Telemark Cryogenics 1200 User manual

Telemark Cryogenics Microprocessor Based Cryochillers

Page

1

of

63

Revision 1.0.7 October 2018

MICROPROCESSOR BASED

WATER VAPOR CRYO-CHILLER

Part No 19-0001-00

Copyright © Telemark Cryogenics, 1998-2018 – All rights reserved

Rev 1.0.7 October 2018

www.telemark.com

Brand or products names are trademarks or registered trademarks

of their respective companies.

INSTRUCTION MANUAL

Models Covered in this manual

1200, 1800, 1800EXT, 2400, 3000, 3600

Telemark Cryogenics Microprocessor Based Cryochillers

Page

2

of

63

Revision 1.0.7 October 2018

Model 3600 Water Vapor Cryo-Chiller

(Dual Coil Unit)

Telemark Cryogenics Microprocessor Based Cryochillers

Page 3of 63

Revision 1.0.7 October 2018

TABLE OF CONTENTS

Page

Table of Contents 3

Safety Warnings 7

Warranty 10

User Responsibility Intended Use of Equipment 11

Manufacturing Standards 11

1

Specifications

Models 1200, 1800 and 1800EXT 12

Models 2400, 3000 and 3600 13

1.1 Environmental Requirements 14

1.2 Recommended Breaker and Wire size 14

1.3 Physical Dimensions 15

2

Installation

Cautionary Notes 16

2.0 Unpacking and Inspection 17

2.1 System Pressure 18

2.2 Location 19

2.3 Panel removal 19

2.4 Water Connections 20

2.5 Refrigerant Line Connection 21

2.5.1 Metal O Seals 22

2.5.2 Using Gauge Manifolds 22

2.5.3 Access Valve 22

2.5.4 Connections 23

2.5.5 Evacuate Refrigerant Lines 23

2.5.6 Sealing Refrigerant Lines 23

2.5.7 Refitting Valve Access Cover 23

2.5.8 Refrigerant Line Notes 24

2.6 Electrical Connections 26

2.6.1 Main Power Connection 26

2.6.2 Cable Entry Point 26

2.6.3 Terminal Torque Requirements 26

2.6.4 Transformer Taping 27

2.7 Remote Connections 28

2.7.1 Digital Remote Control 29

2.7.1.2 Analogue Outputs 31

Telemark Cryogenics Microprocessor Based Cryochillers

Page 4of 63

Revision 1.0.7 October 2018

2.8 Ethernet Communications 32

2.8.1 Ethernet Setup 33

2.8.2 Serial Commands Available 35

2.8.3 Using TCP/IP GUI 36

2.8.4 User Configuration 39

3

Operation

3.0 Controls and Display 42

3.0.1 LCD Display 42

3.0.2 Scroll Push Button 44

3.0.3 Cool Push Button 44

3.0.4 Defrost Push Button 44

3.0.5 Standby Push Button 44

3.0.6 ON/OFF Puss Button 45

3.1 Operation 45

3.1.0 Main Isolator 45

3.1.1 Turning On the Unit 45

3.1.2 Standby 45

3.1.3 Cool 45

3.1.4 Defrost 45

3.1.5 Defrost Recovery Period 46

3.2 Normal Operating Ranges 46

4

Trouble Shooting Guide

4.0 Refrigeration Leaks 47

4.1 Alarm Codes/Messages 47

4.2 Safety Systems 48

4.2.1 Hardware Safety systems 48

4.3 Trouble Shooting Guide 50

4.4 Use of Top-off Charges 53

4.5 Emerson Compressor trouble

Shooting guide 53

4.5.1 Emerson Diagnostics 55

5

Decommissioning 58

6

Design of Cryo-coils 59

7

Chinese Hazardous Substance Concentration Table 63

Telemark Cryogenics Microprocessor Based Cryochillers

Page 5of 63

Revision 1.0.7 October 2018

LIST OF FIGURES/ILLUSTRATIONS

Figures Page

1 Removing Unit from Transport Pallet 18

2 System Pressure Gauge 18

3 Services Panel 19

4 Water Flow requirements 20

5 Position of Hand Valves 21

6 Refrigerant Line Connections 21

7 Access Hand Valve 22

8 Refrigerant Manifold 22

9 Refrigerant Line Insulation 24

10 Metal “O” Ring Removal Tool 25

11 Main Isolator Wiring 26

12 Transformer Tapings 27

13 37 Way Amp Connector 30

14 Ethernet cable (crossed) 32

15 Network Connection Window 33

16 Network Properties 33

17 TCP/IP 34

18 TCP/IP Settings 34

19 TCP/IP GUI 36

20 Ethernet TCP/IP & RS232/485 Help 38

21 “cal2309” Setup Screen 39

22 Front Panel Push Buttons 42

23 Wait Start LCD Display 42

24 Pre-Cool LCD Display 43

25 Standby LCD Display 43

26 Cool LCD Display 43

27 Over Pressure Alarm LCD Display 48

28 DP High LCD Display 48

29 Emerson Compressor Front Panel 54

30 Emerson Compressor Internal Parts 54

Telemark Cryogenics Microprocessor Based Cryochillers

Page 6of 63

Revision 1.0.7 October 2018

LIST OF TABLES/INFORMATION

Table Page

1 Model 1200. 1800 & 1800 EXT Specifications 12

2 Model 2400, 3000 & 3600 Specifications 13

3 Environmental Operating Conditions 14

4 Recommended Breaker and Wire Size 14

5 Physical Dimensions 15

6 Recommended Breaker and Wire Size 27

7 37 Way Connector Pin Connection Details 29

8 Volt vs. Temperature Conversion 31

9 Serial Communication read/write Commands 35

10 Display Mnemonics and their Meaning 43

11 Normal Operating range Parameters 46

12 Alarms and Error Codes 48

13 Trouble Shooting Guide 50

14 Trouble Shooting Guide – Emerson compressor 56

15 Maximum Recommended Coil Surfaces 60

T

WARNING

1)

The sy

signific

(a)

(b)

(c)

(d)

(e)

WARNING

The system

both a fros

known asp

taken and

personnel

WARNING

Removal o

operator to

electrocuti

THE P

PROBA

THE P

DUTY

THE E

THE O

BE SO

Telemark Cryogenics

Microprocessor Based Cr

Page

7

of

63

Revision

SAFETY WARNI

system contains specific hazards, which

ificant danger to personal safety;

High voltage electrical components and

hi

refrigerant gases, which are a significa

hazard.

R

efrigerant gases, which will cause asph

confined areas.

R

efrigerant gases, which if exposed

temperatures decompose to form very

products – never smok

e in the vicinity o

any other similar system including the gas

W

ater in close proximity to high voltage ele

Hot and cold surface

s which represent a

burn / frostbite hazard.

tem contains

gases under pressure, which ma

rostbite hazard and a burn hazard. Refrigerant

sphyxiates and are mildly narcotic. Precautio

d work must only be carried out by suitably qu

el

.

l of any panels other than the front door will ex

r to high voltage components, which may resu

ution.

PHRASE WARNING IS USED WHERE THER

BABILITY OF PERSONAL INJURY OR DEA

PROVISIONS HIGHLIGHTED BE IGNORED.

Y OF BOTH THE INSTALLER/OWNER AND OP

EQUIPMENT TO BE FAMILIAR AND COM

P

OPERATION AND USES OF THE PRODUCT

OUGHT FROM THE MANUFACTURER.

Cryochillers

ion 1.0.7 October 2018

NING

S

ch present a

high

-pressure

icant frostbite

sphyxiation in

ed to high

ery toxic by

-

y of a

UNIT or

gas cylinders.

electricity.

t a significant

ay constitute

nt gases are

tions must be

qualified

l expose the

sult in a fatal

ERE IS A HIGH

EATH SHOULD

D. IT IS THE

OPERATOR OF

PETENT WITH

CT. HELP MAY

T

WARNING

During ins

voltage co

electrocuti

WARNING

U

nits mus

Failure to c

with or rem

machine.

WARNING

Isolate sys

used is co

within the

three powe

Feed cable

having firs

primary gr

WARNING

Failure to r

fatal electr

be in place

WARNING

Always iso

attaching t

additional

WARNING

Failure to l

catastroph

risk from f

shutdown

guidance.

WARNING

The r

refriger

health

precau

a)

A

A

Telemark Cryogenics

Microprocessor Based Cr

Page

8

of

63

Revision

nstallation there is the potential to be exposed

components (up to

400v ac), which may result

ution.

ust always be operated with a suitable ground/

to comply may result in fatal electrocution. Nev

remove any ground/earth connection from insi

ystem before connection. Ensure the connect

compliant with local electrical requirements. C

e unit is tri

-

rated to CSA/UL/CE norms. There

wer wires and one ground wire; there is no ne

ble through gland and terminate at main syste

irst removed the protective cover. Ground the

ground point.

to replace

isolator cover exposes operators to

ctrocution. It is essential this primary protecti

ce before the system is energised.

isolate the system through the main circuit bre

g the

remote control. When in remote operatio

al care to prevent personal injury.

to leak test the system as a whole, may result i

phic release of refrigerant, which presents a v

frostbite and or

asphyxiation. See emergenc

n procedures and material safety data sheet f

e.

refrigeration system contains a mixed

gerants and polio

-

ester oil. These do not pr

th risks, but it is essential

that the follo

autions are followed:

A

lways wear eye protection.

A

lways wear surgical type rubber or latex glo

Cryochillers

ion 1.0.7 October 2018

ed to high

ult in a fatal

d/earth line.

ever tamper

side of

the

ction cable

. Cabling

re

must be

neutral line.

tem isolator,

the

UNIT at

to potentially

ction always

breaker before

tion take

lt in the

very high

ncy

t for

ed blend of

present acute

llowing basic

loves.

T

CAUTION

CAUTION

Telemark w

consequent

misuse of th

CAUTION

If the equip

manufactur

by impaired

CAUTION

It is the resp

county, stat

related to s

each install

equipment

CAUTION

-

HOT SU

High tempe

Avoid conta

during norm

CAUTION

-

COLD S

Freeze Burn

normal ope

CAUTION

-

PRESUR

Unit contain

system is c

for leaks. D

their design

manufactur

CAUTION

-

HAND V

Closure of t

temperature

systems wa

cryogenical

is causing g

lines.

The ph

produc

provis

Telemark Cryogenics

Microprocessor Based Cr

Page

9

of

63

Revision

will not be responsible or liable for either dire

ential personal injury or loss claims arising fro

f the product.

ipment is used in a

manner not specified by th

turer, the protection provided by the equipmen

red

esponsibility of the user to make sure all local,

tate and national codes, regulations, rules and

safety

and safe operating conditions are mee

allation. The safety of any system incorporatin

nt is the responsibility of the assembler of the

URFACE

peratures are generated during normal operati

ntact with exposed pipe

-

work as this can get h

rmal operation.

SURFACE

urn Risk. Very low temperatures generated du

peration. Avoid contact with exposed pipe

-

wo

URISED GAS

ains pressurised gas. Do not open hand valve

connected to a Cryo

-

coil, which has been che

. Do not connect the system to other systems

ign and application has been approved by the

turer

VALVES

f the hand valves while the system is at cryog

ures may damage the valve seats and invalida

warranty. It must only be attempted on a

cally cold system in the case of an emergency,

g gross leakage f

rom the Cryo-

coil or refrigera

phrase

“

Caution

”

indicates a risk of damage t

uct or

associated plant and machinery if the

isions are not followed

carefully.

Cryochillers

ion 1.0.7 October 2018

irect or

from the

the

ent may

al,

nd laws

eet for

ting the

e system.

ation.

t hot

during

work

.

lves until

hecked

s unless

e

ogenic

date the

cy, which

rant

e to the

Telemark Cryogenics Microprocessor Based Cryochillers

Page 10 of 63

Revision 1.0.7 October 2018

WARRANTY

Telemark Cryogenics Cryochiller products are warranted to be free from

defects in materials and/or workmanship under normal usage until warranty

effective date listed on serial number label. Telemark Cryogenics’ obligation

under this Warranty is limited to the repair or replacement, at its option, of any

parts, which upon examination at the Telemark Cryogenics factory or by an

authorised sales/service representative, shall appear to have become

defective. Correction of defects by repair or replacement shall be either at the

Telemark factory or in-situ by an authorised service representative. The

location of repair shall be at the discretion of Telemark Cryogenics. Repairs

carried out at Telemark Cryogenics factory shall be FOB Telemark factory

and shall constitute fulfilment of obligations to the purchaser. All

transportation costs for defective parts or products shall be borne by the

purchaser. Telemark Cryogenics will not be liable for loss, damage, or other

expenses directly or indirectly arising from the use of its products or from any

other causes. Telemark assumes no liability for expenses or repairs made

outside of its factory by non-authorised personnel.

All claims on account of defective material or workmanship shall be deemed

waived unless made in writing within the aforementioned warranty period.

The foregoing Warranty is in lieu of all other warranties expressed or implied.

Telemark neither assumes nor authorises any other person to assume any

other obligation or liabilities in conjunction with the sale of its products. This

Warranty shall be void if the equipment has been subject to misuse,

negligence or application outside of recommended operating environment or

conditions. The Warranty will also be invalidated if the identification numbers

of the system have been altered, defaced or removed.

The Warranty is not intended to supplant any statutory rights the purchaser

may have.

Unit start and end dates are printed on the unit’s serial number label.

USER RESPONSIBILITY

The user is responsible for proper installation, operation and ordinary

maintenance of the equipment following the procedures in this manual. The

warranty may be void if the equipment is improperly installed. Alteration of

the design and or any function of the equipment voids the warranty and is

entirely the responsibility of the user.

Telemark will not be held responsible or liable for either director

consequential personal injury or loss claims arising from the misuse of the

product

The user should read this manual in its entirety before carrying out any

work and or operation of a Telemark Cryochiller.

Telemark Cryogenics Microprocessor Based Cryochillers

Page 11 of 63

Revision 1.0.7 October 2018

INTENDED USE OF THE

EQUIPMENT

Water vapor Cryochiller is a device that improves the performance of vacuum

pumping due to the efficient trapping of water vapor in the chamber.

Classically a Cryochiller is used with an evaporative surface (Meissner/cryo-

coil), which is located within the vacuum chamber. When in this configuration

a Telemark Cryochiller is an ultrahigh performance vacuum pump capable of

pumping water vapor and other condensable gases at speeds far in excess of

conventional vacuum pumps.

A Telemark Cryochiller couples speed with a sophisticated computer control

package which includes a simple and adaptable user interface with isolated

inputs/outputs and Ethernet comms package as standard. RS232 and RS485

serial communication options are available.

The ranges of tasks to which your Cryochiller can be applied are not limited to

pumping water vapor in vacuum. Many are used as substrate coolers (chuck

coolers) or other applications where a continuous level of high power cooling

in the range –100 to –150

o

c is required.

STANDARDS

The device is compatible in terms of electromagnetic compatibility and safety

standards. Applicable standards:

EMC: DIRECTIVE 2014/30/UE - STANDARD EN 61326-1:2013

LVD: DIRECTIVE 2014/35/EU - STANDARD EN 61010-1:2011

And applicable causes of the standard: EN 378-2:2008

Telemark Cryogenics Microprocessor Based Cryochillers

Page 12 of 63

Revision 1.0.7 October 2018

1

SPECIFICATIONS

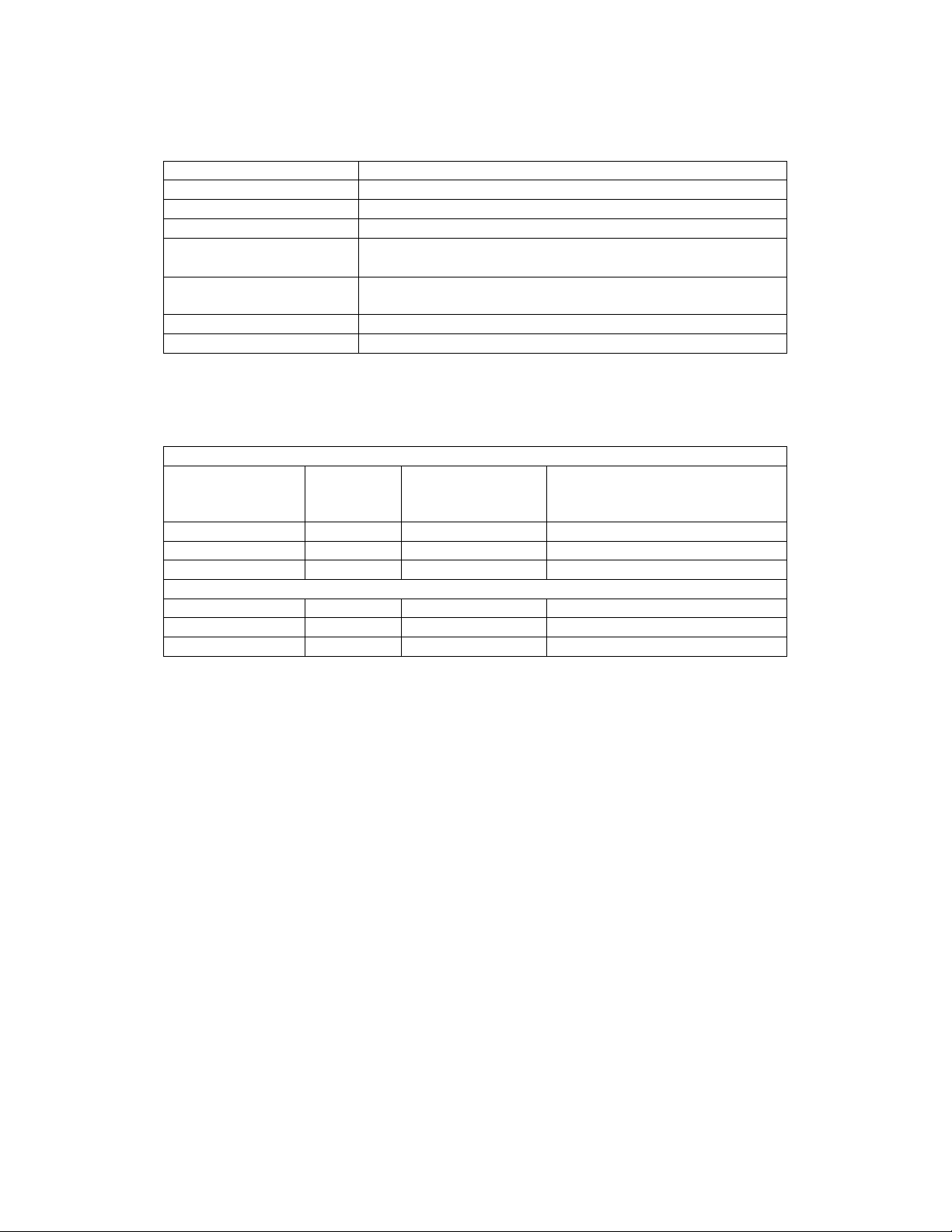

Model

1200

Model

1800

Model

1800EXT

Maximum Load (Watts) 1,200 1,800 1,800

Typical

Pumping Speed (l/sec) 65,000 100,000 100,000

Ultimate Vacuum 2 x10

-

8

mbar (2 x10

-

6

Pa) 2 x10

-

8

mbar (2 x10

-

6

Pa) 2 x10

-

8

mbar (2 x10

-

6

Pa)

Weight (Kg) 193 (432 lbs) 243 (536 lbs) 243 (536 lbs)

Size inch (mm)

L

W

H

24 (559)

22 (610)

59.5 (1511)

24 (559)

22 (610)

59.5 (1511)

24 (559)

22 (610)

59.5 (1511)

Power supply

380-444VAC 3 ph 50Hz

460VAC 3 ph 60 Hz

200-230VAC 3 Ph 50/60 Hz

380-444VAC 3 ph 50Hz

460VAC 3 ph 60 Hz

200-230VAC 3 Ph 50/60 Hz

380-444VAC 3 ph 50Hz

460VAC 3 ph 60 Hz

200-230VAC 3 Ph 50/60 Hz

Wire/Cable Connection 3 Phase + Ground (Earth) 3 Phase + Ground (Earth) 3 Phase + Ground (Earth)

Full Load Current draw @

60 Hz (Amps)

@200-230VAC

@380-440VAC

20

10

30

15

30

15

Start Up Max

Current Draw @ 60 Hz

(Amps)

@200-230VAC

@380-440

30

15

60

30

60

30

Compressor Horsepower

(HP) 4.5 (3.35kW) 7.5 (5.59Kw) 7.5 (5.59kW)

Water Requirements

(l/min)

@ 15°C

@ 25°C

@ 32°C

5

10

20

5

10

20

5

10

20

Water Connections All Models ¾” NPT Female

Water Resistivity All Models >0.1MChloride Free

Water Ph All Models 6.5 - 8

Refrigeration Connections ½” Metal Seal ½” Metal Seal ½” Metal Seal

Max Coil Length (Meters)

Using ½” Cu tube 20 (65.6 ft) 25 (82 ft) 25 (82 ft)

Max Surface area (M

2

) 0.79 (≈8.57 ft

2

) 0.99 (≈10.72 ft

2

) 0.99 (≈10.72 ft

2

)

*Avg. Cool Time (mins) 2-5 2-5 2-5

*Avg. Defrost Time (mins) 2-4 2-4 2-4

∆T Coil in/Coil Out (°C) ≈5 ≈5 ≈5

Digital Remote

Connections

Input Voltage range

18-24VDC (30VDC MAX) 18-24VDC (30VDC MAX) 18-24VDC (30VDC MAX)

Digital Remote

Connections

Output Voltage range

Relay contact closure 200

VAC or 100VDC Max at

300mA

Relay contact closure 200

VAC or 100VDC Max at

300mA

Relay contact closure 200

VAC or 100VDC Max at

300mA

Balance Pressure Range

as Shipped from Telemark

USA facility

(PSI) @20°C

(hand valves closed)

270-300

(1.86-2.07MPa)

220-250

(1.51-1.72MPa)

180-210

(1.24-1.45MPa)

Table 1 Model 1200, 1800, 1800EXT Specifications

Telemark Cryogenics Microprocessor Based Cryochillers

Page

13

of

63

Revision 1.0.7 October 2018

Model

2400

Model

3000

Model

3600

Maximum Load (Watts) 2400 3000 3,600

Typical

Pumping Speed (l/sec) 135,000 165,000 200,000

Ultimate Vacuum 2 x10

-

8

mbar (2 x10

-

6

Pa) 2 x10

-

8

mbar (2 x10

-

6

Pa) 2 x10

-

8

mbar (2 x10

-

6

Pa)

Weight (Kg) 243 (485 lbs) 384 (845 lbs) 412 (930 lbs)

Size inch (mm)

L

W

H

24 (559)

22 (610)

59.5 (1511)

35.3 (897)

23.6 (897)

70.25 (1784)

35.3 (897)

23.6 (897)

70.25 (1784)

Power supply

380-444VAC 3 ph 50Hz

460VAC 3 ph 60 Hz

200-230VAC 3 Ph 50/60 Hz

380-444VAC 3 ph 50Hz

460VAC 3 ph 60 Hz

200-230VAC 3 Ph 50/60 Hz

380-444VAC 3 ph 50Hz

460VAC 3 ph 60 Hz

200-230VAC 3 Ph 50/60 Hz

Wire/Cable Connection 3 Phase + Ground (Earth) 3 Phase + Ground (Earth) 3 Phase + Ground (Earth)

Full Load Current draw @

60 Hz (Amps)

@200-230VAC

@380-440VAC

40

20

50

25

60

30

Start Up Max

Current Draw @ 60 Hz

(Amps)

@200-230VAC

@380-440

60

30

60

30

85

45

Compressor Horsepower

(HP) 10 (7.46kW) 13 (9.69kW) 15 (11.19kW)

Water Requirements (l/min)

@ 15°C

@ 25°C

@ 32°C

6

12

30

6

12

30

8

16

30

Water Connections ¾” NPT Female

Water Resistivity All Models >0.1MChloride Free

Water (Ph) All Models 6.5 - 8

Refrigeration Connections ½” Metal Seal ½” Metal Seal ½” Metal Seal

Max Coil Length (Meters)

Using ½” Cu tube 35 (114.8 ft) 40 (131.2 ft) 50 (164.0 ft)

Max Surface area (M

2

) 1.39 (≈15 ft

2

) 1.59 (≈17.1 ft

2

) 1.99 (≈21.42 ft

2

)

*Avg. Cool Time (mins) 2-5 2-5 2-5

*Avg. Defrost Time (mins) 2-4 2-4 2-4

∆T Coil in/Coil Out (°C) ≈5 ≈5 ≈5

Digital Remote

Connections

Input Voltage range

18-24VDC (30VDC MAX) 18-24VDC (30VDC MAX) 18-24VDC (30VDC MAX)

Digital Remote

Connections

Out Voltage range

Relay contact closure 200

VAC or 100VDC Max at

300mA

Relay contact closure 200

VAC or 100VDC Max at

300mA

Relay contact closure 200

VAC or 100VDC Max at

300mA

Balance Pressure Range

as shipped from Telemark

USA facility

(PSI) @20°C

(hand valves closed)

190-220

(1.31-1.52MPa)

250-280

(1.72-1.93MPa)

250-280

(1.72-1.93MPa)

IMPORTANT

.

The above performance figures are based for a unit

running at 60Hz mains power frequency. For units running on 50 Hz

mains frequency the figures above need to be de-rated by 0.83.

Table 2 Model 2400, 3000, 3600 Specifications

Telemark Cryogenics Microprocessor Based Cryochillers

Page 14 of 63

Revision 1.0.7 October 2018

1.1 Environmental conditions (all models)

Parameter Value

Type Indoor use

Altitude

Up to 2000m

Temperature range (°C) 5 - 40

Humidity (%Rh) Maximum relative 80% for temperatures up to 31

⁰

C

decreasing linearly to 50% relative humidity at 40

⁰

C

Mains supply voltage

fluctuations

Up to 10% of the nominal voltage

Pollution degree 2

Overvoltage category

II

Table 3 Environmental Conditions

1.2 Croychiller - recommended circuit breaker Values and Wire Size

200-230VAC Vac Three-Phase

Nominal current

rating[A]

Fuse

Rating [A]

Minimum copper

wire

AWG/mm

2

Cable Type

(recommended)

30 70 8 / 10 H07RN-F 450/750V 4G10

50 100 6 / 16 H07RN-F 450/750V 4G16

60 125 4 / 25 H07RN-F 450/750V 4G25

380-444VAC Three-Phase

15 30 14 / 2.5 H07RN-F 450/750V 4G2.5

25 45 10 / 6 H07RN-F 450/750V 4G6

30 60 10 / 6 H07RN-F 450/750V 4G6

Table 4 Recommended Breaker and Wire Size

Telemark Cryogenics Microprocessor Based Cryochillers

Page

15

of

63

Revision 1.0.7 October 2018

1.3 Cryochiller Physical Dimensions

Model A (inch) A (mm) B (inch) B (mm) C (inch) C (mm)

1200 22 559 24 610 59.5 1511

1800 22 559 24 610 59.5 1511

1800EXT 22 559 24 610 59.5 1511

2400 22 559 24 610 59.5 1511

3000 23.6 599 35.3 897 70.25 1784

3600 23.6 599 35.3 897 70.25 1784

A

A

B

B

C

C

Table 5 Physical Dimensions

T

Safety and

Caution

WARNING

Failing to leak

catastrophic r

from frostbite

procedure an

WARNING

The system

u

components.

always isolate

system. A qu

connections

,

WARNING

The system c

both a frostbit

known

asphy

taken. Work

Always wear

WARNING

All refrigeratio

manipulated m

laws require i

certification o

countries mig

regulations sh

be paid to con

Telemark Cryogenics

Microprocessor Based Cr

Page

16

of

63

Revision

INSTALLAT

onary Notes for Installation.

ak test the system as a whole may result in the

ic release of refrigerant, which presents a very hig

ite and/or asphyxiation. See emergency shut

dow

and

material safety data sheet.

uses

high voltage (208 or 415VAC) and high pow

ts. To avoid the possibility of a fatal electrical sho

late the unit from the mains supply before working

qualified technician, as for all high power electrica

, should carry out the electrical work

contains gases under pressure, which may cons

tbite hazard and a burn hazard. Refrigerant gases

hyxiates

and are mildly narcotic. Precautions mus

rk must only be carried out by suitably qualified pe

ar suitable eye and protection

ation work in which the refrigerant gas is moved or

d must be

done by a qualified technician. Many n

e individuals who perform such work must have a

of Refrigeration Technician. Other laws in variou

ight govern use or service of this system. Local

should be s

trictly adhered to. Particular attention

containment and recovery of refrigerants.

Cryochillers

ion 1.0.7 October 2018

2

ATION

high risk

own

power

hock

ng on the

ical

nstitute

ses are

ust be

personnel.

or

y national

a

ious

al

ion should

T

WARNING-

TIP OVER RI

Use proper

from the pa

WARNING –

HEAVY OBJ

Telemark

to 412Kg (9

result in inj

CAUTION

–

PRESU

Unit contain

system is co

leaks. Do n

design and

and t

hey ha

CAUTION

–

ENVIRO

Do not relea

dangerous;

regarding th

Safety Data

to your loca

2.0

Unpacking and Inspe

Before unpacking the

condition.

The case is reusable a

respect. When remov

containing the

refriger

components are not

d

2.1 The unit

is mounted to

on which the unit is

No

or

the

Telemark Cryogenics

Microprocessor Based Cr

Page

17

of

63

Revision

RISK

per lifting equipment and protocols when removing

pallet

BJECT RISK

Cryochillers weigh a minimum of 193Kg (432

lb)

g (930lb). Failure to follow correct lifting practices

injury or death

SURISED GAS

ains pressurised gas. Do not open hand valves un

connected to a Cryo

-

coil, which has been checke

o not connect the system to other systems unless

d application has been approved by the manufac

have been assessed fro leak tightness

IROMENTAL RISK

lease refrigerant into the atmosphere it is illegal an

s; please refer to your local authorities instruction

the disposal of reclaimed refrigerants.

Read the

ta Sheet before installing the system. Verify com

cal

regulations.

spection

he unit please verify that the packaging is in good

le and recyclable. Please treat the environment w

oving the unit from the case ensure that any bags

eration line connections, tool kit and other essent

discarded.

to the pallet with four

packing bolts

. The woode

is shipped must be removed prior to installatio

Note:

The unit must only be moved either by forkl

or strapping through the fork lift truc

k points locate

the side of the unit.

Cryochillers

ion 1.0.7 October 2018

ing the unit

lb) and up

es may

until

ked for

ss their

acturer,

l and

ons

he Material

mpliance

od

t with

gs/boxes

ential

den

pallet

tion

.

rklift truck

ated to

Telemark Cryogenics Microprocessor Based Cryochillers

Page

18

of

63

Revision 1.0.7 October 2018

2.2 System Pressure

The unit is shipped fully charged. See Tables 1 and 2 (Section 1

“Specifications”) above for shipping pressure range of each model. The exact

shipping pressure is noted on the packing list. A pressure gauge is mounted

behind the front panel or to the right hand side of the unit. The static pressure

may vary by up to +/- 16 psi due to changes in the ambient temperature.

Fig 1 Removing Unit from transportation pallet

Fig 2 Pressure gauge

Telemark Cryogenics Microprocessor Based Cryochillers

Page

19

of

63

Revision 1.0.7 October 2018

2.3 Location

The unit should be placed and a clean level floor and positioned to minimise

the length of the refrigeration lines. It is also important that the lines are well

supported and are manufactured from annealed copper tubing allowing for

thermal expansion and vibration. The units should be placed at least 3”

(80mm) away from the nearest obstructions to allow for sufficient air flow to

the unit.

2.4 Panel Removal.

Remove the front panel to gain access to “hand valve” gas box. Remove the

6 (or 8 screws depending upon model) and remove the front panel exposing

the hand valves. Remove the right hand side panel where the isolator handle

is located.

Note: the panel can only be removed with the isolator

switch in the “OFF” position

Fig 3 Services Panel

Remote

Interface

Connector

Power Cable Entry

Point

Main

Power

Isolator

Digital Interface

Port (Ethernet)

Balance/Suction

Pressure Gauge

24 VDC Circuit

Breaker

Telemark Cryogenics Microprocessor Based Cryochillers

Page

20

of

63

Revision 1.0.7 October 2018

2.5 Water Connections

The advanced design of the unit means it is capable of operating over a

wide range of water temperatures. While Liquid Line temperature (LT on the

display) is preset to 40°C maximum, there is littl e loss of performance with

water (outlet – this is not displayed on the unit) temperatures as high as 35

°

C.

Higher water temperatures result in a slight loss of capacity while water colder

than 15°C will slow the systems response and lead to undue condensation on

water lines.

In-house re-circulating water-cooling system is required. Water must be free

from chlorides and sufficiently soft to prevent the build up of lime scale (0.1

M

resistivity). Ensure that the water is clean and free from any clogging

debris. The Ph value should be between 6.5 and 8. The water inlet and

outlet pipe-work needs to have a minimum diameter of ¾ inch (15mm). The

use of a suitable biocide can be beneficial when used in closed loop water

systems.

Connect the water lines to the unit ensuring the correct orientation of the

water lines (see fig 3 above). Turn on water flow and ensure no leakage is

present at connectors. Open the cabinet and check visually for water

leaks inside the cabinet.

Water temperature below ambient temperature, may cause condensation.

Additional insulation of the internal water lines may be required if the cooling

water temperature is low and the ambient humidity is high.

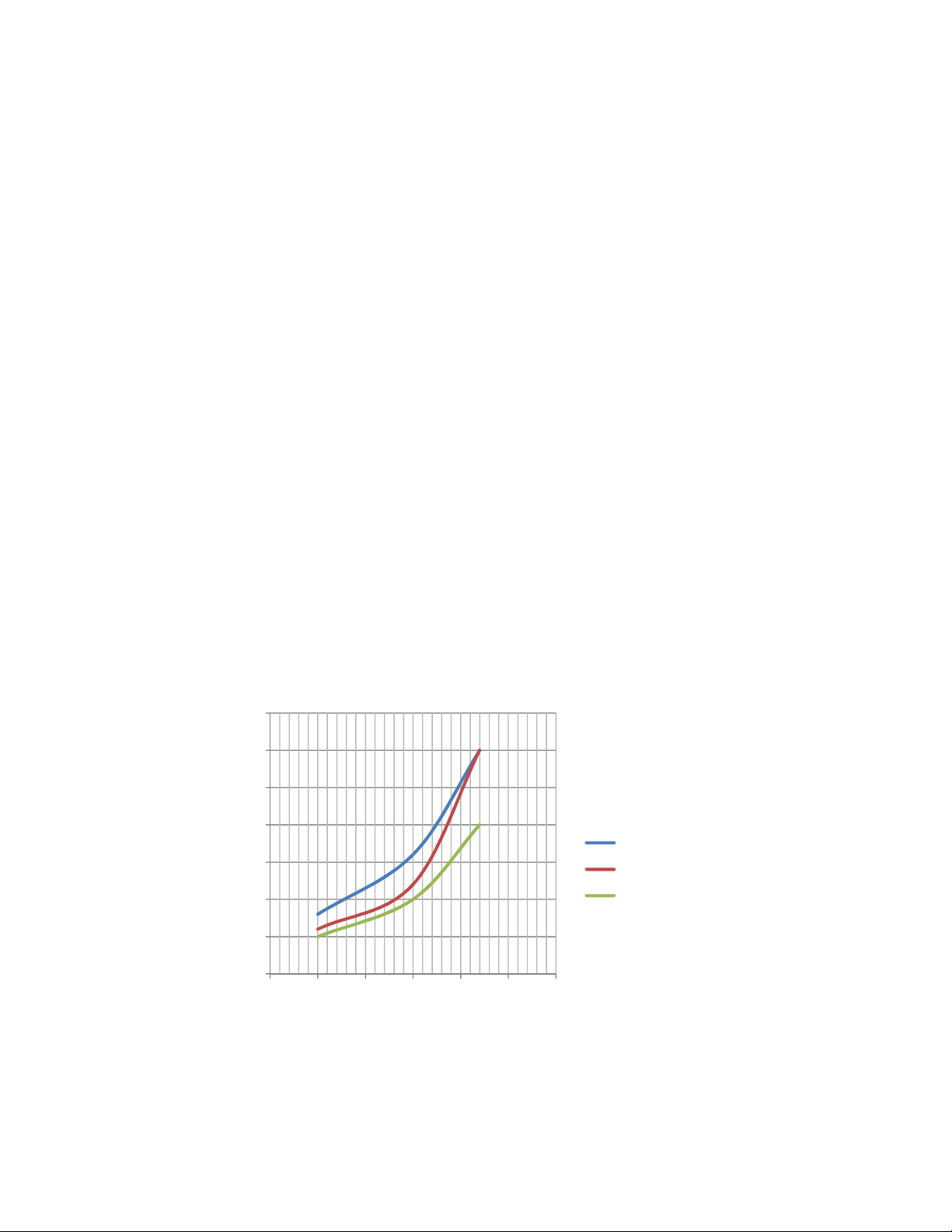

The graph (fig 4) below indicates the cooling water flow required at varying

inlet temperatures. As a practical limit, a flow rate of 30 l/min is

approximately equivalent to a 15psi (1bar) pressure drop across the Unit.

0

5

10

15

20

25

30

35

10 15 20 25 30 35 40

Water Flow (l/min)

Water Temperature (C)

3600

3000, 2400

1200,1800 1800EXT

Fig 4, Water flow Requirements

This manual suits for next models

5

Table of contents

Other Telemark Cryogenics Laboratory Equipment manuals