- 2 -

REFRIGERATION SYSTEMWIRING

3. REFRIGERATION SYSTEM

3.1 General

The OPA 465–960 models have two independent

refrigeration circuits and two compressors to provide

the exibility and economy of two stage operation, i.e.

utilising one or two circuits as conditions vary, plus the

advantage of staggered starting.

Units are supplied with a UC6 service interface display

tted for ease of service, maintenance and trouble

shooting. Operating pressures and status can be read

from its various display screens (refer user manual).

Each refrigeration system has been charged with

HFC-410A (R410A) refrigerant; refer wiring diagram

specication table for amount. This charge is based

on nominal capacity, nominal conditions and nominal

airow and is sufcient under these conditions to

maintain a refrigerant superheat of approximately 6

Kelvin. If the unit is installed in subtropical or tropical

conditions, has a high fresh air content or has been

installed with maximum supply

air quantity, the superheat should be checked and if

found to be above 6 Kelvin, refrigerant may need to

be added to the system to return the superheat to the

factory required state. These readings should be taken

with each stage operating independently and after the

space has achieved conditions. The additional charge

should be recorded for future reference.

3.2 Compressors

The compressors are directional scroll type. The

compressor lubricant is polyolester oil (POE). Note, this

oil absorbs moisture quickly if exposed to open air.

On commissioning, the compressors must be checked

for correct rotation (refer Start Up Procedure). A

time delay prevents simultaneous starting of the

compressors.

3.3 Economiser (Option)

If the outdoor air temperature or heat (enthalpy) content

preferably, is below that of the return air the fresh air

damper opens and the return air damper closes to

provide the rst stage of cooling. The fresh air damper

should return to minimum setting and the return air

damper open before the compressors are allowed to

operate to provide further cooling.

3.4 Setting Supply Air Flow

If the indoor air returning to the unit is regularly

expected to be above 50%RH, then the coil face

velocity should be limited to be 2.5 m/s or less (refer Air

Handling graph on page 5).

High humidity levels can occur in tropical or subtropical

conditions, and/or when heavily moisture laden fresh

air is introduced. Select a fan speed that avoids water

carry-over problems.

In a free blow or low resistance application, beware

of exceeding the fan motor’s full load amp limit (refer

wiring diagram).

The indoor air fan motor is tted with a factory set

adjustable pitch pulley. Instructions for the adjustment

of pulleys is included on the back page of the supplied

Commissioning Sheet. One revolution of adjustment is

equal to approx. 7% change in air volume ow rate.

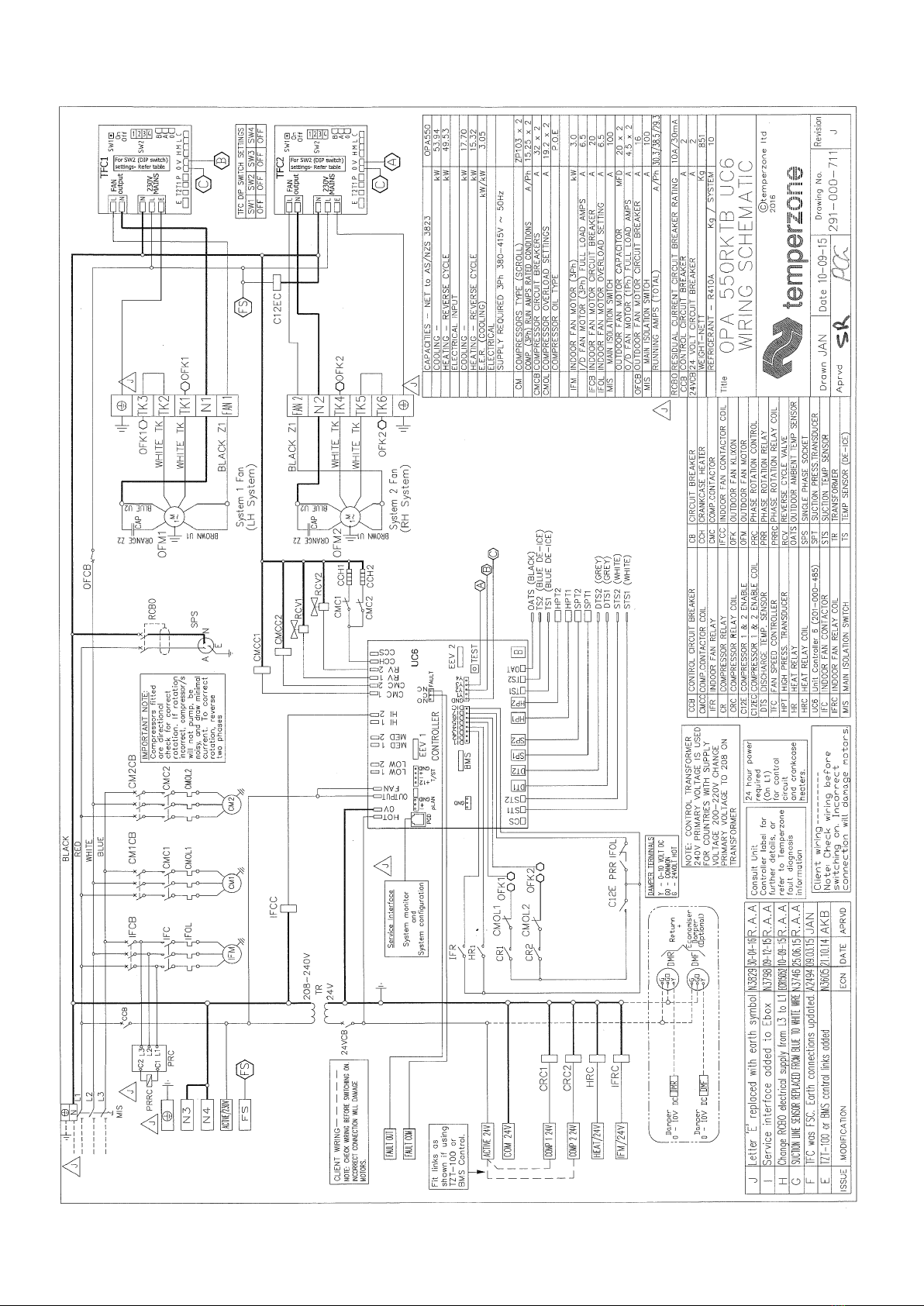

4. WIRING

4.1 Electrical Requirements

Electrical work must be done by a qualied electrician.

DANGER LIVE ELECTRICAL CONNECTIONS. ONLY QUALIFIED

PERSONS WHO ARE COMPETENTLY TRAINED SHOULD

PERFORM SERVICE AND MAINTENANCE TASKS.

The unit must be wired directly from a distribution board

by means of a circuit breaker or H.R.C. fuse, and a

mains isolator provided - preferably close to the unit.

Note: DO NOT USE REWIRABLE FUSES.

The OPA unit is provided with a 24V ac control circuit

thermostat (TZT Optional), on/off switch and/or time

clock, eld supplied and tted. The control transformer

240V primary is used for countries with 230-240V

power supply. Alternatively control can be via a Modbus

connection.

For countries with supply voltages 200-220V, change

the primary voltage on the transformer to 208V.

Standard units are suitable for use with thermostats

with either manual Heat/Cool selection or automatic

changeover subject to the contact ratings of the

thermostats.

A 24 hour power supply to the compressor crank case

heaters is required, otherwise the warranty is void.

4.2 Unit Controller (UC6)

The temperzone Unit Controller 6 (UC6) combines the

µPC controller board from Carel plus an interface board

to connect temperzone standard sensors and plugs.

The UC6 receives requests such as “Unit On/Off”,

“Start 1 or 2 compressors”, “Activate HEAT (Reverse

Cycle)” and transfers these requests to the outputs after

enforcing safety timers. The UC6 ensures unit safety by

continuously monitoring input signals such as pressures

and temperatures. Beside the normal controls and unit

safety the UC6 has many other functions, for example

head pressure control, capacity control, superheat

control, serial communications and more.

The Unit Controller provides system protection

functions such as coil frost protection, de-icing, high

head pressure and low suction pressure cut-out. It also

protects against rapid cycling of the compressor(s) and

loss of refrigerant. The UC6 regulates the superheat

of the refrigeration system by controlling the position

of an electronic expansion valve (EEV). Various

methods of head pressure control (or limiting) are

employed in temperzone units. The particular method

used varies from model to model, but is also handled

by the Unit Controller. In combination, these features

deliver optimised performance across a wide operating

temperature range.

As a result of the UC6’s control of these inter-related

functions, the outdoor fans may take some time to start

rotating after each compressor start. They may also run

on when the compressor stops. The fans will stop during

a de-ice cycle and the speed will vary either smoothly,

or in steps, in order to protect against excessively low or

high head pressure.

Refer to temperzone for operation & fault diagnostics

information OR www.temperzone.biz.