TempSen TPLR-120 Series User manual

TOUCH SCREEN PAPERLESS RECORDER

www.tempsendevices.net

Page 1

USER MANUAL

MULTICOLOR

TOUCH SCREEN PAPERLESS RECORDER

TPLR-120 Series

TEMPSEN DEVICES

Plot No : 2&3, Balaji Nagar, 4

th

Street, Mettukuppam, Thoraipakkam, Chennai-600097

Tele fax : +91-44-24581758,Mobil : +91-9841201758, Customer Care :+91-9841291758

Website : www.tempsendevices.net

TOUCH SCREEN PAPERLESS RECORDER

www.tempsendevices.net

Page 2

WHEN YOU RECEIVE THIS INSTRUMENT...

Thank you for purchasing the TEMPSEN DEVICES, TPLR-120 MULTI COLOR TOUCH SCREEN PAPERLESS

RECORDER. Please read the instruction manual carefully and use the instrument correctly.

TEMPSEN DEVICES assumes no liability to any party for any loss or damage, direct or indirect, caused

by the use or any unpredictable defect of the product.

Cleaning of the front panel should be limited to wiping lightly with a dry cloth.

Check that all of the following items are present.

•Paperless Recorder Range

•Input Type

•Output indication

•Communication interface

•A pair of mounting bracket

•Operating Voltage

•Serial link cable between Recorder& PC Output.

•PEN DRIVE use after antivirus scanning

INSTALLATION

Installation Location

Install the control panel in a location that meets the following criteria.

(1) Little or no mechanical vibration.

(2) No corrosive gases.

(3) Minimal temperature fluctuations and near normal temperature.

(4) Not directly subject to radiant heat.

(5) Not subject to strong electromagnetic field.

(6) No direct exposure to water.

WIRING

Wiring precautions

While wiring take the following precautions.

(1) Field wiring to the instrument, should be placed so as to avoid blocking the air flow, yet

Provide a suitable service loop to allow easy removal of unit with wiring attached.

(2) Wires should be tied to maintain an order in the event they must be disconnected for

Any reason.

(3) For connecting the wire to the terminals, we recommend use of crimp terminal lugs with

Insulated sleeves.

(4) Route the input circuit wiring away as possible from the power and ground circuits to avoid

Noise pickup.

(5) Use proper-shielded wire to avoid electromagnetic interference.

TOUCH SCREEN PAPERLESS RECORDER

www.tempsendevices.net

Page 3

SPECIFICATION OF TOUCH SCREEN PROCESS DATA LOGGER :

General

Input Resolution: 0.1% of full scale.

Input Channels: 8 or 16 channel direct universal input.

Measurement Rate: 4 channels per second on all direct input channels

Internal Temperature Reference : 0 to 60 °C

Analog Inputs

DC Voltage: 0-5 VDC with accuracy 0.1%.

DC Current: 4-20mA, 0-20mA ,Accuracy: +/-0.1% with built in shunt.

Thermocouple

Resolution: 1°C or optional 0.1 °C

Reference junction compensation: Yes

Type Range (°C) Accuracy (°C)

J -200 to -100°C +/-2.5 °C

-100 to 1200 °C +/- 1.5 °C

K -270 to -100 °C +/- 2.5 °C

-100 to 1372 °C +/- 1.5 °C

T -270 to -100 °C +/- 2.5 °C

-100 to 400 °C +/- 1.5 °C

E -270 to -100 °C +/- 2.5 °C

-100 to 1000 °C +/- 1.5 °C

N -270 to -100 °C +/- 2.5 °C

-100 to 1300 °C +/- 1.5 °C

S -50 to 1768 °C +/- 3 °C

B 0 to 1820 °C +/- 4 °C

RTD

Base Accuracy: 0.2% or 0.5 °C (1 °F).Resolution: 0.1 °C

2 or 3 wire connection. Cable compensation to +50 ohm.

Open and short circuit detection.

Type Range °C Accuracy (°C)

100 ohm Pt. 385 -200 to 400 °C +/- 0.2 °C

1000 ohms 0 to 50 °C +/- 0.2 °C (optional Fixed Input only)

Recording

Recording Rates: User programmable from 1 sample per second to 1

sample every 10 hours

Data Format: .Txt file; can be easily open able by variety of softwares.

Data Storage Capacity:512 kb internal memory and this data can be

Easily moved to memory stick connected to USB Port.

Data Scaling and statistics : By PC Software

Communication Specification

Communication Output : RS 232 (or) RS 485 (or) USB (or) Ethernet (TCP/IP) Optional

Advanced communication function provides high accuracy and stable multi-channel analog data sampling function to

host computer. Also provides direct communication port to dot matrix printer and USB 2.0 pen drive option in the front

panel of the Paperless Recorder.

TOUCH SCREEN PAPERLESS RECORDER

www.tempsendevices.net

Page 4

GPRS with SMS and Mail : Optional

SMS : 5 Mobile Numbers with Low & High Alarm SMS After 30 minutes

Email : 3 mail ID with Manual/ Auto mail Every day 12 AM Time Duration 1 hour per data

Power

Requirements: 100 to 240 VAC, 50/60Hz. 20 VA max. Optional 24 VDC

Power Fail Protection

Programmed parameters stored in non-volatile memory. Clock battery backed. Clock battery to be replaced

once in 5Years, one 3V Lithium cell easily replaceable.

Transmitter Power supply Output: Optional isolated 24Vdc@120mA output

Input / Output

Relay Output : 2 relay outputs, (normally open, Close & pole contacts) rated at 30 VDC @ 0.5A or

230Vac @ 5Amp Max.Additional relay outputs (optional) : 12 Relay card; separate DIN rail

Mounting Card interfaced with RS-232 or RS-485 interface with this unit

Memory specification

Internal memory: 20,000 Reading per channel.

The data logger consists of internal memory storage capacity of above specified range provides a wide

range of application in data storage for all channels individually

Recording data on storage media

Using the Setup menu, the user can log the data in internal memory. If this memory is full the logged data can be

transferred to external storage media connected on USB Port.

Record rate 8 channel 16 channel

1 Sec 9 Hrs 4.5 Hrs

10 Sec 90Hrs 45 Hrs

1 min 540 Hrs 270 Hrs

10 min 5400 Hrs 2700 Hrs

The above table shows the number of maximum readings can be stored internal memory by changing record time After

the above prescribed time the data must be transferred to USB storage media so as internal memory get free to store

the new readings .

Display

Type: Color Active Matrix TFT Liquid Crystal Display

Size: 8 inch diagonal Resolution:

640 (W) x 480 (H) pixels

Interface: Resistive analog touch screen control

Display Modes: Graphic trending (horizontal) Bar Graphs( Vertical )

Digital Readout (Single or multi-channel) Alarms and event log settable.

Historical trends: In PC Software.

Display Windows: Time/Date Graphics (bars large digital graph) Disk

Status System Status Menu Button Bar Alarms/ events

TOUCH SCREEN PAPERLESS RECORDER

www.tempsendevices.net

Page 5

PC Based Software

External PC software the user is able to manipulate the graph to make it easy to see interaction

between recorded channels, or change the Color schemes, expand, compress, zoom and print. The same

analysis tool used for multi-channel graph and used to scroll through data

Optional : FDA Title 21 CFR Part 11 Compliant Software & Web server Based Software

Safety and Environmental

Operating Range: 0 °C to 60 °C, 10% to 90% RH non-condensing

Dimension: Bezel dimension - 195(H) x 300(W) x 5mm above panel.

Unit dimension : 195 ( H) x 300 (W) x 75 ( D) mm depth.

Panel Cut out : 175 ( H) x 255(W) mm

Protection : IP65 for front bezel when mounted in panel.

Safety : Meets the requirements of EN61010-1 when installed in accordance with the

instructions in the Manual.

UL and c UL : Pending

EMC : Meets the requirements of EN61326 and CE directive 89/336/EEC & EN12830

Weight : Approximately 3.0 kg.

Recorder Dimensions Panel Cut out

TOUCH SCREEN PAPERLESS RECORDER

www.tempsendevices.net

Page 6

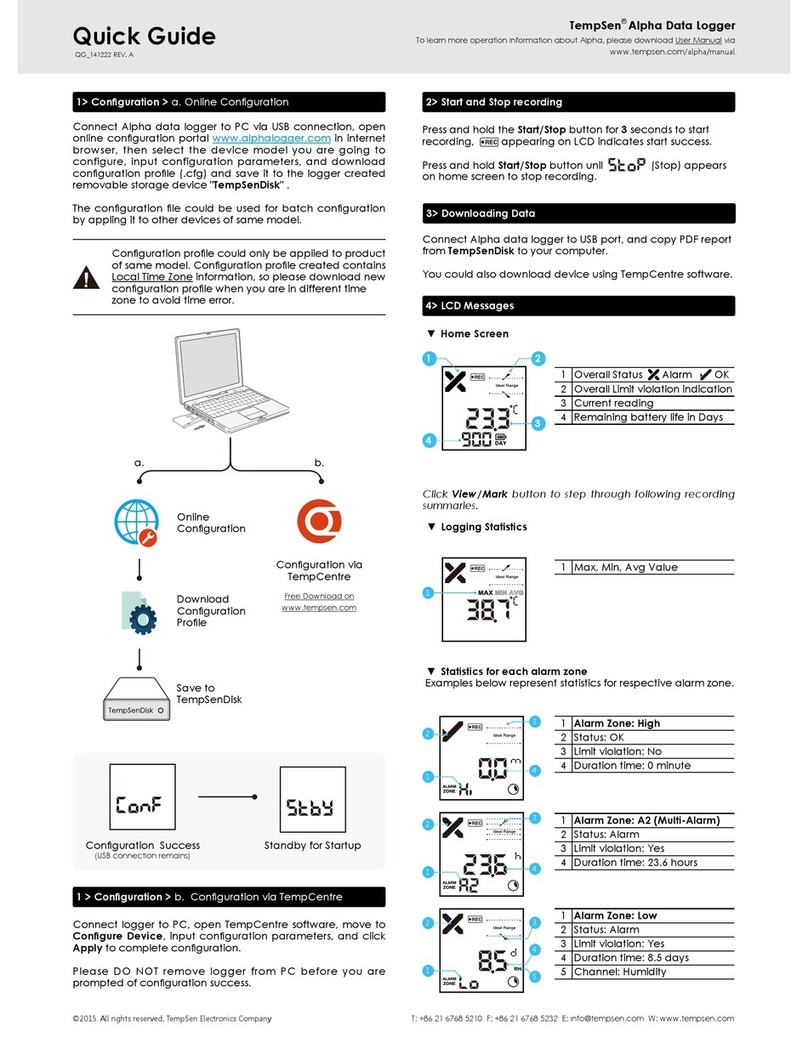

OPERATING PARAMETER SETTING

Switch ON the device, the following display will show the channel readings. It will take a few seconds.

CONFIGURATION SETTING

Click CONFIG in the display, Enter the password to progress into the Setting Screen.

TOUCH SCREEN PAPERLESS RECORDER

www.tempsendevices.net

Page 7

After entering the password, the setting screen will be displayed as shown below

TIME & DATE SETTINGS

In Setting -> SET Real Time Clock, Set the real time & date details. Click OK to save the settings.

TOUCH SCREEN PAPERLESS RECORDER

www.tempsendevices.net

Page 8

LOG TIME SETTINGS

In Setting -> SET Log Time, Set the Log Time Of The Logger. Click Ok to save the settings.

PASSWORD SETTINGS

In Setting -> Click SET Password, this feature is used to change password of the user.

TOUCH SCREEN PAPERLESS RECORDER

www.tempsendevices.net

Page 9

CHANNEL PARAMETER SETTINGS

In Setting -> SET Channel Parameters, Select the Alarm Range, Offset, Decimal, Sensor and Channels.

ALARM :

Set the alarm range from the specified values.

Low : -999

High : 9999

RANGE :

Set the range with respect to the Sensor type specification.(REF PAGE NO:3)

OFFSET :

Set the offset range from -999 to 999, Default set “0”

DECIMAL :

Set the decimal point from 0 to 3 for Linear Inputs only

ALARM INDICATION STATUS

Once the alarm is “ON” the acknowledgement ( ACK) shows in GRAPH Key

Alarm Status Display Color

Normal : BLACK

High : RED

Low : BLUE

TOUCH SCREEN PAPERLESS RECORDER

www.tempsendevices.net

Page 10

COPY MEMORY :

Insert an USB 2.0 drive in the front panel of the Logger.

In Setting -> Click COPY Memory, this feature is used to copy the Logger memory in to the Pen Drive.

If USB 2.0 drive is not inserted in the drive, an error screen, PEN DRIVE PROBLEM!!! Will be displayed.

ERASE :

To clear the entire data from the Logger memory permanently,

In Setting -> ERASE ALL!!

TOUCH SCREEN PAPERLESS RECORDER

www.tempsendevices.net

Page 11

PRINT MEMORY :

Insert an Ink jet printer through the PRINTER PORT provided in the back panel of Logger.

In Setting -> Click PRINT Memory, the entire memory will be printed.

GRAPH :

After completing all the Settings, Click HOME icon in the Setting screen.

Click GRAPH icon, to display the channel readings individually.

TOUCH SCREEN PAPERLESS RECORDER

www.tempsendevices.net

Page 12

TERMINAL DETAILS:

ID NUMBER :

In Setting -> ID NUMBER SETTING for Multi Logger Software

DATA LOGGING OFF

Logging Off The Data Logger, Click HOME icon in the Setting screen

In Setting ->DATA LOGGING OFF

Input Terminal

Communication port

Print

er

Port

Power Supply

High & Low Alarm

TOUCH SCREEN PAPERLESS RECORDER

www.tempsendevices.net

Page 13

MAINTENANCE

Basic troubleshooting procedure

The following questions should be asked & appropriate action is to be taken to the negative answers.

All major corrective action can be accomplished by replacing the basic unit. No special tools are

Required except screwdriver & multi meter.

1) When you switching ON the unit check whether the display is showing anything? If yes then go

For step 2. If no check for the power input connections, check whether the unit is getting proper supply

at proper terminals. Connecting the supply to the wrong terminals may damage the unit permanently.

2) Check the display whether it shows the actual value properly. If yes follow step 3,if no check the sensor

Input; check whether the sensor or input is connected at proper terminals in proper way (+ve & -ve

polarity). If sensor is open or not connected then “999.9" will appear on display.

3) After connecting the sensor if the actual value shown is not proper then check the calibration is

Correct according to the calibration constant table.

In case if fault developed other than the above mentioned,

contact

TEMPSEN DEVICES, CHENNAI-600097 , TN , INDIA , Cell : +91-9841201758, Phone : +91-44-24581758

,

Email : solution@tempsendevices.net,tempsen@yahoo.com , web: www.tempsendevices.net

Table of contents

Other TempSen Data Logger manuals

TempSen

TempSen ITAG 4 SP User manual

TempSen

TempSen ITAG 4 User manual

TempSen

TempSen ITAG 4 User manual

TempSen

TempSen Tempod 30 User manual

TempSen

TempSen ITAG3 Series User manual

TempSen

TempSen ITAG 3 Series User manual

TempSen

TempSen Alpha T30 User manual

TempSen

TempSen Alpha User manual

TempSen

TempSen Tempod 30 User manual