED WATER VAPOR

CRYO-CHILLER

INSTRUCTION MANUAL

Part No 19-0001-00

Models Covered in this manual 1200, 1800, 1800EXT, 2400, 3000, 3600, 4800

Copyright © Telemark Cryogenics, 1998-2021 –All rights reserved

Manual Rev 1.0.9 March 2021

telemark.com

Download the current version of this manual at

https://telemark.com/water-vapor-cryochiller/cryochiller-models/

Brand and product names are trademarks or registered trademarks of their respective companies

Cryogenics

Cryogenics Microprocessor Based Cryochillers INTRODUCTION

telemark.com 2 of 81

Rev 1.0.9

TABLE OF CONTENTS

1INTRODUCTION..........................................................................7

1.1 SAFETY WARNINGS ...........................................................................7

1.2 WARRANTY........................................................................................11

1.3 USER RESPONSIBILITY....................................................................12

1.4 INTENDED USE OF THE EQUIPMENT .............................................12

1.5 STANDARDS ......................................................................................13

2SPECIFICATIONS .....................................................................14

2.1 GAS CWP CHART..............................................................................17

2.2 ENVIRONMENTAL CONDITIONS......................................................17

2.3 RECOMMENDED BREAKER AND WIRE SIZE .................................18

2.4 PHYSICAL DIMENSIONS...................................................................19

3INSTALLATION .........................................................................20

3.1 UNPACKING AND INSPECTION .......................................................22

3.2 SYSTEM PRESSURE.........................................................................23

3.3 LOCATION..........................................................................................23

3.4 PANEL REMOVAL..............................................................................23

3.5 WATER CONNECTIONS....................................................................24

3.6 REFRIGERANT LINE CONNECTION ................................................26

3.6.1 Refrigerant Line Installation Notes....................................................................... 29

3.7 MAIN ELECTRICAL CONNECTIONS.................................................32

3.7.1 Transformer Connections .................................................................................... 33

3.8 REMOTE CONNECTIONS .................................................................35

3.8.1 Digital Remote Control. ........................................................................................ 35

3.8.2 Analogue Output voltage ..................................................................................... 38

3.9 ETHERNET COMMUNICATION.........................................................39

3.9.1 Ethernet (Laptop) set up ...................................................................................... 40

3.9.2 Commands Available when Using Ethernet, RS232/485 Control........................ 42

3.9.3 Using TCPIP-RS232/485/Ethernet GUI ............................................................... 43

3.9.4 GUI Button/Screen Functions .............................................................................. 43

Cryogenics Microprocessor Based Cryochillers INTRODUCTION

telemark.com 3 of 81

Rev 1.0.9

3.9.5 “cal2309” Screen (User Configuration screen) .................................................... 45

3.9.6 USING THE TCPIP-RS232/485 PROGRAM....................................................... 48

4OPERATION..............................................................................58

4.1 CONTROLS AND DISPLAYS .............................................................58

4.1.1 LCD Display ......................................................................................................... 58

4.2 SCROLL PUSH BUTTON ...................................................................60

4.3 PUSH BUTTONS ................................................................................60

4.3.1 COOL Push Button(s)/Indicators(s) ..................................................................... 60

4.3.2 STOP/RESET Push Button.................................................................................. 60

4.4 OPERATION .......................................................................................61

4.4.1 Turn on the main ISO isolator .............................................................................. 61

4.4.2 Turning the Unit On.............................................................................................. 61

4.4.3 Standby ................................................................................................................ 61

4.4.4 Cool...................................................................................................................... 61

4.4.5 Defrost.................................................................................................................. 61

4.4.6 Defrost Recovery Period...................................................................................... 61

4.5 NORMAL OPERATING RANGES.......................................................62

5TROUBLE SHOOTING GUIDE..................................................63

5.1 TROUBLE SHOOTING .......................................................................63

5.2 REFRIGERATION LEAKS ..................................................................63

5.3 ALARM CODES/MESSAGES .............................................................63

5.4 SAFETY SYSTEMS ............................................................................64

5.4.1 Hardware Safety systems .................................................................................... 64

5.5 TROUBLE SHOOTING GUIDE...........................................................65

5.6 THE USE OF “TOP-OFF” GAS CHARGES ........................................69

5.7 EMERSON (COPELAND™) COMPRESSOR.....................................69

5.7.1 Compressor Diagnostics ...................................................................................... 71

6DECOMMISSIONING.................................................................75

7DESIGN OF CRYO-COILS ........................................................77

8CHINESE SAFETY DATA SHEET.............................................80

Cryogenics Microprocessor Based Cryochillers INTRODUCTION

telemark.com 4 of 81

Rev 1.0.9

LIST OF FIGURES

Figure 3-1, Removing Unit from Transportation Pallet...............................................................22

Figure 3-2, Pressure Gauge......................................................................................................23

Figure 3-3, Service Panel..........................................................................................................24

Figure 3-4, Water flow Requirements........................................................................................25

Figure 3-5, Position of Hand Valves ..........................................................................................26

Figure 3-6, Refrigerant Line Connections..................................................................................27

Figure 3-7, Access Valve ..........................................................................................................28

Figure 3-8, Refrigerant Manifold................................................................................................28

Figure 3-9, Refrigerant Line Insulation ......................................................................................31

Figure 3-10, Metal O-ring Removal Tool ...................................................................................32

Figure 3-11, Main Isolator Wiring ..............................................................................................33

Figure 3-12, Transformer Tapings.............................................................................................34

Figure 3-13, 37-Way Amphenol™ Connector, Front view .........................................................37

Figure 3-14, Ethernet cable (crossed) .......................................................................................39

Figure 3-15, Network Connection Window ................................................................................40

Figure 3-16, Network Properties ...............................................................................................40

Figure 3-17, TCP/IP ..................................................................................................................41

Figure 3-18, Set up for TCP/IP..................................................................................................41

Figure 3-19, TCP/IP GUI...........................................................................................................43

Figure 3-20, Ethernet TCP/IP and RS232/485 Help Screens ....................................................45

Figure 3-21, “cal2309” Screen Setup ........................................................................................46

Figure 3-22, Change Com Port .................................................................................................49

Figure 3-23, Select Com Port....................................................................................................49

Figure 3-24, Com Connection Shown .......................................................................................50

Figure 3-25, Enter rip ................................................................................................................50

Figure 3-26 Display IP Address.................................................................................................51

Figure 3-27, Change Remote Host............................................................................................51

Figure 3-28, Go to IP Properties ...............................................................................................52

Figure 3-29, Check IP Addresses..............................................................................................52

Figure 3-30, Parameter Setup...................................................................................................53

Figure 3-31, Select IP Address for Changing ............................................................................53

Cryogenics Microprocessor Based Cryochillers INTRODUCTION

telemark.com 5 of 81

Rev 1.0.9

Figure 3-32, Enter new IP address............................................................................................54

Figure 3-33, Disconnect TCP/IP................................................................................................55

Figure 3-34, Change Remote Host IP address..........................................................................55

Figure 3-35, Disconnect TCP/IP Again......................................................................................56

Figure 3-36, Check first three IP numbers.................................................................................57

Figure 3-37, Connect to Remote Host.......................................................................................57

Figure 4-1, Front Panel Push Buttons (Single Coil Unit Shown) ................................................58

Figure 4-2, LCD Display, Wait...................................................................................................58

Figure 4-3, LCD Display, Pre-Cool............................................................................................59

Figure 4-4, , LCD Display, Ready..............................................................................................59

Figure 4-5, LCD Display, Cool...................................................................................................59

Figure 5-1, “OVER PRESSURE” Alarm Message .....................................................................64

Figure 5-2, “E1” With Fault Shown as “DP HIGH” .....................................................................64

Figure 5-3, Emerson Compressor Front Panel Fault Code LED’s .............................................70

Figure 5-4, Emerson Compressor Internal Electronic Parts.......................................................70

Cryogenics Microprocessor Based Cryochillers INTRODUCTION

telemark.com 6 of 81

Rev 1.0.9

LIST OF TABLES

Table 2-1, Model 1200, 1800, 1800EXT, 2400 Specifications ...................................................15

Table 2-2, Model 3000, 3600, 4800 Specifications....................................................................16

Table 2-3, Current Models Gas CWP Chart ..............................................................................17

Table 2-4, Discontinued Models Gas CWP Chart......................................................................17

Table 2-5, Environmental Conditions ........................................................................................17

Table 2-6, Recommended Breaker and Wire Size ....................................................................18

Table 2-7, Physical Dimensions ................................................................................................19

Table 3-1, Cryochiller Recommended Circuit Breaker value and Wire Size ..............................33

Table 3-2, Pin Connection for 37-way Amphenol Connector .....................................................37

Table 3-3, Volts vs. Temp Analog Output..................................................................................38

Table 3-4, Write Serial Commands ...........................................................................................42

Table 3-5, Read Serial Commands ...........................................................................................42

Table 4-1, Display Mnemonics and Their Meaning....................................................................59

Table 4-2, Normal Operating Ranges........................................................................................62

Table 5-1, Listing of Alarm Messages and Error Codes ............................................................64

Table 5-2, Troubleshooting Guide.............................................................................................68

Table 5-3, Emerson LEDs.........................................................................................................74

Table 7-1, Coil Surfaces and Theoretical Pumping ...................................................................78

Cryogenics Microprocessor Based Cryochillers INTRODUCTION

telemark.com 7 of 81

Rev 1.0.9

1 INTRODUCTION

1.1 SAFETY WARNINGS

THE PHRASE WARNING IS USED WHERE THERE IS A HIGH

PROBABILITY OF PERSONAL INJURY OR DEATH SHOULD

THE PROVISIONS HIGHLIGHTED BE IGNORED. IT IS THE

DUTY OF BOTH THE INSTALLER/OWNER AND OPERATOR

OF THE EQUIPMENT TO BE FAMILIAR AND COMPETENT

WITH THE OPERATION AND USES OF THE PRODUCT.

HELP MAY BE SOUGHT FROM THE MANUFACTURER.

Cryogenics Microprocessor Based Cryochillers INTRODUCTION

telemark.com 8 of 81

Rev 1.0.9

WARNING

1) The system contains specific hazards, which present a

significant danger to personal safety:

(a) High voltage electrical components and high-pressure

refrigerant gases, which are a significant frostbite

hazard.

(b) Refrigerant gases, which will cause asphyxiation in

confined areas.

(c) Refrigerant gases, which if exposed to high

temperatures decompose to form very toxic by-

products –never smoke in the vicinity of a UNIT

or any other similar system including the gas

cylinders.

(d) Water in close proximity to high voltage electricity.

(e) Hot and cold surfaces which represent a significant

burn / frostbite hazard.

WARNING

The system contains gases under pressure, which may

constitute both a frostbite hazard and a burn hazard.

Refrigerant gases are known asphyxiates and are mildly

narcotic. Precautions must be taken, and work must only be

carried out by suitably qualified personnel.

WARNING

Removal of any panels other than the front door will expose

the operator to high voltage components, which may result

in a fatal electrocution.

WARNING

During installation there is the potential to be exposed to

high voltage components (up to 400v ac), which may result

in a fatal electrocution.

Cryogenics Microprocessor Based Cryochillers INTRODUCTION

telemark.com 9 of 81

Rev 1.0.9

WARNING

Units must always be operated with a suitable ground/earth

line. Failure to comply may result in fatal electrocution.

Never tamper with or remove any ground/earth connection

from inside of the machine.

WARNING

Isolate system before connection. Ensure the connection

cable used is compliant with local electrical requirements.

Cabling within the unit is tri-rated to CSA/UL/CE norms.

There must be three power wires and one ground wire;

there is no neutral line. Feed cable through gland and

terminate at main system isolator, having first removed the

protective cover. Ground the UNIT at primary ground point.

WARNING

Failure to replace isolator cover exposes operators to

potentially fatal electrocution. It is essential this primary

protection always be in place before the system is

energized.

WARNING

Always isolate the system through the main circuit breaker

before attaching the remote control. When in remote

operation take additional care to prevent personal injury.

WARNING

Failure to leak test the system as a whole, may result in the

catastrophic release of refrigerant, which presents a very

high risk from frostbite and or asphyxiation. See emergency

shutdown procedures and material safety data sheet for

guidance.

Cryogenics Microprocessor Based Cryochillers INTRODUCTION

telemark.com 10 of 81

Rev 1.0.9

WARNING

The refrigeration system contains a mixed blend of

refrigerants and polio-ester oil. These do not present

acute health risks, but it is essential that the following

basic precautions are followed:

a. Always wear eye protection.

b. Always wear surgical type rubber or latex gloves.

CAUTION

CAUTION

Telemark will not be responsible or liable for either direct

or consequential personal injury or loss claims arising

from the misuse of the product.

CAUTION

If the equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment

may by impaired

CAUTION

It is the responsibility of the user to make sure all local,

county, state and national codes, regulations, rules, and

laws related to safety and safe operating conditions are

meet for each installation. The safety of any system

incorporating the equipment is the responsibility of the

assembler of the system.

The phrase “Caution”indicates a risk of damage to

the product or associated plant and machinery if the

provisions are not followed carefully.

Cryogenics Microprocessor Based Cryochillers INTRODUCTION

telemark.com 11 of 81

Rev 1.0.9

CAUTION - HOT SURFACE

High temperatures are generated during normal

operation. Avoid contact with exposed pipework as this

can get hot during normal operation.

CAUTION - COLD SURFACE

Freeze Burn Risk. Very low temperatures generated

during normal operation. Avoid contact with exposed

pipework.

CAUTION - PRESURISED GAS

Unit contains pressurized gas. Do not open hand valves

until system is connected to a Cryo-coil, which has been

checked for leaks. Do not connect the system to other

systems unless their design and application has been

approved by the manufacturer

CAUTION - HAND VALVES

Closure of the hand valves while the system is at

cryogenic temperatures may damage the valve seats and

invalidate the systems warranty. It must only be

attempted on a cryogenically cold system in the case of

an emergency, which is causing gross leakage from the

Cryo-coil or refrigerant lines.

1.2 WARRANTY

Telemark Cryogenics Cryochiller products are warranted to be free from defects in

materials and/or workmanship under normal usage until warranty effective date listed on

serial number label. Telemark Cryogenics’obligation under this warranty is limited to the

repair or replacement, at its option, of any parts, which upon examination at the

Telemark Cryogenics factory or by an authorized sales/service representative, shall

appear to have become defective. Correction of defects by repair or replacement shall

be either at the Telemark factory or in-situ by an authorized service representative. The

Cryogenics Microprocessor Based Cryochillers INTRODUCTION

telemark.com 12 of 81

Rev 1.0.9

location of repair shall be at the discretion of Telemark Cryogenics. Repairs carried out

at Telemark Cryogenics factory shall be FOB Telemark factory and shall constitute

fulfilment of obligations to the purchaser. All transportation costs for defective parts or

products shall be borne by the purchaser. Telemark Cryogenics will not be liable for

loss, damage, or other expenses directly or indirectly arising from the use of its products

or from any other causes. Telemark assumes no liability for expenses or repairs made

outside of its factory by non-authorized personnel.

All claims on account of defective material or workmanship shall be deemed waived

unless made in writing within the warranty period. The foregoing warranty is in lieu of all

other warranties expressed or implied. Telemark neither assumes nor authorizes any

other person to assume any other obligation or liabilities in conjunction with the sale of

its products. This warranty shall be void if the equipment has been subject to misuse,

negligence, or application outside of recommended operating environment or

conditions. The warranty will also be invalidated if the identification numbers of the

system have been altered, defaced, or removed.

The warranty is not intended to supplant any statutory rights the purchaser may have.

Unit start and end dates are printed on the unit’s serial number label.

1.3 USER RESPONSIBILITY

The user is responsible for proper installation, operation and ordinary maintenance of

the equipment following the procedures in this manual. The warranty may be void if the

equipment is improperly installed. Alteration of the design and or any function of the

equipment voids the warranty and is entirely the responsibility of the user.

Telemark will not be held responsible or liable for either director consequential personal

injury or loss claims arising from the misuse of the product

The user should read this manual in its entirety before carrying out any work and or

operation of a Telemark Cryochiller.

1.4 INTENDED USE OF THE EQUIPMENT

Water vapor Cryochiller is a device that improves the performance of vacuum pumping

due to the efficient trapping of water vapor in the chamber.

Classically a Cryochiller is used with an evaporative surface (Meissner/cryo-coil), which

is located within the vacuum chamber. When in this configuration a Telemark

Cryochiller is an ultrahigh performance vacuum pump capable of pumping water vapor

and other condensable gases at speeds far more than conventional vacuum pumps.

A Telemark Cryochiller couples speed with a sophisticated computer control package

which includes a simple and adaptable user interface with isolated inputs/outputs and

Ethernet comms package as standard. RS232 and RS485 serial communication options

are available.

Cryogenics Microprocessor Based Cryochillers INTRODUCTION

telemark.com 13 of 81

Rev 1.0.9

The ranges of tasks to which your Cryochiller can be applied are not limited to pumping

water vapor in vacuum. Many are used as substrate coolers (chuck coolers) or other

applications where a continuous level of high-power cooling in the range –100 to –

150oc is required.

1.5 STANDARDS

The device is compatible in terms of electromagnetic compatibility and safety standards.

Applicable standards:

EMC: DIRECTIVE 2014/30/UE - STANDARD EN 61326-1:2013

LVD: DIRECTIVE 2014/35/EU - STANDARD EN 61010-1:2011

And applicable causes of the standard: EN 378-2:2008

Cryogenics Microprocessor Based Cryochillers SPECIFICATIONS

telemark.com 14 of 81

Rev 1.0.9

2 SPECIFICATIONS

Specifications for models 1200, 1800, 1800EXT, 2400, 3000, 3600 and 4800 are on the

following pages.

Cryogenics Microprocessor Based Cryochillers SPECIFICATIONS

telemark.com 15 of 81

Rev 1.0.9

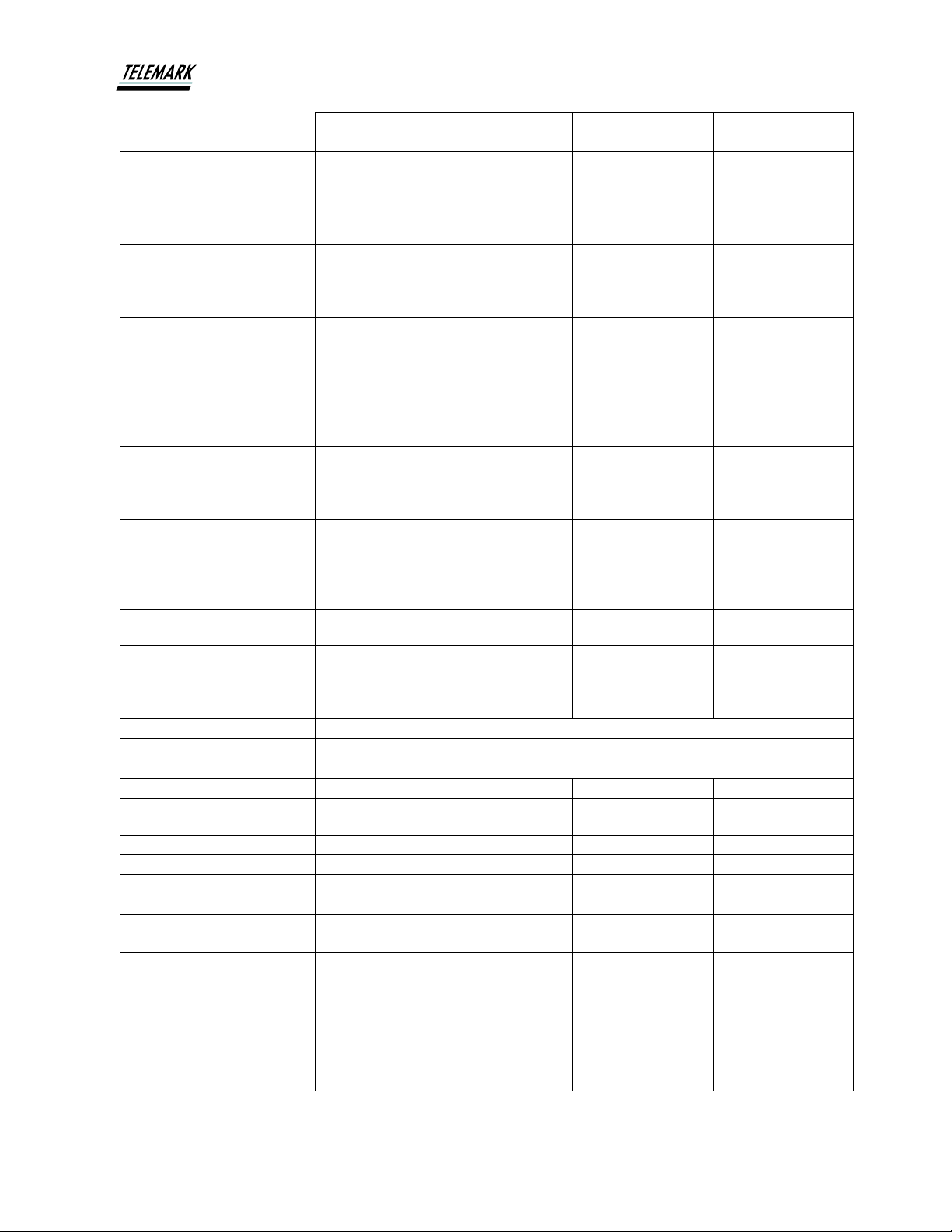

Model 1200

Model 1800

Model 1800EXT

Model 2400

Maximum Load (Watts)

1,200

1,800

1,800

2400

Typical Pumping Speed

(l/sec)

65,000

100,000

100,000

135,000

Ultimate Vacuum

2 x10-8 mbar

(2 x10-6Pa)

2 x10-8 mbar

(2 x10-6Pa)

2 x10-8 mbar

(2 x10-6Pa)

2 x10-8 mbar

(2 x10-6Pa)

Weight (Kg)

193 (432 lbs)

243 (536 lbs)

243 (536 lbs)

243 (536 lbs)

Size inch (mm)

L

W

H

24 (559)

22 (610)

59.5 (1511)

24 (559)

22 (610)

59.5 (1511)

24 (559)

22 (610)

59.5 (1511)

24 (559)

22 (610)

59.5 (1511)

Power supply

380-444VAC 3 ph

50Hz

460VAC 3 ph 60 Hz

200-230VAC 3 Ph

50/60 Hz

380-444VAC 3 ph

50Hz

460VAC 3 ph 60

Hz

200-230VAC 3 Ph

50/60 Hz

380-444VAC 3 ph

50Hz

460VAC 3 ph 60 Hz

200-230VAC 3 Ph

50/60 Hz

380-444VAC 3 ph

50Hz

460VAC 3 ph 60 Hz

200-230VAC 3 Ph

50/60 Hz

Wire/Cable Connection

3 Phase + Ground

(Earth)

3 Phase +

Ground (Earth)

3 Phase + Ground

(Earth)

3 Phase + Ground

(Earth)

Full Load Current draw @

60 Hz (Amps)

@200-230VAC

@380-440VAC

20

10

30

15

30

15

40

20

Start Up Max

Current Draw @ 60 Hz

(Amps)

@200-230VAC

@380-440

30

15

60

30

60

30

60

30

Compressor Horsepower

(HP)

4.5 (3.35kW)

7.5 (5.59kW)

7.5 (5.59kW)

10 (7.46kW)

Water Requirements (l/min)

@ 15°C

@ 25°C

@ 32°C

5

10

20

5

10

20

5

10

20

6

12

30

Water Connections

All Models ¾” NPT Female

Water Resistivity

All Models >0.1MΩ Chloride Free

Water pH

All Models 6.5 - 8

Refrigeration Connections

½” Metal Seal

½” Metal Seal

½” Metal Seal

½” Metal Seal

Max Coil Length (Meters)

Using ½” Cu tube

20 (65.6 ft)

25 (82 ft)

25 (82 ft)

35 (114.8 ft)

Max Surface area (M2)

0.79 (≈8.57 ft2)

0.99 (≈10.72 ft2)

0.99 (≈10.72 ft2)

1.39 (≈15 ft2)

*Avg. Cool Time (mins)

2-5

2-5

2-5

2-5

*Avg. Defrost Time (mins)

2-4

2-4

2-4

2-4

ΔT Coil in/Coil Out (°C)

≈5

≈5

≈5

≈5

Digital Remote Connections

Input Voltage range

18-24VDC

(30VDC MAX)

18-24VDC

(30VDC MAX)

18-24VDC (30VDC

MAX)

18-24VDC (30VDC

MAX)

Digital Remote Connections

Output Voltage range

Relay contact

closure 200 VAC

or 100VDC Max at

300mA

Relay contact

closure 200 VAC

or 100VDC Max

at 300mA

Relay contact

closure 200 VAC or

100VDC Max at

300mA

Relay contact

closure 200 VAC or

100VDC Max at

300mA

Balance Pressure Range as

Shipped from Telemark

USA facility (PSI) @20°C

(hand valves closed)

270-300

(1.86-2.07MPa)

220-250

(1.51-1.72MPa)

180-210

(1.24-1.45MPa)

190-220

(1.31-1.52MPa)

Table 2-1, Model 1200, 1800, 1800EXT, 2400 Specifications

Cryogenics Microprocessor Based Cryochillers SPECIFICATIONS

telemark.com 16 of 81

Rev 1.0.9

Model 3000

Model 3600

Model 4800

Maximum Load (Watts)

3000

3,600

4,800

Typical Pumping Speed

(l/sec)

165,000

200,000

275,000

Ultimate Vacuum

2 x10-8 mbar

(2 x10-6Pa)

2 x10-8 mbar

(2 x10-6Pa)

2 x10-8 mbar

(2 x10-6Pa)

Weight (Kg)

384 (845 lbs)

412 (930 lbs)

433 (955 lbs)

Size inch (mm)

L

W

H

35.3 (897)

23.6 (897)

70.25 (1784)

35.3 (897)

23.6 (897)

70.25 (1784)

35.3 (897)

23.6 (897)

70.25 (1784)

Power supply

380-444VAC 3 ph

50Hz

460VAC 3 ph 60 Hz

200-230VAC 3 Ph

50/60 Hz

380-444VAC 3 ph

50Hz

460VAC 3 ph 60 Hz

200-230VAC 3 Ph

50/60 Hz

380-444VAC 3 ph

50Hz

460VAC 3 ph 60 Hz

200-230VAC 3 Ph

50/60 Hz

Wire/Cable Connection

3 Phase + Ground

(Earth)

3 Phase + Ground

(Earth)

3 Phase + Ground

(Earth)

Full Load Current draw @ 60

Hz (Amps)

@200-230VAC

@380-440VAC

50

25

60

30

75

37

Start Up Max

Current Draw @ 60 Hz

(Amps)

@200-230VAC

@380-440

60

30

85

45

100

60

Compressor Horsepower

(HP)

13 (9.69kW)

15 (11.19kW)

20 (14.91kW)

Water Requirements (l/min)

@ 15°C

@ 25°C

@ 32°C

6

12

30

8

16

30

10

18

32

Water Connections

¾” NPT Female

Water Resistivity

All Models >0.1MΩ Chloride Free

Water pH

All Models 6.5 - 8

Refrigeration Connections

½” Metal Seal

½” Metal Seal

½” Metal Seal

Max Coil Length (Meters)

Using ½” Cu tube

40 (131.2 ft)

50 (164.0 ft)

65 (213.3 ft)

Max Surface area (M2)

1.59 (≈17.1 ft2)

1.99 (≈21.42 ft2)

2.52 (≈27.13 ft2)

*Avg. Cool Time (mins)

2-5

2-5

2-5

*Avg. Defrost Time (mins)

2-4

2-4

2-4

ΔT Coil in/Coil Out (°C)

≈5

≈5

≈5

Digital Remote Connections

Input Voltage range

18-24VDC

(30VDC MAX)

18-24VDC

(30VDC MAX)

18-24VDC

(30VDC MAX)

Digital Remote Connections

Out Voltage range

Relay contact

closure 200 VAC

or 100VDC Max at

300mA

Relay contact

closure 200 VAC

or 100VDC Max at

300mA

Relay contact

closure 200 VAC

or 100VDC Max at

300mA

Balance Pressure Range as

shipped from Telemark USA

facility (PSI) @20°C

(hand valves closed)

250-280

(1.72-1.93MPa)

250-280

(1.72-1.93MPa)

250-280

(1.72-1.93MPa)

Table 2-2, Model 3000, 3600, 4800 Specifications

Cryogenics Microprocessor Based Cryochillers SPECIFICATIONS

telemark.com 17 of 81

Rev 1.0.9

IMPORTANT.The above performance figures are based for a unit running at

60Hz mains power frequency. For units running on 50 Hz mains frequency

the figures above need to be de-rated by 0.83.

2.1 GAS CWP CHART

Current Production Models

Mass (kg)

GWP

CO2 tons eq

1200

2.94

3840

11.29

1800

3.50

3758

13.156

2400

3.56

3877

13.802

3000

5.55

4569

25.357

3600

5.15

4489

23.118

Top Off

0.83

5512

4.575

Table 2-3, Current Models Gas CWP Chart

Discontinued Models

Mass (kg)

GWP

CO2 tons eq

1000

3.54

3842

13.59

2000

4.74

3886

18.42

3500

5.83

4330

25.24

Table 2-4, Discontinued Models Gas CWP Chart

2.2 ENVIRONMENTAL CONDITIONS

Environmental conditions for all models.

Parameter

Value

Type

Indoor use

Altitude

Up to 2000m

Temperature range (°C)

5 - 40

Humidity (%Rh)

Maximum relative 80% for temperatures up to 31 ⁰C

decreasing linearly to 50% relative humidity at 40 ⁰C

Mains supply voltage

fluctuations

Up to 10% of the nominal voltage

Pollution degree

2

Overvoltage category

II

Table 2-5, Environmental Conditions

Cryogenics Microprocessor Based Cryochillers SPECIFICATIONS

telemark.com 18 of 81

Rev 1.0.9

2.3 RECOMMENDED BREAKER AND WIRE SIZE

Recommended circuit breaker values and wire size for cryochillers.

200-230VAC Vac Three-Phase

Nominal current

rating[A]

Fuse

Rating [A]

Minimum copper

wire

AWG/mm2

Cable Type

(recommended)

30

70

8 / 10

H07RN-F 450/750V 4G10

50

100

6 / 16

H07RN-F 450/750V 4G16

60

125

4 / 25

H07RN-F 450/750V 4G25

380-444VAC Three-Phase

15

30

14 / 2.5

H07RN-F 450/750V 4G2.5

25

45

10 / 6

H07RN-F 450/750V 4G6

30

60

10 / 6

H07RN-F 450/750V 4G6

Table 2-6, Recommended Breaker and Wire Size

Cryogenics Microprocessor Based Cryochillers SPECIFICATIONS

telemark.com 19 of 81

Rev 1.0.9

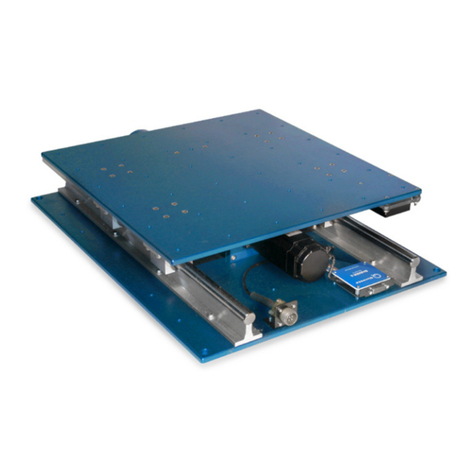

2.4 PHYSICAL DIMENSIONS

Model

A (inch)

A (mm)

B (inch)

B (mm)

C (inch)

C (mm)

1200

22

559

24

610

59.5

1511

1800

22

559

24

610

59.5

1511

1800EXT

22

559

24

610

59.5

1511

2400

22

559

24

610

59.5

1511

3000

23.6

599

35.3

897

70.25

1784

3600

23.6

599

35.3

897

70.25

1784

4800

23.6

599

35.3

897

70.25

1784

Table 2-7, Physical Dimensions

Cryogenics Microprocessor Based Cryochillers INSTALLATION

telemark.com 20 of 81

Rev 1.0.9

3 INSTALLATION

Safety and Cautionary Notes for Installation.

WARNING

Failing to leak test the system may result in the catastrophic

release of refrigerant, which presents a very high risk from

frostbite and/or asphyxiation. See emergency shut down

procedure and material safety data sheet.

WARNING

The system uses high voltage (208 or 415VAC) and high-power

components. To avoid the possibility of a fatal electrical shock

always isolate the unit from the mains supply before working on

the system. A qualified technician, as for all high-power

electrical connections, should carry out the electrical work

This manual suits for next models

1

Table of contents

Other Telemark Cryogenics Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Steinberg Systems

Steinberg Systems SBS-LBM-200 user manual

Monmouth Scientific

Monmouth Scientific Ductaire Pro DP700 operating & maintenance manual

World Precision Instruments

World Precision Instruments KITE Care and maintenance

HKBN

HKBN SensePlus user guide

Koehler

Koehler HKV4000 Operation and instruction manual

Idexx

Idexx Quanti-Tray 2X user manual