TEMPLARI SPA

Via C. Battisti, 169 - 35031 Abano Terme (PD) Italy

www.templari.com

Instruction manual (Translation of the original instructions)

vers. 21/07/23 - KITA R32-R290 - EN

3/126

MONOBLOCK HEAT PUMP - KITA

13.5.1 Preparing the condensate drain ................................................................................................................. 57

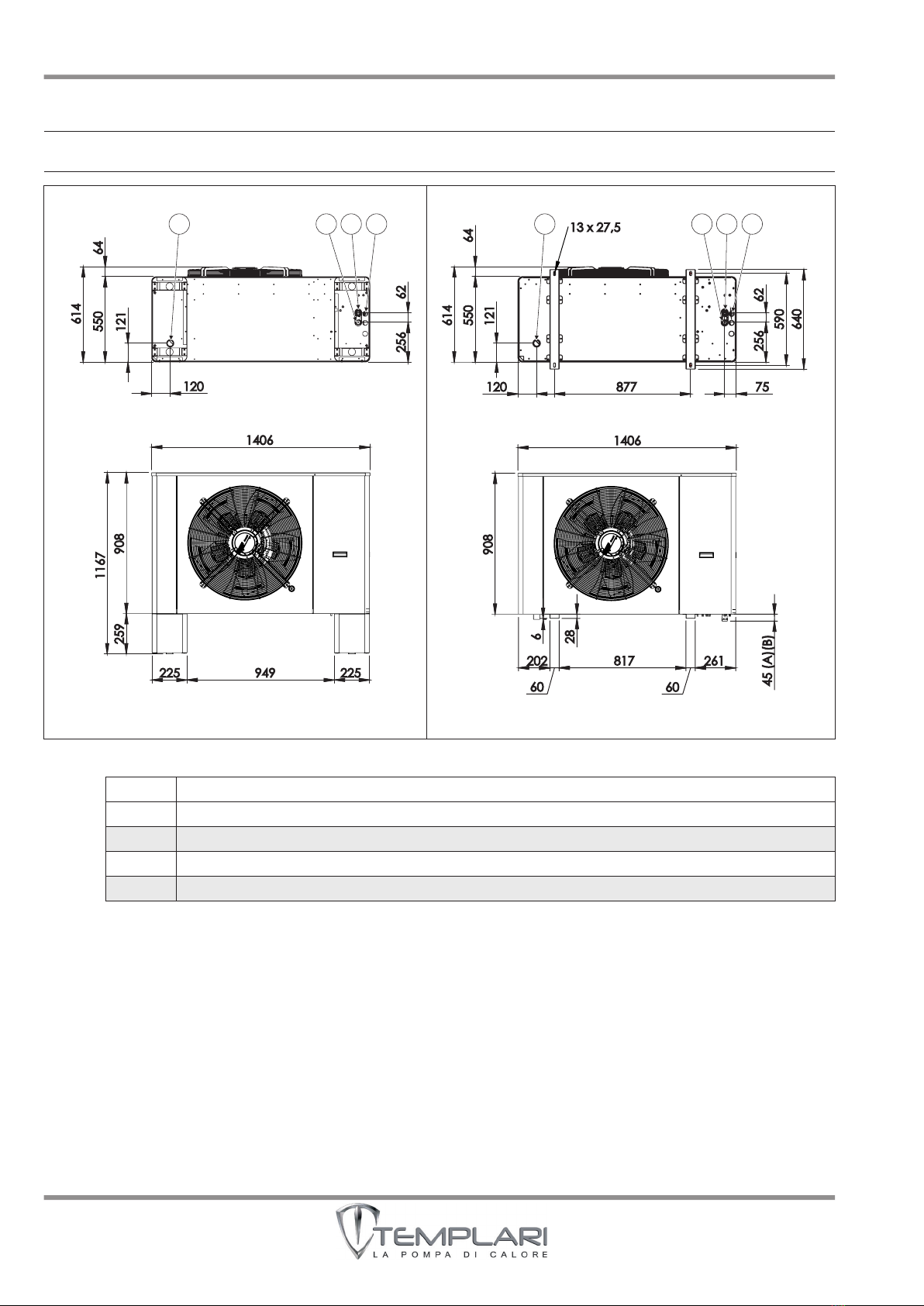

13.6 Levelling the machine.......................................................................................................................................... 58

13.7 Installing the probes ............................................................................................................................................ 59

13.8 Installing the venting valves ................................................................................................................................ 59

13.9 Connections ........................................................................................................................................................ 59

13.9.1 Connection to the water energy source...................................................................................................... 59

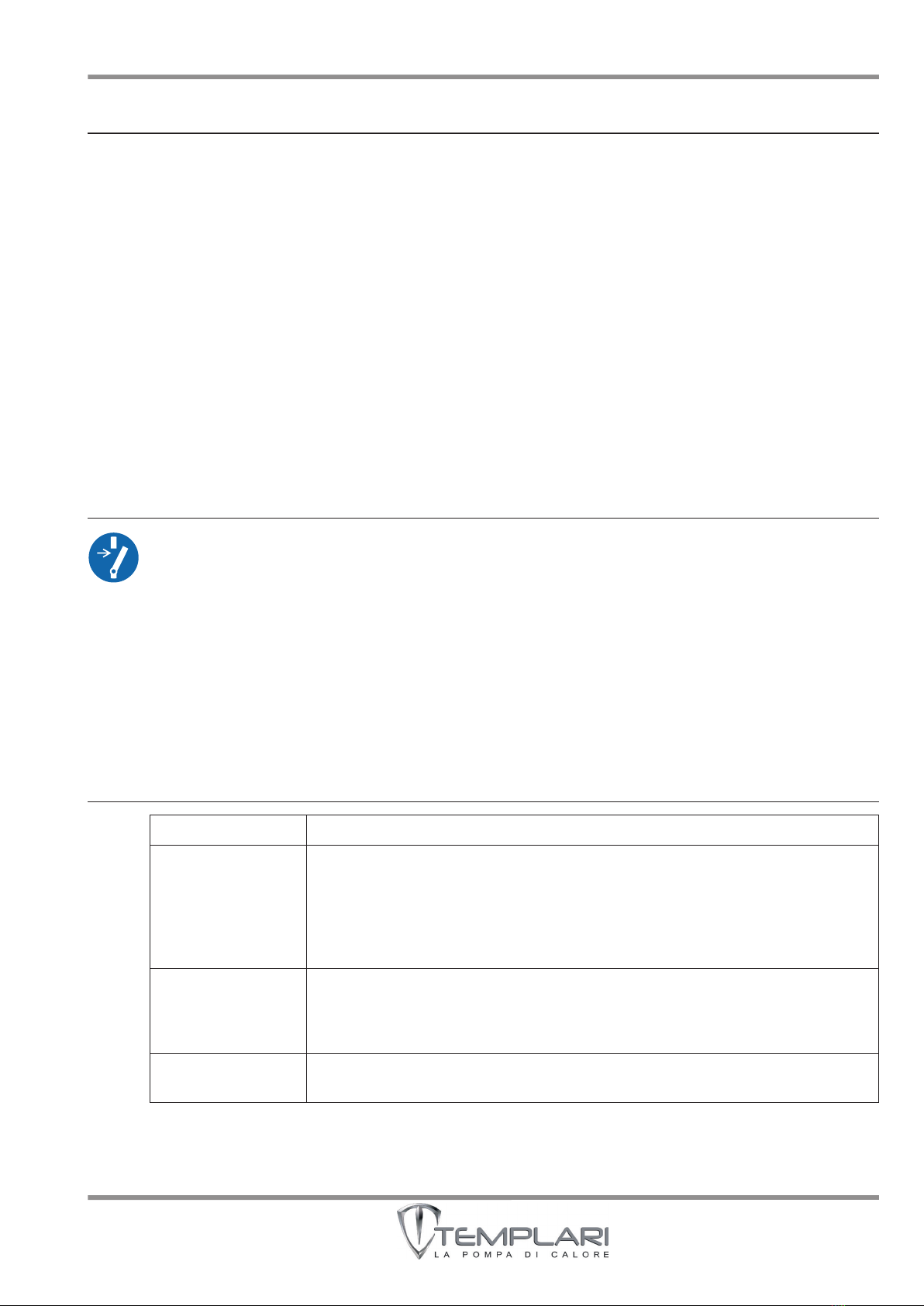

13.9.2 Choice of system layout ............................................................................................................................. 61

13.9.3 Connection to the electrical energy source ............................................................................................... 64

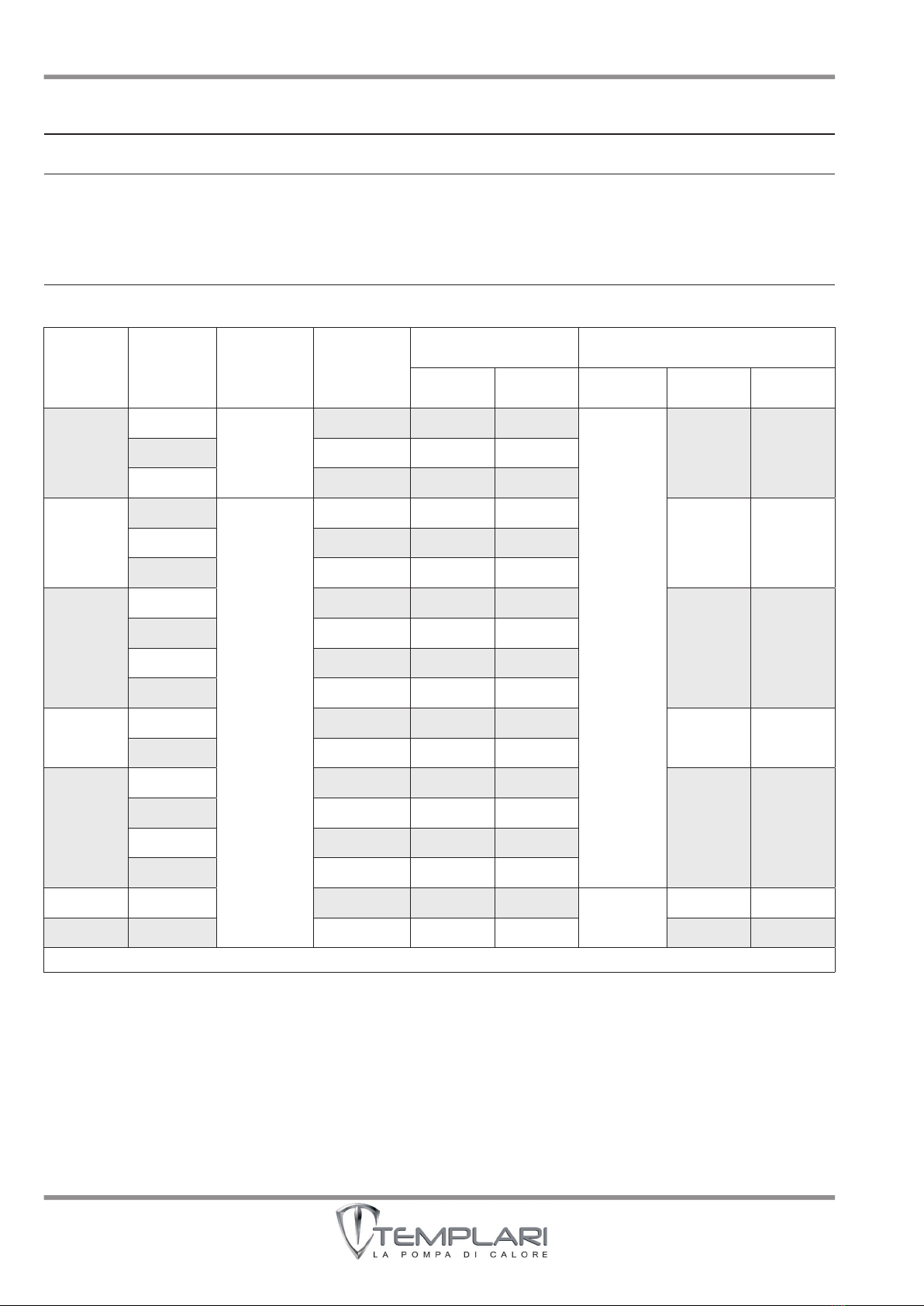

13.9.4 Indicative section for cables and internal protections................................................................................. 65

13.10 Probes and remote panel.................................................................................................................................. 66

13.11 Terminal wiring .................................................................................................................................................. 67

13.11.1 OutdoorunitμPCwiring ............................................................................................................................. 67

13.11.2 Digital outputs............................................................................................................................................. 68

13.11.3 Digital inputs............................................................................................................................................... 68

13.11.4 Analog outputs ........................................................................................................................................... 68

13.11.5 Analog inputs.............................................................................................................................................. 68

13.11.6 ElectronicboardμPC ................................................................................................................................. 69

13.11.7 SG-Probe electronic board......................................................................................................................... 70

13.11.8 Secondary electrical panel terminal board - K-Touch panel connection..................................................... 71

13.11.9 T-SPLIT module ......................................................................................................................................... 72

13.11.10 Three-way valve connection ..................................................................................................................... 73

13.11.11 Plant Aware function.................................................................................................................................. 74

13.11.12 Electrical connection - “Multi-KITA” ........................................................................................................... 76

13.12 SG Ready protocol............................................................................................................................................ 77

13.13 Smart-Grid Operation........................................................................................................................................ 78

13.13.1 PGD (screen) ............................................................................................................................................. 79

14 USE OF THE MACHINE..........................................................................................................................80

14.1 Checks and operations before commissioning.................................................................................................... 80

14.2 Starting the machine for testing .......................................................................................................................... 80

14.3 Checks and operations after commissioning....................................................................................................... 81

14.4 Testing................................................................................................................................................................. 81

14.5 K-Touch panel ..................................................................................................................................................... 82

14.5.1 General Notices.......................................................................................................................................... 82

14.5.2 Preparing the machine for connecting the K-Touch panel.......................................................................... 82

14.6 Connection to the Kita heat pump....................................................................................................................... 84

14.7 HCC Connection (Example)................................................................................................................................ 85

14.8 PGD control terminal (optional)........................................................................................................................... 86

14.8.1 Fastening the terminal................................................................................................................................ 86

14.8.2 Terminal functions ...................................................................................................................................... 87

14.8.3 Terminal display.......................................................................................................................................... 88

14.9 Main menu........................................................................................................................................................... 89

14.10 ON-OFF menu .................................................................................................................................................. 90

14.11 Clock/Time slots Menu...................................................................................................................................... 92

14.12 Inputs/Outputs menu......................................................................................................................................... 93

14.13 Alarm Log menu................................................................................................................................................ 95

14.14 Card change menu............................................................................................................................................ 95