Temposonics E Series User manual

Operation Manual

E-Series IO-Link

Magnetostrictive Linear Position Sensors

Temposonics® E-Series IO-Link

Operation Manual

Table of contents

1. Introduction..................................................................................................................................................... 3

1.1 Purpose and use of this manual ................................................................................................................................................................ 3

1.2 Used symbols and warnings ..................................................................................................................................................................... 3

2. Safety instructions............................................................................................................................................. 3

2.1 Intended use.............................................................................................................................................................................................. 3

2.2 Forseeable misuse..................................................................................................................................................................................... 3

2.3 Installation, commissioning and operation................................................................................................................................................ 4

2.4 Safety instructions for use in explosion-hazardous areas.......................................................................................................................... 4

2.5 Warranty.................................................................................................................................................................................................... 4

2.6 Return ....................................................................................................................................................................................................... 4

3. Identification.................................................................................................................................................... 5

3.1 Order code of Temposonics®EH ............................................................................................................................................................... 5

3.2 Order code of Temposonics® EP/EL........................................................................................................................................................... 6

3.3 Order code of Temposonics® EP2.............................................................................................................................................................. 7

3.4 Order code of Temposonics® ER................................................................................................................................................................ 8

3.5 Nameplate ................................................................................................................................................................................................. 9

3.6 Approvals .................................................................................................................................................................................................. 9

3.7 Scope of delivery....................................................................................................................................................................................... 9

4. Product description and commissioning ..................................................................................................................10

4.1 Functionality and system design ............................................................................................................................................................. 10

4.2 Styles and installation of Temposonics® EH............................................................................................................................................. 11

4.3 Styles and installation of Temposonics® EP/EL........................................................................................................................................ 13

4.4 Styles and installation of Temposonics® EP2........................................................................................................................................... 14

4.5 Styles and installation of Temposonics® ER............................................................................................................................................. 15

4.6 Magnet installation .................................................................................................................................................................................. 16

4.7 Electrical connections.............................................................................................................................................................................. 18

4.8 Frequently ordered accessories............................................................................................................................................................... 19

5. Operation.......................................................................................................................................................21

5.1 Identification parameter........................................................................................................................................................................... 22

5.2 Standard commands ............................................................................................................................................................................... 22

5.3 Measuring parameter .............................................................................................................................................................................. 23

5.4 Offset....................................................................................................................................................................................................... 23

5.5 Switch points........................................................................................................................................................................................... 25

5.6 Set measurement range .......................................................................................................................................................................... 26

5.7 Error/warning messages ......................................................................................................................................................................... 27

5.8 Data storage mechanism......................................................................................................................................................................... 28

5.9 Device access lock .................................................................................................................................................................................. 29

6. Maintenance and troubleshooting .........................................................................................................................29

7.1 Error conditions, troubleshooting............................................................................................................................................................ 29

7.2 Maintenance............................................................................................................................................................................................ 29

7.3 Repair...................................................................................................................................................................................................... 29

7.4 List of spare parts ................................................................................................................................................................................... 29

7.5 Transport and storage ............................................................................................................................................................................. 29

7. Removal from service/dismantling ........................................................................................................................29

8. Technical data.................................................................................................................................................30

8.1 Technical data of Temposonics® EH......................................................................................................................................................... 30

8.2 Technical data of Temposonics® EP/EL.................................................................................................................................................... 31

8.3 Technical data of Temposonics® EP2 ....................................................................................................................................................... 32

8.4 Technical data of Temposonics® ER......................................................................................................................................................... 33

9. Appendix .......................................................................................................................................................34

Temposonics® E-Series IO-Link

Operation Manual

I 3 I

1.2 Used symbols and warnings

Warnings are intended for your personal safety and for avoidance of

damage to the described product or connected devices. In this doc-

umentation, safety information and warnings to avoid dangers that

might affect the life and health of operating or service personnel or

cause material damage are highlighted by the pictogram defined

below.

1. Introduction

1.1 Purpose and use of this manual

Before starting the operation of Temposonics position sensors, read

this documentation thoroughly and follow the safety information.

Keep the manual for future reference!

Symbol Meaning

NOTICE

This symbol is used to point to situations

that may lead to material damage, but not

to personal injury.

2. Safety instructions

2.1 Intended use

This product may be used only for the applications defined under item

1 and only in conjunction with the third-party devices and components

recommended or approved by Temposonics. As a prerequisite of

proper and safe operation the product requires correct transport,

storage, mounting and commissioning and must be operated with

utmost care.

1. The sensor systems of all Temposonics®series are intended

exclusively for measurement tasks encountered in industrial,

commercial and laboratory applications. The sensors are

considered as system accessories and must be connected

to suitable evaluation electronics, e.g. a PLC, IPC, indicator

or other electronic control unit.

Foreseeable misuse Consequence

Wrong sensor connection The sensor will not work

properly or can be damaged

Operate the sensor out of the

operating temperature range

No signal output –

the sensor can be damaged

Power supply is out of the

defined range

Signal output is wrong/

no signal output/

the sensor will be damaged

Position measurement is

influenced by an external

magnetic field

Signal output is wrong

Cables are damaged

Short circuit – the sensor can

be damaged/sensor does not

respond

Spacers are missing/

installed in a wrong order Error in position measurement

Wrong connection

of ground/shield

Signal output is disturbed –

the electronics can be damaged

Use of a magnet that is not

specified by Temposonics Error in position measurement

Do not reprocess the sensor afterwards.

The sensor might be damaged.

Do not step on the sensor.

The sensor might be damaged.

2.2 Forseeable misuse

The content of this technical documentation and of its appendix

is intended to provide information on mounting, installation and

commissioning by qualified automation personnel 1or instructed

service technicians who are familiar with the project planning and

dealing with Temposonics sensors.

1/ The term “qualified technical personnel” characterizes persons who:

•are familiar with the safety concepts of automation technology applicable to the

particular project

•are competent in the field of electromagnetic compatibility (EMC)

•have received adequate training for commissioning and service operations

•are familiar with the operation of the device and know the information required

for correct operation provided in the product documentation

Temposonics® E-Series IO-Link

Operation Manual

I 4 I

2.3 Installation, commissioning and operation

The position sensors must be used only in technically safe condition.

To maintain this condition and to ensure safe operation, installation,

connection and service, work may be performed only by qualified

technical personnel.

If danger of injury to persons or of damage to operating equipment

is caused by sensor failure or malfunction, additional safety measures

such as plausibility checks, limit switches, EMERGENCY STOP

systems, protective devices etc. are required. In the event of trouble,

shut down the sensor and protect it against accidental operation.

Safety instructions for commissioning

To maintain the sensor's operability, it is mandatory to follow

the instructions given below.

1. Protect the sensor against mechanical damage during

installation and operation.

2. Do not open or dismantle the sensor.

3. Connect the sensor very carefully and pay attention to the

polarity of connections and power supply.

4. Use only approved power supplies.

5. It is indispensable to ensure that the specified permissible

limit values of the sensor for operating voltage,

environmental conditions, etc. are met.

6. Check the function of the sensor regularly and provide

documentation of the checks.

7. Before applying power, ensure that nobody’s safety

is jeopardized by starting machines.

2.4 Safety instructions for use in explosion-hazardous areas

The sensor is not suitable for operation in explosion-hazardous areas.

2.5 Warranty

Temposonics grants a warranty period for its position sensors and

supplied accessories relating to material defects and faults that occur

despite correct use in accordance with the intended application 2.

The Temposonics obligation is limited to repair or replacement of any

defective part of the unit. No warranty can be provided for defects

that are due to improper use or above average stress of the product,

as well as for wear parts. Under no circumstances will Temposonics

accept liability in the event of offense against the warranty rules, no

matter if these have been assured or expected, even in case of fault or

negligence of the company.

Temposonics explicitly excludes any further warranties. Neither

the company’s representatives, agents, dealers nor employees are

authorized to increase or change the scope of warranty.

2.6 Return

For diagnostic purposes, the sensor can be returned to Temposonics.

Any shipment cost is the responsibility of the sender 2.

For a corresponding form, see chapter "9. Appendix" on page 34.

NOTICE

When returning sensors, place protective caps on male and female

connectors of the sensor. For pigtail cables, place the cable ends in

a static shielding bag for electrostatic discharge (ESD) protection.

Fill the outer packaging around the sensor completely to prevent

damage during transport.

2/ See also applicable Temposonics terms of sales and delivery on:

www.temposonics.com

Temposonics® E-Series IO-Link

Operation Manual

I 5 I

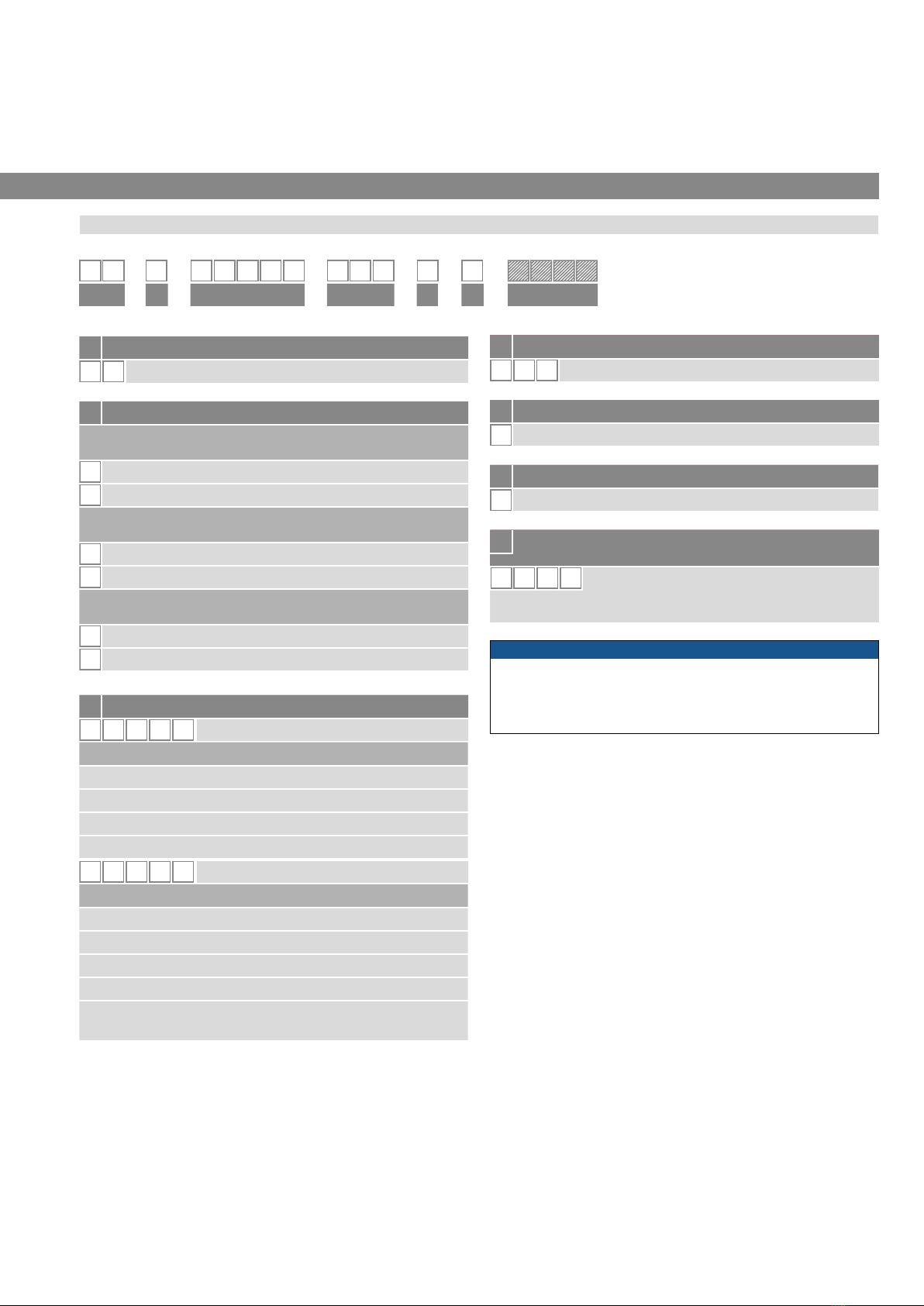

3.1 Order code of Temposonics®EH

3. Identification

a Sensor model

E H Rod

b Design

EH rod-style sensor with housing material 1.4305 (AISI 303)

and rod material 1.4301 (AISI 304)

KThreaded fl ange M18×1.5-6g, Ø 7 mm rod

LThreaded fl ange ¾" - 16 UNF -3A, Ø 7 mm rod

EH rod-style sensor with housing material 1.4305 (AISI 303)

and rod material 1.4306 (AISI 304L)

MThreaded fl ange M18×1.5-6g, Ø 10 mm rod

SThreaded fl ange ¾"- 16 UNF -3A, Ø 10 mm rod

EH rod-style sensor with housing material 1.4404 (AISI 316L)

and rod material 1.4404 (AISI 316L)

FThreaded flange ¾"-16 UNF-3A, Ø 10 mm rod

WThreaded flange M18×1.5-6g, Ø 10 mm rod

c Stroke length

X X X X M 0050…2540 mm

Standard stroke length (mm) Ordering steps

50… 500 mm 5 mm

500… 750 mm 10 mm

750…1000 mm 25 mm

1000…2540 mm 50 mm

X X X X U001.0…100.0 in.

Standard stroke length (in.) Ordering steps

1… 20 in. 0.2 in.

20… 30 in. 0.4 in.

30… 40 in. 1.0 in.

40…100 in. 2.0 in.

Non-standard stroke lengths are available;

must be encoded in 5 mm/0.1 in. increments.

.

dConnection type

D4 4 M12 male connector (4 pin)

dConnection type

D4 4 M12 male connector (4 pin)

eOperating voltage

1+24 VDC (±25 %)

eOperating voltage

1+24 VDC (±25 %)

f Output

KIO-Link

f Output

KIO-Link

g

Advanced single-position measurement or multi-position

measurement (optional)

1Z 0 X Number of magnets

01…04 position and velocity (1…4 magnet(s))

01…08 position (1…8 magnet(s))

g

Advanced single-position measurement or multi-position

measurement (optional)

1Z 0 X Number of magnets

01…04 position and velocity (1…4 magnet(s))

01…08 position (1…8 magnet(s))

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

E H D 4 4 1K

a b c d e f g

optional

NOTICE

• The number of magnets is limited by the stroke length. The mini-

mum allowed distance between magnets (i.e. front face of one to

the front face of the next one) is 75 mm (3 in.).

• Use magnets of the same type for multi-position measurement.

NOTICE

• The number of magnets is limited by the stroke length. The mini-

mum allowed distance between magnets (i.e. front face of one to

the front face of the next one) is 75 mm (3 in.).

• Use magnets of the same type for multi-position measurement.

Temposonics® E-Series IO-Link

Operation Manual

I 6 I

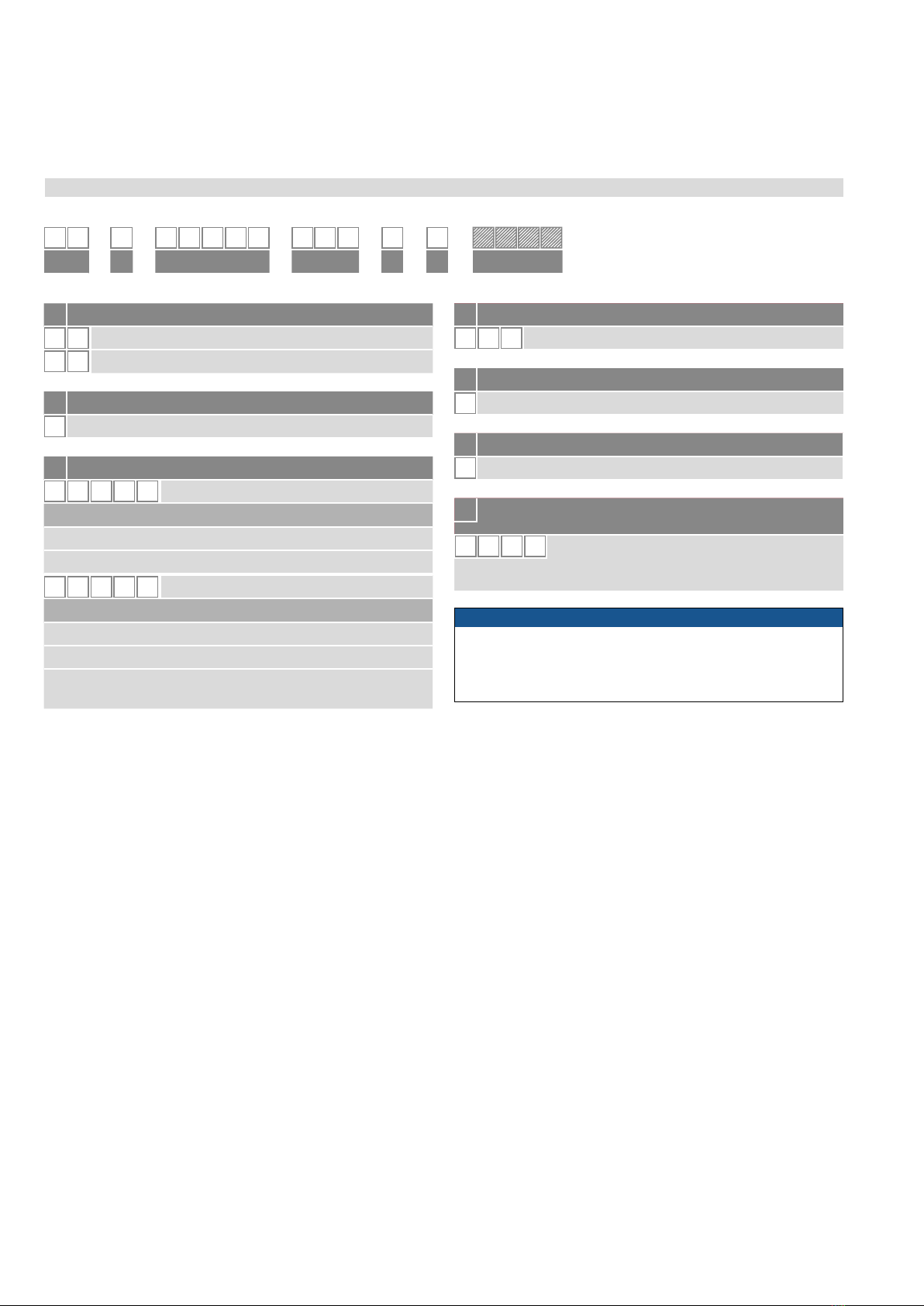

3.2 Order code of Temposonics® EP/EL

dConnection type

D4 4 M12 male connector (4 pin)

dConnection type

D4 4 M12 male connector (4 pin)

eOperating voltage

1+24 VDC (±25 %)

eOperating voltage

1+24 VDC (±25 %)

f Output

KIO-Link

f Output

KIO-Link

gAdvanced single-position measurement or multi-position

measurement (optional)

1Z 0 X Number of magnets

01…04 position and velocity (1…4 magnet(s))

01…08 position (1…8 magnet(s))

gAdvanced single-position measurement or multi-position

measurement (optional)

1Z 0 X Number of magnets

01…04 position and velocity (1…4 magnet(s))

01…08 position (1…8 magnet(s))

a Sensor model

E P Ultra low pro le

E L Compact pro le

b Design

0Without position magnet

c Stroke length

X X X X M 0050…2540 mm

Standard stroke length (mm) Ordering steps

50… 500 mm 25 mm

500…2540 mm 50 mm

X X X X U001.0…100.0 in.

Standard stroke length (in.) Ordering steps

1… 20 in. 1.0 in.

20…100 in. 2.0 in.

Non-standard stroke lengths are available;

must be encoded in 5 mm/0.1 in. increments.

.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

E0D 4 4 1K

a b c d e f g

optional

NOTICE

• The number of magnets is limited by the stroke length. The mini-

mum allowed distance between magnets (i.e. front face of one to

the front face of the next one) is 75 mm (3 in.).

• Use magnets of the same type for multi-position measurement.

Temposonics® E-Series IO-Link

Operation Manual

I 7 I

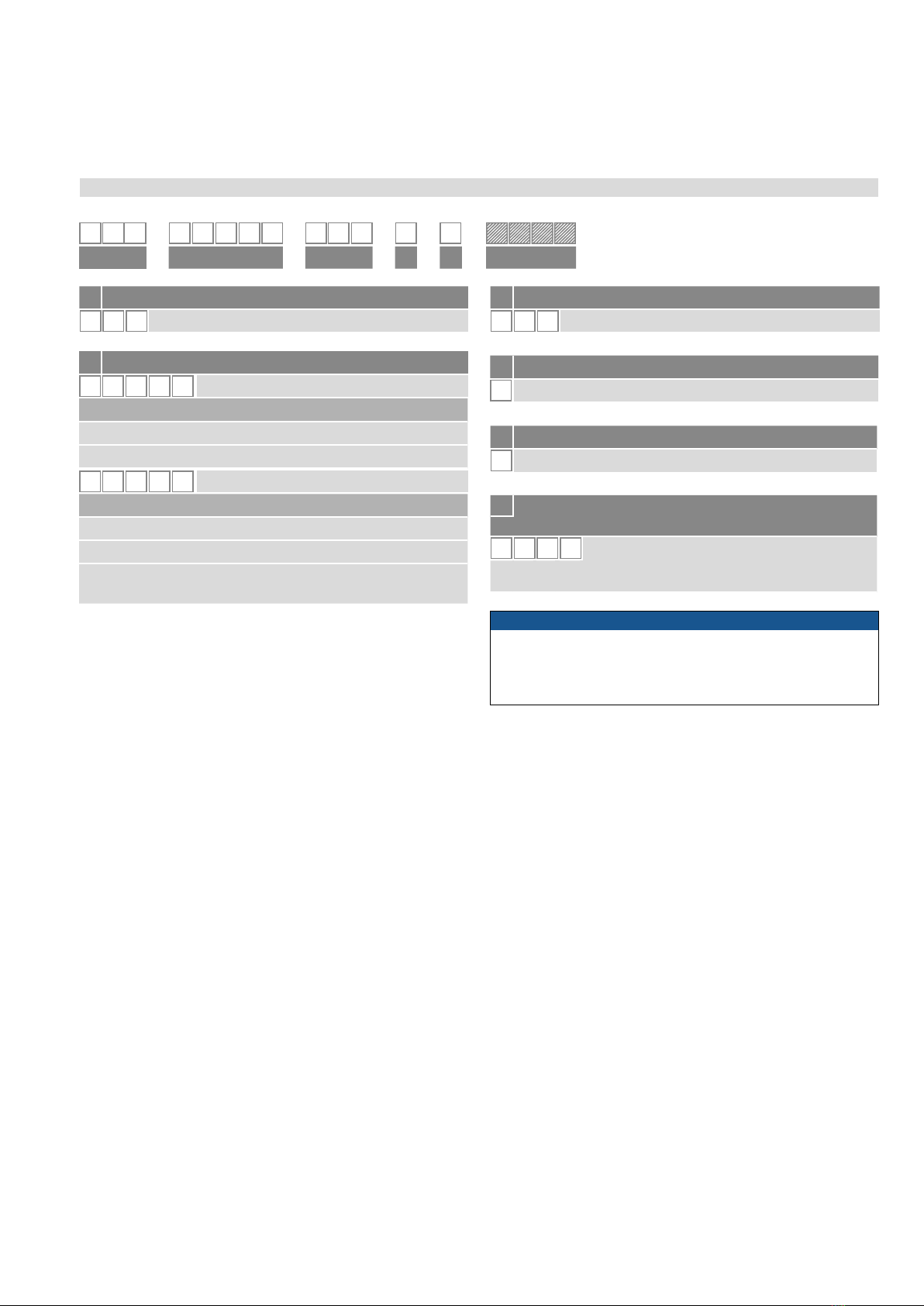

3.3 Order code of Temposonics® EP2

c Connection type

D 4 4 M12 (4 pin) male connector

d Operating voltage

1+24 VDC (±25 %)

e Output

KIO-Link

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

E P 2D 4 4 1K

a b c d e f

f Advanced single-position measurement or

multi-position measurement (optional)

1Z 0 X Number of magnets

01…04 position and velocity (1…4 magnet(s))

01…08 position (1…8 magnet(s))

a Sensor model

E P 2 Smooth pro le

b Stroke length

X X X X M 0050…2540 mm

Standard stroke length (mm) Ordering steps

50… 500 mm 25 mm

500…2540 mm 50 mm

X X X X U 001.0…128.0 in.

Standard stroke length (in.) Ordering steps

2… 20 in. 1.0 in.

20…100 in. 2.0 in.

Non-standard stroke lengths are available;

must be encoded in 5 mm/0.1 in. increments.

.

NOTICE

• The number of magnets is limited by the stroke length.

The minimum allowed distance between magnets (i.e. front face

of one to the front face of the next one) is 75 mm (3 in.).

• Use magnets of the same type for multi-position measurement.

Temposonics® E-Series IO-Link

Operation Manual

I 8 I

3.4 Order code of Temposonics® ER

d Connection type

D 4 4 M12 (4 pin) male connector

e Operating voltage

1+24 VDC (±25 %)

f Output

KIO-Link

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

E R D 4 4 1K

a b c d e f g

gAdvanced single-position measurement

1 Z 0 1 Number of magnets

1 position and velocity (1 magnet)

aSensor model

E R Aluminum cylinder with a guided driving rod

b Design

MInside thread M6 at end of rod

(For metric stroke length measurement)

SInside thread ¼"-28 UNF at end of rod

(For US customary stroke length measurement)

c Stroke length

X X X X M 0050…1500 mm

Standard stroke length (mm) Ordering steps

50…500 mm 25 mm

500…1500 mm 50 mm

X X X X U002.0…060.0 in.

Standard stroke length (in.) Ordering steps

2…22 in. 1.0 in.

22…60 in. 2.0 in.

Non-standard stroke lengths are available;

must be encoded in 5 mm/0.1 in. increments.

.

Temposonics® E-Series IO-Link

Operation Manual

I 9 I

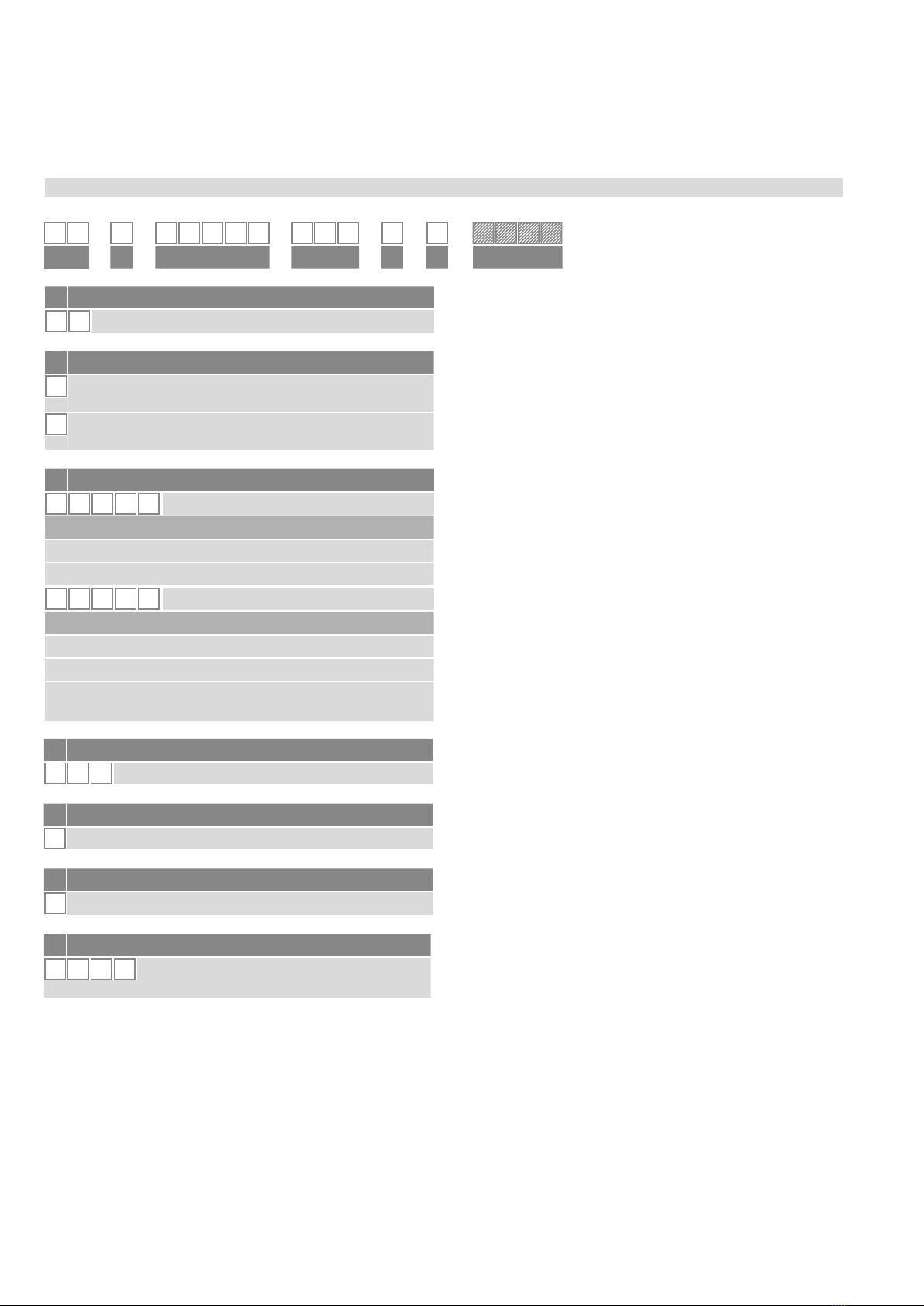

3.5 Nameplate

3.6 Approvals

• CE certified

• UKCA certified

• EAC certified

• UL certified

• Metrology certificate of Kazakhstan

Fig.1: Example of nameplate of an E-Series EH sensor

NOTICE

For a detailed overview of the certications, see

www.temposonics.com

E

E-Series

temposonics.com

EHM0200MD441K

S/N: 70008887

Sensor model

Part No.

Serial number

Stroke length (e.g. 200 mm)

Output

Connection type

Operating voltage

3.7 Scope of delivery

EH (rod sensor):

• Sensor

• O-ring

EP (compact profile sensor):

• Sensor

• 2 mounting clamps up to 1250 mm (50 in.) stroke length +

1 mounting clamp for each 500 mm (20 in.) additional stroke length

EL (ultra low profile sensor):

• Sensor

• 2 mounting clamps up to 1250 mm (50 in.) stroke length +

1 mounting clamp for each 500 mm (20 in.) additional stroke length

EP2 (smooth profile sensor):

• Sensor

• 2 mounting clamps up to 1250 mm (50 in.) stroke length +

1 mounting clamp for each 500 mm (20 in.) additional stroke length

ER (aluminum cylinder with a guided driving rod sensor):

• Sensor

Temposonics® E-Series IO-Link

Operation Manual

I 10 I

4.1 Functionality and system design

Product designation

• Position sensor Temposonics®E-Series

Sensor model

• Temposonics®EH (rod sensor)

• Temposonics®EP (compact profile sensor)

• Temposonics®EP (ultra low profile sensor)

• Temposonics®EP2 (smooth profile sensor)

• Temposonics®ER (aluminum cylinder with a guided driving

rod sensor)

Stroke length

• EH 50…2540 mm (2…100 in.)

• EP 50…2540 mm (2…100 in.)

• EL 50…2540 mm (2…100 in.)

• EP2 50…2540 mm (2…100 in.)

• ER 50…1500 mm (2…60 in.)

Output signal

• IO-Link

Application

The Temposonics position sensors are used for measurement and

conversion of the length (position) variable in the fields of automated

systems and mechanical engineering.

Principle of operation and system construction

4. Product description and commissioning

4

5

3

1

Measurement cycle

1Current pulse generates magnetic eld

2Interaction with position magnet eld

generates torsional strain pulse

3Torsional strain pulse propagates

4Strain pulse detected by converter

5Time-of-fl ight converted into position

Sensing element (Waveguide)

Position magnet (Magnetic eld)

Torsional strain pulse converter

2

Fig.2: Time-of-flight based magnetostrictive position sensing principle

Modular mechanical and electronic construction

• The sensor rod or profile protects the inner sensor element.

• The sensor electronics housing, a rugged construction, contains

the complete electronic interface with active signal conditioning.

• The external position magnet is a permanent magnet. Mounted on

the mobile machine part, it travels along the sensor rod or profile

and triggers the measurement through the sensor rod wall.

• The sensor can be connected directly to a control system.

Its electronics generates a strictly position proportional signal

output between start and end position.

MEASURING TECHNOLOGY

The absolute, linear position sensors provided by Temposonics rely on

the company’s proprietary magnetostrictive technology, which can

determine position with a high level of precision and robustness.

Each Temposonics position sensor consists of a ferromagnetic

waveguide, a position magnet, a strain pulse converter and a supporting

electronics. The magnet, connected to the object in motion in the

application, generates a magnetic eld at its location on the waveguide.

A short current pulse is applied to the waveguide. This creates a

momentary radial magnetic eld and torsional strain on the waveguide.

The momentary interaction of the magnetic elds releases a torsional

strain pulse that propagates the length of the waveguide. When the

ultrasonic wave reaches the beginning of the waveguide it is converted

into an electrical signal. Since the speed of the ultrasonic wave in the

waveguide is precisely known, the time required to receive the return

signal can be converted into a linear position measurement with both

high accuracy and repeatability.

Temposonics® E-Series IO-Link

Operation Manual

I 11 I

Hydraulics sealing

The flange contact surface is sealed via an O-ring in the undercut

(Fig.46).

For threaded flange (¾"-16 UNF-3A) »F« / »L« / »S«:

O-ring 16.4 × 2.2 mm (0.65 × 0.09 in.) (part no. 560315)

For threaded flange (M18×1.5-6g) »K« / »M« / »W«:

O-ring 15.3 × 2.2 mm (0.60 × 0.09 in.) (part no. 401133)

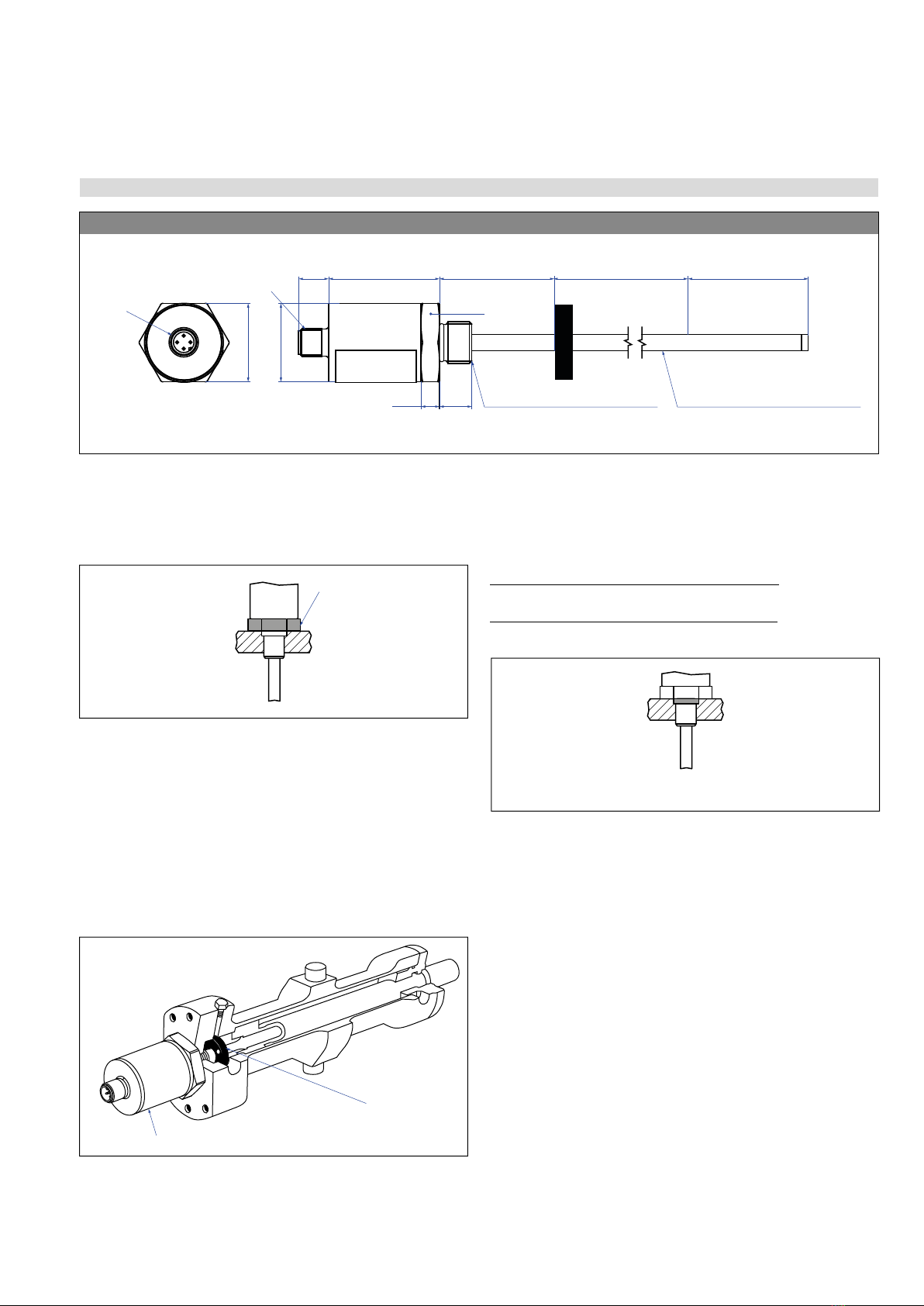

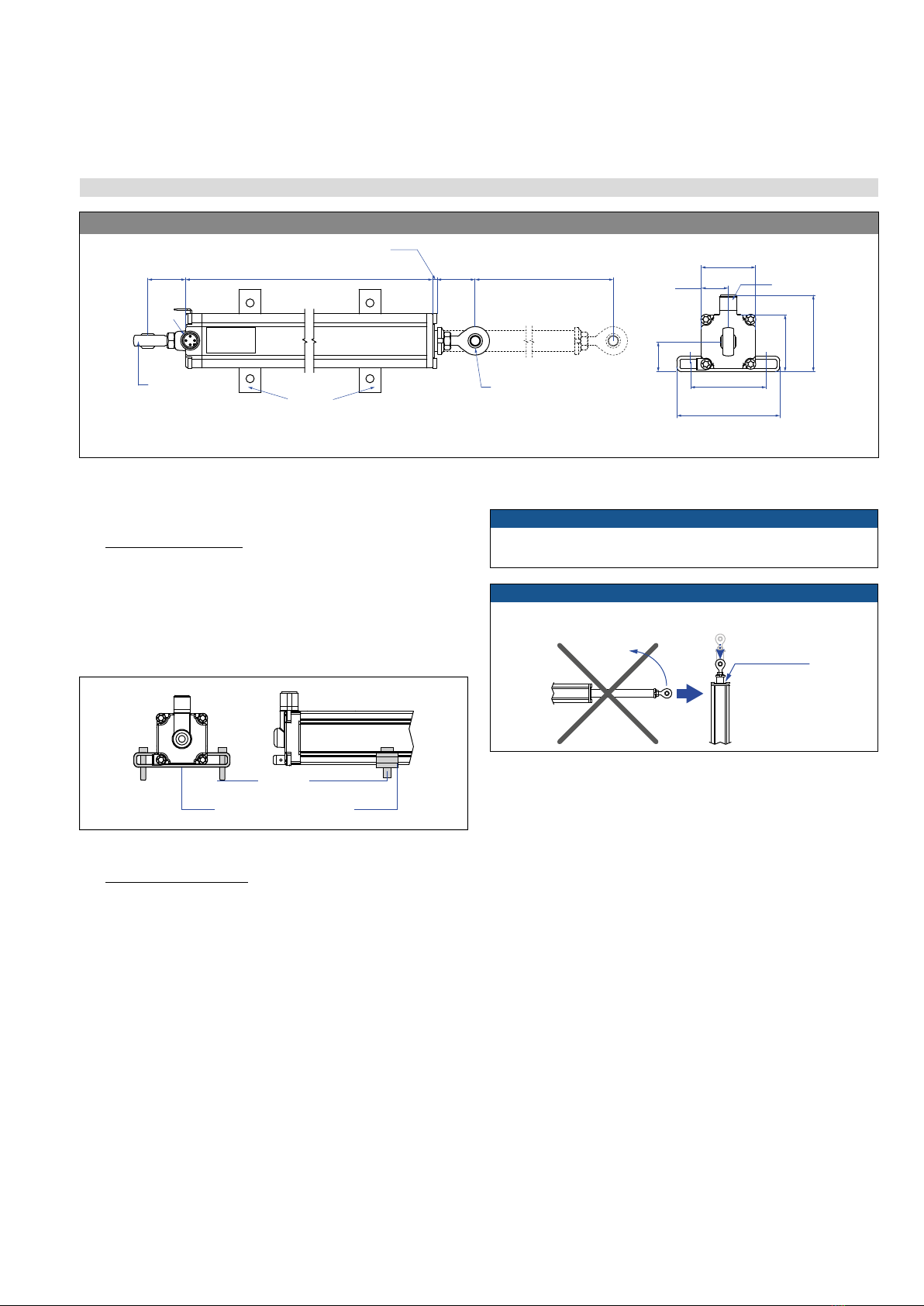

4.2 Styles and installation of Temposonics® EH

• Note the fastening torque of 50 Nm.

• Seat the flange contact surface completely on the cylinder

mounting surface.

• The cylinder manufacturer determines the pressure-resistant

gasket (copper gasket, O-ring, etc.).

• The position magnet should not grind on the sensor rod.

• The piston rod drilling

(EH-K/-L: Ø 7 mm rod: ≥ Ø 10 mm (≥ Ø 0.40 in.);

EH-M/-S/-F/-W: Ø 10 mm rod: ≥ Ø 13 mm (≥ Ø 0.52 in.))

depends on the pressure and piston speed.

• Adhere to the information relating to operating pressure.

• Protect the sensor rod against wear.

Installation of EH with threaded flange

Fix the sensor rod via threaded flange M18×1.5-6g or ¾"-16 UNF-3A.

Fig.3: Temposonics®EH sensor

Fig.4: Mounting example of threaded flange

Installation of a rod-style sensor in a fluid cylinder

The rod-style version has been developed for direct stroke

measurement in a fluid cylinder. Mount the sensor via threaded flange

or a hex nut.

• Mounted on the face of the piston, the position magnet travels

over the rod without touching it and indicates the exact position

through the rod wall – independent of the hydraulic fluid.

• The pressure resistant sensor rod is installed into a bore in the

piston rod.

Fig.5: Sensor in cylinder

In the case of threaded flange M18×1.5-6g, a screw hole based on

ISO 6149-1 (Fig.7) must be provided. See ISO 6149-1 for further

information.

Fig.6: Possibility of sealing

EH with threaded fl ange M18×1.5-6g or ¾"-16 UNF-3A

Magnet

M12

Ø 34

(Ø 1.34)

A/F 34

Sensor electronics housing

48

(1.89)

13

(0.51)

Dead zone

63.5

(2.5)

Stroke length

50…2540

(2…100)

8

(0.31)

Sensor rod: Ø 7 ± 0.10 (Ø 0.28 ± 0.01)

Sensor rod: Ø 10 ± 0.13 (Ø 0.39 ± 0.01)

Null zone

51

(2.01)

14

(0.55)

A/F 34

Flange »K«, »M«, »W«: M18×1.5-6g

Flange »F«, »L«, »S«: ¾"-16 UNF-3A

4 pin

Controlling design dimensions are in millimeters and measurements in ( ) are in inches

Fastening torque

50 Nm

Sealing via O-ring

in the flange undercut

Position magnet

Sensor electronics housing

Temposonics® E-Series IO-Link

Operation Manual

I 12 I

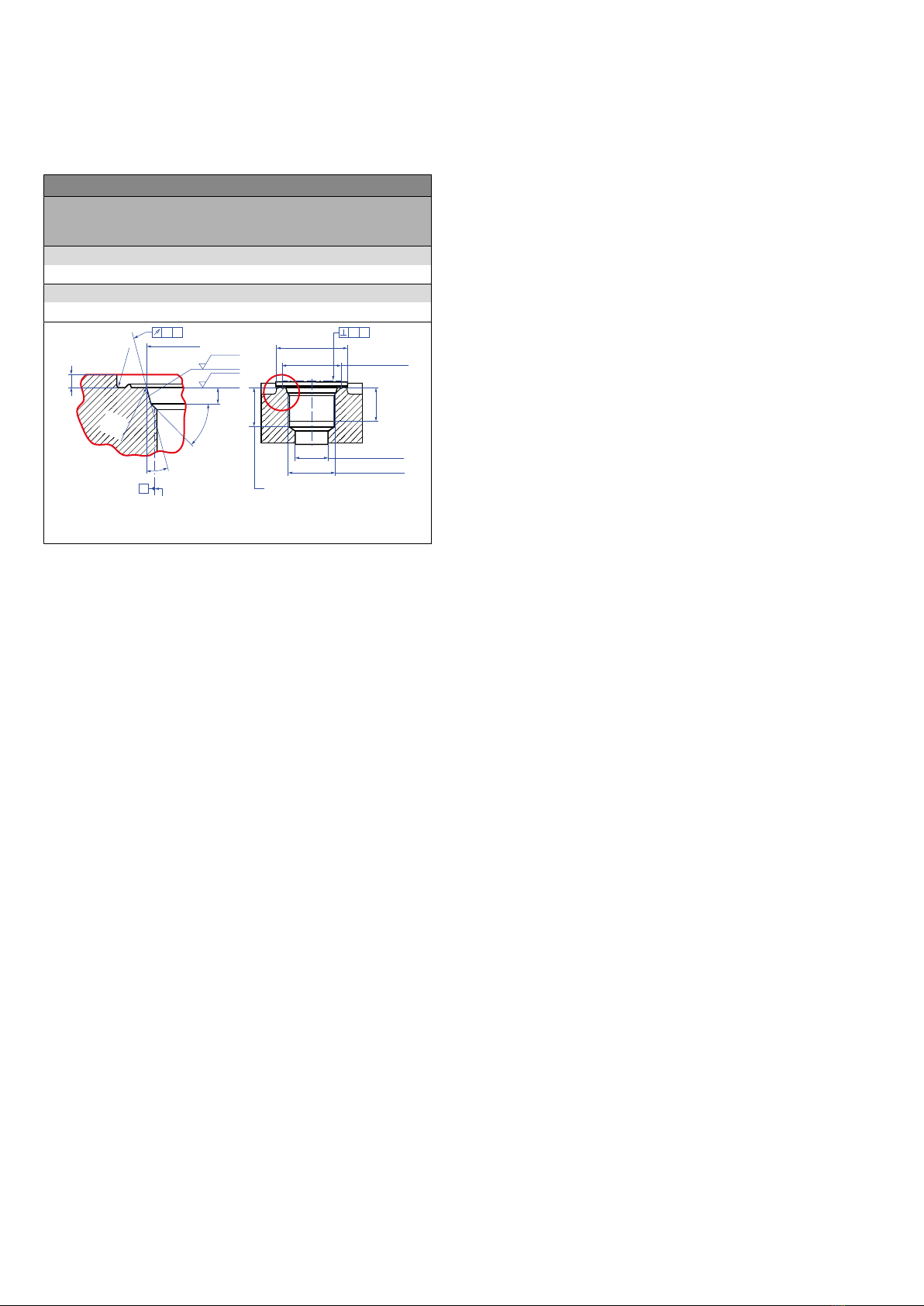

Fig.7: Notice for metric threaded flange M18×1.5-6g based on DIN ISO 6149-1

Notice for metric threaded fl anges

Thread

(d1×P)

d2d3d4d5

+0.1

0

L1

+0.4

0

L2L3L4Z°

±1°

EH-K (Ø 7 mm rod)

M18×1.5-6g 55 ≥ 10 24.5 19.8 2.4 28.5 2 26 15°

EH-M/-W (Ø 10 mm rod)

M18×1.5-6g 55 ≥ 13 24.5 19.8 2.4 28.5 2 26 15°

Ød

5

Ra 3.2

Ra 3.2

Pitch diameter

A

A

Thread

(d

1

× P)

Ød

3

(Reference)

A

Ød

2

Ød

4

(Gauging)

This dimension applies when

tap drill cannot pass through

entire boss.

≤ R0.4

R0.3

R0.1

Z°

4

5

°

±

5

°

L

3

L

1

L

2

L

4

A0.1 A0.2

Controlling design dimensions are in millimeters

Temposonics® E-Series IO-Link

Operation Manual

I 13 I

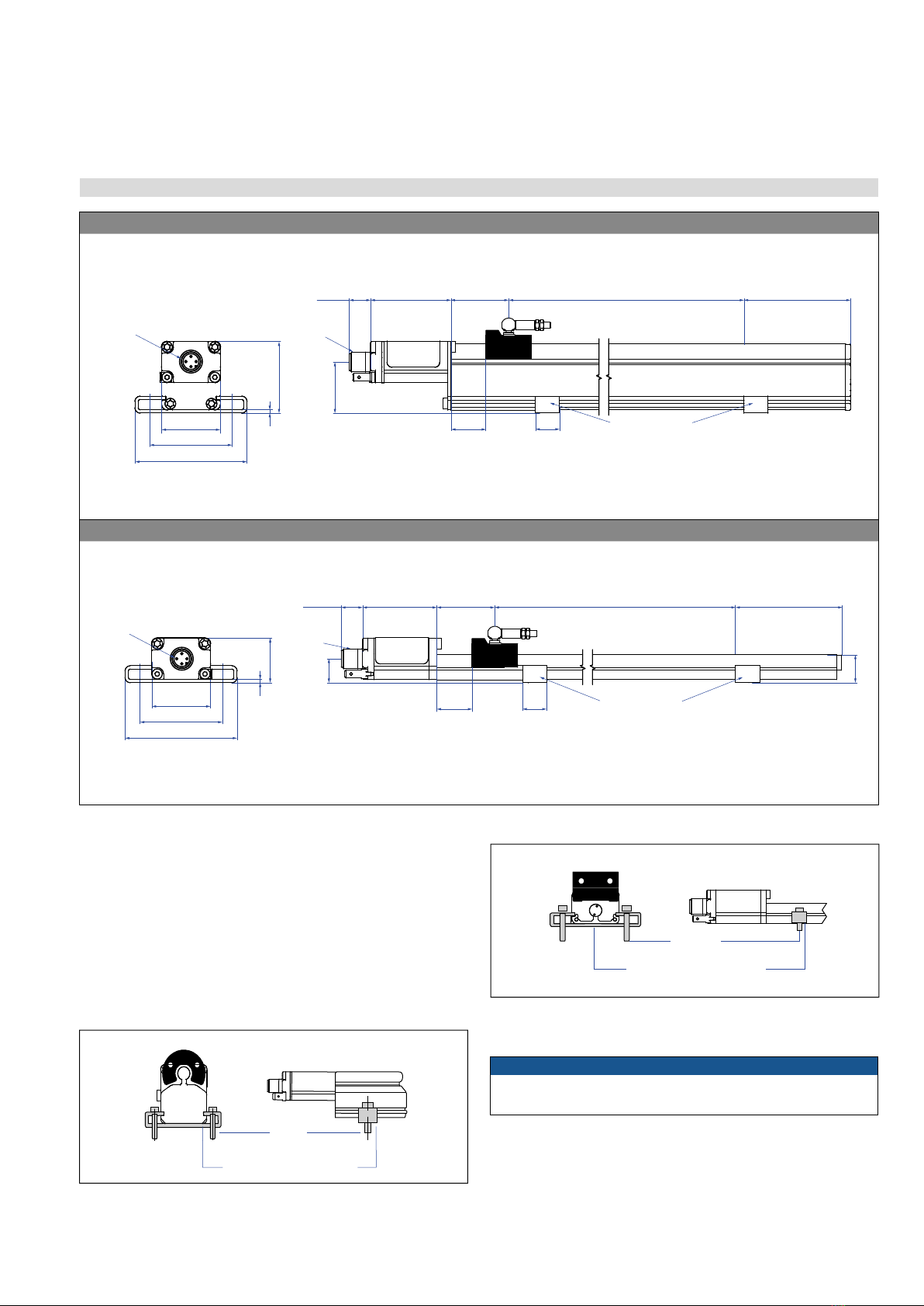

4.3 Styles and installation of Temposonics® EP/EL

Fig.8: E-Series EP and EL with magnet slider

Installation of EP/EL

The position sensor can be installed in any position. Normally,

the sensor is firmly installed and the position magnet is fastened

to the mobile machine part. Thus it can travel along the measuring

rod without touching it. The sensor is fitted on a flat machine surface

using the mounting clamps (Fig.9). A length-dependent number of

these clamps are delivered with the sensor and must be distributed

over the profile at regular distances. For fastening use M5×20 screws

to DIN 6912 that should be tightened with a fastening torque of 5 Nm.

Fig.9: EP with mounting clamps with cylinder screw M5×20 (part no. 403 508)

Fig.10: EL with mounting clamps with cylinder screw M5×20 (part no. 403 508)

NOTICE

Take care to mount the sensor in an axially parallel position to

avoid damage of the carriage, magnet and sensor rod.

Adjustable mounting clamps

M5×20

Fastening torque: 5 Nm

Adjustable mounting clamps

M5×20

max. 5 Nm

EP

Magnet

4 pin M12

50 (1.97)

68 (2.68)

14.6

(0.57)

31

(1.22)

41

(1.61)

35.6 (1.40)

Sensor

electronics

housing

48.8

(1.92)

13

(0.51)

Stroke length

50…2540

(2…100)

Dead zone

68

(2.68)

Null zone

35

(1.38)

2 (0.08)

Mounting clamps

*Measuring start

Magnet slider S: 19 (0.75)

Magnet slider V: 19 (0.75)

U-magnet OD33: 35 (1.38)

Block magnet L: 32.5 (1.28)

*

EL

Magnet

M12

Sensor

electronics

housing

45

(1.77)

13

(0.51)

14.6

(0.57)

Stroke length

50…2540

(2…100)

Dead zone

68

(2.68)

17

(0.67)

27

(1.06)

2 (0.08)

35.6 (1.40)

68 (2.68)

50 (1.97)

14.5

(0.57)

4 pin

Null zone

35

(1.38)

Mounting clamps

*

*Measuring start:

Magnet slider S: 19 (0.75)

Magnet slider V: 19 (0.75)

Block magnet L: 32.5 (1.28)

Controlling design dimensions are in millimeters and measurements in ( ) are in inches

Temposonics® E-Series IO-Link

Operation Manual

I 14 I

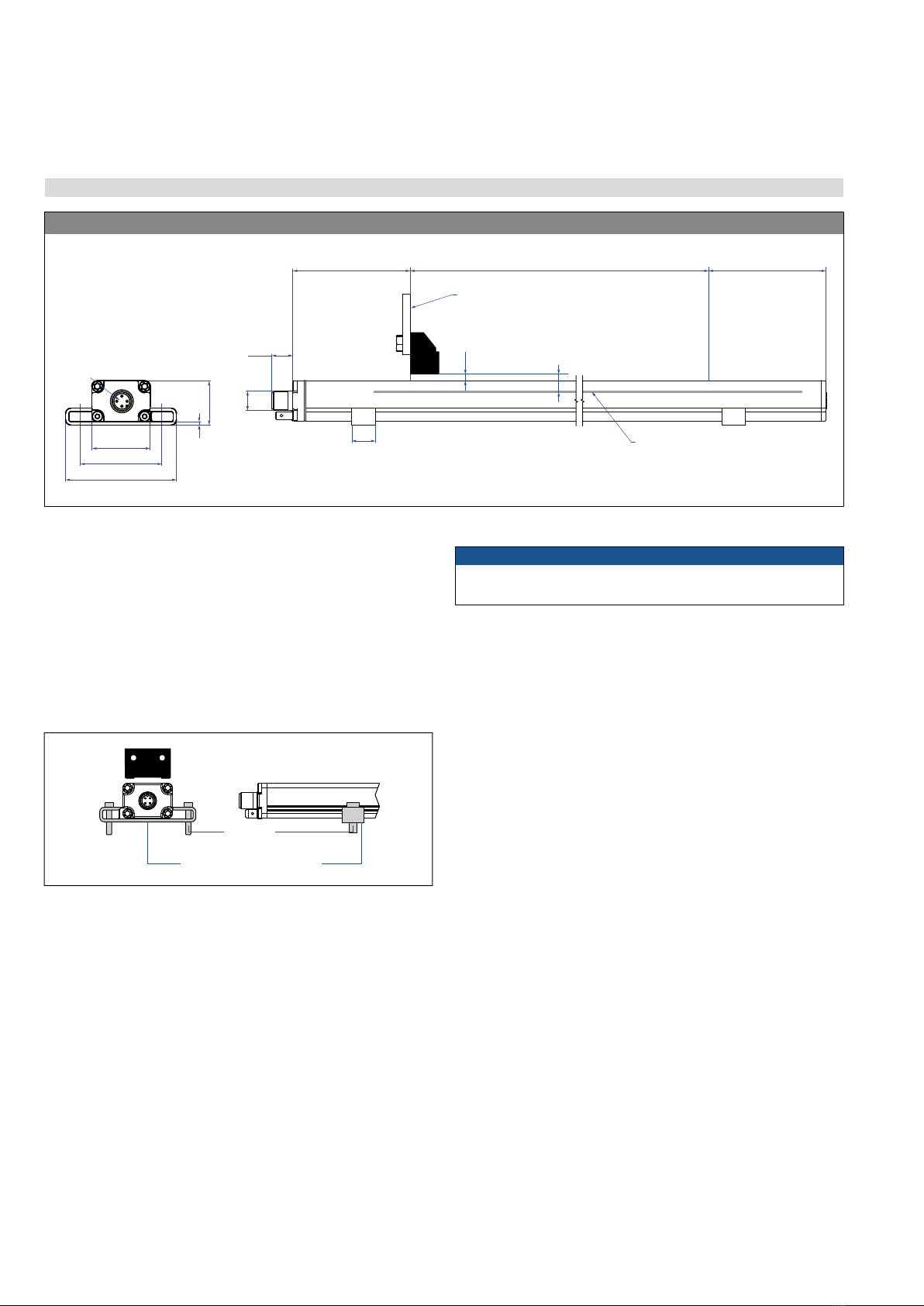

4.4 Styles and installation of Temposonics® EP2

Fig.11: Temposonics EP2

Fig.12: Mounting clamps with cylinder screw M5×20 (part no. 403 508)

NOTICE

Take care to mount the sensor in an axially parallel position to

avoid damage of the carriage, magnet and sensor rod.

Installation of EP2

The position sensor can be installed in any position. Normally,

the sensor is firmly installed and the position magnet is fastened

to the mobile machine part. Thus it can travel along the measuring

rod without touching it. The sensor is fitted on a flat machine surface

using the mounting clamps (Fig.12). A length-dependent number of

these clamps are delivered with the sensor and must be distributed

over the profile at regular distances. For fastening use M5×20 screws

to DIN 6912 that should be tightened with a fastening torque of 5 Nm.

EP2

Magnet

Magnet

Stroke length

50…2540

(2…100)

M12

Null zone

73

(2.87)

13

(0.51)

14.6

(0.57)

Dead zone

73

(2.87)

27

(1.06)

2 (0.08)

35.6 (1.40)

68 (2.68)

50 (1.97)

4 pin

Mounting support

3 ± 2 (0.12 ± 0.08)

8 ± 2 (0.31 ± 0.08)

Sensing element

inside the sensor

Controlling design dimensions are in millimeters and measurements in ( ) are in inches

Adjustable mounting clamps

M5×20

Fastening torque: 5 Nm

Temposonics® E-Series IO-Link

Operation Manual

I 15 I

4.5 Styles and installation of Temposonics® ER

Fig.13: Temposonics ER

Fig.14: Mounting clamps with cylinder screw M5×20 (part no. 403 508)

NOTICE

Take care to mount the sensor in an axially parallel position to

avoid damage of the carriage and sensor rod.

NOTICE

Do not raise up the ER sensor, if the lifting rod is extended.

It causes

serious damage

There are two ways to install the sensor ER:

1. Via the mounting clamps

The position sensor can be installed in any position. The sensor

is fitted on a flat machine surface using the mounting clamps

(Fig.14). A length-dependent number of must be distributed over

the profile at regular distances. For fastening use M5×20 screws

to DIN 6912 that should be tightened with a fastening torque of

5 Nm.

2. Via the adjustable rod end

The position sensor can be installed in any position.

The sensor is mechanically connected via adjustable rod ends

(for ER-M: part no. 254 210 / for ER-S: part no. 254 235)

ER

50

(1.97)

51

(2.01)

Stroke length

50…1500

(2…60)

M12×1

37.8

(1.49)

68

(2.68)

17.8

(0.7)

20

(0.79)

25

(1)

25

(1)

Optional:

Adjustable

rod end M6 /

¼"-28 UNF

Optional:

Adjustable

rod end M6 /

¼"-28 UNF

4 pin

Optional:

Mounting clamps

132.5 + stroke length

(5.22 + stroke length)

35.5

(1.40)

3

(0.12)

Controlling design dimensions are in millimeters and measurements in ( ) are in inches

Adjustable mounting clamps

M5×20

Fastening torque: 5 Nm

Temposonics® E-Series IO-Link

Operation Manual

I 16 I

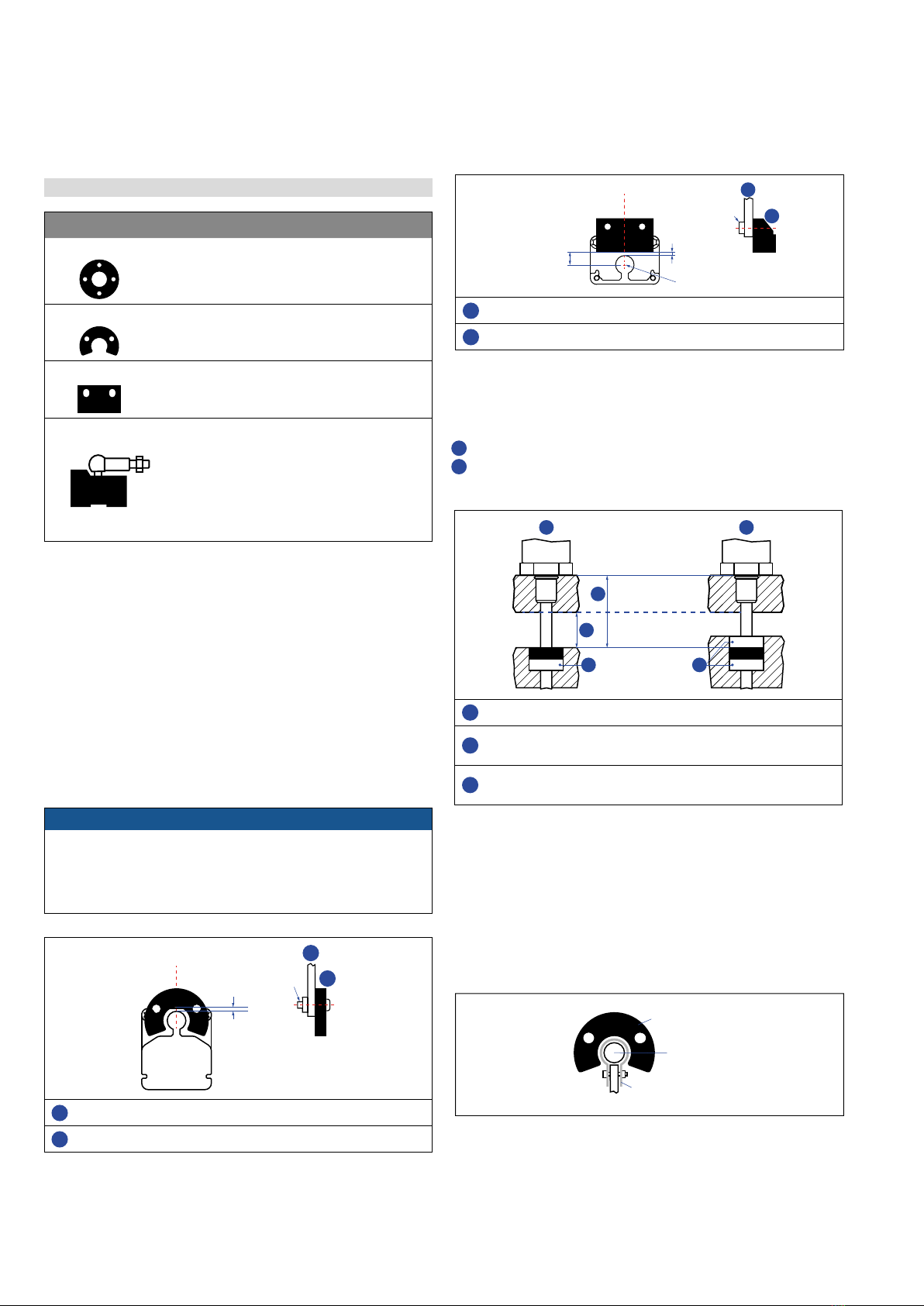

4.6 Magnet installation

Sensors with stroke lengths ≥ 1 meter (3.3 ft.)

Support horizontally installed sensors with a stroke length from

1 meter (3.3 ft.) mechanically at the rod end. Without the use

of a support, rod and position magnet may be damaged. A false

measurement result is also possible. Longer rods require evenly

distributed mechanical support over the entire length (e.g. part no.

561 481). Use an U-magnet (Fig.19) for measurement.

NOTICE

Mount ring magnets and U-magnets concentrically.

Mount block magnets centrically over the sensor rod or the sensor

profile. Do not exceed the maximum acceptable gap (Fig.16,

Fig.17).

Controlling design dimensions are in millimeters and measurements in ( ) are in inches

Fig. 15: Typical use of magnets

Mounting the ring magnets, U-magnets & block magnets

Install the magnet using non-magnetic material for mounting

device, screws, spacers etc.. The magnet must not grind on

the sensor rod. Alignment errors are compensated via the air gap.

• Permissible surface pressure: Max. 40 N/mm2 (only for ring

magnets and U-magnets)

• Fastening torque for M4 screws: 1 Nm; use washers, if necessary

• Minimum distance between position magnet and any magnetic

material has to be 15 mm (0.6 in.) (Fig.18).

• If no other option exists and magnetic material is used,

observe the specified dimensions (Fig.18).

Magnet mounting with magnetic material

When using magnetic material the dimensions of Fig.18 must

be observed.

A If the position magnet aligns with the drilled piston rod

B If the position magnet is set further into the drilled piston rod,

install another non-magnetic spacer above the magnet.

Fig.16: Mounting of U-magnet (part no. 251 416-2), example of EP sensor

Fig.17: Mounting of block magnet (part no. 403 448), example of EL sensor

Fig.18: Installation with magnetic material

Fig.19: Example of sensor support (part no. 561 481)

M4 1

2

Air gap:

1.75 ±1

1U-magnet

2Non-magnetic mounting plate

M4

2

1

8 ±2

(0.31 ±0.08) Sensing element

Air gap: 3 ±2

(0.12 ±0.08)

1Block magnet

2Non-magnetic mounting plate

Magnet Magnet

1

2

3

A B

Magnetic

material

3

1Null zone, depends on sensor model

2Distance between position magnet and any magnetic material

(≥ 15 mm (≥ 0.6 in.))

3Non-magnetic spacer (≥ 5 mm (≥ 0.2 in.)) –

Recommendation: 8 mm (0.31 in.)

U-magnet

Sensor rod

Non-magnetic fixing clip

Magnet Typical sensors Benefi ts

Ring magnets Rod model

(EH)

• Rotationally symmetrical

magnetic eld

U-magnets Profi le &

rod models

(EH, EP)

• Height tolerances can be

compensated, because the

magnet can be lifted off

Block magnets Profi le &

rod models

(EH, EP, EL, EP2)

• Height tolerances can be

compensated, because the

magnet can be lifted off

Magnet sliders Profi le models

(EP, EL)

• The magnet is guided by

the pro le

• The distance between the

magnet and the waveguide

is strictly de ned

• Easy coupling via the

ball joint

Temposonics® E-Series IO-Link

Operation Manual

I 17 I

Start and end positions of the position magnets

Consider the start and end positions of the position magnets during

the installation. To ensure that the entire stroke length is electrically

usable, the position magnet must be mechanically mounted as

follows.

Fig.20: Start- and end positions of magnets, part 1

Fig.21: Start- and end positions of magnets, part 2

Controlling design dimensions are in millimeters and measurements in ( ) are in inches

Multi-position measurement

The minimum distance between the magnets is 75 mm (3 in.).

EH with ring magnets/U-magnets

≥75 (≥ 3)

EH with block magnets

≥75 (≥ 3)

EP with magnet sliders

≥75 (≥ 3)

EP with U-magnets

≥75 (≥ 3)

EP with block magnets

≥75 (≥ 3)

EL with magnet sliders

≥75 (≥ 3)

EL with block magnets

≥75 (≥ 3)

EP2 with block magnets

≥75 (≥ 3)

E-Series EH with ring- / U-magnet

Start position

51 (2.01)

End position

63.5 (2.5)

E-Series EH with block magnet

Start position

48.5 (1.91)

End position

66 (2.6)

E-Series EP with magnet slider “S”, “N”, “V”, “G”

Start position

19 (0.75)

End position

84 (3.3)

E-Series EP with U-magnet

Start position

35 (1.38)

End position

68 (2.68)

E-Series EP with block magnet

Start position

32.5 (1.29)

End position

70.5 (2.78)

E-Series EL with magnet slider “S”, “N”, “V”, “G”

Start position

19 (0.75)

End position

84 (3.3)

E-Series EL with block magnet

Start position

32.5 (1.29)

End position

70.5 (2.78)

E-Series EP2 with block magnet

Start position

73 (2.87)

End position

73 (2.87)

E-Series EH with ring- / U-magnet

Start position

51 (2.01)

End position

63.5 (2.5)

E-Series EH with block magnet

Start position

48.5 (1.91)

End position

66 (2.6)

E-Series EP with magnet slider “S”, “N”, “V”, “G”

Start position

19 (0.75)

End position

84 (3.3)

E-Series EP with U-magnet

Start position

35 (1.38)

End position

68 (2.68)

E-Series EP with block magnet

Start position

32.5 (1.29)

End position

70.5 (2.78)

E-Series EL with magnet slider “S”, “N”, “V”, “G”

Start position

19 (0.75)

End position

84 (3.3)

E-Series EL with block magnet

Start position

32.5 (1.29)

End position

70.5 (2.78)

E-Series EP2 with block magnet

Start position

73 (2.87)

End position

73 (2.87)

Fig.22: Minimum distance for multi-position measurement

Temposonics® E-Series IO-Link

Operation Manual

I 18 I

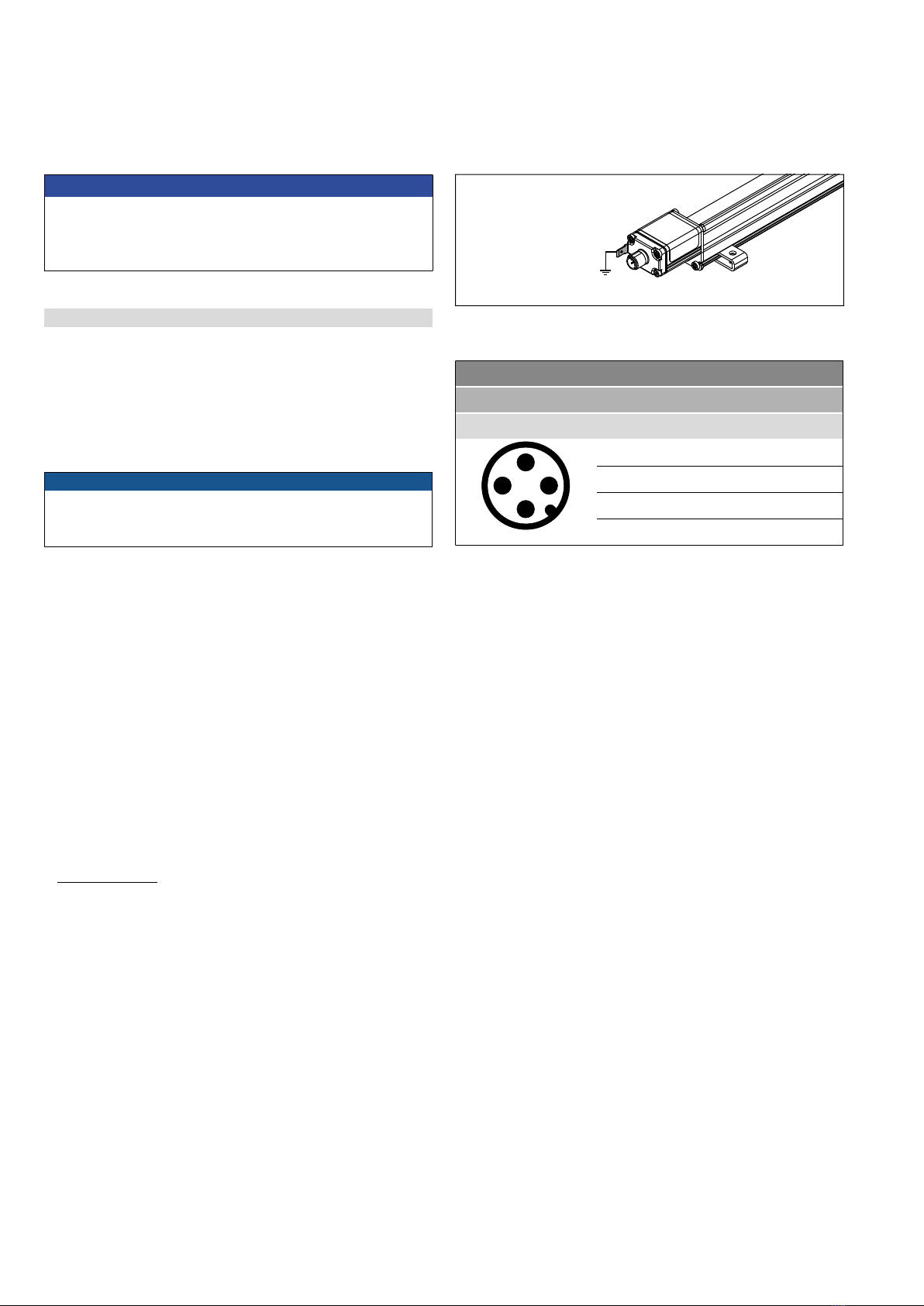

4.7 Electrical connections

Placement of installation and cabling have decisive influence on

the sensor‘s electromagnetic compatibility (EMC). Hence correct

installation of this active electronic system and the EMC of the

entire system must be ensured by using suitable metal connectors,

shielded* cables and grounding. Overvoltages or faulty connections

can damage its electronics despite protection against wrong polarity.

Instructions for connection

• Use low-resistant twisted pair and shielded cables. Connect

the shield to ground externally via the controller equipment.

• Keep control and sign leads separate from power cables and

sufficiently far away from motor cables, frequency inverters,

valve lines, relays, etc..

• Use only connectors with metal housing and connect the shielding

to the connector housing.

• Keep the connection surface at both shielding ends as large

as possible. Connect the cable clamps to function as a ground.

• Keep all non-shielded leads as short as possible.

• Keep the earth connection as short as possible with a large

cross section. Avoid ground loops.

• With potential differences between machine and electronics earth

connections, no compensating currents are allowed to flow across

the cable shielding.

Recommendation:

Install potential compensating leads with large cross section or use

cables with separate double shielding, and connect only one end of

the shield.

• Use only stabilized power supplies in compliance with the specified

connecting values.

Grounding of profile and rod sensors

Connect the sensor electronics housing to machine ground. Ground

sensor types EP, EL, EP2 and ER via ground lug as shown in Fig.23.

The sensor type EH is grounded via thread.

*/ The use of shielded cables is a recommendation of Temposonics to afford a better

protection against signal disturbances

NOTICE

1. Do not mount the sensors in the area of strong magnetic or

electric noise fields.

2. Never connect/disconnect the sensor when voltage is applied.

Fig.23: Grounding via ground lug e.g. profile sensor

Fig.24: Connector wiring D44

D44

Signal + power supply

M12 male connector Pin Function

2

1

4

3

View on sensor

1 +24 VDC (−15/+20 %)

2 DI/DQ

3 DC Ground (0 V)

4 C/Q

NOTICE

For multi-position measurement, use magnets of the same type.

Do not fall below the minimum distance between the magnets of

75mm (3 in.) for multi-position measurement. Contact Temposonics

if you need a magnet distance < 75 mm (3 in.).

Temposonics® E-Series IO-Link

Operation Manual

I 19 I

4.8 Frequently ordered accessories

Position magnets

Ø 32.8

(Ø 1.29)

Ø 23.8

(Ø 0.94)

Ø 13.5

(Ø 0.53)

Ø 4.3

(Ø

0.17)

7.9

(0.31)

Ø 25.4

(

Ø

1)

Ø 13.5

(

Ø

0.53) 7.9

(0.31)

Ø 13.5

(Ø 0.53)

Ø 17.4

(Ø 0.69)

7.9

(0.31)

Ø 32.8

(Ø 1.29)

Ø 23.8

(Ø 0.94)

Ø 13.5

(Ø 0.53)

Ø 4.3

(Ø 0.17)

60°

140°

3

(0.12)

7.9

(0.31)

Ring magnet OD33

Part no. 201 542-2

Ring magnet OD25.4

Part no. 400 533

Ring magnet OD17.4

Part no. 401 032

U-magnet OD33

Part no. 251 416-2

Material: PA ferrite GF20

Weight: Approx. 14 g

Surface pressure: Max. 40 N/mm2

Fastening torque for M4 screws: 1 Nm

Operating temperature:

−40…+105 °C (−40…+221 °F)

Material: PA ferrite

Weight: Approx. 10 g

Surface pressure: Max. 40 N/mm2

Operating temperature:

−40…+105 °C (−40…+221 °F)

Material: PA neobond

Weight: Approx. 5 g

Surface pressure: Max. 20 N/mm2

Operating temperature:

−40…+105 °C (−40…+221 °F)

Material: PA ferrite GF20

Weight: Approx. 11 g

Surface pressure: Max. 40 N/mm2

Fastening torque for M4 screws: 1 Nm

Operating temperature:

−40…+105 °C (−40…+221 °F)

Position magnets

Ø 19.8

(Ø 0.78)

Ø 30.5

(Ø 1.2)

7.6

(0.3)

M5

20

(0.79)

43

(1.69)

14

(0.55)

17.2 (0.67)

40 (1.57)

18°

25.3 (1)

40 (1.57)

18°

57 (2.24) 14

(0.55)

25.3 (1)

8.2 (0.32)

49 (1.93)

M5

19.5 (0.77)

1.5

(0.06)

33 (1.3)

14

(0.55)

20.5

(0.81)

14.9 (0.59)

8 ± 2 (0.31 ± 0.08)

Distance to sensor element

Ø 4.3

(Ø 0.17)

Ring magnet

Part no. 402 316

Magnet slider S, joint at top

Part no. 252 182

Magnet slider V, joint at front

Part no. 252 184

Block magnet L

Part no. 403 448

Material: PA ferrite coated

Weight: Approx. 13 g

Surface pressure: Max. 20 N/mm2

Operating temperature:

−40…+100 °C (−40…+212 °F)

Material: GRP, magnet hard ferrite

Weight: Approx. 35 g

Operating temperature:

−40…+85 °C (−40…+185 °F)

Material: GRP, magnet hard ferrite

Weight: Approx. 35 g

Operating temperature:

−40…+85 °C (−40…+185 °F)

Material: Plastic carrier with hard ferrite

magnet

Weight: Approx. 20 g

Fastening torque for M4 screws: 1 Nm

Operating temperature:

−40…+75 °C (−40…+167 °F)

This magnet may infl uence the sensor

performance speci cations for some

applications.

Magnet spacer Sealing

Ø 14.3

(Ø 0.56)

Ø 23.8

(Ø 0.94)

Ø 31.8

(Ø 1.25)

Ø 4.3

(Ø 0.17)

3.2

(0.13)

Ø 15.3

(Ø 0.6)

Ø 2.2

(Ø 0.09)

Ø 16.4

(Ø 0.65)

Ø 2.2

(Ø 0.09)

Magnet spacer

Part no. 400 633

O-ring for threaded fl ange

M18×1.5-6g

Part no. 401 133

O-ring for threaded fl ange

¾"-16 UNF-3A

Part no. 560 315

Material: Aluminum

Weight: Approx. 5 g

Surface pressure: Max. 20 N/mm2

Fastening torque for M4 screws: 1 Nm

Material: Fluoroelastomer

Durometer: 75 ± 5 Shore A

Operating temperature:

−40…+204 °C (−40…+400 °F)

Material: Fluoroelastomer

Durometer: 75 ± 5 Shore A

Operating temperature:

−40…+204 °C (−40…+400 °F)

– Additional options available in our Accessories Guide 551 444

Controlling design dimensions are in millimeters and measurements in ( ) are in inches

Temposonics® E-Series IO-Link

Operation Manual

I 20 I

3/ Follow the manufacturer‘s mounting instructions

Controlling design dimensions are in millimeters and measurements in ( ) are in inches

Color of connectors and cable jacket may change. Colors of the cores and technical properties remain unchanged.

Cable connectors 3Cables

53

(2.09)

Ø 20

(

Ø 0.79)

38

(1.5)

Ø 20

(Ø 0.79)

57

(2.25)

M12 A-coded female connector

(4 pin/5 pin), straight

Part no. 370 677

M12 A-coded female connector

(5 pin), angled

Part no. 370 678

Cable with M12 A-coded female

connector (5 pin), straight – pigtail

Part no. 370 673

Cable with M12 A-coded female

connector (5 pin), angled – pigtail

Part no. 370 675

Material: GD-Zn, Ni

Termination: Screw

Contact insert: CuZn

Cable Ø: 4…8 mm (0.16…0.31 in.)

Wire: 1.5 mm²

Operating temperature:

−30…+85 °C (−22…+185 °F)

Ingress protection: IP67 (correctly tted)

Fastening torque: 0.6 Nm

Material: GD-Zn, Ni

Termination: Screw; max. 0.75 mm²

Contact insert: CuZn

Cable Ø: 5…8 mm (0.2…0.31 in.)

Wire: 0.75 mm2 (18 AWG)

Operating temperature:

−25…+85 °C (−13…+185 °F)

Ingress protection: IP67 (correctly tted)

Fastening torque: 0.4 Nm

Material: PUR jacket; black

Features: Shielded

Cable length: 5 m (16.4 ft)

Ingress protection: IP67 (correctly tted)

Operating temperature:

−25…+80 °C (−13…+176 °F)

Material: PUR jacket; black

Features: Shielded

Cable length: 5 m (16.4 ft)

Ingress protection: IP67 (correctly tted)

Operating temperature:

−25…+80 °C (−13…+176 °F)

Hex nut Mounting hardware Mounting clamp

M18×1.5-6g

A/F 27

8.7

(0.34)

¾"-16 UNF-3A

A/F 28

11

(0.43)

20 (0.79)

60 (2.36)

16 (0.63)

12 (0.47)

3.2 (0.13)

Ø 3.2 (Ø 0.13)

M3 fastening screws (6×)

4 Holes

Ø 5.4 (Ø 0.21) 31 (1.22) 9 (0.35)

50 (1.97)

2 (0.08)

68 (2.68)

10 (0.39)

Mounting clamp width:

14.6 (0.57)

Hex jam nut M18×1.5-6g

Part no. 500 018

Hex jam nut ¾"-16 UNF-3A

Part no. 500 015

Fixing clip

Part no. 561 481

Mounting clamp

Part no. 403 508

Material: Steel, zinc plated Material: Steel, zinc plated Application: Used to secure sensor

rods (Ø 10 mm (Ø 0.39 in.)) when

using an U-magnet or block magnet

Material: Brass, non-magnetic

Material: Stainless steel 1.4301/1.4305

(AISI 304/303)

Rod ends

26.5 (1.04)

M6

36.5 (1.44)

Ø 6

(Ø 0.24)

26,5

¼"-28 UNF

36,5

Ø 6,35

Rod end with M6 thread

Part no. 254 210

Rod end with ¼"-28 UNF thread

Part no. 254 235

Material: Galvanized steel

Material: Galvanized steel NOTICE

The wiring of the cables is available in the accessories brochure

(document no. 551444)

Other manuals for E Series

1

This manual suits for next models

5

Table of contents

Other Temposonics Accessories manuals