Temelsan DK 1500 LS User manual

DK 1500 LS

PLC CONTROLLED VERTICAL

BANDSAW MACHINE

P a g e | 1

TEMELSAN MAKİNA SAN. VE TİC. LTD. ŞTİ.

Akçaburgaz Mah. Muhsin Yazıcıoğlu Cad. No:55/1 Esenyurt / İstanbul / TÜRKİYE

TEL: +90 (212) 544-2518 FAX: +90 (212) 577-6557 www.temelsan.com temelsan@temelsan.com

INDEX

1. ABOUT US ............................................................................................................... 4

2. CONDITIONS OF OPERATION .................................................................................... 5

3. SAFETY STIPULATIONS ............................................................................................ 5

4. SAFETY SIGNS ON THE MACHINE AND THEIR MEANINGS ............................................ 6

5. GENERAL DESCRIPTION OF THE MACHINE ................................................................ 7

5.1. Description of the Machine..................................................................................... 7

5.2. Expansion of the Model Name................................................................................. 7

5.3. List of Machine Models .......................................................................................... 7

5.4. Machine type and Specifications ............................................................................. 8

5.4.1. Machine type: DK-1500-LS.................................................................................. 8

5.4.2. Machine specifications........................................................................................ 8

6. Sample of Machine Name Plate .................................................................................. 9

7. GENERAL PRINCIPLE OF OPERATION ...................................................................... 10

8. PREREQUISITS OF TRANSPORTATION ..................................................................... 11

8.1. Transportation style............................................................................................ 11

8.2. Precautions........................................................................................................ 11

8.3. Conditions for transportation ............................................................................... 11

Congragulations to your new TEMELSAN VERTICAL BANDSAW MACHINE DK 1500 LS…

P a g e | 2

TEMELSAN MAKİNA SAN. VE TİC. LTD. ŞTİ.

Akçaburgaz Mah. Muhsin Yazıcıoğlu Cad. No:55/1 Esenyurt / İstanbul / TÜRKİYE

TEL: +90 (212) 544-2518 FAX: +90 (212) 577-6557 www.temelsan.com temelsan@temelsan.com

8.4. Storing Conditions .............................................................................................. 11

9. INSTALLATION AND OPERATIONAL INSTRUCTIONS ................................................. 12

9.1. UNLOADING....................................................................................................... 12

9.2. INSTALLATION................................................................................................... 13

9.3. OPERATIONAL INSTRUCTIONS ............................................................................ 15

9.3.1. Operation of the Machine.................................................................................. 15

10. TRAINING .......................................................................................................... 16

11. SPARE PART LIST ............................................................................................... 16

12. SERVICE ............................................................................................................ 16

13. PLANNED MAINTENANCE CHART ........................................................................ 17

13.1. DAILY MAINTENANCE...................................................................................... 17

13.2. WEEKLY MAINTENANCE.................................................................................. 17

13.3. MONTHLY MAINTENANCE ............................................................................... 17

13.4. BI-ANNUAL MAINTENANCE.............................................................................. 17

14. TROUBLESHOOTING ........................................................................................... 17

15. GUARANTEE CERTIFICATE .................................................................................. 22

16. DECLARATION OF CONFORMITY.......................Hata! Yer işareti tanımlanmamış.

CONTROL PANEL......................................................................................................... 24

USER LOGIN AND LOGOUT .......................................................................................... 25

PASSWORD CONFIGURATION...................................................................................... 33

I-O TRACKING PAGES.................................................................................................. 38

P a g e | 3

TEMELSAN MAKİNA SAN. VE TİC. LTD. ŞTİ.

Akçaburgaz Mah. Muhsin Yazıcıoğlu Cad. No:55/1 Esenyurt / İstanbul / TÜRKİYE

TEL: +90 (212) 544-2518 FAX: +90 (212) 577-6557 www.temelsan.com temelsan@temelsan.com

ALARM & WARNING LIST AND TROUBLESHOOTTING.................................................... 47

FUNCTION OF MANUAL HYDRAULIC VALVE .................................................................. 54

Given Tention to the bandsaw blade : ....................................................................... 54

Loosen Tension on bandsaw blade and change the blade :......................................... 55

BLADE CHANGE INSTRUCTION .................................................................................... 55

APPENDICES ............................................................................................................... 55

Appendix 1 Exploded Views and Technical Representation of Parts or Main Units ................ 56

FREE WHEEL AND SHAFT ......................................................................................... 56

MAIN BLADE MOTOR SHAFT..................................................................................... 57

TENTION WHEEL AND SHAFT................................................................................... 58

RACK (GUIDE POST) ................................................................................................ 59

BLADE GUIDES ........................................................................................................ 60

HYDRAULIC UNIT .................................................................................................... 61

TENSION VALVE ...................................................................................................... 62

BALLSCREW AND SERVO MOTOR.............................................................................. 63

Appendix 2 Electrical Diagrams ...................................................................................... 65

P a g e | 4

TEMELSAN MAKİNA SAN. VE TİC. LTD. ŞTİ.

Akçaburgaz Mah. Muhsin Yazıcıoğlu Cad. No:55/1 Esenyurt / İstanbul / TÜRKİYE

TEL: +90 (212) 544-2518 FAX: +90 (212) 577-6557 www.temelsan.com temelsan@temelsan.com

1. ABOUT US

Temelsan, by the in-depth experience in the business, utilizing the latest technology sustains the

continuous production of machines.

Temelsan gained a unique status in production of flash butt welding machines beside the

manufacture of bandsaw machines all around the world. There are numerous customers who

are using Temelsan brand flash butt welding machines; not only the bandsaw blade

manufacturers and distributors but also GRP pipe manufacturers utilizing filament winding

method.

Temelsan as being family owned company and established in 1976 started the business with the

production of vertical bandsaw machines which are used for accurate and mass production

cutting in the business fields such as automotive, aerospace, household-related, etc.

Our own products

Block/Plate Cutting Vertical Bandsaw Machine: DK-3500

Vertical Bandsaw Machines: DK-400 series, DK-600 series, DK-900 series, DK-1100, DK-1500,

DK-2000, DK-3500

Flash butt Welding Machines, KN 41 HBS , KN 67 HBS, KN 67 HBA, KN 100 HBA and KN 100 PLC

Horizontal Bandsaw Machines: CUT-300 STO

Resistance Welders used on Vertical Bandsaw Machines: MD-02 and MD-03

Grinder (used to grind the flash on the bandsaw blade after being welded): TAS-10001-RT / SL

Shear Cutter (used to cut the tips of bandsaw blades to prepare for welding): MAK-01, MAK-01

HP (manual and hydrau-pneumatic types)

P a g e | 5

TEMELSAN MAKİNA SAN. VE TİC. LTD. ŞTİ.

Akçaburgaz Mah. Muhsin Yazıcıoğlu Cad. No:55/1 Esenyurt / İstanbul / TÜRKİYE

TEL: +90 (212) 544-2518 FAX: +90 (212) 577-6557 www.temelsan.com temelsan@temelsan.com

2. CONDITIONS OF OPERATION

In order to run the machine here is the electrical requirements,

Phase-Neutr: 240 V 50 Hz

Phase-Phase: 400 V 50 Hz

Attent that all the doors are closed while the machine is running.

3. SAFETY STIPULATIONS

Never do maintenance and repair work when the machine is energized.

Never step over the cables and the equipments.

Never remove or replace the covers with the non-standardized one of electrical

motors, fans, moving parts.

Never come close to the machine and never perform any action till all the moving

parts of the machine stop completely.

P a g e | 6

TEMELSAN MAKİNA SAN. VE TİC. LTD. ŞTİ.

Akçaburgaz Mah. Muhsin Yazıcıoğlu Cad. No:55/1 Esenyurt / İstanbul / TÜRKİYE

TEL: +90 (212) 544-2518 FAX: +90 (212) 577-6557 www.temelsan.com temelsan@temelsan.com

4. SAFETY SIGNS ON THE MACHINE AND THEIR MEANINGS

ATTENTION! LIVE ELECTRICITY

ATTENTION! DANGER

P a g e | 7

TEMELSAN MAKİNA SAN. VE TİC. LTD. ŞTİ.

Akçaburgaz Mah. Muhsin Yazıcıoğlu Cad. No:55/1 Esenyurt / İstanbul / TÜRKİYE

TEL: +90 (212) 544-2518 FAX: +90 (212) 577-6557 www.temelsan.com temelsan@temelsan.com

5. GENERAL DESCRIPTION OF THE MACHINE

5.1. Description of the Machine

VERTICAL BANDSAW MACHINE DK 1500 LS

5.2. Expansion of the Model Name

DK-X00. 0X (S1)

DK : VERTICAL BANDSAW MACHINE

X00 : Throat width (distance between the vertical frame and the bandsaw blade

0X : Sub-model of the actual model

(S1) : CE certified (Some models without S1 designation might have CE certification whereas the ones

with S1 designation certainly have.)

5.3. List of Machine Models

The machines are classified according to the throat width and the types of accessories equipped

as standard and produced:

DK-400 ÖZEL DK-400. 01/EXPORT DK-400. 01 DK-400. 01 S1

DK-400. 02 DK-400. 03 DK-400. 03 S1 DK-400. 04

DK-400. 05 DK-400. 05 S1 DK-400. 08 DK-600 ÖZEL

DK-600. 01 DK-600. 02 DK-600. 03 DK-900 ÖZEL

DK-900. 03 DK-1100 DK-2000 DK-3500

The machines with CE certification are listed below:

DK-400. 01 S1 DK-400. 03 S1 DK-400. 05 S1 DK-400. 08

DK-600. 03 DK-900. 03 DK-1500 DK-3500

P a g e | 8

TEMELSAN MAKİNA SAN. VE TİC. LTD. ŞTİ.

Akçaburgaz Mah. Muhsin Yazıcıoğlu Cad. No:55/1 Esenyurt / İstanbul / TÜRKİYE

TEL: +90 (212) 544-2518 FAX: +90 (212) 577-6557 www.temelsan.com temelsan@temelsan.com

5.4. Machine type and Specifications

5.4.1. Machine type: DK-1500-LS

5.4.2. Machine specifications

Main Motor

7,5 kW

Dimension of Table

800 x 1500 mm

Cutting Height Over Table

1200 mm

Throat Width

800 mm

Cutting Speed

2-1000 mm/min

Servo Travel Stroke

1500 mm

Equipment Configuration Providing the Speed Adjustment

Frequency Invertor

/ PLC

Length of applicable bandsaw blade

6850 mm

Width and wall-thickness of applicable bandsaw blade

54x1,3 / 54x1,6 mm

Height of the table from the ground

910 mm

Weight of the machine

7000

P a g e | 10

TEMELSAN MAKİNA SAN. VE TİC. LTD. ŞTİ.

Akçaburgaz Mah. Muhsin Yazıcıoğlu Cad. No:55/1 Esenyurt / İstanbul / TÜRKİYE

TEL: +90 (212) 544-2518 FAX: +90 (212) 577-6557 www.temelsan.com temelsan@temelsan.com

7. GENERAL PRINCIPLE OF OPERATION

Field of Application : Used for cutting all kinds of metals in straight or curve-form.

Principle of operation : The machine will be operated by one personnel only. The operatör

places the metal workpiece on the table of the machine and fixes it with the vise(s). Turns the

machine ON from the main switch. By pressing the GREEN button, initializes the rotation of

bandsaw blade. Adjusts the speed of rotation noticing the type and the hardness of the

workpiece. If the machine is equipped with a hydraulic table, then the speed of the hydraulic

table must also be adjusted according to the type and the hardness of the part to be cut. The

operatör can start cutting.

Attention! The operator must stand at the point shown as (X) below when the machine runs.

P a g e | 11

TEMELSAN MAKİNA SAN. VE TİC. LTD. ŞTİ.

Akçaburgaz Mah. Muhsin Yazıcıoğlu Cad. No:55/1 Esenyurt / İstanbul / TÜRKİYE

TEL: +90 (212) 544-2518 FAX: +90 (212) 577-6557 www.temelsan.com temelsan@temelsan.com

8. PREREQUISITS OF TRANSPORTATION

8.1. Transportation style

VERTICAL BANDSAW MACHINE is monolithic during the transportation.

8.2. Precautions

•The machine can only be lifted by using proper rope hung on the head of the

machine itself.

8.3. Conditions for transportation

The notices of transportations are listed below:

a) Placing the machine on the transporting vehicle firmly and tightened with ropes to

eliminate possible bending and vibration during the journey.

b) The height of the tunnels and the bridges along the travelling route must be taken into

account. It is very important especially for DK-3500 and above.

8.4. Storing Conditions

a) Roof of the storing area must be closed.

b) There must not be any contact with moisture/water around, on top or under the machine.

c) It must be prohibited for unauthorized personnel to come across/intervene with the

machine

d) There must be no risk of fire in the area to be stored.

After connecting the electrical cables, authorized an experienced personnel will make the

necessary adjustments and commission the machine.

P a g e | 12

TEMELSAN MAKİNA SAN. VE TİC. LTD. ŞTİ.

Akçaburgaz Mah. Muhsin Yazıcıoğlu Cad. No:55/1 Esenyurt / İstanbul / TÜRKİYE

TEL: +90 (212) 544-2518 FAX: +90 (212) 577-6557 www.temelsan.com temelsan@temelsan.com

9. INSTALLATION AND OPERATIONAL INSTRUCTIONS

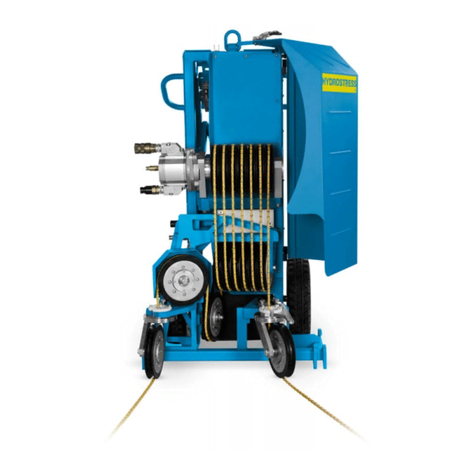

9.1. UNLOADING

Machine should be carried as below drawing. Customer is fully responsible to provide

necessary ropes.

Please check the rope hanging at below drawing.

Please remove both upper covers before you carry machine.

P a g e | 13

TEMELSAN MAKİNA SAN. VE TİC. LTD. ŞTİ.

Akçaburgaz Mah. Muhsin Yazıcıoğlu Cad. No:55/1 Esenyurt / İstanbul / TÜRKİYE

TEL: +90 (212) 544-2518 FAX: +90 (212) 577-6557 www.temelsan.com temelsan@temelsan.com

9.2. INSTALLATION

Placing the machine to the final installation area will be done by the customer itself.

The customer is fully responsible of the accidents caused by imporper lifting, carrying and

placing the machine to the installation area.

Installation, Setup, Commissioning and Initial Operation is under the responsibility of the

customer except DK-3500. All the machines except DK-3500 are monolithic and need the

electrical connection only.

If the electrical connections is done by unauthorized personnel the warranty voids immediately

and the manufacturer will not be responsible of any circumstances.

The customer is responsible to provide the cables to be connected to the electrical panel of the

machine.

To provide the cables to the electrical cabinet and to provide electricity are under customer’s

responsibility.

Electrical connections must be done by qualified electricians only.

The manufacturer will not be responsible if unauthorized and unexperienced electrical

technician intervenes the machine.

The customer has the right to claim an authorized personnel from the manufacturer to

check what has been done. Then the customer has to pay for the costs of international flight

tickets, hotel accommodation, food and beverage, etc. for 2 personnel from the

manufacturer.

Make sure that there is no obstacle around/on/in the machine.

1. Connect 5x4 TTR type of cables to the power terminals in the electrical panel of the

machine.

Attention! The machine must be grounded by a yellow-green colored cable.

2. Turn the main switch on. Press the green button controlling the main motor. Now the

speed control is possible. Press plus-minus signed buttons next to the speed control

equipment to change the speed of rotation of the bandsaw blade.

P a g e | 14

TEMELSAN MAKİNA SAN. VE TİC. LTD. ŞTİ.

Akçaburgaz Mah. Muhsin Yazıcıoğlu Cad. No:55/1 Esenyurt / İstanbul / TÜRKİYE

TEL: +90 (212) 544-2518 FAX: +90 (212) 577-6557 www.temelsan.com temelsan@temelsan.com

NOTE: If the main motor is running in opposite direction then 2 phases of the electrical

connections must be interchanged to gain the correct direction of rotation. If any of

those doors of the machine is open then the machine will not run. Besides, if the

bandsaw blade is not tightened to a certain level, the sensor switch of the bandsaw

blade breakage will block the machine as if the bandsaw blade is broken.

3. Now check the direction of rotation of the hydraulic motor. Check if it rotates in the

direction of the arrow sign located on the motor itself.

4. Before replacing the bandsaw blade; open the 3 of those covers in front side of the

machine and loosen the bandsaw blade tightening shaft. By pulling the loosened

bandsaw blade towards yourself, let it free from the wheels and the guides.

To install a new bandsaw blade, follow the procedure in reverse direction and apply

tightening pressure.

ATTENTION! Before replacement of the bandsaw blade turn the machine off from the

main switch.

While installing the new bandsaw blade notice that the teeth form should be towards

yourself.

The bandsaw blade might elongate due to the heat emission during running; check the bandsaw

blade, tighten it if necessary.

5. Depending on the diameter and the height of the workpiece adjust the upper bearing of

the bandsaw blade (the one next to the rack) to prevent collision with the workpiece

during running and fix the handle.

ATTENTION!: The more close the upper bearing mechanism is to the workpiece the

more sharp, perpendicular and smooth the cutting will be.

P a g e | 15

TEMELSAN MAKİNA SAN. VE TİC. LTD. ŞTİ.

Akçaburgaz Mah. Muhsin Yazıcıoğlu Cad. No:55/1 Esenyurt / İstanbul / TÜRKİYE

TEL: +90 (212) 544-2518 FAX: +90 (212) 577-6557 www.temelsan.com temelsan@temelsan.com

9.3. OPERATIONAL INSTRUCTIONS

9.3.1. Operation of the Machine

It is completely under the responsibility of the customer itself. On the other hand if the

customer contacts the manufacturer for some advice, the manufacturer will support the

customer.

Check the Appendix 1 to know about the control panel of the machine.

Steps of the operation

1) Depending of the height of workpiece adjust the inserts to the closest location to the

workpiece.

2) Choose the right teeth form for the bandsaw blade which will be used to cut the

workpiece.

3) Adjust the rotational speed and the speed of the Servo controlled table according to the

workpiece to be cut.

4) At each bandsaw blade replacement, make sure that the bandsaw blade bearings and

the inserts touch parallel to the workpiece. This should be done for the one at the lower

wheel.

P a g e | 16

TEMELSAN MAKİNA SAN. VE TİC. LTD. ŞTİ.

Akçaburgaz Mah. Muhsin Yazıcıoğlu Cad. No:55/1 Esenyurt / İstanbul / TÜRKİYE

TEL: +90 (212) 544-2518 FAX: +90 (212) 577-6557 www.temelsan.com temelsan@temelsan.com

10. TRAINING

Training at the manufacturer’s site will be free of charge. If requested at the buyer’s site then the

flight tickets, hotel accommodation, food and beverage costs for 2 persons from the

manufacturer will be paid by the buyer. If an unauthorized personnel deal with the machine the

warranty voids immediatley.

11. SPARE PART LIST

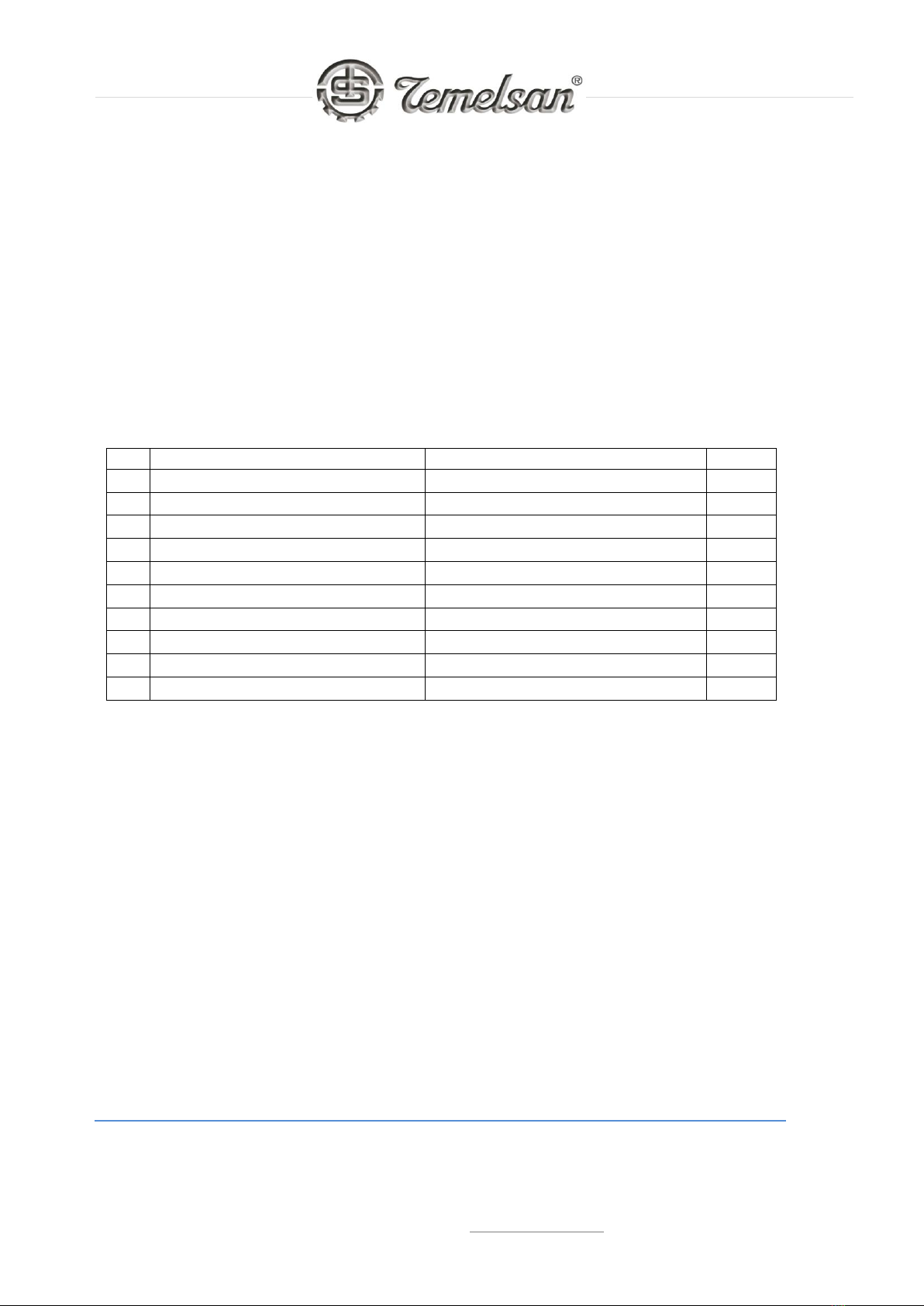

MECHANICAL AND ELECTRICAL SPARE PART LIST

DESIGNATION

TYPE

Q’TY

1

MAIN MOTOR

ELECTRICAL

1

2

HYDRAULIC MOTOR

ELECTRICAL

1

3

BANDSAW INSERTS

STEEL

2

4

FREE WHEEL

CAST IRON

1

5

UPPER WHEEL

CAST IRON

1

6

WHEEL OF GEAR

CAST IRON

1

7

SERVO MOTOR

ELECTRICAL

1

8

SERVO GEARBOX

MECHANIC

1

9

HYDRAULIC TENTION UNIT

MECHANIC

1

10

CONTROL MONITOR

ELECTRONIC

1

12. SERVICE

The necessary parts will be distributed by the manufacturer once the buyer claims during repair

work or maintenance.

During warranty period at any circumstances where the unauthorized personnel use the

machine the warranty will void immediately.

The warranty is a limited warranty and covers the spare parts only. If the buyer claims service

from the manufacturer then the service cost, flight tickets, hotel accommodation, food and

beverage costs for 2 persons will be paid by the buyer.

P a g e | 17

TEMELSAN MAKİNA SAN. VE TİC. LTD. ŞTİ.

Akçaburgaz Mah. Muhsin Yazıcıoğlu Cad. No:55/1 Esenyurt / İstanbul / TÜRKİYE

TEL: +90 (212) 544-2518 FAX: +90 (212) 577-6557 www.temelsan.com temelsan@temelsan.com

13. PLANNED MAINTENANCE CHART

13.1. DAILY MAINTENANCE

a) Open all the covers and clean all the parts inside with an air gun.

b) During down-times, the bandsaw blade should be loose; untighten it.

c) Clean up the chips on those of 3 wheels every day.

13.2. WEEKLY MAINTENANCE

Inspect the guides of blade. Replace it if necessary.

13.3. MONTHLY MAINTENANCE

a) Check the level of lubricant of hydraulic system. If the level is not full then add the

lubricant.

b) Check the valves. If oil is leaking replace them.

c) Lubricate the bandsaw blade tensioning unit.

d) Rack-shaft should be lubricated.

13.4. BI-ANNUAL MAINTENANCE

The initial oil of gear should be replaced after 300 hours of operation. Then replace the oil of the

gear bi-annually. The oil no. is 140.

14. TROUBLESHOOTING

To gain optimal performance is only possible to have an optimal combination of bandsaw blade

and bandsaw machine. The main sources of the problems confronted are; wrong feeding force,

wrong saw speed, wrong coolant concentration, wrong teeth form and improper repair work

done.

P a g e | 18

TEMELSAN MAKİNA SAN. VE TİC. LTD. ŞTİ.

Akçaburgaz Mah. Muhsin Yazıcıoğlu Cad. No:55/1 Esenyurt / İstanbul / TÜRKİYE

TEL: +90 (212) 544-2518 FAX: +90 (212) 577-6557 www.temelsan.com temelsan@temelsan.com

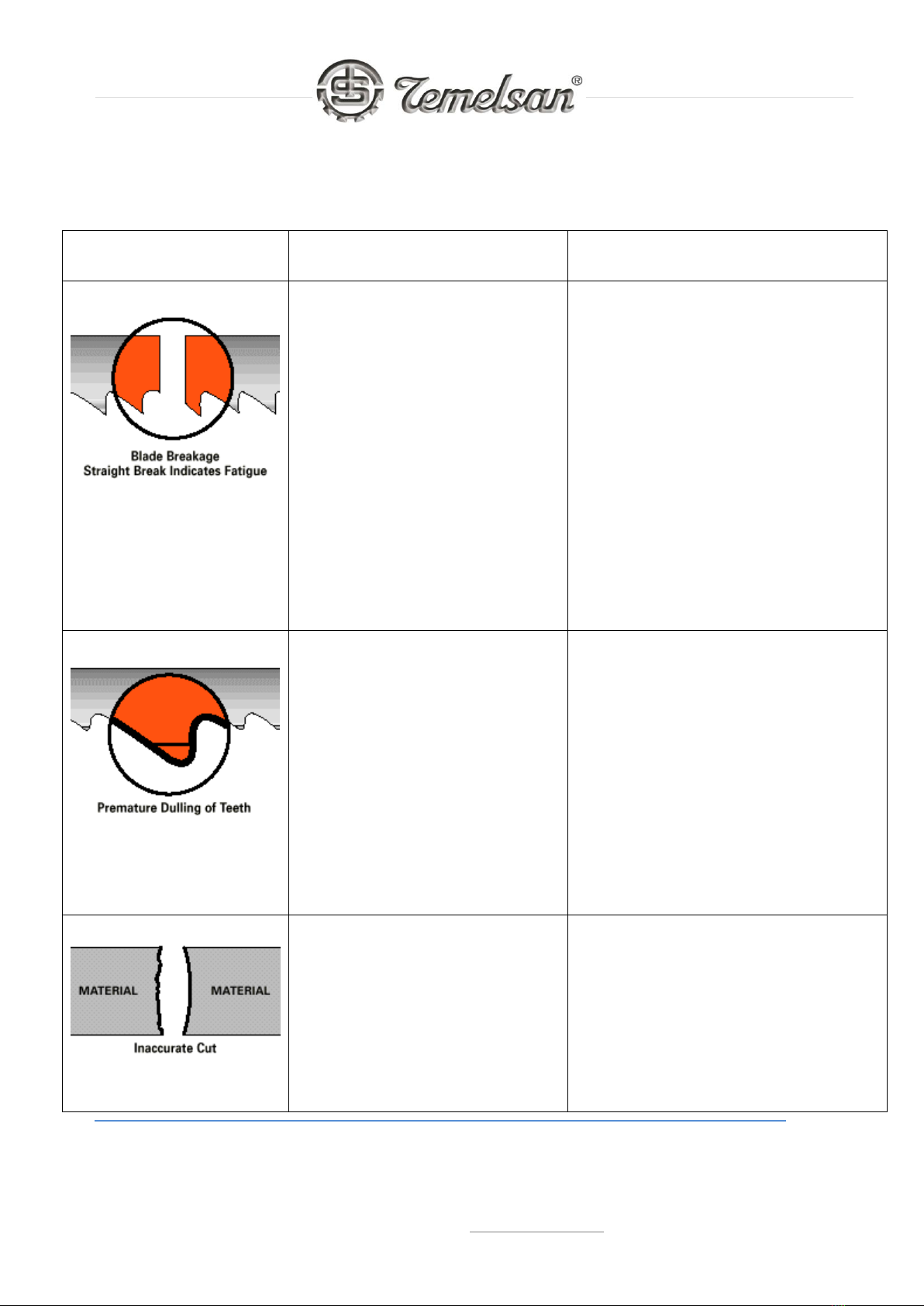

Problem

Probable Cause

Solution

•Incorrect blade

•Band tension too high

•Excessive feed

•Incorrect cutting fluid

•Wheel diameter too small

for blade being used

•Worn or chipped

pressure block (back-up

guide)

•Blade rubbing on wheel

flanges

•Teeth in contact with

work before starting saw

•Side guides too tight

•Teeth too coarse. Check your

cutting chart

•Reduce band tension. See

Machine Operator's Manual

•Reduce feed pressure

•Check your coolant

•Use thinner blade and lower

speed

•Check pressure block. Replace

if worn

•Adjust wheel alignment

•Allow 1/2" clearance before

starting cut

•See Machine Operator's

Manual

•Blade teeth inverted

(backwards)

•Improper break-in period

•Hard spots in material

(like scale)

•Material work hardened

(check for hardness and

adjust feed)

•Improper cutting fluid or

mixture

•Speed and feed too high

•Install blade correctly

•Reduce feeds and speeds

during break-in period in

accordance with

manufacturers'

recommendations

•Check material for actual

hardness - hard spots like

scale or flame cut surfaces

•Increase feed pressure

•Check your coolant

•Check your cutting chart

•Teeth dull

•Over or under feed

•Improper pitch blade

•Cutting fluid not applied

evenly

•Incorrect blade (too

many teeth per inch)

•Guides worn or loose

•Use new blade

•Check your cutting chart

•Check your cutting chart

•Adjust coolant nozzles

•Check your cutting chart

•Tighten or replace guides

P a g e | 19

TEMELSAN MAKİNA SAN. VE TİC. LTD. ŞTİ.

Akçaburgaz Mah. Muhsin Yazıcıoğlu Cad. No:55/1 Esenyurt / İstanbul / TÜRKİYE

TEL: +90 (212) 544-2518 FAX: +90 (212) 577-6557 www.temelsan.com temelsan@temelsan.com

•Over feed

•Lack of band tension

•Tooth set damage

•Loose guide arms or set

too far from work

•Check your cutting chart *

•Check Operator's Manual for

correct tension

•Check material hardness

•Adjust arm as close to work as

possible - tighten and align.

Check guide

•Improper or lack of

cutting fluid

•Wrong coolant

•Excessive speed or

pressure

•Incorrect blade (wrong

pitch)

•Check your coolant

•Check your coolant

•Reduce speed or pressure.

Check your cutting chart *

•Check your coolant

•Incorrect feed and/or

speed

•Incorrect blade (wrong

pitch)

•Saw guides not adjusted

properly

•Check your cutting chart

•Check your cutting chart

•Adjust or replace saw guides

•Indexing out of sequence

•Material loose in vise

•Check for correct indexing

sequence (head rise)

•Check hydraulic pressure

•Feed pressure too high

•Tooth lodged in cut

•No cutting fluid or incorrect

coolant

•Hard spots, scale,

inclusions, etc.

•Incorrect blade (wrong

pitch)

•Work spinning in vise; loose

"nest" or bundles

•Reduce feed pressure and/or

speed. See your cutting chart

•Never enter same (old blade), cut

with new blade

•Check your coolant

•Check hardness. Descale and/or

anneal if necessary

•Check your cutting chart

•Check hydraulic pressure; be

sure work is firmly held

Table of contents

Popular Saw manuals by other brands

Mafell

Mafell Z 5 Ec Original operating instructions and spare parts list

DeWalt

DeWalt D28871 instruction manual

Bosch

Bosch GKS 18 V-LI Professional Original instructions

compa

compa FC 300 RAP Operator's handbook

EFA

EFA SKR 23 Operating Instructions, Maintenance instructions, Spare Part List

Meec tools

Meec tools 242-106 User instructions