Temposonics GB Series User manual

Operation Manual

GB-Series SSI

Magnetostriktive Lineare Positionssensoren

2

Temposonics®GB-Series SSI

Operation Manual

Table of contents

1. Introduction.......................................................................................................................................................3

1.1 Purpose and use of this manual....................................................................................................................................................................3

1.2 Used symbols and warnings .........................................................................................................................................................................3

2. Safety instructions...............................................................................................................................................3

2.1 Intended use..................................................................................................................................................................................................3

2.2 Forseeable misuse.........................................................................................................................................................................................3

2.3 Installation, commissioning and operation....................................................................................................................................................4

2.4 Safety instructions for use in explosion-hazardous areas .............................................................................................................................4

2.5 Warranty........................................................................................................................................................................................................4

2.6 Return ...........................................................................................................................................................................................................4

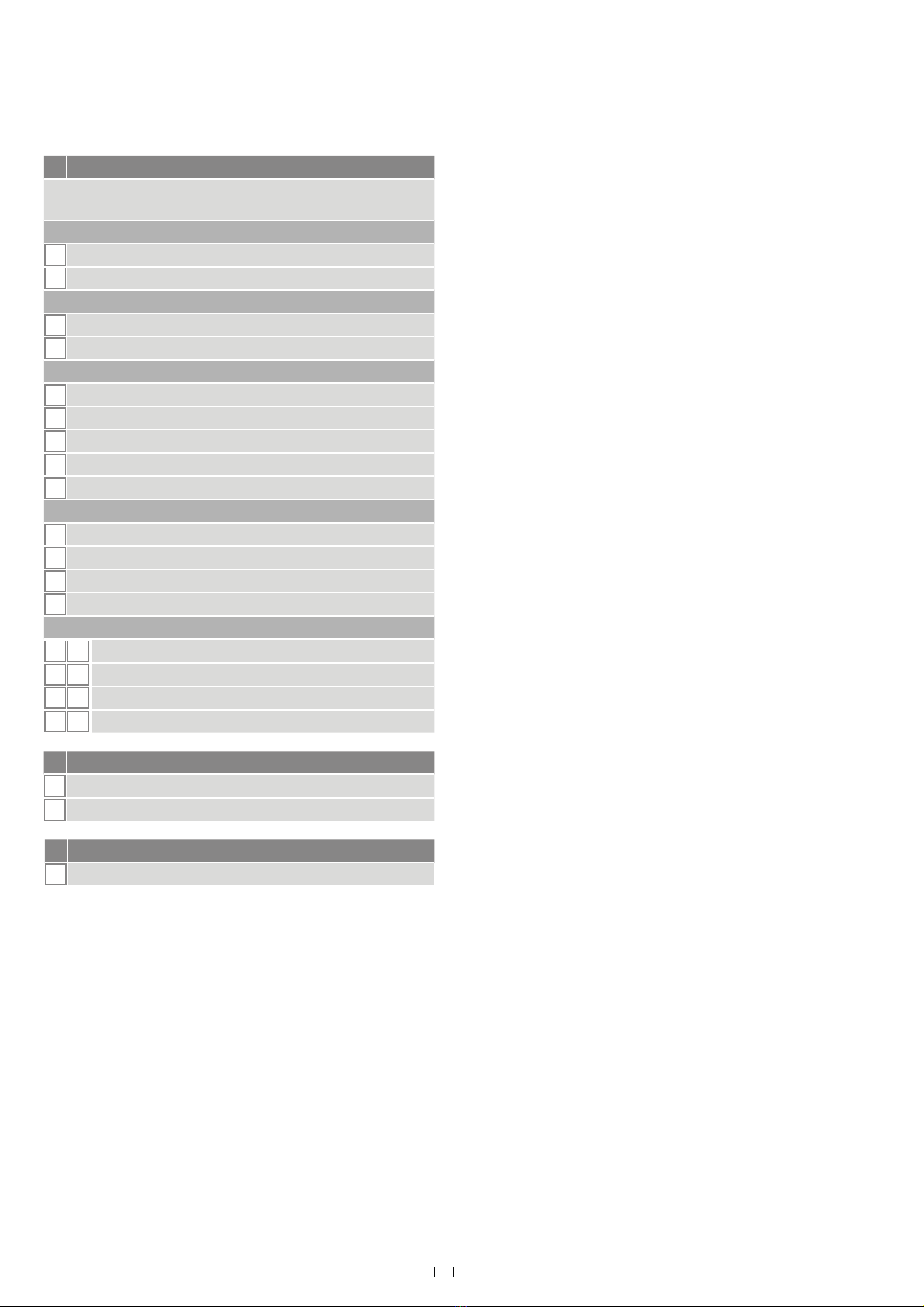

3. Identification......................................................................................................................................................5

3.1 Order code Temposonics®GB ....................................................................................................................................................................... 5

3.2 Nameplate (example) ....................................................................................................................................................................................7

3.3 Approvals ......................................................................................................................................................................................................7

3.4 Scope of delivery........................................................................................................................................................................................... 7

4. Product description and commissioning .....................................................................................................................7

4.1 Functionality and system design ...................................................................................................................................................................7

4.2 Styles and installation of Temposonics®GB-J / GB-K / GB-N / GB-S............................................................................................................. 8

4.3 Styles and installation of Temposonics®GB-M / GB-T / GB-B .....................................................................................................................10

4.4 Magnet installation......................................................................................................................................................................................12

4.5 Change orientation of sensor electronics housing.......................................................................................................................................14

4.6 Replacement of base unit............................................................................................................................................................................14

4.7 Electrical connection ...................................................................................................................................................................................15

4.8 Frequently ordered accessories...................................................................................................................................................................16

5. Operation........................................................................................................................................................ 18

5.1 Getting started.............................................................................................................................................................................................18

5.2 Programming and configuration .................................................................................................................................................................18

6. Maintenance and troubleshooting .......................................................................................................................... 21

6.1 Error conditions, troubleshooting................................................................................................................................................................21

6.2 Maintenance................................................................................................................................................................................................21

6.3 Repair..........................................................................................................................................................................................................21

6.4 List of spare parts .......................................................................................................................................................................................21

6.5 Transport and storage ................................................................................................................................................................................. 21

7. Removal from service / dismantling........................................................................................................................ 21

8. Technical data.................................................................................................................................................. 22

8.1 Technical data GB-J / GB-K / GB-N / GB-S.................................................................................................................................................. 22

8.2 Technical data GB-M / GB-T ........................................................................................................................................................................ 23

9. Appendix ........................................................................................................................................................ 24

3

Temposonics® GB-Series SSI

Operation Manual

1. Introduction

1.1 Purpose and use of this manual

The content of this technical documentation and of its appendix is

intended to provide information on mounting, installation and com-

PLVVLRQLQJE\TXDOLğHGDXWRPDWLRQSHUVRQQHO1or instructed service

technicians who are familiar with the project planning and dealing

with Temposonics®sensors.

1.2 Used symbols and warnings

Warnings are intended for your personal safety and for avoidance of

damage to the described product or connected devices. In this doc-

umentation, safety information and warnings to avoid dangers that

might affect the life and health of operating or service personnel or

cause material damage are highlighted by the preceding pictogram,

ZKLFKLVGHğQHGEHORZ

2. Safety instructions

2.1 Intended use

7KLVSURGXFWPD\EHXVHGRQO\IRUWKHDSSOLFDWLRQVGHğQHGXQGHULWHP

1 and only in conjunction with the third-party devices and compo-

nents recommended or approved by MTS Sensors. As a prerequisite

of proper and safe operation, the product requires correct transport,

storage, mounting and commissioning and must be operated with

utmost care.

1. The sensor systems of all Temposonics®series are intended

exclusively for measurement tasks encountered in industrial,

commercial and laboratory applications. The sensors are

considered as system accessories and must be connected to

suitable evaluation electronics, e.g. a PLC, IPC, indicator or

other electronic control unit.

Before starting the operation of Temposonics®position sensors read

this documentation thoroughly and follow the safety information.

Keep the manual for future reference!

Symbol Meaning

This symbol is used to point to situations

that may lead to material damage, but not to

personal injury.

NOTICE

2.2 Forseeable misuse

Do not step on the sensor.

The sensor might be damaged.

Do not alter the sensor afterwards.

The sensor might be damaged.

1/ 7KHWHUPTXDOLğHGWHFKQLFDOSHUVRQQHOFKDUDFWHUL]HVSHUVRQVZKR

• are familiar with the safety concepts of automation technology applicable to the

particular project,

• DUHFRPSHWHQWLQWKHğHOGRIHOHFWURPDJQHWLFFRPSDWLELOLW\(0&

• have received adequate training for commissioning and service operations

• are familiar with the operation of the device and know the information required for

correct operation provided in the product documentation.

Foreseeable misuse Consequence

Wrong sensor connection The sensor will not work

properly or can be damaged

Operate the sensor out of the

operating temperature range

No signal output

The sensor can be damaged

Power supply is out of the

defined range

Signal output is wrong /

no signal output /

the sensor can be damaged

Position measurement is

influenced by an external

magnetic field

Signal output is wrong

Cables are damaged

Short circuit – the sensor can

be destroyed / sensor does not

respond

Spacers are missing /

installed in wrong order Error in position measurement

Wrong connection

of ground / shield

Signal output is disturbed

The electronics can be damaged

Use of a magnet that is not

certified by MTS Sensors Error in position measurement

4

Temposonics®GB-Series SSI

Operation Manual

2.3 Installation, commissioning and operation

The position sensors must be used only in technically safe condition.

To maintain this condition and to ensure safe operation, installation,

FRQQHFWLRQDQGVHUYLFHZRUNVKRXOGRQO\EHSHUIRUPHGE\TXDOLğHG

technical personnel.

If danger of injury to persons or of damage to operating equipment is

caused by sensor failure or malfunction, additional safety measures

VXFKDVSODXVLELOLW\FKHFNVOLPLWVZLWFKHV(0(5*(1&<6723V\V-

tems, protective devices etc. are required. In the event of trouble, shut

down the sensor and protect it against accidental operation.

Safety instructions for commissioning

To maintain the sensor's operability, it is mandatory to follow the

instructions given below.

1. Protect the sensor against mechanical damage during installation

and operation.

2. Do not open or dismantle the sensor.

3. Connect the sensor very carefully and pay attention to the polarity

of connections and power supply.

4. Use only approved power supplies.

5. ,WLVLQGLVSHQVDEOHWRHQVXUHWKDWWKHVSHFLğHGSHUPLVVLEOHOLPLW

values of the sensor for operating voltage, environmental condi-

tions, etc. are met.

6. Check the function of the sensor regularly and provide documenta-

tion of the checks.

7. %HIRUHDSSO\LQJSRZHUHQVXUHWKDWQRERG\łVVDIHW\LVMHRSDUGL]HG

by starting machines.

2.4 Safety instructions for use in explosion-hazardous areas

7KHVHQVRULVQRWVXLWDEOHIRURSHUDWLRQLQH[SORVLRQKD]DUGRXVDUHDV

2/ See also applicable MTS Sensors terms of sales and delivery on

www.mtssensors.com

2.5 Warranty

MTS Sensors grants a warranty period for the Temposonics®posi-

tion sensors and supplied accessories relating to material defects and

faults that occur despite correct use in accordance with the intended

application 2. The MTS Sensors obligation is limited to repair or re-

SODFHPHQWRIDQ\GHIHFWLYHSDUWRIWKHXQLW1RZDUUDQW\FDQEHSURYLG-

ed for defects that are due to improper use or above average stress of

the product, as well as for wear parts.

Under no circumstances will MTS Sensors accept liability in the event

of offense against the warranty rules, no matter if these have been as-

sured or expected, even in case of fault or negligence of the company.

MTS Sensors explicitly excludes any further warranties.

1HLWKHUWKHFRPSDQ\łVUHSUHVHQWDWLYHVDJHQWVGHDOHUVQRUHPSOR\HHV

DUHDXWKRUL]HGWRLQFUHDVHRUFKDQJHWKHVFRSHRIZDUUDQW\

2.6 Return

For diagnostic purposes, the sensor can be returned to MTS Sensors

or a repair facility explicitly authorized by MTS Sensors. Any shipment

cost is the responsibility of the sender 2. For a corresponding form,

see chapter “9. Appendix” on page 24.

5

Temposonics® GB-Series SSI

Operation Manual

3. ,GHQWLğFDWLRQ

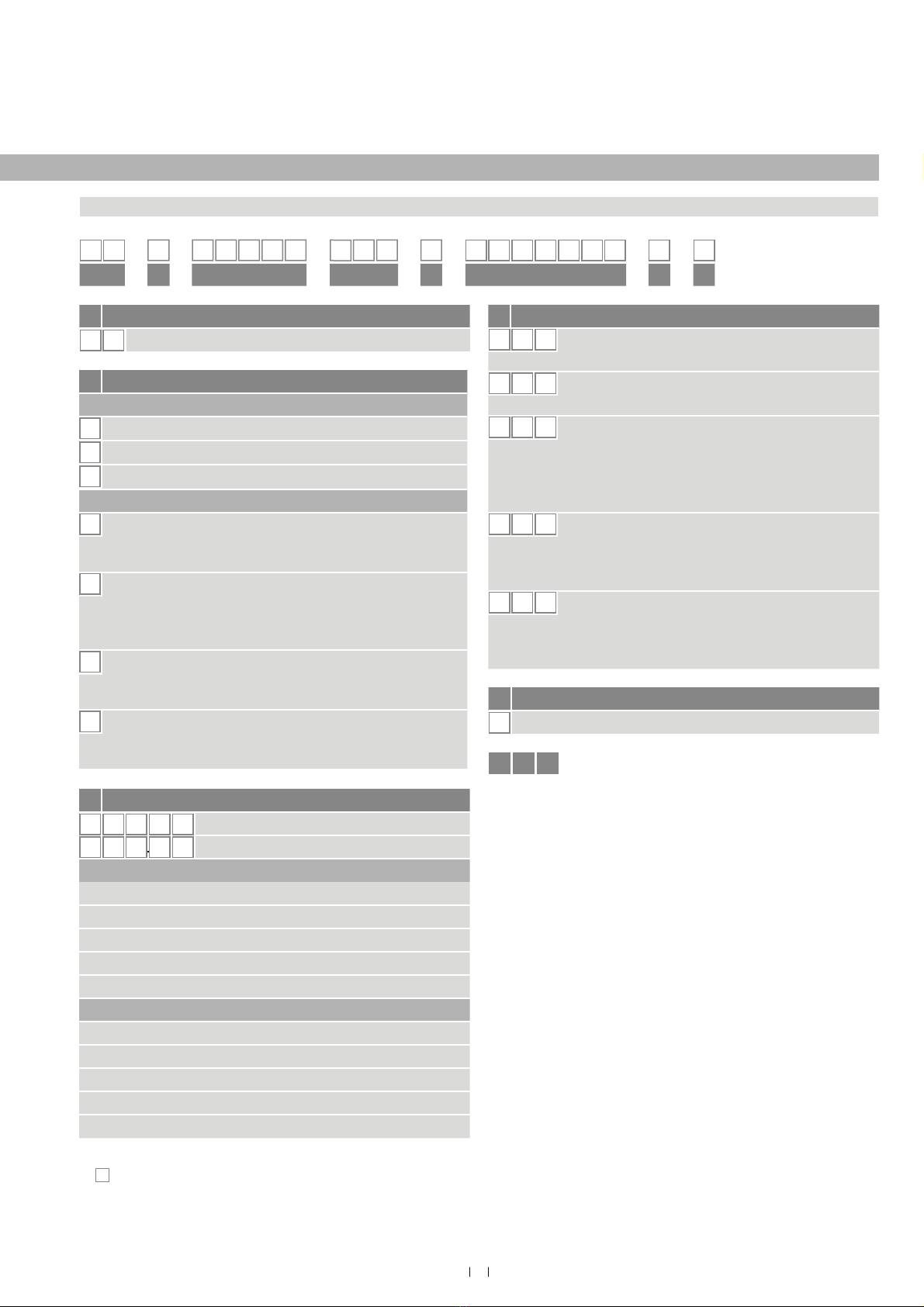

3. rder code Temposonics®GB

Trademarks and trade names mentioned in this document are those of their

respective owners.

d onnector type

4 0PDOHFRQQHFWRUSLQ

1RWHWKHRSHUDWLQJWHPSHUDWXUHRIWKHFRQQHFWRU

0PDOHFRQQHFWRUSLQ

1RWHWKHRSHUDWLQJWHPSHUDWXUHRIWKHFRQQHFWRU

+Ľ+ĽP4;;P385FDEOH

SDUWQR

+Ľ+ĽIW4 ft 385FDEOH

SDUWQR

1RWHWKHRSHUDWLQJWHPSHUDWXUHRIWKHFDEOH

T 7Ľ7ĽP4;;P7HĠRQ®cable

SDUWQR

7Ľ7ĽIW4 ft 7HĠRQ®cable

SDUWQR

9Ľ9ĽP4 m Silicone cable

SDUWQR

9Ľ9ĽIW4 ft Silicone cable

SDUWQR

e perating oltage

9'&ũ

a Sensor model

G B 5RG

3/ 7KHVHQVRULQVWDLQOHVVVWHHO$,6,/LVRQO\DYDLODEOHZLWKIROORZLQJRSWLRQ

SũĽŹ&ũĽŹ)

*/ 1RQVWDQGDUGVWURNHOHQJWKVDUHDYDLODEOHPXVWEHHQFRGHGLQPPLQLQFUHPHQWV

4/ (QFRGHLQPHWHUVLIXVLQJPHWULFVWURNHOHQJWK(QFRGHLQIHHWLIXVLQJ86FXVWRPDU\

stroke length

12 3 45679111 12 1314151617 19 2 21

G B S

a c d e f gh

.

c Stroe length

25325 mm

ĽLQ

Standard stroe length mm rdering steps

25 5 mm 5 mm

5 75 mm 1 mm

751 mm 25 mm

125 mm 5 mm

25325 mm 1 mm

Standard stroe length in. rdering steps

1 2 in. .2 in.

2 3 in. .5 in.

3 4 in. 1. in.

41 in. 2. in.

ĽLQ 4. in.

esign

*%ZLWKWKUHDGHGĠDQJH

B%DVHXQLWIRUWKUHDGHGĠDQJHVŊ0ʼnDQGŊ7ʼnUHSODFHPHQWRQO\

7KUHDGHGĠDQJHZLWKĠDWIDFH0ūJ

T7KUHDGHGĠDQJHZLWKUDLVHGIDFHŧ81)$

*%ZLWKSUHVVXUHğWĠDQJH

ousing material stainless steel .435 ISI 33,

rod material stainless steel .43 ISI 34

3UHVVXUHğWĠDQJHPPPPURGEDU

ousing material stainless steel .435 ISI 33,

rod material stainless steel .436 .43 ISI 34

3UHVVXUHğWĠDQJHPPPPURGZLWKEXVKLQJ

on rod end

ousing material stainless steel .444 ISI 36,

rod material stainless steel .444 ISI 363

3UHVVXUHğWĠDQJHPPPPURG

Sousing material stainless steel .435 ISI 33,

rod material stainless steel .436 .43 ISI 34

3UHVVXUHğWĠDQJHPPPPURG fSee next page

gh

6

Temposonics®GB-Series SSI

Operation Manual

g perating temperature

ũĽŹ&ũĽŹ)

SũĽŹ&ũĽŹ)

h rogramming

ia cable

f utput

S 4 5 6

Synchronous Serial Interface

ata length ox no. 4

25 bit

224 bit

utput format ox no. 5

Binary

G*UD\

Resolution ox no. 6

.5 mm

2.1 mm

3.5 mm

4.1 mm

5.2 mm

iltering performance ox no.

1RğOWHU

2$YHUDJHğOWHU

3$YHUDJHğOWHU

4$YHUDJHğOWHU

erformance ox no. ,

Measuring direction forward, asynchronous measurement

Measuring direction reverse, asynchronous measurement

2 Measuring direction forward, synchronous measurement

3Measuring direction reverse, synchronous measurement

7

Temposonics® GB-Series SSI

Operation Manual

3.2 ameplate example

3.3 pproals

&(FHUWLğFDWLRQ

4. roduct description and commissioning

3.4 Scope of deliery

GB- GB- GB- GB-S(rod sensor with pressure fit flange)

Sensor

O-ring

ack-up ring

GB- GB-T (rod sensor with threaded flange)

Sensor

O-ring

GB-B (base unit for rod sensor with threaded flange)

Sensor

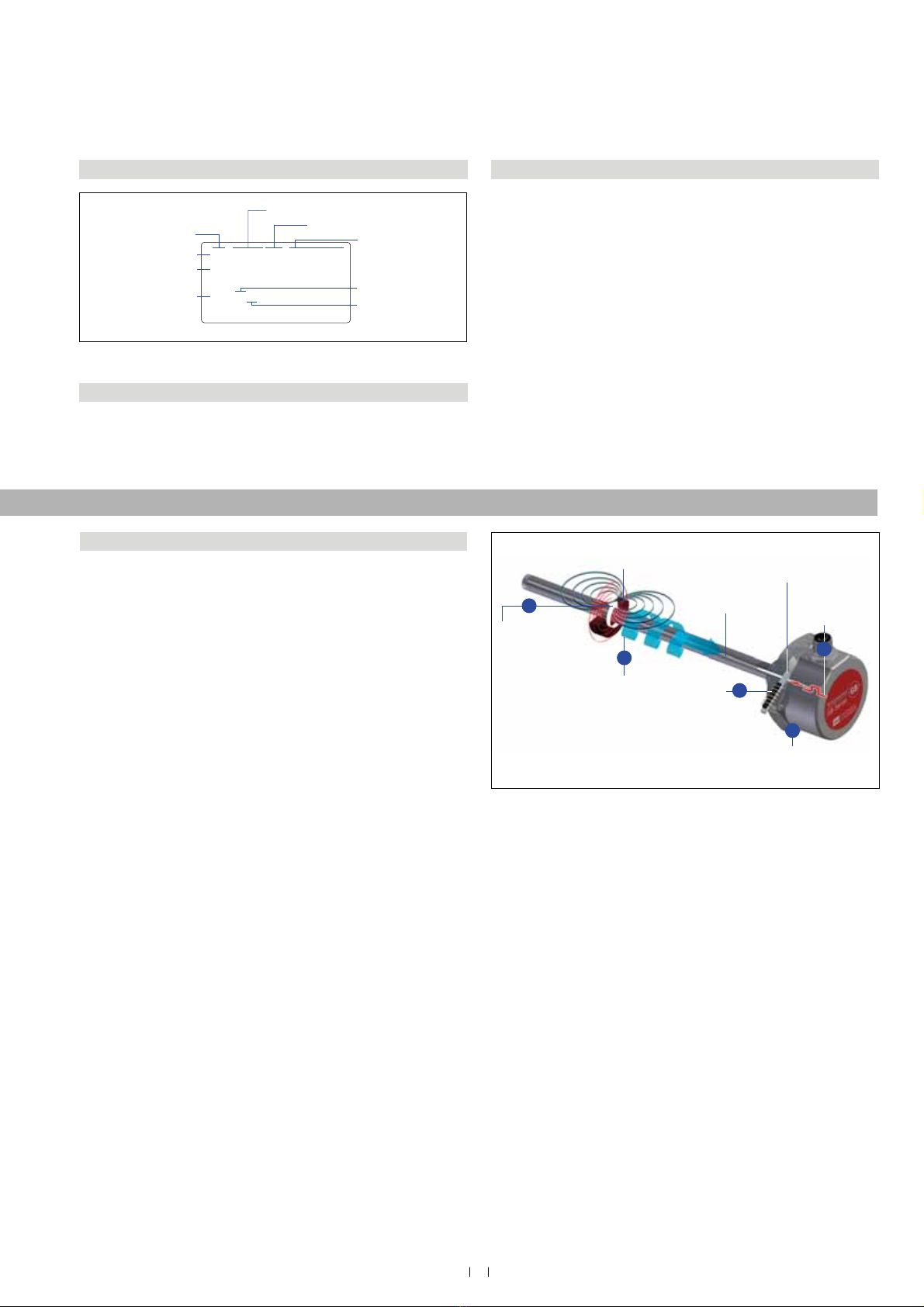

4. unctionality and system design

roduct designation

Position sensor Temposonics®*%6HULHV

Sensor model

Temposonics®*%-*%.*%1*%6*%0*%7VHQVRUURG

Stroke length 25PPĽLQ

utput signal

SSI

pplication

Temposonics®position sensors are used for measurement and con-

YHUVLRQRIWKHOHQJWKSRVLWLRQYDULDEOHLQWKHğHOGVRIDXWRPDWHG

systems and mechanical engineering.

rinciple of operation and system construction

The absolute, linear position sensors provided by MTS Sensors

rely on the companys proprietary Temposonics®magnetostrictive

technology, which can determine position with a high level of

SUHFLVLRQDQGUREXVWQHVV(DFK7HPSRVRQLFV®position sensor

consists of a ferromagnetic waveguide, a position magnet, a strain

pulse converter and supporting electronics. The magnet, connected

WRWKHREMHFWLQPRWLRQLQWKHDSSOLFDWLRQJHQHUDWHVDPDJQHWLFğHOG

at its location on the waveguide. A short current pulse is applied to

WKHZDYHJXLGH7KLVFUHDWHVDPRPHQWDU\UDGLDOPDJQHWLFğHOGDQG

torsional strain on the waveguide. The momentary interaction of the

PDJQHWLFğHOGVUHOHDVHVDWRUVLRQDOVWUDLQSXOVHWKDWSURSDJDWHVWKH

length of the waveguide. hen the ultrasonic wave reaches the end of

the waveguide it is converted into an electrical signal. Since the speed

of the ultrasonic wave in the waveguide is precisely known, the time

required to receive the return signal can be converted into a linear

position measurement with both high accuracy and repeatability.

odular mechanical and electronic construction

The sensor rod protects the inner sensor element.

The sensor electronics housing, a rugged stainless steel

construction, contains the complete electronic interface with active

signal conditioning.

The external position magnet is a permanent magnet. Mounted on

the mobile machine part, it travels along the sensor rod and triggers

the measurement through the sensor rod wall.

The sensor can be directly connected to a control system. Its

electronics generates a position signal output proportional to the

start and end of the active measuring range.

Fig. 1: Example of a nameplate of a GB-S sensor

Fig. 2: 7LPHRIĠLJKWEDVHGPDJQHWRVWULFWLYHSRVLWLRQVHQVLQJSULQFLSOH

5

Sensing element

(Waveguide)

Position magnet (Magnetic field) Torsional strain

pulse converter

4

Current pulse

generates

magnetic field

Interaction with

position magnet

field generates

torsional strain

pulse Torsional strain

pulse propagates

Strain pulse

detected by

converter

Time-of-flight converted

into position

1

2

3

GBS0850MD701S2G5100SC

0.02 mm / 24 Bit gray

Grd.: 2807.46 m/s

FNr. 1601 0376

1601037616010376160103761601

Sensor model

Stroke length (e.g. 850 mm)

Connection type

Output

version

Part no.

Output

Production no. Week

Year

Temposonics®GB-Series SSI

Operation Manual

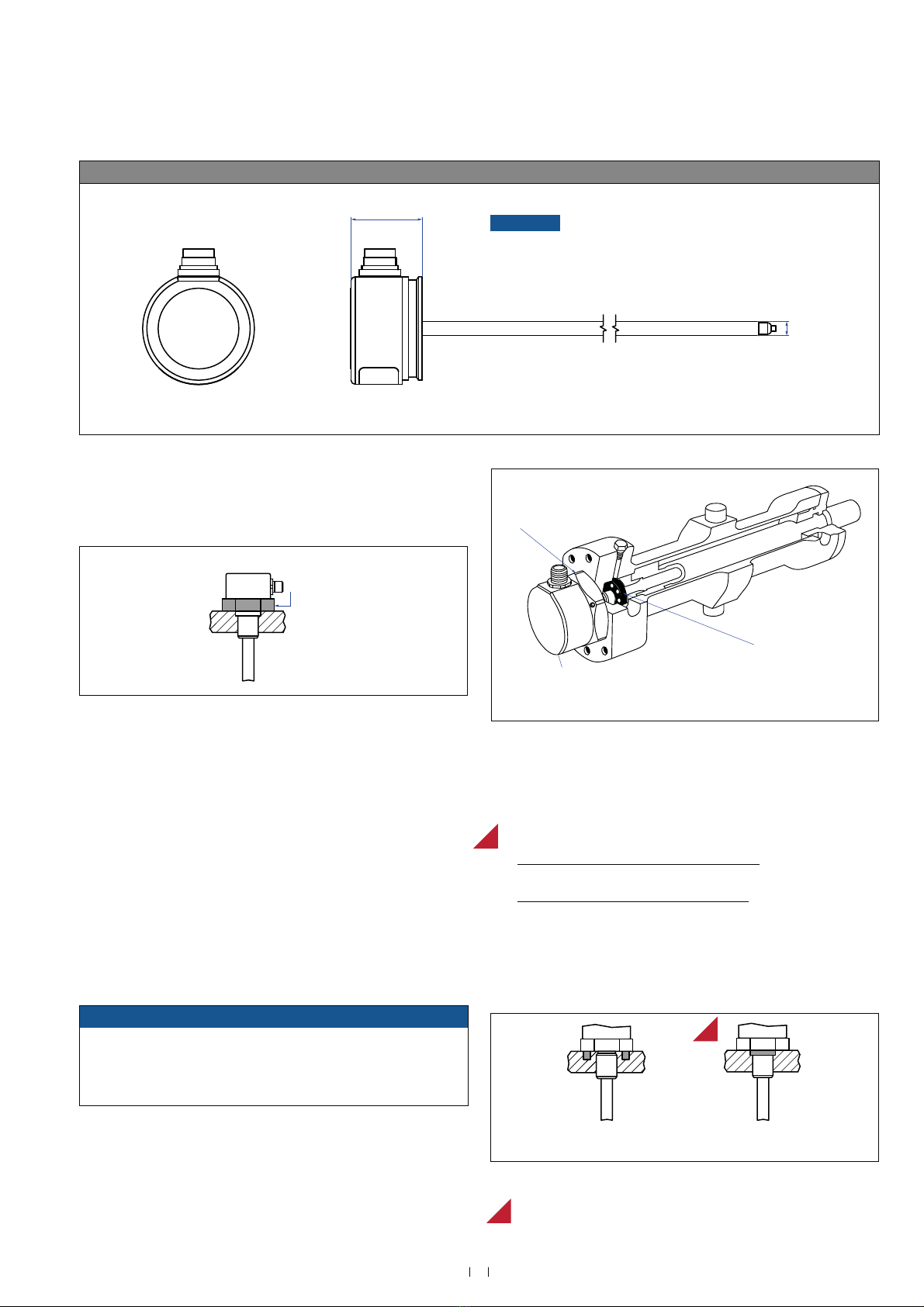

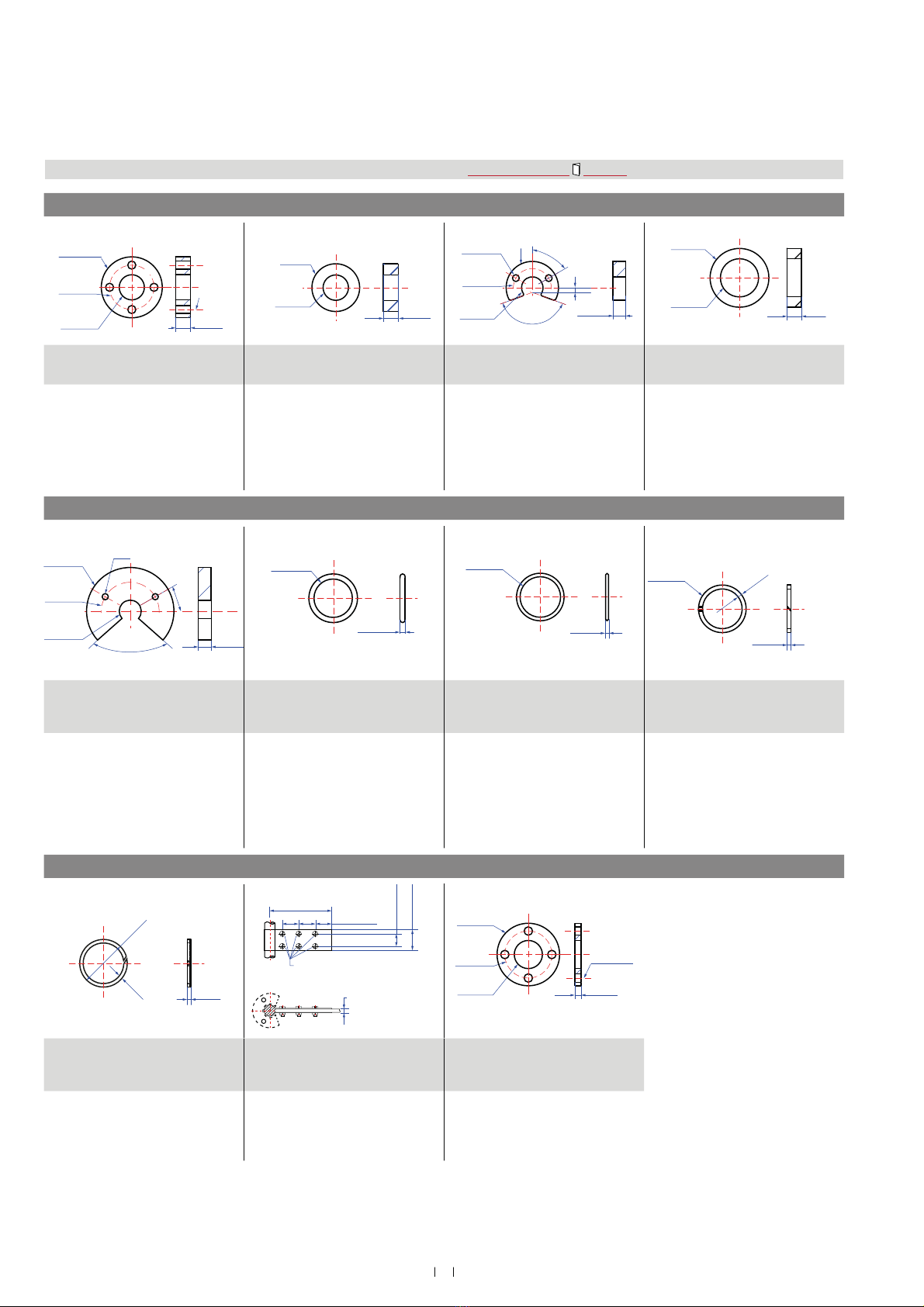

Fig. 3: 7HPSRVRQLFV®GB-N / GB-S / GB-K / GB-J

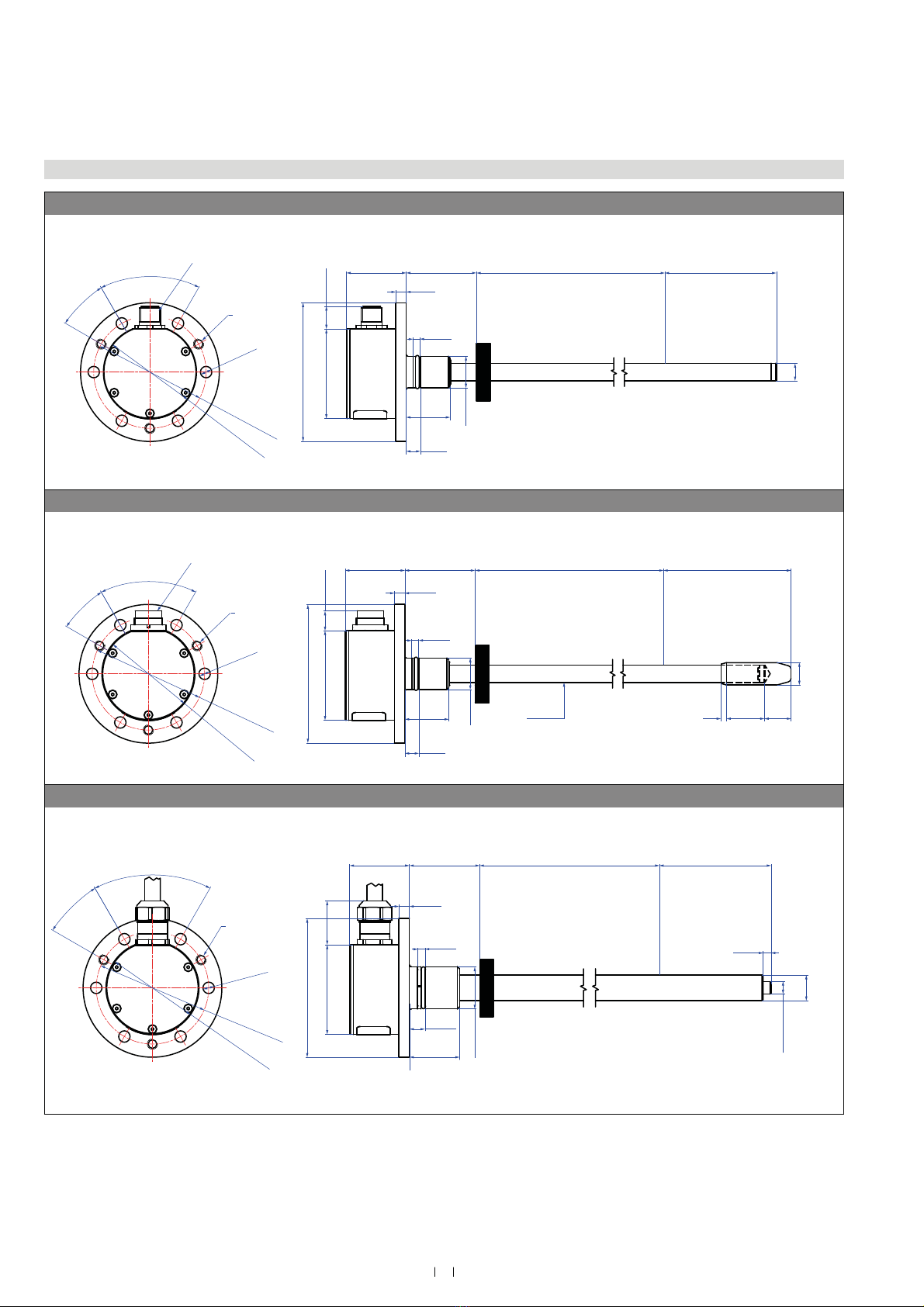

4.2 Styles and installation of Temposonics®GB- GB- GB- GB-S(rod sensor with pressure fit flange)

GB- GB-S, example With 2 connector

agnet

1 .13

.39 .1

79 3.11

13

.51

25

1

1 f7

6

.24

51

2.1

M6 3

64 2.52

6.5

.26

6

3

53 2.9

Stroe length

25 325

1 12

ull zone

4

1.57

ead zone

63.5

2.5

.1

.32

4.1

.16

2 connector

Sensor electronics

housing

34

1.34

GB-, example With 6 connector

agnet

79 3.11

1 f7

11.3

.44

51

2.1

6

.24

25

1

1

.39

3

.12

22

.7

15

.59

12. .1

.5 .4

M6 3

64 2.52

6.5

.26

6

3

53 2.9

Sensor electronics

housing

34

1.34

Stroe length

25 325

1 12

ull zone

4

1.57

ead zone

7.5

3.1

.1

.32

4.1

.16

6 connector

GB-, example With cale outlet

agnet

25

1

79 3.11

51

2.1

6

.24

M6 3

6.5

.26

64 2.52

6

3

53 2.9

Stroe length

25 325

112

ull zone

4

1.57

ead zone

73.5

2.9

12.7 .13

.5 .1

6.2

.244

4

.16

4.1

.16

.5

.31

25

.9

Sensor electronics

housing

34

1.34

21 f6

&RQWUROOLQJGHVLJQGLPHQVLRQVDUHLQPLOOLPHWHUVDQGPHDVXUHPHQWVLQDUHLQLQFKHV

9

Temposonics® GB-Series SSI

Operation Manual

,QVWDOODWLRQRI*%ZLWKSUHVVXUHğWĠDQJH

0RXQWWKHVHQVRUYLDSUHVVXUHğWĠDQJHWKURXJKWKHERUHVLQWKH

VHQVRUHOHFWURQLFVKRXVLQJZLWKPDFKLQHVFUHZV0ū$

,62

Fig. 4: ,QVWDOODWLRQRI*%ZLWKSUHVVXUHğWĠDQJHŊ6ʼnŊ1ʼn

Fig. 5: 6HQVRULQF\OLQGHU

Installation of a rod-style sensor in a hydraulic cylinder

The rod-style version has been developed for direct stroke measure-

ment in a hydraulic cylinder. Mount the sensor through the bores in

WKHVHQVRUHOHFWURQLFVKRXVLQJZLWKPDFKLQHVFUHZV0ū$

,62

Mounted on the face of the piston, the position magnet travels

over the rod without touching it and indicates the exact position

WKURXJKWKHURGZDOOŋLQGHSHQGHQWRIWKHK\GUDXOLFĠXLG

The pressure resistant sensor rod is installed into a bore in the

piston rod.

ydraulics sealing

6HDOWKHĠDQJHFRQWDFWVXUIDFHYLD2ULQJLQWKHXQGHUFXWDVVKRZQLQ

Fig. 6.

)RUSUHVVXUHğWĠDQJHI*%.*%1*%6

2ULQJūPP[LQSDUWQR

)RUSUHVVXUHğWĠDQJHI*%-

25LQJūPP[LQSDUWQR

Fig. 6: Sealing

1RWHWKHIDVWHQLQJWRUTXHRIPDFKLQHVFUHZVRI1P

6HDWWKHĠDQJHFRQWDFWVXUIDFHFRPSOHWHO\RQWKHF\OLQGHUPRXQWLQJ

surface.

The cylinder manufacturer determines the pressure-resistant

JDVNHWFRSSHUJDVNHW2ULQJHWF

The position magnet should not grind on the sensor rod.

7KHSLVWRQURGGULOOLQJ*%1*%6ŰPPŰLQ

*%-*%.ŰPPŰLQGHSHQGVRQWKHSUHVVXUH

and piston speed.

Adhere to the information relating to operating pressure.

Protect the sensor rod against wear.

Fastening torque

6 Nm

Sensor electronics housing

with sensor rod

Position magnet

Sealing via O-ring

in the flange undercut

1

Temposonics®GB-Series SSI

Operation Manual

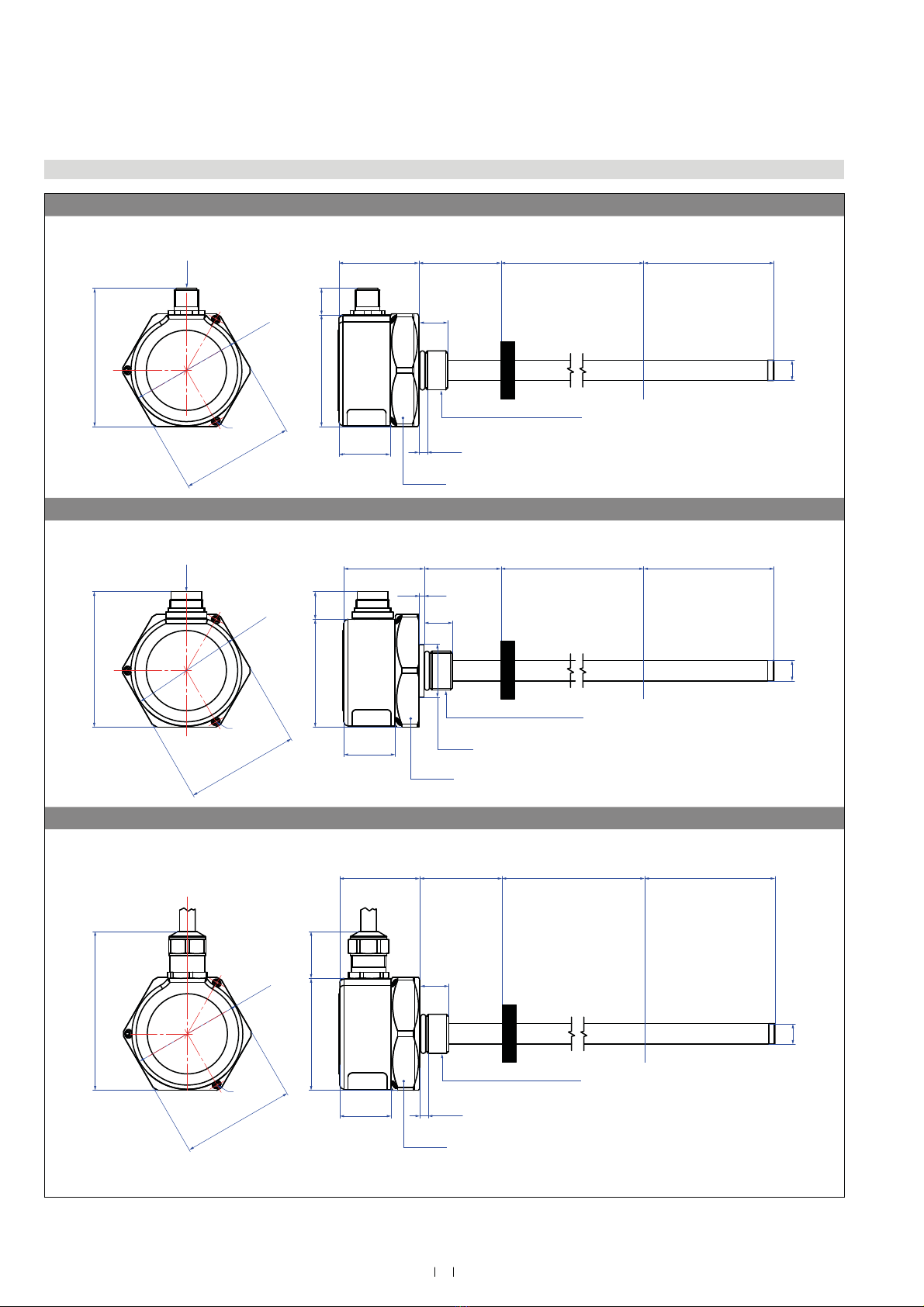

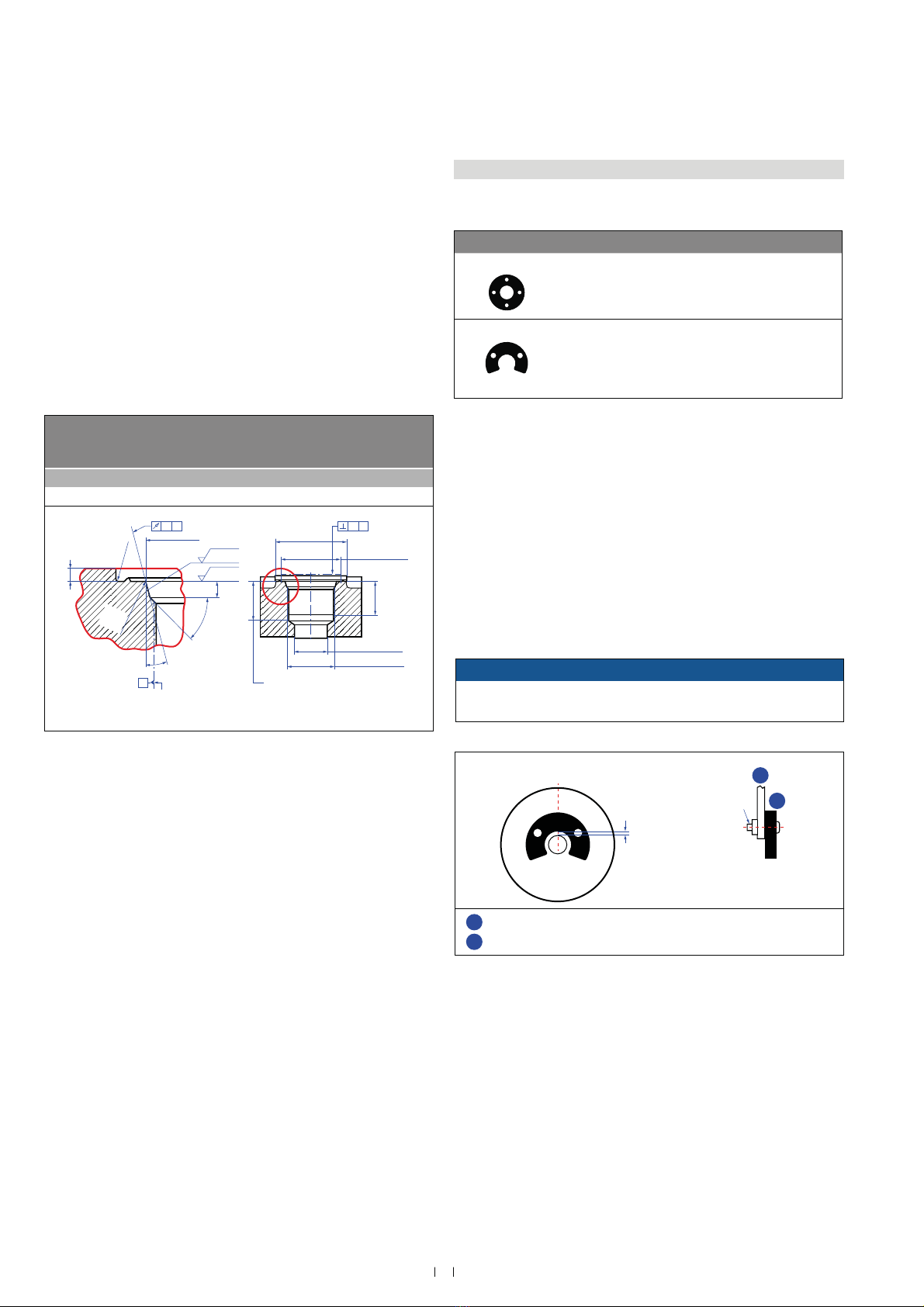

0FRQQHFWRU([DPSOH:LWKĠDWIDFHGĠDQJH

Ø10 ± 0.13

(Ø 0.39 ± 0.01)

67.5

(2.66)

Ø54

(Ø 2.13)

54.5

(2.15)

13

(0.51)

4.1

(0.16)

14

(0.55)

Null zone

40

(1.57)

Dead zone

63.5

(2.5)

M12 connector

Threaded flange »M«:

M18×1.5-6g

M4 (3×)

55

(2.17)

25

(1)

Stroke length

25…3250

(1…128)

Sensor electronics

housing

39

(1.54)

Magnet

A/F 55

0FRQQHFWRU([DPSOH:LWKUDLVHGIDFHGĠDQJH

Ø10 ± 0.13

(Ø 0.39 ± 0.01)

66

(2.6)

52.5

(2.07)

13.5

(0.53)

14

(0.55)

Null zone

40

(1.57)

Sensor electronics

housing

39

(1.54)

25

(1)

M16 connector

Threaded flange »T«:

¾"-16 UNF-3A

Ø54

(Ø 2.13)

M4 (3×)

55

(2.17)

Stroke length

25…3250

(1…128)

Dead zone

63.5

(2.5)

Magnet

2.5

(0.1)

Ø 25.4

(Ø 1)

A/F 55

&DEOHRXWOHW([DPSOH:LWKĠDWIDFHGĠDQJH

Threaded flange »M«:

M18×1.5-6g

55

(2.17)

M4 (3×)

77.4

(3.05)

Ø54

(Ø 2.13)

54.5

(2.15)

22.9

(0.9)

25

(1)

4.1

(0.16)

14

(0.55)

Null zone

40

(1.57)

Stroke length

25…3250

(1…128)

Dead zone

63.5

(2.5)

Ø10 ± 0.13

(Ø 0.39 ± 0.01)

Sensor electronics

housing

39

(1.54)

Magnet

A/F 55

&RQWUROOLQJGHVLJQGLPHQVLRQVDUHLQPLOOLPHWHUVDQGPHDVXUHPHQWVLQDUHLQLQFKHV

8QOHVVRWKHUZLVHVWDWHGDSSO\WRWKHJHQHUDOWROHUDQFHVDFFRUGLQJWR',1,62P

4.3 Styles and installation of Temposonics®GB- GB-T GB-B(rod sensor with threaded flange)

)LJ7HPSRVRQLFV®GB-M / GB-T

11

Temposonics® GB-Series SSI

Operation Manual

,QVWDOODWLRQRI*%ZLWKWKUHDGHGĠDQJHŊ0ʼnŊ7ʼn

)L[WKHVHQVRUURGYLDWKUHDGHGĠDQJH0ūJRUŧ81)$

Base unit xample 6 connector

34.5

(1.36)

Ø 6.81

(Ø 0.27)

&RQWUROOLQJGHVLJQGLPHQVLRQVDUHLQPLOOLPHWHUVDQGPHDVXUHPHQWVLQDUHLQLQFKHV

8QOHVVRWKHUZLVHVWDWHGDSSO\WRWKHJHQHUDOWROHUDQFHVDFFRUGLQJWR',1,62P

)LJ7HPSRVRQLFV®GB-B

Fig. 9: 0RXQWLQJH[DPSOHRIWKUHDGHGĠDQJHŊ0ʼnŊ7ʼn

NOTICE 7KH*%%LVRQO\IRUUHSODFHPHQW

8VHWKH*%%VHQVRUZLWKDURGRIWKH*%0RU*%7VHQVRURQO\

Installation of a rod-style sensor in a hydraulic cylinder

The rod-style version has been developed for direct stroke

measurement in a hydraulic cylinder. Mount the sensor via

WKUHDGHGĠDQJH

Mounted on the face of the piston, the position magnet travels

over the rod without touching it and indicates the exact position

WKURXJKWKHURGZDOOŋLQGHSHQGHQWRIWKHK\GUDXOLFĠXLG

The pressure resistant sensor rod is installed into a bore in the

piston rod.

The base unit is mounted by means of only three screws. It is the

only part that needs to be replaced if servicing is required, i.e. the

hydraulic circuit remains closed. For more information see chapter

Ń5HSODFHPHQWRIEDVHXQLWńRQSDJH

Fig. 10: 6HQVRULQF\OLQGHU

ydraulics sealing

7KHUHDUHWZRZD\VIRUVHDOLQJWKHĠDQJHFRQWDFWVXUIDFH)LJ

1. $VHDOLQJE\XVLQJDQ2ULQJHJūPPūLQ

in a cylinder end cap groove.

2. A sealing via an O-ring in the undercut.

)RUWKUHDGHGĠDQJHŧ81)$*%7

2ULQJūPPūLQSDUWQR

)RUWKUHDGHGĠDQJH0ūJ*%7

2ULQJūPPūLQSDUWQR

,QWKHFDVHRIWKUHDGHGĠDQJH0ūJDVFUHZKROHEDVHGRQ

,62)LJPXVWEHSURYLGHG6HH,62IRUIXUWKHU

information.

Fig. 11: 3RVVLELOLWLHVRIVHDOLQJ

NOTICE

The orientation of the sensor electronics housing respectively of

WKHHOHFWULFDOFRQQHFWLRQRIVHQVRUPRGHOV*%0DQG*%7FDQEH

changed after mounting. For more information see chapter “4.5

Change orientation of sensor electronics housing” on page 14.

MTS recommendation

R

R

R

Fastening torque

50 Nm

In the event of servicing, the sensor rod

with flange remains in the cylinder

Position magnet

Base unit

The sensor electronics housing

with sensing element can be replaced

Sealing via O-ring

in the flange undercut

Sealing via O-ring

in cylinder end cap groove

12

Temposonics®GB-Series SSI

Operation Manual

Fig. 12: 1RWLFHIRUWKUHDGHGĠDQJH0ūJEDVHGRQ',1,62

1RWHWKHIDVWHQLQJWRUTXHRI1P

6HDWWKHĠDQJHFRQWDFWVXUIDFHFRPSOHWHO\RQWKHF\OLQGHUPRXQWLQJ

surface.

The cylinder manufacturer determines the pressure-resistant

JDVNHWFRSSHUJDVNHW2ULQJHWF

The position magnet should not grind on the sensor rod.

7KHSLVWRQURGGULOOLQJŰPPŰLQGHSHQGVRQWKH

pressure and piston speed.

Adhere to the information relating to operating pressure.

Protect the sensor rod against wear.

1RWLFHIRUPHWULFWKUHDGHGĠDQJH

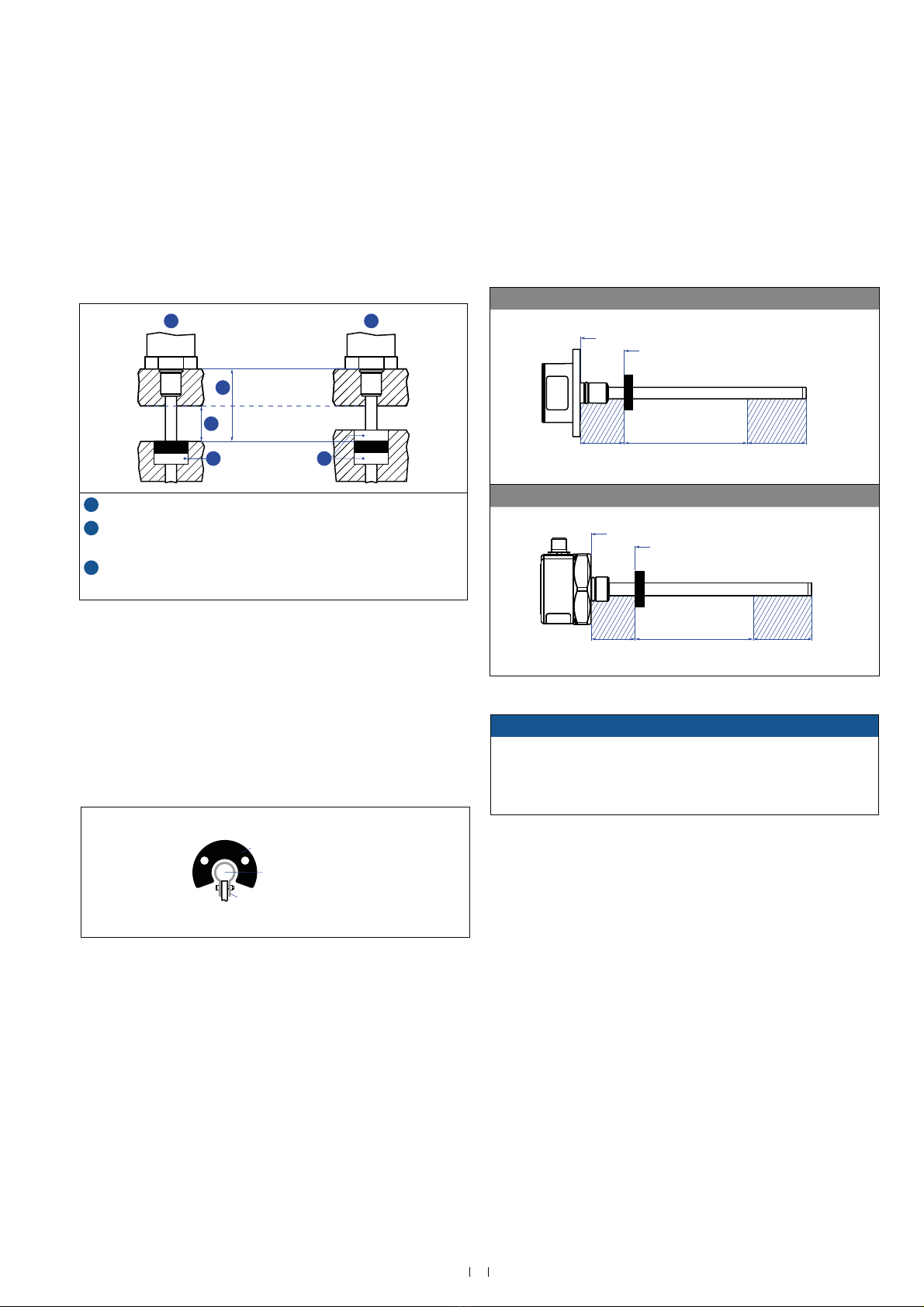

4.4 agnet instal lation

Typical use of magnets

agnet %HQHğWV

Ring magnets 5RWDWLRQDOO\V\PPHWULFDOPDJQHWLFğHOG

-magnets eight tolerances can be compensated

ounting ring magnets and -magnets

Install the magnet using non-magnetic material for mounting

device, screws, spacers etc.. The magnet must not grind on

the sensor rod. Alignment errors are compensated via the air gap.

3HUPLVVLEOHVXUIDFHSUHVVXUH0D[1PP2

)DVWHQLQJWRUTXHIRU0VFUHZV1PXVHZDVKHULIQHFHVVDU\

Minimum distance between position magnet and any magnetic

PDWHULDOKDVWREHPPLQ)LJ

If no other option exists and magnetic material is used, observe the

VSHFLğHGGLPHQVLRQV)LJ

Fig. 13: 7\SLFDOXVHRIULQJPDJQHWVDQG8PDJQHWV

NOTICE

Mount ring magnets and U-magnets concentrically.

Do not exceed the maximum acceptable gap.

Fig. 14: 0RXQWLQJRI8PDJQHWSDUWQR

&RQWUROOLQJGHVLJQGLPHQVLRQVDUHLQPLOOLPHWHUVDQGPHDVXUHPHQWVLQDUHLQLQFKHV

Thread

d

d2d3d4d5

.

.4

234

GB-

0ūJ Ű Ű 24.5 2.4 226 Ź

Ød

5

Ra 3.2

Ra 3.2

Pitch diameter

A

A

Thread

(d

1

× P)

Ød

3(Reference)

A

Ød

2

Ød

4(Gauging)

This dimension applies when

tap drill cannot pass through

entire boss.

≤ R0.4

R0.3

R0.1

Z°

4

5

°

±

5

°

L

3

L

1

L

2

L

4

A0.1 A0.2

&RQWUROOLQJGHVLJQGLPHQVLRQVDUHLQPLOOLPHWHUV

M4 1

2

Air gap

Concentric mounting

of U-magnet

Part no. 201 553:

3 ±1 (0.12 ±0.04)

Part no. 251 416-2:

1.75 ±1 (0.07 ±0.04)

U-magnet

Non-magnetic mounting plate and fasteners

1

2

13

Temposonics® GB-Series SSI

Operation Manual

agnet mounting ith magnetic material

hen using magnetic material the dimensions of Fig. 15 must

be observed.

A.If the position magnet aligns with the drilled piston rod

B.If the position magnet is set further into the drilled piston rod,

LQVWDOODQRWKHUQRQPDJQHWLFVSDFHUHJSDUWQRDERYH

the magnet.

6HQVRUVZLWKVWURNHOHQJWKVŰPHWHUIW

6XSSRUWKRUL]RQWDOO\LQVWDOOHGVHQVRUVZLWKDVWURNHOHQJWKIURPPHWHU

mechanically at the rod end. ithout the use of a support, rod and posi -

tion magnet may be damaged. A false measurement result is also possi-

ble. onger rods require evenly distributed mechanical support over the

HQWLUHOHQJWKHJSDUWQR8VHDQ8PDJQHW)LJIRU

measurement.

Fig. 16: ([DPSOHRIVHQVRUVXSSRUW

ctie measuring range

The technical data of each sensor is checked as well as documented

DQGWKHDFWLYHVWURNHOHQJWKXVHIXOHOHFWULFDOVWURNHZLWKLWVVWDUWDQG

HQGSRVLWLRQLVDGMXVWHGGXULQJğQDOLQVSHFWLRQDQGWHVWLQJ)LJ

To ensure that the entire measuring range can be used electrically, the

SRVLWLRQPDJQHWPXVWEHPRXQWHGPHFKDQLFDOO\DVIROORZV

*%6HULHVZLWKSUHVVXUHğWĠDQJHZLWKULQJ8PDJQHW

40 Stroke length 63.5

Reference edge of mounting

Start position

*%6HULHVZLWKWKUHDGHGĠDQJHZLWKULQJ8PDJQHW

40 Stroke length 63.5

Reference edge of mounting

Start position

)LJ$FWLYHPHDVXULQJUDQJH

NOTICE

On all sensors, the areas left and right of the active stroke length

DUHSURYLGHGIRUQXOODQGGHDG]RQH7KHVH]RQHVVKRXOGQRWEH

used for measurement, however the active stroke length

can be exceeded.

&RQWUROOLQJGHVLJQGLPHQVLRQVDUHLQPLOOLPHWHUVDQGPHDVXUHPHQWVLQDUHLQLQFKHV

Fig. 15: ,QVWDOODWLRQZLWKPDJQHWLFPDWHULDO

Magnet Magnet

1

2

3 3

A B

Magnetic

material

1XOO]RQHGHSHQGVRQVHQVRUPRGHOVHH)LJ

2Distance between position magnet and any magnetic material

ŰPPŰLQ

31RQPDJQHWLFVSDFHUŰPPŰLQŋ

5HFRPPHQGDWLRQPPLQ

U-magnet

Sensor rod

Non-magnetic fixing clip

14

Temposonics®GB-Series SSI

Operation Manual

4.6 Replacement of ase unit

7KHEDVHXQLWRIWKHVHQVRUPRGHOV*%0DQG*%7LVUHSODFHDEOHDV

shown in Fig. 19. The sensor can be replaced without interrupting the

hydraulic circuit.

Base unit GB-B

Sensor electronics housing

Plastic tube with

inner sensor element

. oosen the scres.

You do not need to loosen the screws

(3 screws DIN 915 M4x6 A2)

completely. Normally it is

sufficient if you turn the

screws 4 ×.

A/F 2

2. ull out the ase unit.

There is an O-ring inside the

flange of the GB-M and GB-T

sensor.

Position the O-ring as shown in

the figure before inserting the

new base unit (GB-B).

O-ring

3. Insert the ne ase unit. T ighten the scres.

Fastening torque: 1.6 Nm

4.5 hange orientation of sensor electronics housing

The orientation of the sensor electronics housing respectively of

WKHHOHFWULFDOFRQQHFWLRQRIVHQVRUPRGHOV*%0DQG*%7FDQEH

FKDQJHGDIWHUPRXQWLQJ)ROORZWKHLQVWUXFWLRQVLQ)LJ

)LJ$OLJQVHQVRUHOHFWURQLFVKRXVLQJUHVSHFWLYHO\HOHFWULFDOFRQQHFWLRQRI*%0*%7

Fig. 19: 5HSODFHPHQWRIWKHEDVHXQLW*%%

GB- GB-T sensor

. oosen the scres.

You do not need to loosen the screws (3 screws DIN 915 M4x6 A2)

completely. Normally it is sufficient if you turn the screws 3 ×.

A/F 2

2. Turn the sensor electronics housing to the desired orientation.

360°

3. Tighten the scres.

Fastening torque: 1.6 Nm

15

Temposonics® GB-Series SSI

Operation Manual

4. lectrical connection

3ODFHPHQWRILQVWDOODWLRQDQGFDEOLQJKDYHGHFLVLYHLQĠXHQFHRQWKH

VHQVRUŁVHOHFWURPDJQHWLFFRPSDWLELOLW\(0&+HQFHFRUUHFW

LQVWDOODWLRQRIWKLVDFWLYHHOHFWURQLFV\VWHPDQGWKH(0&RIWKHHQWLUH

system must be ensured by using suitable metal connectors, shielded

cables and grounding. Overvoltages or faulty connections can damage

the sensor electronics despite protection against wrong polarity.

Instruction for connection

Use low-resistance twisted pair and shielded cables. Connect the

shield to ground externally via the controller equipment.

eep control and signal leads separate from power cables and

VXIğFLHQWO\IDUDZD\IURPPRWRUFDEOHVIUHTXHQF\LQYHUWHUVYDOYH

lines, relays, etc..

Use only metal connectors and connect the shielding to the

connector housing.

eep the connection surface at both shielding ends as large as

possible. Connect the cable clamps to function as a ground.

eep all non-shielded leads as short as possible.

eep the ground connections short and with a large cross section.

Avoid ground loops.

ith potential differences between machine and electronics earth

FRQQHFWLRQVQRFRPSHQVDWLQJFXUUHQWVDUHDOORZHGWRĠRZDFURVV

the cable shielding.

5HFRPPHQGDWLRQ,QVWDOOSRWHQWLDOFRPSHQVDWLQJOHDGVZLWKODUJH

cross section, or use cables with separate double shielding, and

connect only one end of the shield.

8VHRQO\VWDELOL]HGSRZHUVXSSOLHVDQGPDNHVXUHWKDWWKHVSHFLğHG

connecting values are met.

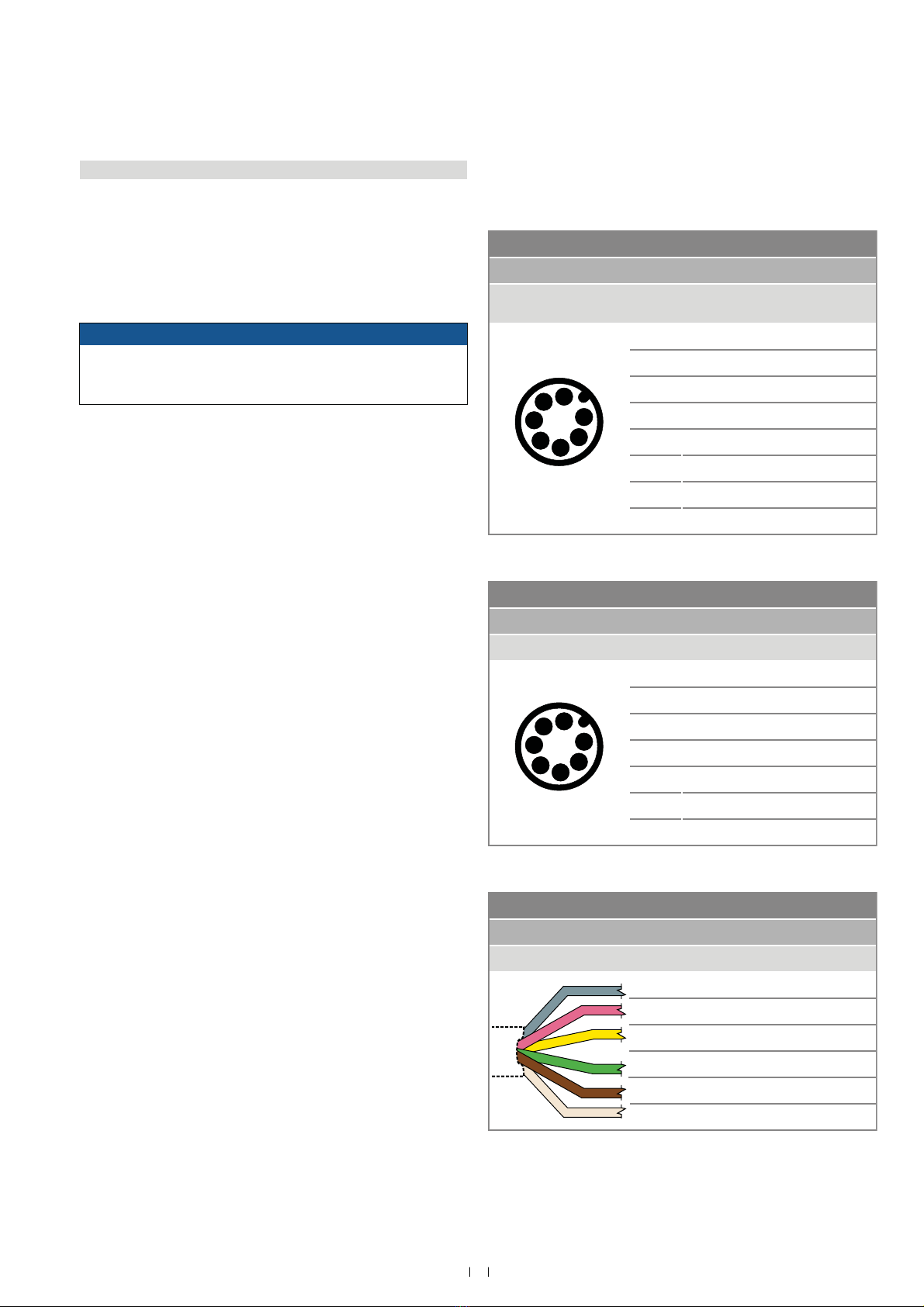

Fig. 20: &RQQHFWRUZLULQJ'0

Fig. 21: &RQQHFWRUZLULQJ'0

onnector iring

Connect the sensor directly to the control system, indicator or other

HYDOXDWLQJV\VWHPVDVIROORZV

Fig. 22: &RQQHFWRUZLULQJFDEOHRXWOHW

NOTICE

Do not mount the sensors in the area of strong magnetic or

HOHFWULFQRLVHğHOGV

1HYHUFRQQHFWGLVFRQQHFWWKHVHQVRUZKHQYROWDJHLVDSSOLHG

Grounding of rod sensors

Connect the sensor electronics housing to the machine ground via

SUHVVXUHğWĠDQJHUHVSHFWLYHO\YLDWKUHDGHGĠDQJH

4

Signal poer supply

2 male connector

-coded

in unction

1

4

2

6

3

5

7

iew on sensor

1&ORFN

2&ORFNũ

3'DWD

4'DWDũ

51RWFRQQHFWHG

61RWFRQQHFWHG

79'&ũ

'&*URXQG9

Signal poer supply

6 male connector in untion

1

4

2

6

3

5

7

iew on sensor

1'DWDũ

2'DWD

3&ORFN

4&ORFNũ

59'&ũ

6'&*URXQG9

71RWFRQQHFWHG

GB ith cale out let T

Signal poer supply

ale olor unction

*< 'DWDũ

P 'DWD

<( &ORFN

*1 &ORFNũ

%1 9'&ũ

'&*URXQG9

16

Temposonics®GB-Series SSI

Operation Manual

4. reuently ordered accessories

&RQWUROOLQJGHVLJQGLPHQVLRQVDUHLQPLOOLPHWHUVDQGPHDVXUHPHQWVLQDUHLQLQFKHV

Additional options available in our $FFHVVRULHV*XLGH 551 444

osition magnets

Ø 32.8

(Ø 1.29)

Ø 23.8

(Ø 0.94)

Ø 13.5

(Ø 0.53)

Ø 4.3

(Ø 0.17)

7.9

(0.31)

Ø 25.4

(

Ø

1)

Ø 13.5

(

Ø

0.53) 7.9

(0.31)

32.

1.29

23.

.94

13.5

.53

4.3

.17

6

14

3

.12

7.9

.31

Ø 19.8

(Ø 0.78)

Ø 30.5

(Ø 1.2)

7.6

(0.3)

Ring magnet 33

art no. 2 542-2

Ring magnet 25.4

art no. 4 533

-magnet 33

art no. 25 46-2

Ring magnet

art no. 42 36

0DWHULDO3$IHUULWH*)

:HLJKW$SSUR[J

6XUIDFHSUHVVXUH0D[1PP2

)DVWHQLQJWRUTXHIRU0VFUHZV1P

2SHUDWLQJWHPSHUDWXUH

ũĽŹ&ũĽŹ)

0DWHULDO3$IHUULWH

:HLJKW$SSUR[J

6XUIDFHSUHVVXUH0D[1PP2

2SHUDWLQJWHPSHUDWXUH

ũĽŹ&ũĽŹ)

0DWHULDO3$IHUULWH*)

:HLJKW$SSUR[J

6XUIDFHSUHVVXUH0D[1PP2

)DVWHQLQJWRUTXHIRU0VFUHZV1P

2SHUDWLQJWHPSHUDWXUH

ũĽŹ&ũĽŹ)

0DWHULDO3$IHUULWHFRDWHG

:HLJKW$SSUR[J

6XUIDFHSUHVVXUH0D[1PP2

2SHUDWLQJWHPSHUDWXUH

ũĽŹ&ũĽŹ)

osition magnet -rings Bac-up ring

Ø 4.5 (Ø 0.18)

Ø 63.5

(Ø 2.5)

Ø 42

(Ø 1.65)

Ø 16

(Ø 0.63) 97°

30°

9.5

(0.37)

15

.59

2

.

Ø 17

(Ø 0.67)

Ø 2

(Ø 0.07)

Ø 18

(Ø 0.71)

1.4

(0.05)

1.5

(0.06)

-magnet 63.5

art no. 2 553

2ULQJIRUSUHVVXUHğWĠDQJHPP

art no. 56 53

2ULQJIRUSUHVVXUHğWĠDQJHPP

art no. 56 43

%DFNXSULQJIRUSUHVVXUHğWĠDQJH

PP

art no. 56 5

0DWHULDO3$*)

PDJQHWVFRPSRXQGğOOHG

:HLJKWApprox. 26 g

6XUIDFHSUHVVXUH1PP2

)DVWHQLQJWRUTXHIRU0VFUHZV1P

2SHUDWLQJWHPSHUDWXUH

ũĽŹ&ũĽŹ)

0DWHULDO)OXRURHODVWRPHU

'XURPHWHU6KRUH$

0DWHULDO).0

'XURPHWHU6KRUH$

2SHUDWLQJWHPSHUDWXUH

ũĽŹ&ũĽŹ)

0DWHULDO37)(EURQ]H

Bac-up ring ptional installation hardare agnet spacer

1.4

(0.05)

1.5

(0.06)

Ø 21

(Ø 0.82)

1.4

1.5

Ø 21

20 (0.79)

60 (2.36)

16 (0.63)

12 (0.47)

3.2 (0.13)

Ø 3.2 (Ø 0.13)

M3 fastening screws (6×) Ø 14.3

(Ø 0.56)

Ø 23.8

(Ø 0.94)

Ø 31.8

(Ø 1.25)

Ø 4.3

(Ø 0.17)

3.2

(0.13)

%DFNXSULQJIRUSUHVVXUHğWĠDQJH

PP

art no. 56 43

)L[LQJFOLSIRUURGZLWKPP

art no. 56 4

agnet spacer

art no. 4 633

0DWHULDO37)( $SSOLFDWLRQ8VHGWRVHFXUHVHQVRU

URGVPPLQZKHQ

using an U-magnet or block magnet

0DWHULDO%UDVVQRQPDJQHWLF

0DWHULDO$OXPLQXP

:HLJKW$SSUR[J

6XUIDFHSUHVVXUH0D[1PP2

)DVWHQLQJWRUTXHIRU0VFUHZV1P

17

Temposonics® GB-Series SSI

Operation Manual

5/ Follow the manufacturers mounting instructions

&RQWUROOLQJGHVLJQGLPHQVLRQVDUHLQPLOOLPHWHUVDQGPHDVXUHPHQWVLQDUHLQLQFKHV 0DQXDOV6RIWZDUH'0RGHOVDYDLODEOHDW

.mtssensors.com

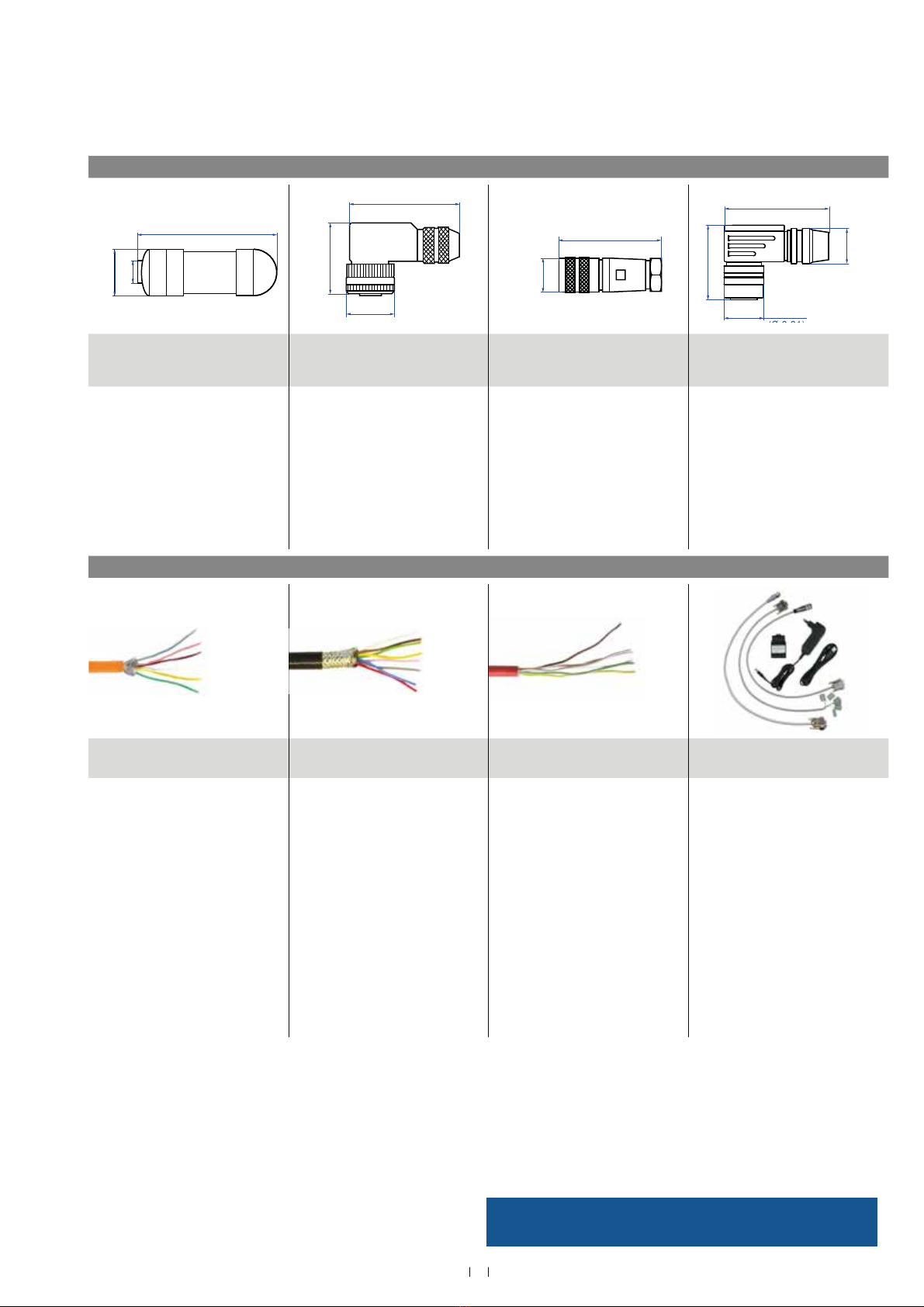

ale connectors 5

~ 60

(~ 2.36)

M12×1

Ø

20 (Ø 0.79)

20

(0.79)

~ 57

(~ 2.24)

38

(1.5)

54

(2.13)

Ø 18

(Ø 0.71)

~ 54

(~2.13)

~ 38

(~ 1.5)

Ø 20.5

(Ø 0 81)

Ø 18

(Ø 0.71)

2 -coded female connector

pin, straight

art no. 3 64

2 -coded female connector

pin, angled

art no. 3 6

6 female connector pin, straight

art no. 3 624

6 female connector pin, angled

art no. 56

+RXVLQJ*'=Q$/

7HUPLQDWLRQ6FUHZ

&RQWDFWLQVHUW&X=Q

&DEOHĽPPĽLQ

:LUHPP2

2SHUDWLQJWHPSHUDWXUH

ũĽŹ&ũĽŹ)

,QJUHVVSURWHFWLRQ,3FRUUHFWO\ğWWHG

)DVWHQLQJWRUTXH1P

+RXVLQJ*'=Q$/

7HUPLQDWLRQ6FUHZ

&RQWDFWLQVHUW&X=Q

&DEOHĽPPĽLQ

:LUHPP2

2SHUDWLQJWHPSHUDWXUH

ũĽŹ&ũĽŹ)

,QJUHVVSURWHFWLRQ,3FRUUHFWO\ğWWHG

)DVWHQLQJWRUTXH1P

0DWHULDO=LQFQLFNHOSODWHG

7HUPLQDWLRQ6ROGHU

&RQWDFWLQVHUW6LOYHUSODWHG

&DEOHFODPS3*

&DEOHĽPPĽLQ

2SHUDWLQJWHPSHUDWXUH

ũĽŹ&ũĽŹ)

,QJUHVVSURWHFWLRQ,3,3

FRUUHFWO\ğWWHG

)DVWHQLQJWRUTXH1P

0DWHULDO=LQFQLFNHOSODWHG

7HUPLQDWLRQ6ROGHU

&RQWDFWLQVHUW6LOYHUSODWHG

&DEOHĽPPĽLQ

:LUHPPš$:*

2SHUDWLQJWHPSHUDWXUH

ũĽŹ&ũĽŹ)

,QJUHVVSURWHFWLRQ,3FRUUHFWO\ğWWHG

)DVWHQLQJWRUTXH1P

ales rogramming tool

R cale

art no. 53 52

7HĠRQ®cale

art no. 53 2

Silicone cale

art no. 53 3

rogramming it

art no. 254 5

0DWHULDO385MDFNHWRUDQJH

)HDWXUHV7ZLVWHGSDLUVKLHOGHG

KLJKO\ĠH[LEOH

&DEOHPPLQ

&URVVVHFWLRQūūPP2

%HQGLQJUDGLXVūIL[HGLQVXODWLRQ

2SHUDWLQJWHPSHUDWXUH

0DWHULDO7HĠRQ®MDFNHWEODFN

)HDWXUHV7ZLVWHGSDLUVKLHOGHGĠH[LEOH

&DEOHPPLQ

&URVVVHFWLRQūūPPš

%HQGLQJUDGLXVŋū

ğ[HGLQVWDOODWLRQ

2SHUDWLQJWHPSHUDWXUH

ũĽŹ&ũĽŹ)

0DWHULDO6LOLFRQHMDFNHWUHG

)HDWXUHV7ZLVWHGSDLUVKLHOGHG

KLJKO\ĠH[LEOH

&DEOHPPLQ

&URVVVHFWLRQūūPPš

%HQGLQJUDGLXVūğ[HGLQVWDOODWLRQ

2SHUDWLQJWHPSHUDWXUH

ũĽŹ&ũĽŹ)

.LWLQFOXGHV

ūLQWHUIDFHFRQYHUWHUER[

ūSRZHUVXSSO\

ūFDEOHFPZLWK0IHPDOH

FRQQHFWRUSLQVWUDLJKWŋ'VXE

IHPDOHFRQQHFWRUSLQVWUDLJKW

ūFDEOHFPZLWK0IHPDOH

FRQQHFWRUSLQVWUDLJKWŋ'VXE

IHPDOHFRQQHFWRUSLQVWUDLJKW

ūFDEOHFPZLWKūWHUPLQDO

clamp D-sub female connector

SLQVWUDLJKW

ū86%FDEOH

6RIWZDUHLVDYDLODEOHDW

www.mtssensors.com

Temposonics®GB-Series SSI

Operation Manual

5. peration

5. Getting started

7KHVHQVRULVIDFWRU\VHWWRLWVRUGHUVL]HVDQGDGMXVWHGLHWKHGLV-

WDQFHEHWZHHQPDJQHWDQGĠDQJHLVVSHFLğHGLQUHVROXWLRQVWHSV

([DPSOH66,YDOXHDWWKHVWDUWRIPHDVXULQJUDQJHPPZLWK

a resolution of 1 m

NOTICE If necessary, the SSI sensors can be re-adjusted using

the service tool described below.

5.2 3URJUDPPLQJDQGFRQğJXUDWLRQ

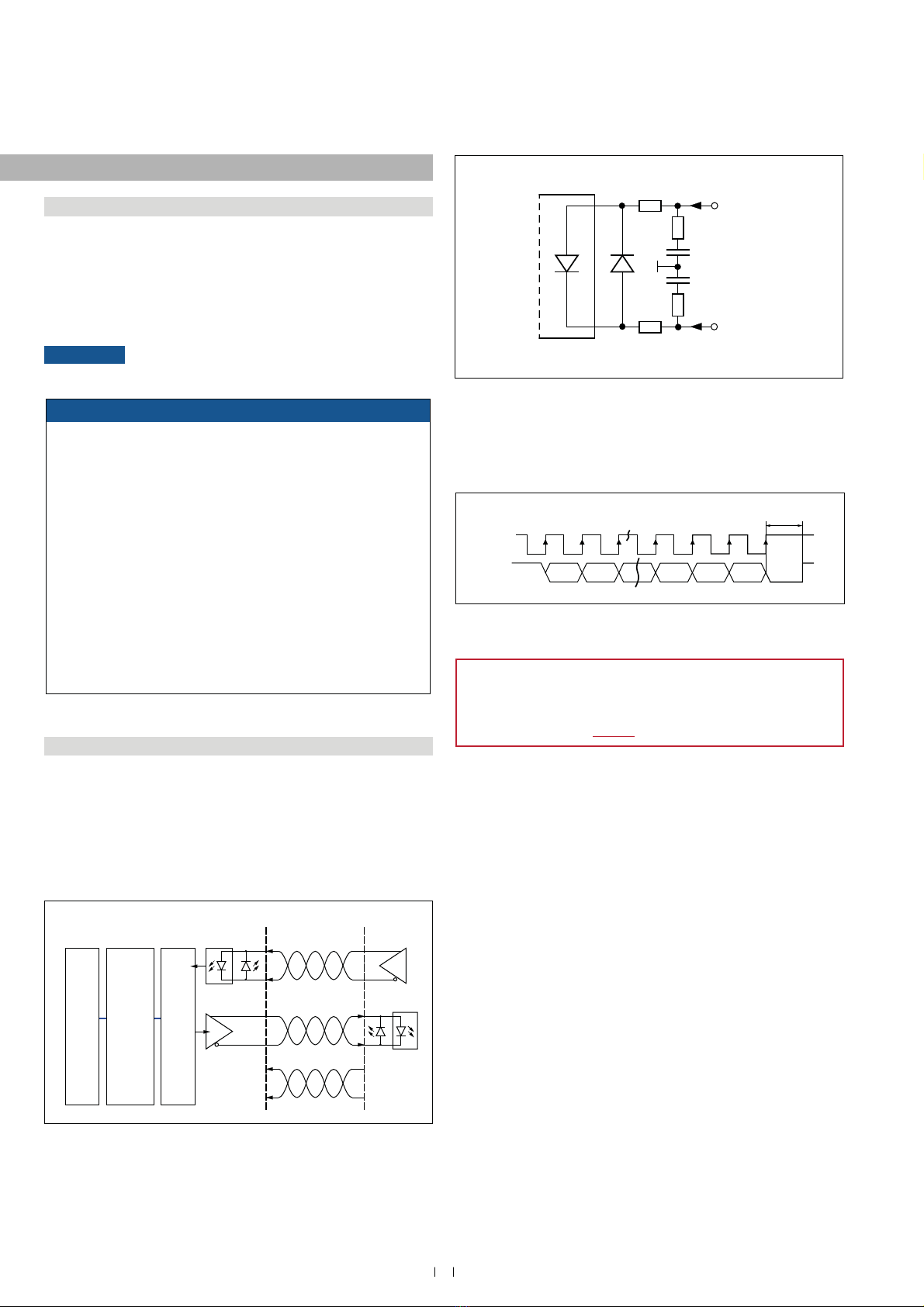

SSI interface

The interface of Temposonics®position sensors corresponds to SSI

industry standard for absolute encoders. Its displacement value is

HQFRGHGLQDELWELQDU\RUJUD\IRUPDWDQGWUDQVPLWWHG56

FRPSDWLEOHYLDZLUHVŋLQGHSHQGHQWRIGDWDZLGWKRIWKHFRGHUHVR-

OXWLRQ

The absolute, parallel position data is continually updated by the

sensor and converted by the shift-register into a serial bit stream

)LJ

Fig. 23: 6FKHPDWLFFRQQHFWLRQ

Fig. 24: ,QSXWZLULQJFORFNFORFNũ

Fig. 25: 7LPLQJGLDJUDP

TS Sensors programming tools

Temposonics®SRVLWLRQVHQVRUVFDQEHDGDSWHGWRPRGLğHG

measurement tasks very easily via the connecting leads without

opening the sensor. For this, the MTS Sensors programming kit is

DYDLODEOHVHHSDJH

7KLVFKDSWHUGHVFULEHVŃSURJUDPPLQJDQGFRQğJXUDWLRQńRIWKH

*%66,VHQVRUYLDFDEOHFRQQHFWLRQ

Ń3URJUDPPLQJDQGFRQğJXUDWLRQńYLD%OXHWRRWK®connection are

explained in document 551649.

NOTICE

sere during commissioning

1. efore initial switch-on, check carefully if the sensor has been

connected correctly.

2. Position the magnet in the measuring range of the sensor

GXULQJğUVWFRPPLVVLRQLQJDQGDIWHUUHSODFHPHQWRIWKHPDJQHW

(QVXUHWKDWWKHVHQVRUFRQWUROV\VWHPFDQQRWUHDFWLQDQ

uncontrolled way when switching on.

(QVXUHWKDWWKHVHQVRULVUHDG\DQGLQRSHUDWLRQPRGHDIWHU

switching on.

5. Check the pre-set span start and end values of the measuring

UDQJH)LJDQGFRUUHFWWKHPYLDWKHFXVWRPHUłVFRQWURO

system if necessary, or via the MTS Sensors service tool.

The operation of the service tool is described in detail on the

following pages.

Sensor input

91 Ω 7 mA

Clock (+)

100 Ω

LED

100 Ω

Clock (−)

91 Ω

Optocoupler

2 V

1 nF

1 nF

Clock (+)

Data (+) MSB LSB

Clock interval min. 16 μs

Logic diagram Sensor Controller

Clock (+)

Clock (−)

Optocoupler

Driver

Data (+)

Data (−)

+24 VDC

0 V

ASIC for parallel and

absolute position data

Microprocessor system

position value = 24 / 25 bit

binary or gray

Shift register

parallel serial converter

19

Temposonics® GB-Series SSI

Operation Manual

NOTICE

1HYHUFRQQHFWGLVFRQQHFWWKHVHQVRUZKHQYROWDJHLVDSSOLHG

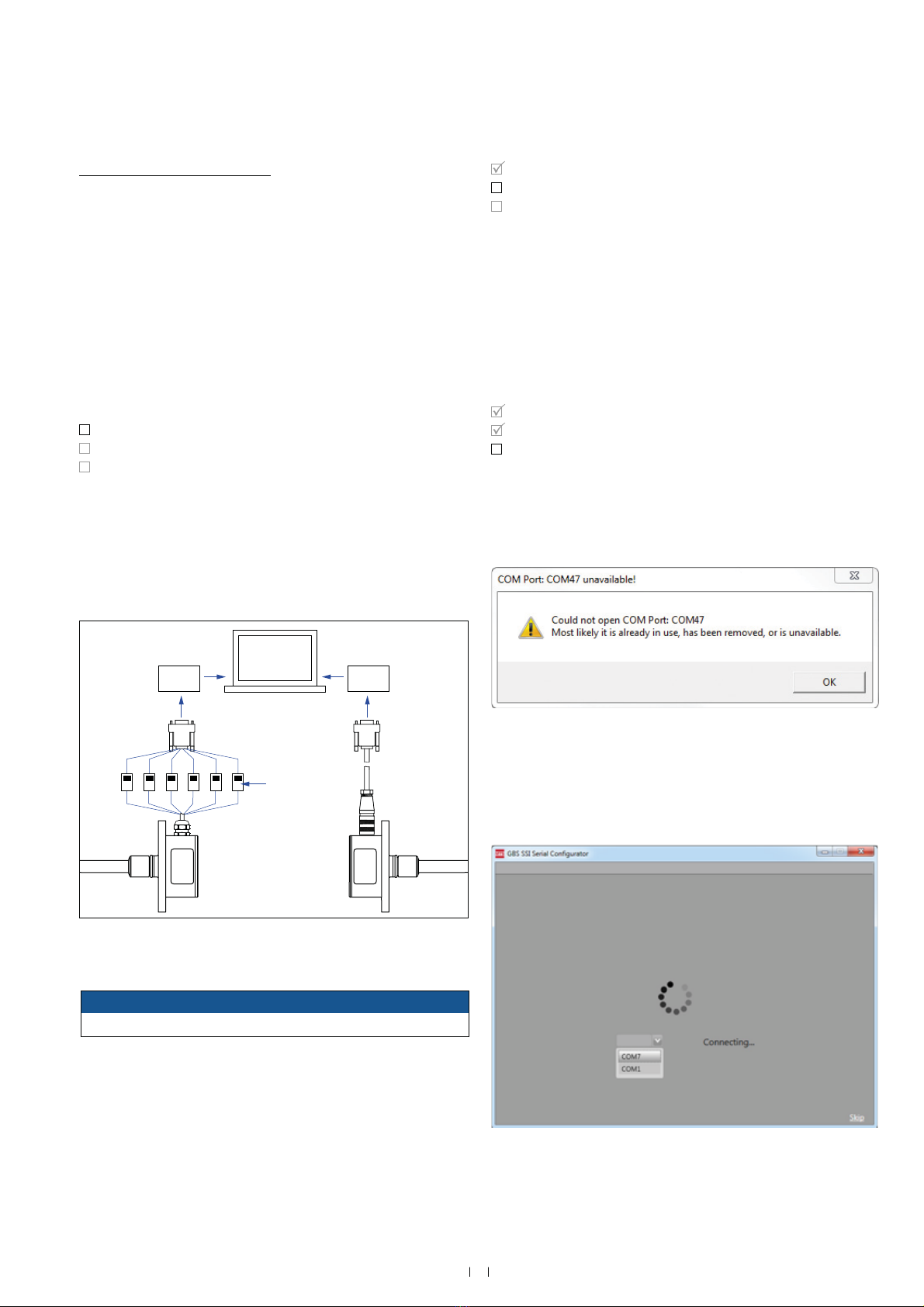

Fig. 26: &RQQHFW3&SURJUDPPHUH[DPSOHRI*%6*%1

IRUVHQVRUVZLWKFDEOHRXWOHWRQWKHOHIWIRUVHQVRUVZLWKFRQQHFWRURXWOHWRQWKHULJKW

Download the current software version from www.mtssensors.com.

,QVWDOOWKHVRIWZDUH1(7)UDPHZRUNDVDGPLQLVWUDWRU&RS\WKHSURJUDP

*%6B66,B6HULDOB&RQğJXUDWRUH[HWR\RXUFRPSXWHUDQGVWDUWLW

6\VWHPUHTXLUHPHQWV

Microsoft indows 7 operating system

0LFURVRIW1(7)UDPHZRUNIURPYHUVLRQRUKLJKHU

$IWHUVWDUWLQJWKHSURJUDP*%666,6HULDO&RQğJXUDWRUWKHVRIWZDUH

connects to the last selected COM Port and the user interface opens

)LJ,IWKH&203RUWLVQRWDYDLODEOHDQHUURUPHVVDJHDSSHDUV

)LJ

6HOHFWWKHULJKW&203RUWIURPWKHOLVWH[DPSOHVHH)LJ

The application will automatically restart and the user interface opens

)LJ

6WHS&RQQHFW3&SURJUDPPHU

Step 2 Install softare

6WHS6WDUWSURJUDP

6WHS&RQQHFW3&SURJUDPPHU

6WHS,QVWDOOVRIWZDUH

Step 3 Start program

Programming kit, part no. 254 59

The PC programmer is a hardware converter between sensor and

serial PC interface. It can be used for adjusting sensor parameters via

computer and the MTS Sensors programming software. The software

for reading and adjusting the sensors requires a indows computer

ZLWKDIUHH86%SRUW<RXFDQDGMXVWWKHIROORZLQJSDUDPHWHUV

Data length and data format

5HVROXWLRQDQGPHDVXULQJGLUHFWLRQ

6\QFKURQRXVDV\QFKURQRXVPHDVXUHPHQW

0HDVXUHPHQWğOWHUPRYLQJDYHUDJHRIRUPHDVXUHPHQWV

Connect the PC programmer with the sensor via the corresponding

adapter cable.

Connect the PC programmer to a US port of the computer.

Connect the power supply via connector.

7KHRXWHUFRQWDFWRIWKHFRQQHFWRULV9JURXQGWKHLQQHUFRQWDFW

is 24 DC.

Step onnect programmer

6WHS,QVWDOOVRIWZDUH

6WHS6WDUWSURJUDPP

)LJ(UURUPHVVDJH&203RUWLVQRWDYDLODEOH

)LJ6HOHFW&203RUW

GY WHBN

WHBN

GY

PK

PK

YE

YE

GN

GN

USB

converter

USB

converter

Spring terminal

2

Temposonics®GB-Series SSI

Operation Manual

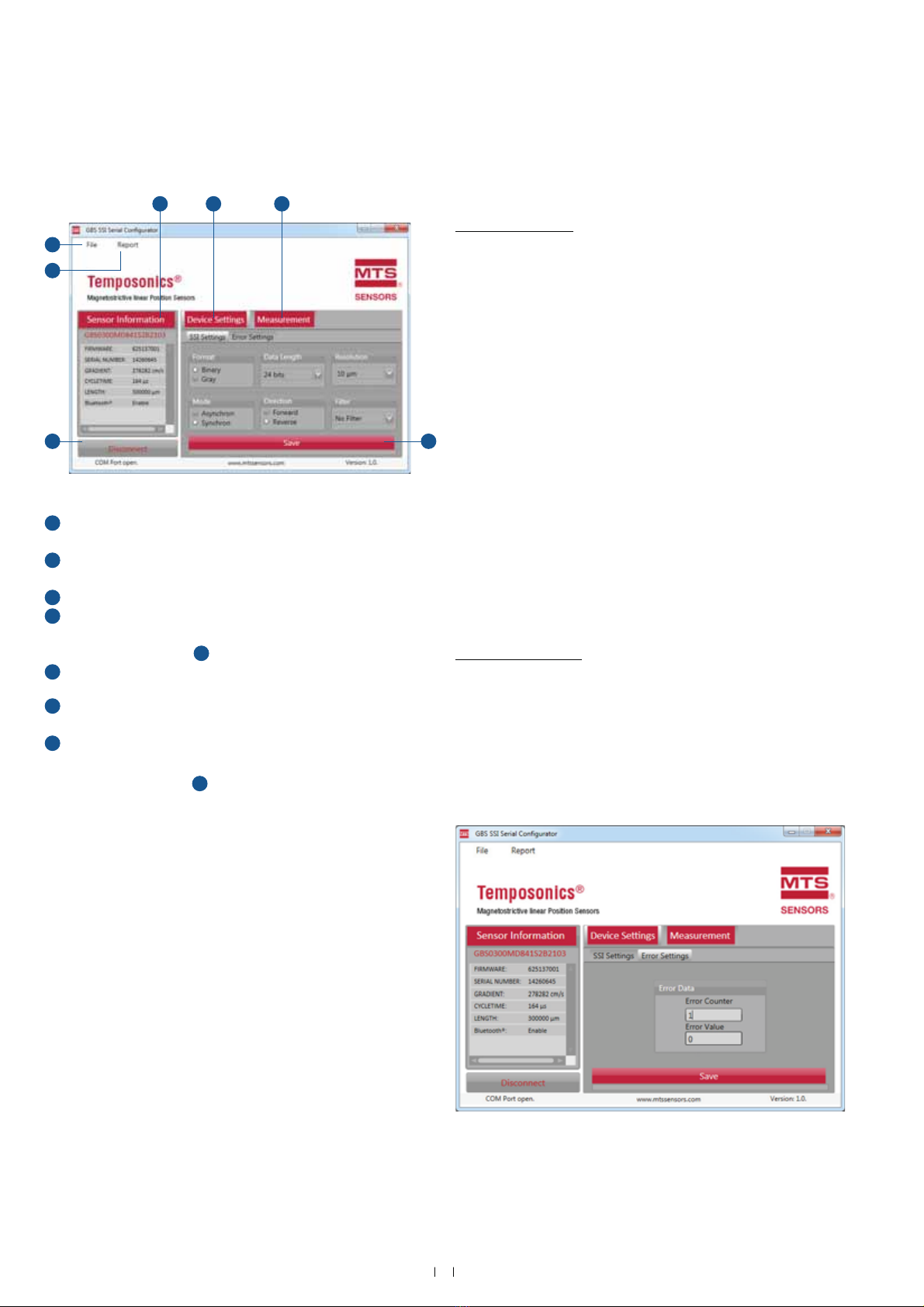

Fig. 29: 8VHULQWHUIDFH*%6HULDO&RQğJXUDWRU

GB SSI softare user interface

Sensor Information contains the invariable sensor parameters,

which were read in automatically when the sensor is connected.

2In the eice SettingsPHQXWKHFRQğJXUDEOHSDUDPHWHUV

66,6HWWLQJV(UURU6HWWLQJVRIWKHVHQVRUFDQEHVHW

3The easurement menu shows the current position of the magnet.

4The Sae button saves any parameter changes you have made.

After that the software restarts for the changes to take effect. The

function easurement 3will then be available again.

5The button isconnect breaks the connection to the COM Port

and closes the software.

6y clicking Report a report document is generated to provide

sensor information.

The ilePHQXDOORZVWKHIROORZLQJVHWWLQJVVHHDOVR)LJ

1. pen8SORDGVGHYLFHVHWWLQJVIURPD;0/ğOHWRWKHVHQVRU

Click the Sae button 4to complete the upload

2. Sae as6DYHVWKHFXUUHQWGHYLFHVHWWLQJVDV;0/ğOH

3. Restore actory Settings5HVWRUHVDQGVDYHVWKHVHQVRUłVIDFWRU\

settings

4. lose&ORVHVWKHVRIWZDUHDSSOLFDWLRQZLWKRXWVDYLQJDQ\

parameters

eice Settings

7KHIROORZLQJSDUDPHWHUVFDQEHPRGLğHG

66,6HWWLQJV)LJ

)RUPDW BinaryGray

'DWD/HQJWK 24 its25 its

5HVROXWLRQ 5 m m2 m 5 m m

0RGH synchron

In asynchronous mode the sensor starts

measuring and provides the position independent

of the PC.

Synchron

In synchronous mode the output of the Temposonics®

SSI sensor is matched to the data request cycle of the

controller.

'LUHFWLRQ orard

Ascending position values from sensor electronics

housing to rod end

Reerse

Ascending position values from rod end to sensor

electronics housing

)LOWHU o ilterilter g. 2ilter g. 4ilter g.

0RYLQJDYHUDJHRIRUPHDVXUHPHQWVIRUQRLVH

reduction

(UURU6HWWLQJV)LJ

(UURU&RXQWHU

(UURU9DOXH

The rror ounter and rror alue settings determine, how often an

HUURUKDVWRRFFXUrror ounterVRWKDWDFHUWDLQrror alue is

shown. The standard settings for the rror ounter is “1” and for the

rror alue it is “”. So every error is shown with an error value of “”.

oth parameters are changeable.

Fig. 30: Error Settings

2 3

45

6

This manual suits for next models

7

Table of contents

Other Temposonics Accessories manuals