TELink BLE 1x6 Test System 3.2 Quick guide

Application Note:

Assembly And Maintenance

Manual for Telink BLE 1x6

Test System 3.2

AN-18071200-E1

Ver 1.0.0

2018/7/12

TELINK SEMICONDUCTOR

Brief:

This document is the assembly and maintenance guide

for Telink BLE 1x6 Test System 3.2, and presents DUT

examples with flash or OTP.

Telink for customer

Assembly And Maintenance Manual for Telink BLE 1x6 Test System 3.2

AN-18071200-E1 1 Ver 1.0.0

Published by

Telink Semiconductor

Bldg 3, 1500 Zuchongzhi Rd,

Zhangjiang Hi-Tech Park, Shanghai, China

© Telink Semiconductor

All Right Reserved

Legal Disclaimer

Telink Semiconductor reserves the right to make changes without further notice to

any products herein to improve reliability, function or design. Telink Semiconductor

disclaims any and all liability for any errors, inaccuracies or incompleteness contained

herein or in any other disclosure relating to any product.

Telink Semiconductor does not assume any liability arising out of the application or

use of any product or circuit described herein; neither does it convey any license

under its patent rights, nor the rights of others

The products shown herein are not designed for use in medical, life-saving, or

life-sustaining applications. Customers using or selling Telink Semiconductor products

not expressly indicated for use in such applications do so entirely at their own risk

and agree to fully indemnify Telink Semiconductor for any damages arising or

resulting from such use or sale.

Information:

For further information on the technology, product and business term, please

contact Telink Semiconductor Company (www.telink-semi.com).

For sales or technical support, please send email to the address of:

telinkcnsales@telink-semi.com

telinkcnsupport@telink-semi.com

Telink for customer

Assembly And Maintenance Manual for Telink BLE 1x6 Test System 3.2

AN-18071200-E1 2 Ver 1.0.0

Revision History

Version

Major Changes

Date

Author

1.0.0

Initial release

2018/7

LWH, LX, Cynthia

Telink for customer

Assembly And Maintenance Manual for Telink BLE 1x6 Test System 3.2

AN-18071200-E1 3 Ver 1.0.0

Table of contents

1Overall Architecture Of 1x6 Test System 3.2..........................................................5

2Hardware Platform Building .................................................................................10

2.1 Check External Antenna.................................................................................10

2.2 Hardware assembly .......................................................................................11

2.3 Cable connection ...........................................................................................13

2.3.1 Test sites on Main board ........................................................................13

2.3.2 Test sites on Display board .....................................................................14

2.3.3 Cable connection between Main board and DUT thimble .....................15

2.3.4 Cable connection between Buzzer board and Thimble board ...............16

2.3.5 Cable connection between Main board and Display board ...................16

2.3.6 Cable connection between Main board and PCB antenna board ..........16

2.3.7 Other cable connection ..........................................................................17

2.4 Check Jig debugging.......................................................................................20

3Firmware Burning For EVK Daughter Boards .......................................................22

3.1 Folder structure for Test Bench Firmware.....................................................22

3.2 Firmware burning for EVK daughter boards..................................................25

4Observe Test Result Via PC Software EvkMonitor ...............................................28

5Update PCBA (DUT) Firmware..............................................................................31

Appendix 1 Test Item List On PC Software “EvkMonitor”......................................34

Appendix 2:Hardware List.........................................................................................40

Appendix 3:Pins on test site of Main board..............................................................41

Appendix 4:Dimension chart of Main board, Thimble board, Display board, EVK

daughter board and Buzzer board...............................................................................43

Telink for customer

Assembly And Maintenance Manual for Telink BLE 1x6 Test System 3.2

AN-18071200-E1 4 Ver 1.0.0

Table of figures

Figure 1 Top view of Main board.........................................................................5

Figure 2 EVK daughter board...............................................................................6

Figure 3 Power board ..........................................................................................6

Figure 4 Display board .........................................................................................7

Figure 5 Thimble board .......................................................................................7

Figure 6 PCB antenna board and RF cable ..........................................................7

Figure 7 Buzzer module.......................................................................................8

Figure 8 System connection chart .......................................................................9

Figure 9 Telink PCB antenna board....................................................................10

Figure 10 Sliding block to fix PCB antenna.......................................................10

Figure 11 Telink PCB antenna dimensions .......................................................10

Figure 12 Top view of Main board ...................................................................11

Figure 13 Assembly chart on the bottom side of Main board.........................12

Figure 14 Top silk-screen sketch of Main board ..............................................13

Figure 15 Bottom silk-screen of Display board ................................................14

Figure 16 Connection points on test site of Display board..............................14

Figure 17 Cable connection chart ....................................................................17

Figure 18 1x6 Test system 3.2 ..........................................................................18

Figure 19 Cable connection sketch of Main board ..........................................18

Figure 20 Cable connection of Display, Antenna, Thimble board and DUT

thimble.........................................................................................................19

Figure 21 Connection chart between EVK daughter board and PC.................25

Figure 22 Firmware burning interface 1 for EVK daughter board....................26

Figure 23 Firmware burning interface 2 for EVK daughter board....................26

Figure 24 EvkMonitor tool interface ................................................................28

Figure 25 Pins on test site of Main board ........................................................41

Figure 26 Dimension chart of Main board.......................................................43

Figure 27 Dimension chart of Thimble board ..................................................43

Figure 28 Dimension chart of Display board....................................................44

Figure 29 Dimension chart of EVK daughter board .........................................44

Figure 30 Dimension chart of Buzzer board ....................................................45

Table of tables

Table 1 Cable connection between thimble board and DUT with flash ..........15

Table 1 Cable connection between thimble board and DUT with OTP ...........15

Telink for customer

Assembly And Maintenance Manual for Telink BLE 1x6 Test System 3.2

AN-18071200-E1 5 Ver 1.0.0

1Overall Architecture Of 1x6 Test System 3.2

Telink BLE 1x6 Test System 3.2 consists of test bench and mechanical structure.

The test bench includes hardware platform and firmware folder, and it’s provided by

Telink; while customer needs to make the mechanical structure suitable for DUT

(Device Under Test), and connect cables according to the guide in this document.

A set of Test Bench mainly contains the following hardware resources.

1) A Main Board provided by Telink. Figure 1 shows the correct direction to place

the Main board.

Figure 1 Top view of Main board

2) Six EVK daughter boards provided by Telink. Each should be burned with the EVK

firmware for test bench.

Telink for customer

Assembly And Maintenance Manual for Telink BLE 1x6 Test System 3.2

AN-18071200-E1 6 Ver 1.0.0

Figure 2 EVK daughter board

3) A Power board provided by Telink. It's pin-to-pin compatible with EVK daughter

board and serves to supply power for test system.

Figure 3 Power board

4) A Display board provided by Telink. Its top side contains six groups of LEDs and

six independent start buttons, while the bottom side contains six connectors.

a) Top view

Telink for customer

Assembly And Maintenance Manual for Telink BLE 1x6 Test System 3.2

AN-18071200-E1 7 Ver 1.0.0

b) Bottom view

Figure 4 Display board

5) Six Thimble boards. Each contains a HDMI connector and soldering points, so

that each test site of Main board can be connected with a DUT via a thimble

board. Figure 5 shows an example of thimble board.

Figure 5 Thimble board

6) Six PCB Antenna boards and six RF cables provided by Telink, as shown in Figure

6.

Figure 6 PCB antenna board and RF cable

Telink for customer

Assembly And Maintenance Manual for Telink BLE 1x6 Test System 3.2

AN-18071200-E1 8 Ver 1.0.0

7) A USB hub and six customized USB cables: The USB hub is used to connect six

EVK daughter boards and PC.

8) A PC. On PC side, the EvkMonitor tool can be used to burn firmware for EVK

daughter boards (refer to Section 3), and user can also observe test result via the

EvkMonitor (refer to Section 4).

9) Six buzzer modules (Dimension: 50.2x16mm): Each is connected with a thimble

board via a rainbow cable, thus it’s connected to corresponding GPIO and Power

of an EVK daughter board via HDMI interface of thimble board. The buzzer

modules are used for Amic test.

Each buzzer board should be placed as close to corresponding Amic as possible.

Do not contact buzzer board with Amic directly, and there should be no obstacle

between them.

Note: Buzzer boards are only supplied for DUT with MIC and not contained in the

hardware resources by default.

Figure 7 Buzzer module

Six EVK daughter boards and Power board are directly connected with

corresponding connectors on the bottom side of the Main board (refer to Section

2.2).

Telink for customer

Assembly And Maintenance Manual for Telink BLE 1x6 Test System 3.2

AN-18071200-E1 9 Ver 1.0.0

Figure below shows the system connection chart.

Figure 8 System connection chart

Telink for customer

Assembly And Maintenance Manual for Telink BLE 1x6 Test System 3.2

AN-18071200-E1 10 Ver 1.0.0

2Hardware Platform Building

2.1 Check External Antenna

Telink test bench adopts external antennas for RF test. Customer needs to check

the consistency of antennas. Figure 9 shows the PCB antenna supplied by Telink.

Figure 9 Telink PCB antenna board

Customer needs to make sliding blocks (as shown in Figure 10) which can fix the

PCB antennas. The sliding blocks are used for distance debugging between the PCB

antennas and PCBAs (DUTs) to guarantee test result consistency.

Figure 10 Sliding block to fix PCB antenna

Figure 11 shows dimensions in mm of the PCB antenna supplied by Telink.

Figure 11 Telink PCB antenna dimensions

Telink for customer

Assembly And Maintenance Manual for Telink BLE 1x6 Test System 3.2

AN-18071200-E1 11 Ver 1.0.0

2.2 Hardware assembly

Connect six EVK daughter boards (EVK0~EVK5) and Power board with

corresponding connector location on the bottom side of the Main board, as shown in

Figure 13.

Figure 12 Top view of Main board

EVK0

EVK2

EVK4

Power

NC

EVK1

EVK3

EVK5

Telink for customer

Assembly And Maintenance Manual for Telink BLE 1x6 Test System 3.2

AN-18071200-E1 12 Ver 1.0.0

Figure 13 Assembly chart on the bottom side of Main board

Note that USB interfaces of the EVK daughter boards, as well as power interface

of the Power board should be placed towards the outside direction of the Main

board.

Power board

EVK0

EVK1

EVK2

EVK3

EVK4

EVK5

NC

Main board

Telink for customer

Assembly And Maintenance Manual for Telink BLE 1x6 Test System 3.2

AN-18071200-E1 13 Ver 1.0.0

2.3 Cable connection

2.3.1 Test sites on Main board

As shown in Figure 14, the top side of the Main board contains six independent

test sites (marked as Site0~Site5 from left to right). Note that the arrow should be

placed towards right.

Figure 14 Top silk-screen sketch of Main board

Each Site on the Main board contains HDMI connector, connector A, flange plate

and connector B from top to bottom. Connector A and B are featured with dual rows,

2.54mm spacing and 2x12pin.

Telink adopts a HDMI cable to connect a thimble board with HDMI connector on

corresponding test site of the Main board, and adopts a gray flat cable to connect a

Display board with corresponding connector B of the Main board.

Please refer to Appendix 3 for illustration of test pins on the main board.

The arrow indicates direction

to place main board.

RF connector negligible to user

Telink for customer

Assembly And Maintenance Manual for Telink BLE 1x6 Test System 3.2

AN-18071200-E1 14 Ver 1.0.0

2.3.2 Test sites on Display board

As shown in Figure 15, the bottom side of the Display board contains six

independent test sites (marked as Site5~Site0 from left to right).

Figure 15 Bottom silk-screen of Display board

Each site (e.g. Site0 in Figure 16) on the Display board contains a mistake-proof

connector (marked as B) featured with dual rows, 2.54mm spacing and 2x12pin.

In Figure 16, Site0 is taken as an example to show the mark of connection points

on each test site of the Display board. G, W, R, Y and Button indicate connection

point Green-LED, White-LED, Red-LED, Yellow-LED, independent start button,

respectively.

Figure 16 Connection points on test site of Display board

G

W

R

Y

Button

GND

Telink for customer

Assembly And Maintenance Manual for Telink BLE 1x6 Test System 3.2

AN-18071200-E1 15 Ver 1.0.0

2.3.3 Cable connection between Main board and DUT thimble

Telink provides six HDMI cables. HDMI connector on each test site of the Main

board should be connected with a thimble board‘s HDMI connector via a HDMI

cable.

If DUT is a device board with flash, up to four cables should be connected

between a thimble board and a DUT.

Table 1 Cable connection between thimble board and DUT with flash

Connection points on

thimble board

Connection points on DUT

3V3D

BAT+

GND

BAT-

SWM

SWS

P45*

Wakeup GPIO*

*Note: Wakeup test supports two methods including timer wakeup and GPIO

wakeup.

1) If using timer wakeup, it’s not needed to connect P45 of thimble board with

DUT’s wakeup GPIO.

2) If using GPIO wakeup, it’s needed to connect P45 of thimble board with

DUT’s wakeup GPIO.

If DUT is a device board with OTP, up to five cables should be connected

between a thimble board and a DUT.

Table 2 Cable connection between thimble board and DUT with OTP

Connection points on

thimble board

Connection points on DUT

3V3D

BAT+

GND

BAT-

SWM

SWS

P45*

Wakeup GPIO *

VPP

VPP

*Note: Wakeup test supports two methods including timer wakeup and GPIO

wakeup.

1) If using timer wakeup, it’s not needed to connect P45 of thimble board with

Telink for customer

Assembly And Maintenance Manual for Telink BLE 1x6 Test System 3.2

AN-18071200-E1 16 Ver 1.0.0

DUT’s wakeup GPIO.

2) If using GPIO wakeup, it’s needed to connect P45 of thimble board with

DUT’s wakeup GPIO.

Figure 17 shows cable connection chart.

Note: To avoid ambient interference, all connection cables between thimble board

and DUT should use STP (Shielded Twisted Pair) cable.

2.3.4 Cable connection between Buzzer board and Thimble board

Each thimble board (connection points: P48, 3V3D, GND) should be connected

with corresponding Buzzer board (connection points: VCC, 3V3B, GND) via a 3P

rainbow cable. (Rainbow cable is supplied by Telink, and user can cut it as needed.)

Figure 17 shows cable connection chart.

Note: Buzzer boards are only supplied for DUT with MIC and not contained in the

hardware resources by default.

2.3.5 Cable connection between Main board and Display board

Telink provides six gray flat cables.

Connector B on each test site of the Main board (connection points: Green-LED,

Red-LED, White-LED, Yellow-LED, Button (Independent start button), GND) should be

connected with connector B on corresponding Site of the Display board (connection

points: G, R, W, Y, Button, GND) via a gray flat cable. Figure 17 shows cable

connection chart.

2.3.6 Cable connection between Main board and PCB antenna board

Flange plate (SMA) on each test site of the Main board should be connected

with corresponding external PCB antenna board via a RF cable. Figure 17 shows cable

connection chart.

Telink for customer

Assembly And Maintenance Manual for Telink BLE 1x6 Test System 3.2

AN-18071200-E1 17 Ver 1.0.0

RF Cable

PCB Antenna

BAT-

BAT+

SWS

DUT thimble

Gray flat Cable

HDMI Cable

Thimble board

STP cables

Display bottom

Main board

Buzzer

GND

VCC

3V3B

Rainbow Cable

VPP

Wakeup IO

Figure 17 Cable connection chart

2.3.7 Other cable connection

The Power board should be connected with power to supply power for test

system.

Each EVK daughter board should be connected with an USB interface of USB

hub via an USB cable. The USB hub should be connected with PC via an USB cable.

User can burn firmware for EVK daughter boards and observe test result via the

EvkMonitor tool on PC side (refer to Section 3 and Section 4).

Telink for customer

Assembly And Maintenance Manual for Telink BLE 1x6 Test System 3.2

AN-18071200-E1 18 Ver 1.0.0

Figure 18 1x6 Test system 3.2

Figure 19 Cable connection sketch of Main board

Main Board

Connect connector B with

gray flat cable

Connect EVK with USB hub

Connect HDMI connector

with HDMI cable

Connect flange plate

with RF cable

Connect USB hub with PC USB

USB hub

Telink for customer

Assembly And Maintenance Manual for Telink BLE 1x6 Test System 3.2

AN-18071200-E1 19 Ver 1.0.0

Figure 20 Cable connection of Display, Antenna, Thimble board and DUT

thimble

Connect Thimble board with HDMI cable

Connect PCB Antenna with RF cable

Connect Display board with gray flat cable

Connect Thimble board with DUT thimble via

STP cables

Connect Thimble board with Buzzer board

via rainbow cable

Telink for customer

Table of contents

Popular Test Equipment manuals by other brands

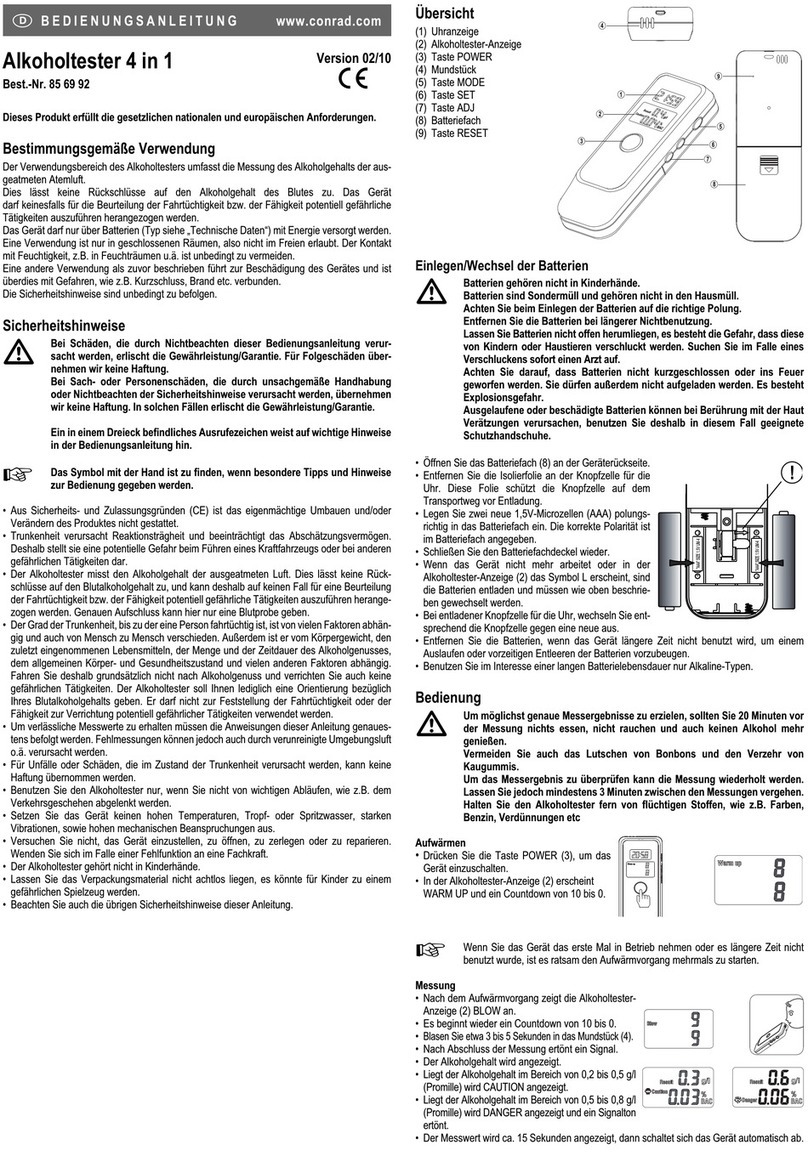

Conrad

Conrad 85 69 92 operating instructions

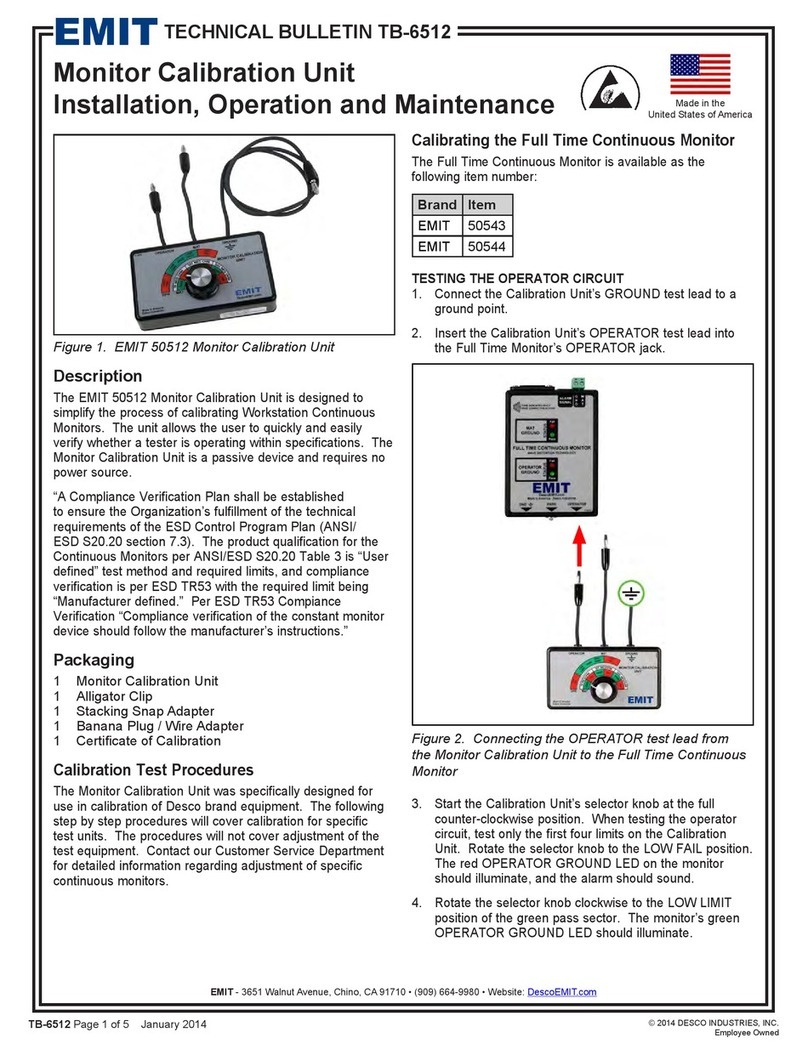

EMIT

EMIT 50512 Technical bulletin

Endress+Hauser

Endress+Hauser nivotester FTL 372-F2E1 manual

Tektronix

Tektronix TMT4 Specification and Performance Verification Technical Reference

Platinum Tools

Platinum Tools Net Prowler TNP700 quick start guide

Hioki

Hioki 3665-20 manual