Temposonics E Series User manual

E-Series IO-Link

Operation Manual

Magnetostrictive Linear Position Sensors

Temposonics® E-Series IO-Link

Operation Manual

Table of contents

1. Introduction..................................................................................................................................................... 3

1.1 Purpose and use of this manual ................................................................................................................................................................ 3

1.2 Used symbols and warnings ..................................................................................................................................................................... 3

2. Safety instructions............................................................................................................................................. 3

2.1 Intended use.............................................................................................................................................................................................. 3

2.2 Forseeable misuse..................................................................................................................................................................................... 3

2.3 Installation, commissioning and operation................................................................................................................................................ 4

2.4 Safety instructions for use in explosion-hazardous areas.......................................................................................................................... 4

2.5 Warranty.................................................................................................................................................................................................... 4

2.6 Return ....................................................................................................................................................................................................... 4

3. Identification.................................................................................................................................................... 5

3.1 Order code of Temposonics®EH ............................................................................................................................................................... 5

3.2 Order code of Temposonics® EP................................................................................................................................................................ 6

3.3 Order code of Temposonics® EL ................................................................................................................................................................ 7

3.4 Order code of Temposonics® EP2.............................................................................................................................................................. 8

3.5 Order code of Temposonics® ER................................................................................................................................................................ 9

3.6 Nameplate ............................................................................................................................................................................................... 10

3.7 Approvals ................................................................................................................................................................................................ 10

3.8 Scope of delivery..................................................................................................................................................................................... 10

4. Product description and commissioning ..................................................................................................................11

4.1 Functionality and system design ............................................................................................................................................................. 11

4.2 Styles and installation of Temposonics® EH............................................................................................................................................. 12

4.3 Styles and installation of Temposonics® EP............................................................................................................................................. 14

4.4 Styles and installation of Temposonics® EL ............................................................................................................................................. 15

4.5 Styles and installation of Temposonics® EP2........................................................................................................................................... 16

4.6 Styles and installation of Temposonics® ER............................................................................................................................................. 17

4.7 Magnet installation .................................................................................................................................................................................. 18

4.8 Electrical connections.............................................................................................................................................................................. 20

4.9 Frequently ordered accessories............................................................................................................................................................... 21

5. Operation.......................................................................................................................................................23

5.1 Identification parameter........................................................................................................................................................................... 23

5.2 Standard commands ............................................................................................................................................................................... 24

5.3 Measuring parameter .............................................................................................................................................................................. 24

5.4 Offset....................................................................................................................................................................................................... 24

5.5 Switch points........................................................................................................................................................................................... 25

5.6 Set measurement range .......................................................................................................................................................................... 26

5.7 Error / warning messages ....................................................................................................................................................................... 27

5.8 Data storage mechanism......................................................................................................................................................................... 27

5.9 Device Access Lock................................................................................................................................................................................. 28

6. Integration into Automation Studio ........................................................................................................................29

6.1 Introduction of "Automation Studio" ........................................................................................................................................................ 29

6.2 Import IODD files .................................................................................................................................................................................... 29

6.3 Configure process data............................................................................................................................................................................ 30

7. Maintenance and troubleshooting .........................................................................................................................33

7.1 Error conditions, troubleshooting............................................................................................................................................................ 33

7.2 Maintenance............................................................................................................................................................................................ 33

7.3 Repair...................................................................................................................................................................................................... 33

7.4 List of spare parts ................................................................................................................................................................................... 33

7.5 Transport and storage ............................................................................................................................................................................. 33

8. Removal from service / dismantling.......................................................................................................................33

9. Technical data.................................................................................................................................................34

9.1 Technical data of Temposonics® EH......................................................................................................................................................... 34

9.2 Technical data of Temposonics® EP ......................................................................................................................................................... 35

9.3 Technical data of Temposonics® EL ......................................................................................................................................................... 36

9.4 Technical data of Temposonics® EP2 ....................................................................................................................................................... 37

9.5 Technical data of Temposonics® ER......................................................................................................................................................... 38

10. Appendix......................................................................................................................................................39

Temposonics® E-Series IO-Link

Operation Manual

I 3 I

1.2 Used symbols and warnings

Warnings are intended for your personal safety and for avoidance

of damage to the described product or connected devices. In this

documentation safety information and warnings to avoid danger

that might affect the life and health of operating or service personnel

or cause material damage are highlighted by the preceding pictogram

which is defined below.

1. Introduction

1.1 Purpose and use of this manual

Before starting the operation of Temposonics®position sensors,

read this documentation thoroughly and follow the safety

information. Keep the manual for future reference!

Symbol Meaning

NOTICE This symbol is used to point to situations

that may lead to material damage, but not

to personal injury.

1/ The term qualified technical personnel characterizes persons who:

• are familiar with the safety concepts of automation technology applicable

to the particular project,

• are competent in the field of electromagnetic compatibility (EMC),

• have received adequate training for commissioning and service operations

• are familiar with the operation of the device and know the information required

for correct operation provided in the product documentation.

2. Safety instructions

2.1 Intended use

This product may be used only for the applications defined under item

1 and only in conjunction with the third-party devices and components

recommended or approved by 5FNQPTPOJDT. As a prerequisite of

proper and safe operation the product requires correct transport,

storage, mounting and commissioning and must be operated with

utmost care.

1. The sensor systems of all Temposonics®series are intended

exclusively for measurement tasks encountered in industrial,

commercial and laboratory applications. The sensors are

considered as system accessories and must be connected

to suitable evaluation electronics, e.g. a PLC, IPC, indicator

or other electronic control unit.

Foreseeable misuse Consequence

Wrong sensor connection The sensor will not work

properly or can be damaged

Operate the sensor out of the

operating temperature range

No signal output

The sensor can be damaged

Power supply is out of the

defined range

Signal output is wrong /

no signal output /

the sensor can be damaged

Position measurement is

influenced by an external

magnetic field

Signal output is wrong

Cables are damaged

Short circuit – the sensor can

be destroyed / sensor does not

respond

Spacers are missing /

are installed in the wrong order Error in position measurement

Wrong connection

of ground / shield

Signal output is disturbed

The electronics can be damaged

Use of a magnet that is not

certified by 5FNQPTPOJDT Error in position measurement

Do not reprocess the sensor afterwards.

ÎThe sensor might be damaged.

Do not step on the sensor.

ÎThe sensor might be damaged.

2.2 Forseeable misuse

The content of this technical documentation and of its appendix

is intended to provide information on mounting, installation and

commissioning by qualified automation personnel 1or instructed

service technicians who are familiar with the project planning and

dealing with Temposonics®sensors.

Temposonics® E-Series IO-Link

Operation Manual

I 4 I

2.3 Installation, commissioning and operation

The position sensors must be used only in technically safe condition.

To maintain this condition and to ensure safe operation, installation,

connection and service, work may be performed only by qualified

technical personnel.

If danger of injury to persons or of damage to operating equipment

is caused by sensor failure or malfunction, additional safety measures

such as plausibility checks, limit switches, EMERGENCY STOP

systems, protective devices etc. are required. In the event of trouble,

shut down the sensor and protect it against accidental operation.

Safety instructions for commissioning

To maintain the sensor's operability, it is mandatory to follow

the instructions given below.

1. Protect the sensor against mechanical damage during

installation and operation.

2. Do not open or dismantle the sensor.

3. Connect the sensor very carefully and pay attention to the

polarity of connections and power supply.

4. Use only approved power supplies.

5. It is indispensable to ensure that the specified permissible

limit values of the sensor for operating voltage,

environmental conditions, etc. are met.

6. Check the function of the sensor regularly and provide

documentation of the checks.

7. Before applying power, ensure that nobody’s safety

is jeopardized by starting machines.

2.4 Safety instructions for use in explosion-hazardous areas

The sensor is not suitable for operation in explosion-hazardous areas.

2/ See also applicable 5FNQPTPOJDT terms of sales and delivery on

www.UFNQPTPOJDT.com

2.5 Warranty

5FNQPTPOJDT grants a warranty period for the Temposonics®position

sensors and supplied accessories relating to material defects and

faults that occur despite correct use in accordance with the intended

application 2. The 5FNQPTPOJDT obligation is limited to repair or

replacement of any defective part of the unit. No warranty can be

provided for defects that are due to improper use or above average

stress of the product, as well as for wear parts. Under no

circumstances will 5FNQPTPOJDT accept liability in the event of offense

against the warranty rules, no matter if these have been assured or

expected, even in case of fault or negligence of the company.

5FNQPTPOJDT explicitly excludes any further warranties. Neither

the company’s representatives, agents, dealers nor employees are

authorized to increase or change the scope of warranty.

2.6 Return

For diagnostic purposes, the sensor can be returned to 5FNQPTPOJDT

or a repair facility explicitly authorized by 5FNQPTPOJDT. Any shipment

cost is the responsibility of the sender 2.

For a corresponding form, see chapter "10. Appendix" on page 39.

Temposonics® E-Series IO-Link

Operation Manual

I 5 I

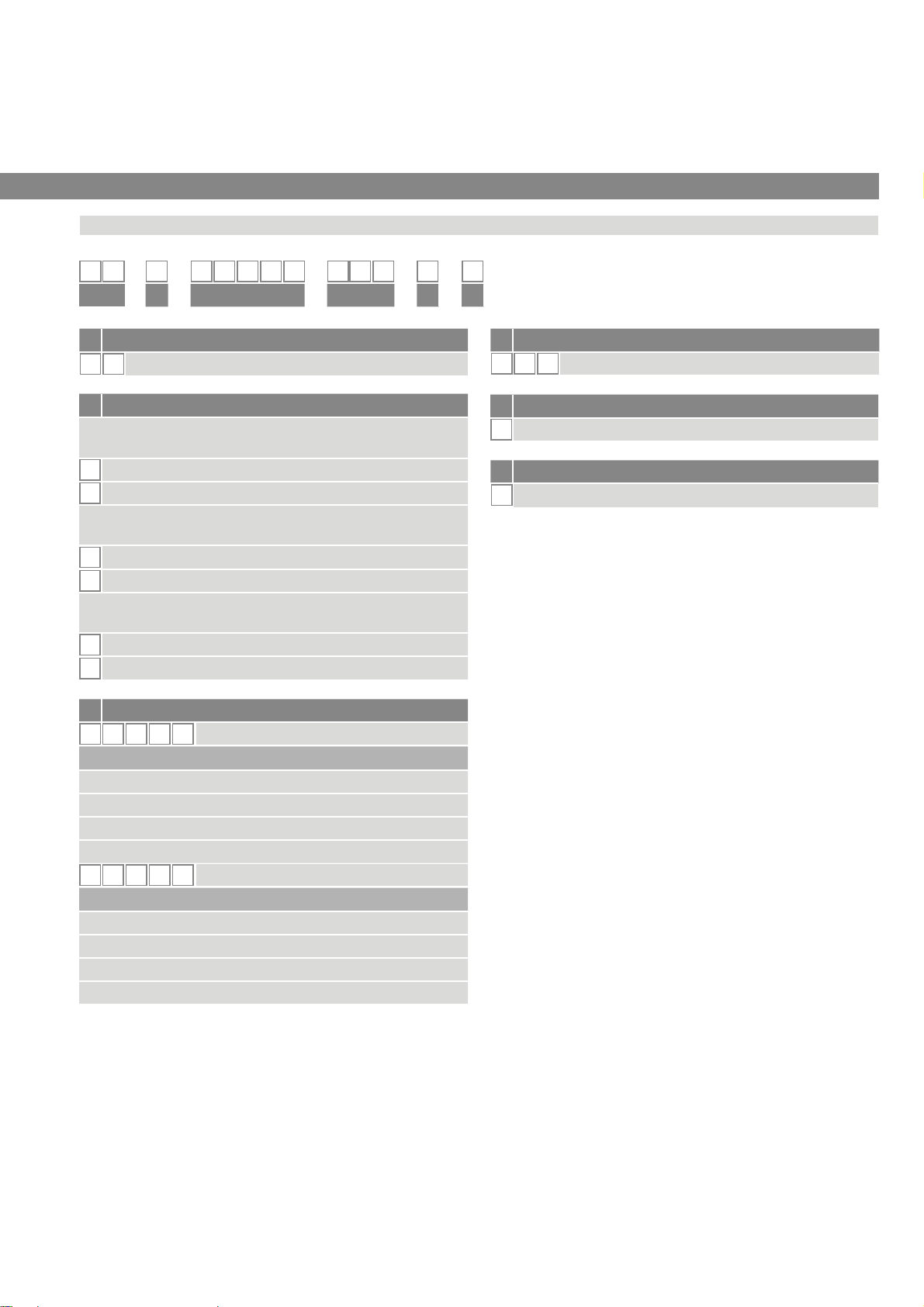

3.1 Order code of Temposonics®EH

*/ Non standard stroke lengths are available; must be encoded in 5 mm / 0.1 in. increments

3. Identification

1 2 3 4 5 6 7 8 9 10 11 12 13

E H D 4 4 1K

ab c d ef

b Design

EH rod-style sensor with housing material 1.4305 (AISI 303)

and rod material 1.4301 (AISI 304)

KFlange M18×1.5-6g, 7 mm rod Ø

LFlange ¾"-16 UNF-3A, 7 mm rod Ø

EH rod-style sensor with housing material 1.4305 (AISI 303)

and rod material 1.4306 (AISI 304L)

MFlange M18×1.5-6g, 10 mm rod Ø

SFlange ¾"-16 UNF-3A, 10 mm rod Ø

EH rod-style sensor with housing material 1.4404 (AISI 316L)

and rod material 1.4404 (AISI 316L)

FFlange ¾"-16 UNF-3A, 10 mm rod Ø

WFlange M18×1.5-6g, 10 mm rod Ø

a Sensor model

E H Rod

d Connection type

D 4 4 M12 (4 pin) male connector

e Operating voltage

1+24 VDC (±25 %)

f Output

KIO-Link

c Stroke length

X X X X M 0050…2540 mm

X X X X U002.0…100.0 in.

.

Standard stroke length (mm*) Ordering steps

50 … 500 mm 5 mm

500 … 750 mm 10 mm

750…1000 mm 25 mm

1000…2540 mm 50 mm

Standard stroke length (in.) Ordering steps

2 … 20 in. 0.2 in.

20 … 30 in. 0.5 in.

30 … 40 in. 1.0 in.

40…100 in. 2.0 in.

Other manuals for E Series

1

Table of contents

Other Temposonics Accessories manuals