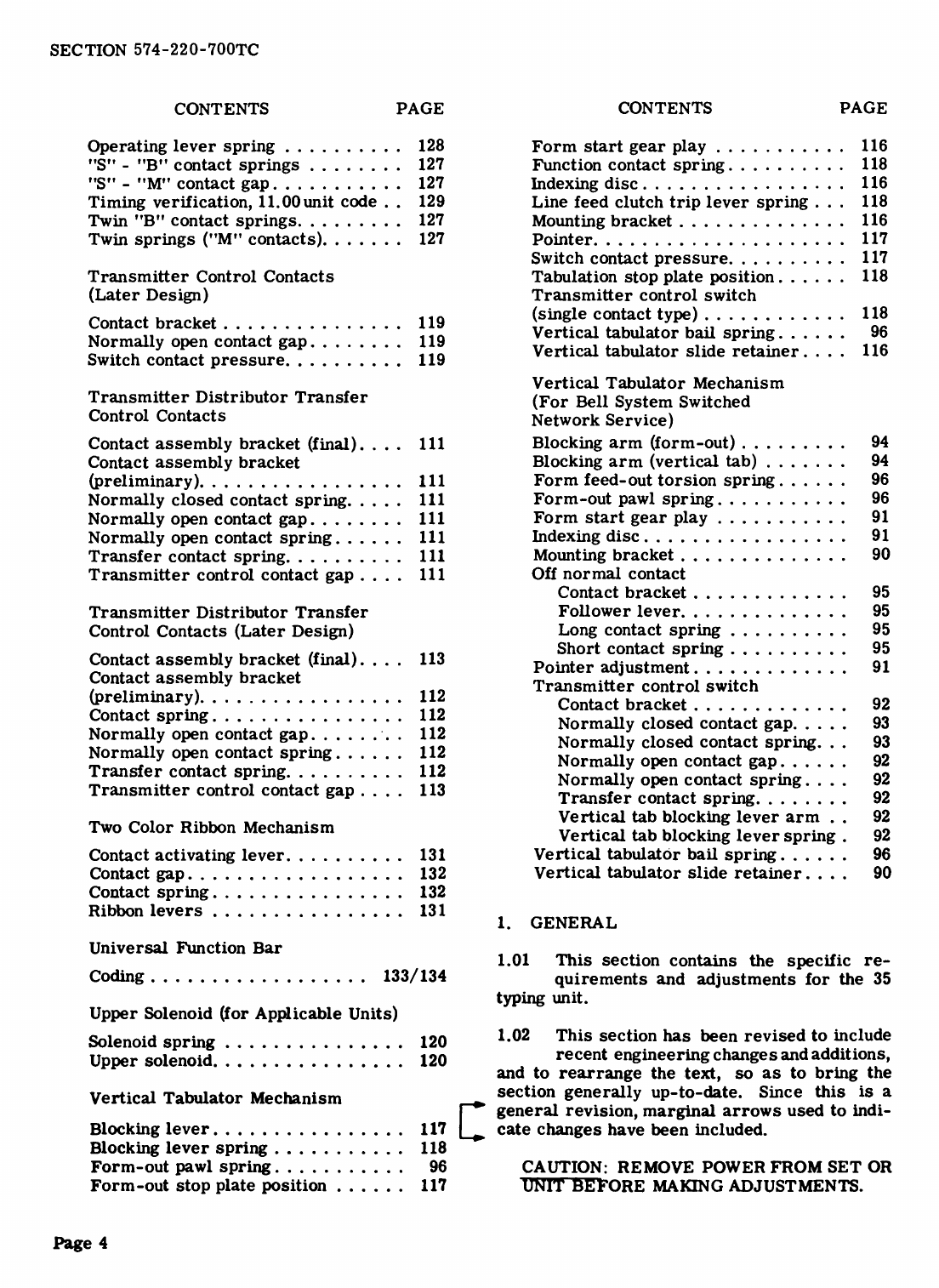

ISS 8, SECTION 574-220-700TC

1.03 The adjustments in this section are ar-

ranged in a sequence that should be fol-

lowed if a complete readjustment of the unit is

undertaken. A complete adjusting procedure

should be read before attempting to make the

adjustment. After an adjustment is completed,

be sure to tighten any nuts or screws that may

have been loosened, unless otherwise instructed.

1. 04 The adjusting illustrations indicate toler-

ances, positions of moving parts, spring

tensions, and the angle at which scales should be

applied. The tools required to make adjustments

and check spring tensions are not supplied with

the equipment, but are listed in Section

570-005-800TC. Springs which do not meet the

requirements, and for which there are no ad-

justing procedures, should be discarded and

replaced by new springs.

1.05 References made to left, right, up, down,

front, rear, etc, apply to the unit in its

normal operating position as viewed from the

front.

1.06 When a requirement calls for a clutch to

be disengaged, the clutch shoe lever must

be fully latched between its trip lever and latch-

lever so that the clutch shoes release their ten-

sion on the clutch drum. When engaged, the

clutch shoe lever is unlatched and the clutch

shoes are wedged firmly against the clutch drum.

Note: When the main shaft is rotated by hand,

the clutch does not fully disengage upon reach-

ing its stop position. In order to relieve drag

and permit the main shaft to rotate freely,

apply pressure on the lug of the clutch disc

with a screwdriver to cause it to engage its

latch lever and fully disengage the clutch.

1.07 To manually operate the typing unit

proceed as follows.

(a)

Attach the TP312709 armature clip to the

selector magnet armature by carefully

placing the spring loop over the magnet ter-

minal insulator. Press down to engage the

hook of the clip on the underside of the arma-

ture and release. The spring tension of the

armature clip will hold the selector arma-

ture in the marking (attracted) position.

(b)

While holding the selector magnet arma-

ture operated by means of the armature

clip, use the handwheel, included with the

special tools for servicing 28 teletypewriter

apparatus, to manually rotate the main shaft

in a counterclockwise direction until all the

clutches are brought to their disengaged

position.

(c)

Fully disengage all clutches in accord-

ance with 1.06, Note.

(d)

Release the selector magnet armature

momentarily to permit the selector

clutch to engage.

(e)

Rotate the main shaft slowly until all the

pushlevers have fallen to the left of their

selecting levers.

(f)

Strip the pushlevers from their selector

levers, which are spacing in the code

combination of the character function that is

being selected, and allow the pushlevers to

move to the right.

(g)

The pushlevers and the selector levers

move in succession starting with the no. 1

to the no. 7; the no. 8 is always marking and

is not equipped with a selector lever.

(h)

Continue to rotate the main shaft until all

operations initiated by the selector action

clear through the unit.

1.08 Where adjustment instructions call for

removal of components, assemblies,

subassemblies or parts, all adjustments which

the removal of these parts might facilitate should

be made before the parts are replaced or as the

equipment is reassembled. When a part mounted

on shims is removed, the number of shims and

their location should be noted so that the iden-

tical pile-up can be made when the part is re-

placed.

1.09 All electrical contact points should meet

squarely. Contacts with the same dia-

meter should not be out of alignment more than

25 percent of the contact diameter. Check con-

tacts for pitting and corrosion and clean or bur-

nish them before making specified adjustment or

tolerance measurement. Avoid sharp kinks or

bends in the contact springs.

CAUTION: KEEP ALL ELECTRICAL CON-

TACTS FREE OF OIL AND GREASE.

1. 10 When making a complete adjustment of

the unit, the following conditioning op-

erations should be performed to prevent damage.

(a) Loosen the shift lever drive arm clamp

screw (2.13).

Page 5