PS-2062 Page 3 of 4 © 2005 DESCO INDUSTRIES INC.

Employee Owned

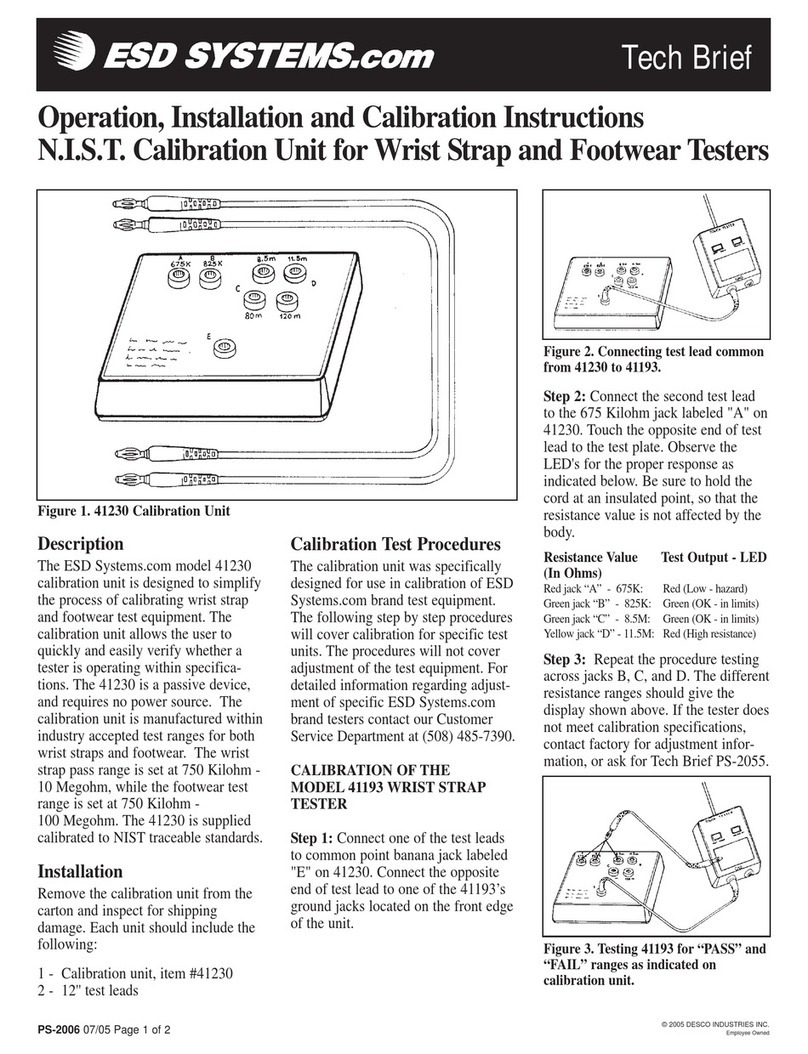

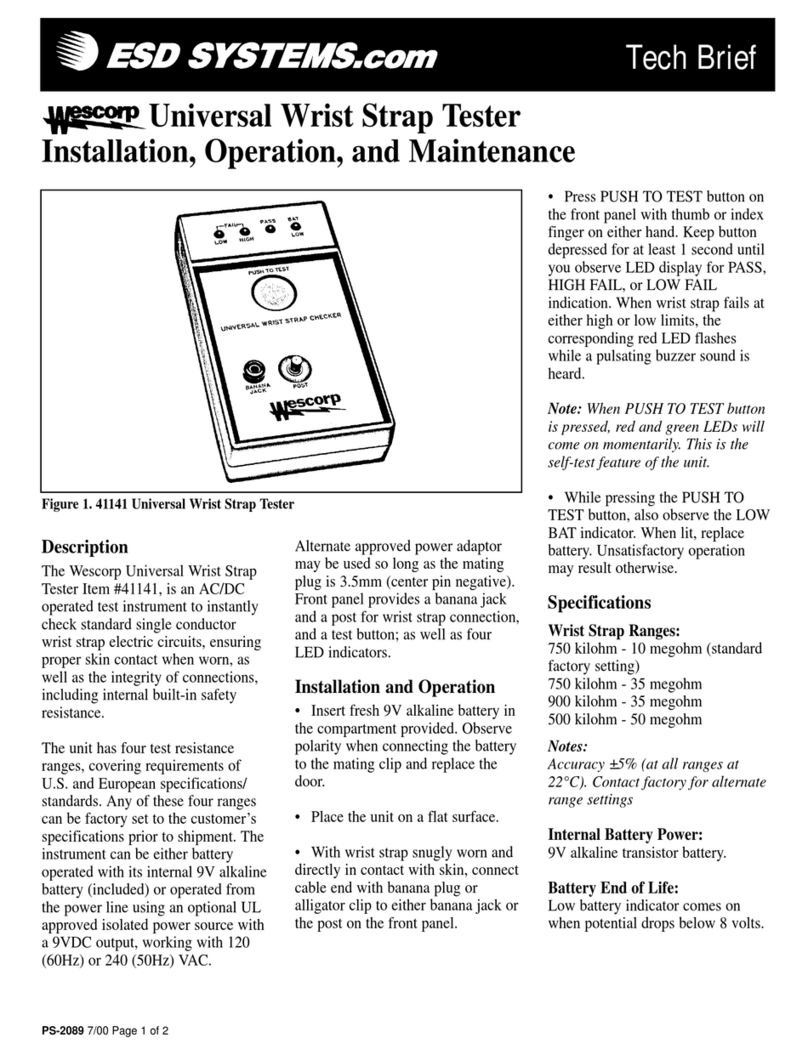

3. POLARITY SELECTION - The

terminals are labeled (+) and (-). To

provide a POSITIVE voltage output,

connect the negative (-) terminal to

ground. Press and hold the power

switch. To provide a NEGATIVE

voltage output, connect the positive

(+) terminal to ground. Press and

hold the power switch.

4. GROUNDING - IMPORTANT!

For the charging unit to work

correctly, the operator or the

fieldmeter must be properly

grounded. A ground path from an

output contact must exist.

5. IONIZER DISCHARGE TIME

MEASUREMENTS - Locate the

42721 and the Isolated Plate

Assembly in the appropriate location

for measurements.

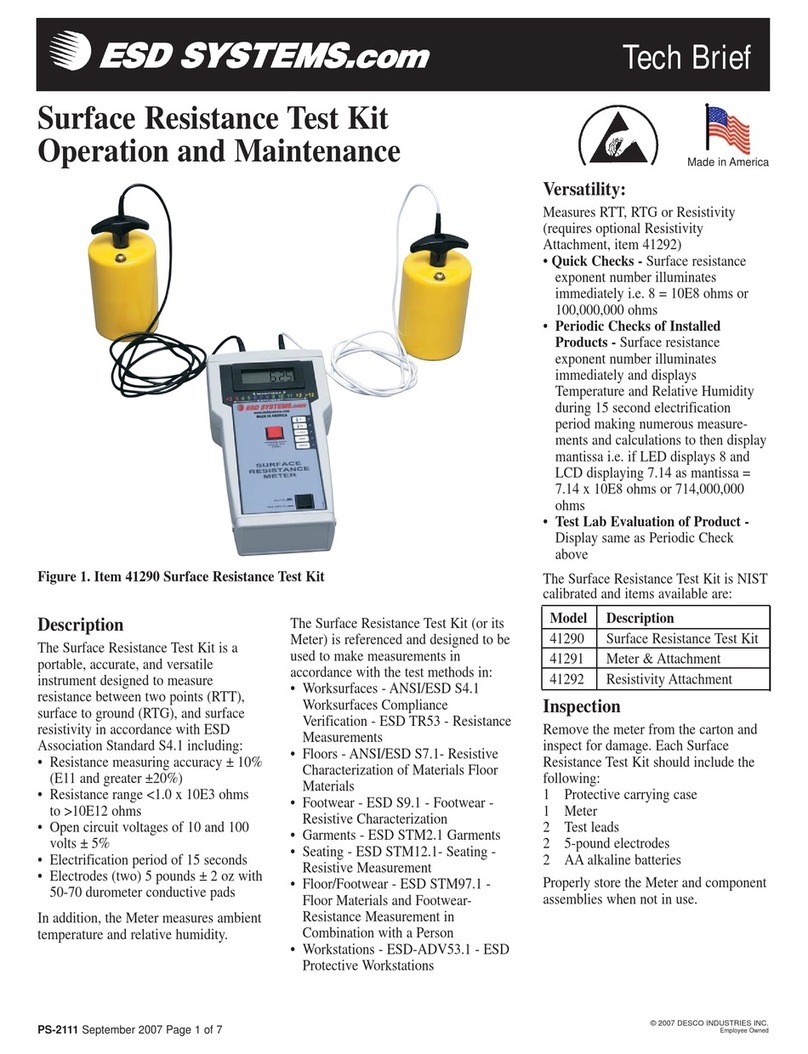

6. POSITIVE DISCHARGE

MEASUREMENT - For positive

discharge measurement, touch the

negative (-) terminal of the Charger

while pressing the charging button

on the Charger. Momentarily touch

the positive terminal to the Isolated

Plate Assembly. The 42721 reads

approximately +1.10kV. By using a

stop watch or other timing device,

determine the time needed for the

voltages to decrease from +1.10kV

to + 0.01kV. This is the positive

discharge time.

7. NEGATIVE DISCHARGE

MEASUREMENTS - For negative

discharge measurements, touch the

(+) output terminal while pressing

the charging button on the Charger.

Momentarily touch the negative

terminal to the Isolated Plate

Assembly. Follow the instructions

for the positive discharge

measurement above.

IMPORTANT: A ground path must

be provided between one of the

output terminals of the charging unit

and the ground reference of the

Fieldmeter and Adapter Plate. This

is normally provided by holding the

Charger in one hand and the

Fieldmeter with Adapter Plate in the

other. If this is not possible, test

leads must be used to connect one to

the Charger output terminals and the

Fieldmeter ground connection.

Calibration

The overall accuracy of the 42755

Test Kit is ± 5% nominal.

Calibration of the Ionization Test Kit

should only be performed by the

factory. The 42755 is calibrated to

NIST traceable standards. Contact

our Customer Service Department

for details.

Maintenance

BATTERY CARE

1. 42721 Fieldmeter - Change

batteries at least once a year. The

unit should be off when replacing the

battery. Normal battery life is about

40 hours of use. Replace the battery

when the “BAT” indicator appears in

the display above the “HOLD”

indicator position for more than an

instant.

2. Charging Unit - Replace the

battery when the charging unit fails

to charge the isolated plate to

±1.10kV.

See specifications for battery

replacement type.

CLEANING

It is important to keep the insulators

on the Isolated Plate Assembly clean

and free of contaminates that may

cause surface leakage. To test the

performance of the Isolated Plate

Assembly, charge the plate and note

the discharge rate in a non-ionized

area. The self discharge rate to 10%

of original voltage should not be less

than five minutes.

The area around the aperture of the

Model 42721 must be kept clean to

ensure accurate, drift-free readings.

Never touch the aperture with

anything. To remove dust or other

particulate matter, use low-pressure

instrument-grade air. To remove

more severe contamination, spray or

flush with the smallest practical

amount of clean technical-grade of

isopropyl alcohol. Then allow the

instrument to air dry for several

hours.

Figure 5. Charging unit controls.

Figure 6. Taking decay measurements.