Ten-Tec 1215 Quick start guide

MODEL 1215

ANTENNA TUNER KIT

ASSEMBLY & OPERATIONAL MANUAL

Release “B” 6/28/11

1 1215 Antenna Tuner Manual Part # 74449

2 1215 Antenna Tuner Manual Part # 74449

TABLE OF CONTENTS

NOTE: This manual is divided into two sections, the “Reference Section” which covers the

meter's specifications and general information and the “Assembly Section” which covers the

actual assembly and check-out of the kit. The “Assembly Section” is last since it will seldom

be referenced after the wattmeter is built and tested for the first time. The “Reference

Section” is essentially the owner's manual for the completed unit.

•REFERENCE SECTION

◦Tuner Specifications

◦General Introduction

◦Circuit Overview

◦Schematic Drawing

◦Parts List / Bracket Drawings

◦Operating Tips

◦Troubleshooting Chart

◦Optional Balun for Balanced Feeders

•ASSEMBLY SECTION

◦Kit Assembly Suggestions

◦Required Tools & Supplies

◦Getting Started

◦Phase I: Assembly of Rotary Inductor (L2)

◦Phase 2: SWR Bridge Circuit Board Assembly

◦Phase 3: Meter Switch & SWR Set Pot Assembly & Wiring

◦Phase 4: Antenna Switch Wiring

◦Phase 5: Chassis Assembly & Wiring

◦Phase 6: Wattmeter Calibration and Checkout

3 1215 Antenna Tuner Manual Part # 74449

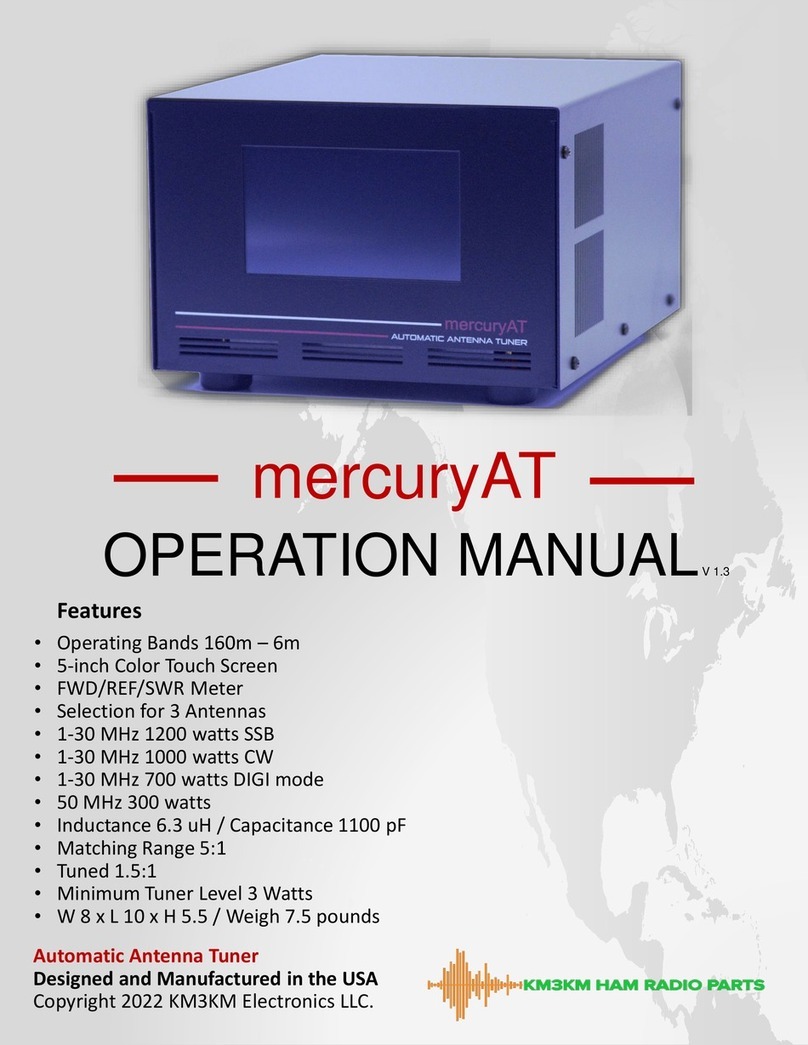

MODEL 1215 TUNER SPECIFICATIONS

CIRCUIT TYPE: High Pass “T” Network

RF POWER RATING: 200 Watts maximum

FREQUENCY RANGE: 1.8 – 30 MHz

WATTMETER RANGES: 20 Watts, 200 Watts

OUTPUT MATCHING RANGE: SWR up to 10:1

INPUT IMPEDANCE: 50ΩResistive when tuner properly matched

CAPACITOR RATING: 10 - 210 pf @ 1000 Volts

INDUCTOR: Toroidal rotary, 0.2 – 18 uH

DC POWER SOURCE: 12 – 16 Volts @ 150 ma (for meter illumination)

ENCLOSURE SIZE: 9.5”W x 4.2”H x 5.5”D

(with knobs & connectors, the overall depth

is approximately 7.25”)

WEIGHT: 3.5 lb (1.8 kg)

4 1215 Antenna Tuner Manual Part # 74449

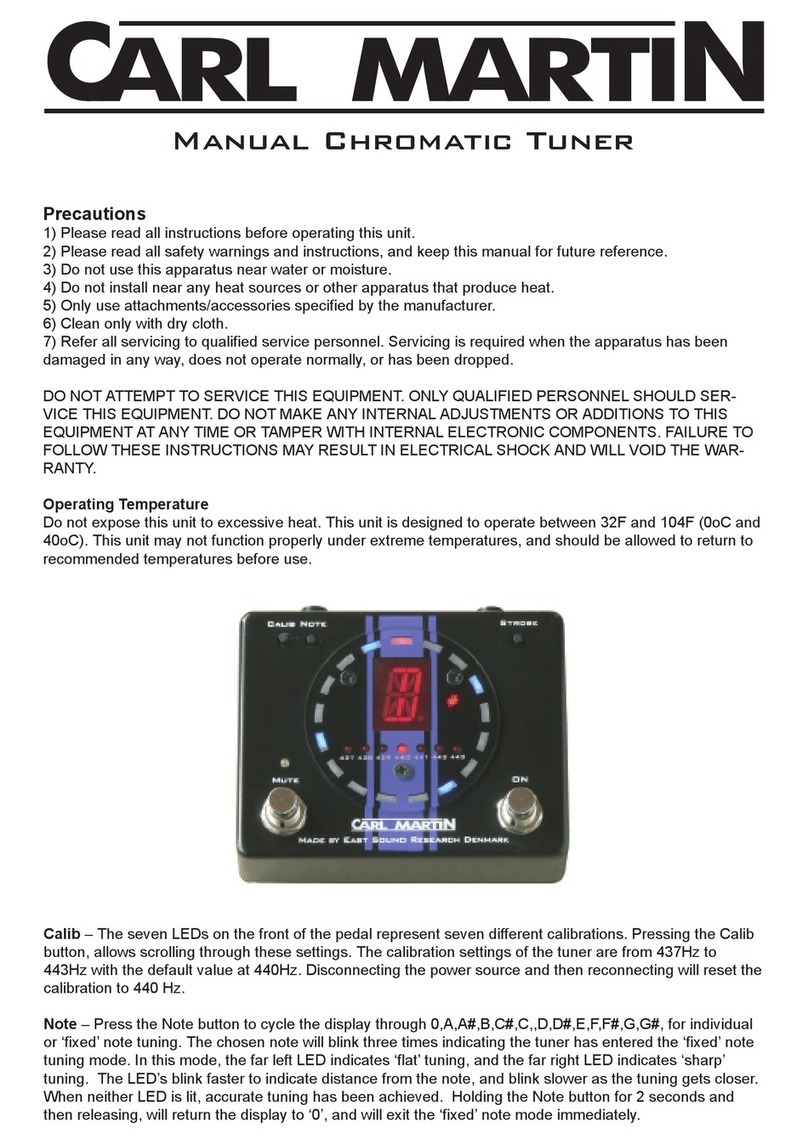

GENERAL INTRODUCTION

The Model 1215 is a full featured antenna tuner designed for the ham operator using

transmitters or transceivers from QRP through 200 watts. A wide matching range combined

with an integral wattmeter and SWR bridge provides all the necessary capabilities to ensure

efficient operation with minimal RF losses due to impedance mismatches between the

feedline and radio. Up to four antennas can be selected via a front panel switch. One of

those antennas can be a single wire antenna and provision has been made to add an internal

balun for connecting to balanced feedlines.

Our goal is to provide the builder with the satisfaction of “doing it yourself” and, in the process,

furthering his or her understanding of the circuit operation. Understanding the circuit

operation removes much of the “mystery” often encountered in adjusting an antenna tuner.

Follow the assembly instructions carefully and you will be rewarded with an antenna tuner

with professional performance and appearance. Should you have any questions, Ten Tec

Customer Service is available to help.

5 1215 Antenna Tuner Manual Part # 74449

CIRCUIT OVERVIEW

1215 BLOCK DIAGRAM

SWR BRIDGE

The internal SWR bridge is physically connected between the tuner input and the radio. The

bridge performs three functions:

1. Measures transmitter output (forward) power

2. Measures the reflected power at the tuner input (“Radio”) port

3. Displays the SWR on the built-in meter

The SWR measurement setting is used when adjusting the tuner for optimum performance.

In this mode, the tuner is adjusted to produce, ideally, a 1:1 SWR as seen by the radio.

The bridge consists of an RF transformer, wound on a toroidal core, with the main

transmission line passing through it. This allows sampling both the forward and reflected

power levels present at that point. The outputs from the transformer are detected by two

Schottky diodes, D1 and D2, and the DC voltage produced is used to drive the meter to

display either the forward or reflected power. When the tuner properly matches the antenna

system to 50Ω, the reflected power reading will be zero.

In the forward power measurement mode, a potentiometer is connected in series with the

meter to display either 20 watts or 200 watts full scale. Once calibrated, the pots should need

no further adjustments.

Since SWR is a measurement of the ratio of forward to reflected power, an “SWR Set” control

is included on the front panel of the tuner. With the transmitter operating at it's desired power

level, the meter is placed in the SWR Set mode and the Set pot is adjusted for a full scale

6 1215 Antenna Tuner Manual Part # 74449

SWR

BRIDGE

“T” MATCHING

NETWORK

BYPASS

ANT #1

ANT #2

ANT #3

ANT #4

SINGLE WIRE

OPTIONAL

BALUN

BALANCE

D

LINE

reading. The switch can then be changed to the “SWR” setting and the value of SWR read

directly. If the output power level is changed, the “Set” pot will need to be readjusted to

maintain an accurate SWR reading.

ANTENNA SELECTION

The antenna tuner is equipped with a five position antenna selector switch. In the first

position, BYPASS, the output of the SWR bridge is connected directly to Antenna Connector

#1. This keeps the power and SWR measurement circuitry active, but bypasses the tuner

circuitry. Note that the bypass position only functions for antenna #1.

In positions 2 through 5, the tuner is connected to antenna ports #1 to #4 in sequence. To

connect a single wire antenna to the tuner, use the insulated terminal indicated on the rear

panel. The antenna switch must be set to Antenna #4 for the single wire feed. To connect the

tuner to an antenna with a balanced feed i.e., ladder line, a balun (balanced to unbalanced

transformer) is required. The 1215 does not come equipped with a balun, however there are

feed through posts on the rear panel which will allow a balun to be mounted internally and it's

connections brought out through the rear panel. A jumper (supplied) between the “Single

Wire” and “Balanced Feeder” post needs to be installed when a balun is being used. As with

the single wire feed, the tuner must be set for Antenna #4 when using the balun. The

“Balanced Feeder” jumper should be removed if Antenna #4 is being used for a coaxial or

single wire antenna feed. Ten Tec offers an internal balun as an accessory for the 1215 tuner.

The model number for that balun is 1216. As an alternative, information on building a balun

can be found in the “Optional Balun” section of this manual or any recent edition of the ARRL

Antenna Book. A web search with the keyword “4:1 balun” will provide many references for

building a balun for tuner applications.

ANTENNA TUNER CIRCUITRY

The antenna tuner is a high pass “T” network with two series variable capacitors and a shunt

variable inductor connected between them and ground. This configuration allows a wide

range of impedances to be matched to the 50Ωoutput impedance of the radio. This

configuration is fairly easy to tune if the proper procedure is followed. The tuning procedure is

outlined in the “Operating Tips” section of the manual.

7 1215 Antenna Tuner Manual Part # 74449

8 1215 Antenna Tuner Manual Part # 74449

1215 ANTENNA TUNER PARTS LIST

9 1215 Antenna Tuner Manual Part # 74449

PART # DESCRIPTION QTY

CHASSIS ASSEMBLY

23227 Cap, Air Variable 2

27007 Lamp Socket, Bayonet 1

30894 10k Panel Mount Pot 1

32077 Rotary Switch ; 3 Pole / 4 Position 1

32098 Rotary Switch ; 2 Pole / 5 Position 1

34011 Pilot Lamp ; Bayonet Base 1

34043 Panel Meter 1

34070 Knob - “Meter Switch” & “SWR Set” 2

34071 Knob - “Antenna Switch” & “Inductance” 2

34072 Knob - “Transmit Match” & “Load Match” 2

35007 SO239 Coax Receptacle 4

35132 DC Power Jack ; 2.1mm 1

35402 DC Power Plug ; 2.1mm x 5.5mm 1

42010 Panel Bushing - “Ant Switch” & “Inductance” 2

46010 Wire, Hookup, #24 Black Stranded 24”

46011 Wire, Hookup, #24 Brown Stranded 15”

46012 Wire, Hookup, #24 Red Stranded 15”

46013 Wire, Hookup, #24 Orange Stranded 12”

46015 Wire, Hookup, #24 Green Stranded 15”

46016 Wire, Hookup, #24 Blue Stranded 12”

46018 Wire, Hookup, #24 Grey Stranded 24”

46019 Wire, Hookup, #24 White Stranded 24”

46057 Wire, Hookup, #24 White / Yellow Stranded 12”

46059 Wire, Hookup, #24 White / Blue Stranded 6”

90681 Nylon Feed-Thru Insulator 6

91217-6 Phenolic Shaft 1

91482 Shaft Coupler – 1/4” 1

93946 Flat Jumper for Rear Panel 1

80925 INDUCTOR SUB-ASSEMBLY

38060 C Ring 1

77001 Copper Braid ; 3/16” Wide 4.8”

80924 Inductor Mount Bracket Assembly 1

21045 Toroid Core – Ferrite (large) 1

46076 #18 Solid, Silver Plated Wire 15 ft

90682 Toroid Bottom Cover 1

90683 Toroid Top Cover 1

90677 Rotor 1

90679 Hub 1

90690 Contact Stiffener 1

90691-1 Modified Contact 2

91369 Aluminum Inductor Shaft ; 1/4” Dia 1

PARTS LIST (CONTINUED)

10 1215 Antenna Tuner Manual Part # 74449

PART # DESCRIPTION QTY

82062 SWR BRIDGE SUB-ASSEMBLY

21003 Toroid Core – Ferrite (small) 1

21007 1mH Inductor 1

23261 Ceramic Capacitor – 0.1uF 2

23371 Ceramic Capacitor – 10pf / 1kv 1

23400 Ceramic Capacitor – 470 pf / 100V 1

28071 Schottky Diode – BAT41 2

30082 1

30136 1

30806 1K Variable Resistor (Pot) 2

35007 SO239 Coax Receptacle 1

46022 Wire, Solid #28 Red 18”

46070 Wire, Solid #28 Green 18”

82080 PC Board Assembly 1

MECHANICAL PARTS

41011 #10 Solder Lug 4

41039 #4 Solder Lug ; internal tooth 3

42003 Rubber Mount Foot 4

51002 #4 Lockwasher 15

51007 #10 Flat Washer ; 7/16” OD 11

51011 Fiber Shoulder Washer ; 5/8” 4

51034 #10 Lockwasher 4

51039 3/8” Flat Washer 4

54002 4-40 Hex Nut 15

54003 3/8”x32 Hex Nut 4

54005 10-32 Hex Nut 4

54016 Self-Threading Nut 1

54017 10-32 Wing Nut 4

54029 2-56 Hex Nut 4

54048 Metric M9 x 0.75mm Nut 1

60001 4-40 x ¼” Screw 2

60003 4-40 x 3/8” Screw 7

60035 10-32 x 3/4” Screw 1

60036 10-32 x 1-1/4” Screw 3

60067 2-56 x 1/4” Screw 4

60069 4-40 x 3/8” Screw w/captive lockwasher 10

60080 4-40 x 3-16” Flat Head Screw 8

60092 Screw, 6-32 x 3/16”, Black 2

65009 #4 x 1/4” Pan Head Screw 2

93954-CN2A Chassis 1

93955 Cover 1

93956 Meter Support Bracket 1

93957 Antenna Switch Bracket 1

68Ω2W Resistor (blue-gray-black)

680Ω1/4W Resistor (blue-gray-brown)

MECHANICAL PARTS IDENTIFICATION

11 1215 Antenna Tuner Manual Part # 74449

OPERATING TIPS

Operation of the tuner is fairly straight forward. The most difficult portion is usually the “first

tuning” for a given band or antenna. The following procedure will greatly simplify this first

tuning, as well as all subsequent tuning:

1. Set the “Transmitter” and “Load” capacitors and the “Inductance” to maximum.

2. Set the “Meter” switch to “SWR SET” and adjust the SWR pot fully counter-clockwise

3. Place the transmitter on frequency and reduce the power as far as possible

4. Key the transmitter and adjust the SWR pot for a full scale reading (increase the

transmitter power slightly if a full scale reading can not be obtained.

5. Set the “Meter” switch to “SWR” and adjust the inductor for a minimum reading

6. Adjust the “Transmitter” and “Load” capacitors for a minimum SWR reading

7. If the SWR can not be reduced to 1:1, adjust the inductor switch one position higher or

lower.

8. Adjust the “Transmitter” and “Load” capacitors for a minimum SWR reading

9. If the SWR is higher than the original value, adjust the inductor switch two positions in

the opposite direction and repeat the capacitor adjustments.

Using this procedure, the minimum SWR should be obtained relatively quickly. Note that

some loads may not be capable of being matched to a 1:1 SWR. In such cases, leave the

tuner set for the lowest SWR achievable. An SWR of 2:1 or less is generally acceptable to

most transmitters and does not result in any appreciable loss in strength of the radiated

signal.

Recording the inductor and capacitor settings for several frequencies across the desired

bands will allow a quick pre-setting of the tuner later on.

Although the tuner is rated to operate at a 200 watt level, it should not be tuned at this level,

other than for minor adjustments of the capacitors. Do not switch the inductor while keyed at

power levels greater than about 25 watts. Always pre-tune the tuner at the lowest possible

power level.

If the tuner is to be used with a single wire feed antenna, connect the feed wire to the “Single

Wire” terminal on the rear panel. The antenna selector switch must then be set to “Antenna

4”. Note that, if a single wire feed is being used, there must not be another antenna

connected to the “Antenna 4” SO-239 connector.

If a balanced feeder is to be used, connect the supplied jumper bar between the “Single Wire”

terminal and one of the “Balanced Line” terminals on the rear panel of the cabinet. The

balanced feeder is then connected to the two Balanced Feeder terminals. NOTE: Using a

balanced feeder requires that a balun be installed! The balun can be enclosed inside the

tuner cabinet and connected to the provided Balanced Line terminals. See the “Optional

Balun” section of this manual for further information. As with the single wire feed, there must

not be any other antenna connected to the “Antenna 4” SO-239 connector when using a

balanced line fed antenna.

12 1215 Antenna Tuner Manual Part # 74449

A final point to remember whenever using an antenna tuner is that the “antenna” itself is not

being tuned. The tuner simply transforms the impedance seen at the radio end of the feedline

to 50 Ohms. Any mismatch between the antenna itself and the feedline will remain

unaffected. That mismatch can only be corrected by installing a matching device directly at

the antenna feedpoint. In most cases, the mismatch between the antenna and feedline is not

the limiting issue. A detailed discussion of this can be found in the ARRL Antenna Book or

other ham publications.

TROUBLESHOOTING CHART

If any difficulties are encountered with the 1215 Tuner, check the following items first:

•Verify that the radio is connected to the “Radio” connector on the rear panel.

•Verify that the Antenna Switch is in the correct position for the antenna being used.

Once the above have been verified, use the following chart if problems still exist:

13 1215 Antenna Tuner Manual Part # 74449

PROBLEM SYMPTOM CHECK THE FOLLOWING:

Power Meter not functioning

Incorrect Power Readings

Arcing inside cabinet

No meter backlight

Room is “hot” with RF

High SWR can not be

reduced

No antenna connected, or wrong antenna selected ; SWR “Set” control

set too high ; Tuner in “Bypass”

SWR Meter not functioning

properly

Check SWR in “Bypass” mode ; Check SWR with a 50

Ώload and tuner

in “Bypass”; Verify setting of SWR “Set” control; Verify radio connected

to “Radio” port

Check operation with tuner in “Bypass” and a 50Ώload connected to

“Ant 1” port. ; Verify that radio is connected to “Radio” port.

Tuning capacitors and / or

inductor have no effect

Verify that tuner is not in “Bypass” ; Confirm that an antenna is

connected and selected.

Check readings with a 50Ωload on “Ant 1” and put tuner in “Bypass” ; If

SWR function is working normally, check power calibration.

Verify that power level is not in excess of 200 watts ; Check that inductor

contact is not “between” two stops. Check that ground braid from

inductor shaft does not contact TX and Load capacitors.

Verify that 12 – 16 VDC is applied to DC input connector. Positive to the

center pin and negative (ground) to the connector shell. Verify that bulb

is not burned out.

Verify that tuner ground lug is connected to station ground along with the

radio. Station ground should be common to all equipment and be tied to

an external ground rod. If a single wire, or balanced feeder, is used, try

re-routing them away from any of the equipment.

If your radio is equipped with an internal SWR / Power meter, it is not unusual for a small

difference to be noted between the SWR shown on the tuner meter and the SWR shown on

the radio's meter. There will be some minor variances due to the differences between the

SWR bridge in the radio and the bridge used in the tuner, however the major contributor is

generally the cable length between the radio and the tuner. That can be verified by

connecting a shorter or longer cable and noting if the difference in readings changes. In a

perfectly matched system, the interconnecting cable length becomes irrelevant. For less than

a perfect match, the measured SWR will vary depending on where along the cable the

measurement is made. In this case, the tuner's SWR meter and the radio's SWR meter are

located at different points on the cable and a reading difference is expected. Note that the

difference in readings will vary with frequency. The lower the frequency, the less difference is

generally seen. Since the radio's SWR meter is measuring the SWR at the radio, rather than

at the input to the tuner, adjust the tuner for minimum SWR as displayed on the radio's SWR

meter.

This assumes that there is no equipment connected between the radio and the tuner i.e., an

external low pass filter or other device. If there is something in between, temporarily connect

the radio directly to the tuner and re-check the readings. If they begin to correlate, the

intermediate device may have a problem or may simply be affecting the match between the

tuner and the radio. If the device is functioning normally, verify that the cables used are good

and, if so, use the SWR meter on the radio when adjusting the tuner.

14 1215 Antenna Tuner Manual Part # 74449

OPTIONAL BALUN FOR USE WITH OPEN WIRE (LADDER LINE) FEEDERS

The 1215 tuner is capable of connecting directly to open wire feeders if a 4:1 balun is

installed. The necessary insulated feed-thru terminals are provided on the rear of the cabinet

which allows for a balun to be installed inside the unit.

A 4:1 balun is a relatively simple device which can be built or purchased at fairly low cost.

Ten Tec offers one, Model # 1216, as an accessory for the 1215 tuner. For further

information, check the Ten Tec web page (www.tentec.com) or call our sales department at

(800) 833-7373. For more information about baluns, a web search using the key words “4:1

balun” will produce a long list of references.

The purpose of the balun is to convert the unbalanced output of the tuner to a balanced

output which will feed the open wire (ladder line) feeders used on several types of broadband

or multi-band antennas.

A balun can be built using a T200A-2 core with 13 bifilar turns of #16 Teflon coated wire,

connected as shown in Figure 1. Alternately, a T-200-2 core with 17 turns of #16 Teflon

coated wire can be used. Power handling capability is about 300 watts.

15 1215 Antenna Tuner Manual Part # 74449

KIT ASSEMBLY

This section of the manual covers assembly of the Model 1215 Tuner. Assembly is done in a

number of “phases” designed to make assembly easier while allowing a number of “break”

points. The assembly phases are:

Phase I: Rotary Inductor Assembly

Phase II: SWR Bridge Circuit Board Assembly

Phase III: Meter Switch & SWR Set Pot Assembly & Wiring

Phase IV: Antenna Switch Wiring

Phase V: Chassis Assembly & Wiring

Phase VI: Wattmeter Calibration & Checkout

NOTE: This manual is available in pdf format at www.tentec.com. The pdf format allows you

to enlarge any of the drawings / photos in the event that there are any questions of what goes

where and how it is mounted and / or connected.

REQUIRED TOOLS / MATERIALS:

Tools / materials required for kit assembly include:

•Needle nose pliers

•Small pair of wire cutters

•Soldering iron (25 – 50W)

•1/2” nut driver or socket

•Digital voltmeter (optional, for calibration)

•Philips head screwdriver

•Small flat (dial) screwdriver

•60 / 40 (or 63 / 37) rosin core electronics solder

•Epoxy glue

Recommended tools include:

•Small bench vise

•Solder removal braid

•Sharp utility knife

•Ruler

•Work gloves (for pulling wire)

16 1215 Antenna Tuner Manual Part # 74449

PHASE 1: ROTARY INDUCTOR ASSEMBLY

Kit Assembly Note: In this section, as in all the others, two check boxes are provided at

each step of the assembly. Check off each step as it is completed. Should you need to go

back to re-check your work, use the second check-off box as each previously completed step

is verified.

OVERVIEW

This sub assembly kit is packed separately for your convenience. Before working with the

Inductor parts kit, please read all of the assembly instructions first. Examine the various parts

and visualize how they fit together. Notice how the grooves in the toroid covers are designed

to assure uniform winding. We recommend building this coil assembly first because it is

necessary to secure the hub to the toroid with an epoxy glue after winding. Other phases of

the kit assembly can be completed while the coil assembly dries.

COIL WINDING PROCEDURE

The most important, and most difficult, part of winding the toroid is to make a good start. After

the first few turns, it will become progressively easier to wind.

While the grooves in the toroid covers provide uniform spacing, the winding must be kept tight

to prevent adjacent turns from shorting together. Treat each turn as having four components:

top, two sides and the inner side. Keep each side as tight as possible. Doing so will result in

smooth operation of the completed assembly. The “top” (outside) layer makes contact with

the rotor and consequently needs the turns to be as equally spaced and flat (tight) as

possible.

To prevent scarring of the silver plated wire, wrap protective tape around each jaw of any

pliers used in the winding process. Alternately, rubber tubing can be slipped over the pliers

jaws.

The wire will be routed through the center of the toroid many times during the winding

process. Avoid kinking the wire as it is passed through.

If a bench vise is used to hold the toroid assembly firmly, cushion the bare vise jaws with

wood shims or plastic strips to prevent damage to the nylon toroid shells.

The following directions presume winding the toroid from one end to the other. Some

builders may prefer to start in the middle and work toward each of the two ends. If you

elect to start in the center, be sure to follow the groove patterns exactly and start with

the middle of the silver plated wire at the midpoint of the toroid.

17 1215 Antenna Tuner Manual Part # 74449

1. □□ Place the toroid core within the two nylon shells. While not necessary, it is OK

to use some glue sparingly to keep everything together (hot glue is ideal for this).

Epoxy glue is required only to secure the hub after winding.

2. □□ While most turns require pulling the full wire length through the center, you can

get started by looping 3 – 5 loose turns, leaving a “pigtail” lead of 6” to 12”.

3. □□ Lock the pigtail wire around the bottom retainer slot (see photo and drawing),

then use padded pliers to tighten the first several windings in place per the details

emphasized in the beginning of the coil winding procedure above.

4. □□ Loop the full length of wire back through the center and form the next turn

tightly. Be careful not to kink the wire.

5. □□ Repeat the preceding steps until all turns are made. It does get easier as the

wire gets shorter!

6. □□ After tightening the final turn, wrap the remaining wire through the other retainer

slot and cut the excess wire to leave another “pigtail” lead of 6” to 12”.

7. □□ Slip the hub into one side of the toroid and visualize the assembly before gluing:

the retainer slots are at the bottom, with the two hub holes aligned horizontally. See

photo on the top of the next page for reference.

18 1215 Antenna Tuner Manual Part # 74449

8. □□ Follow the glue manufacturer's directions and mix enough epoxy glue to

thoroughly coat the portion of the hub to be in contact with the toroid.

9. □□ Glue the hub to the toroid, aligning the hub per step 7. Set the glued assembly

aside with some weight on top or clamp the assembly together.

10.□□ Organize the following for assembly: rotor bracket, contact strips (2), contact

stiffener and two each #2-56 screws and nuts.

11. □□ Assemble the rotor in this order: #2-56 screws, stiffener strip, two contact strips,

bracket and #2-56 hex nuts. (See photo and drawing below – note that the photo

unit has rivets in place of the screws and nuts you will be using)

1. Align the holes of the rotor bracket with the contact strip holes

2. Align the stiffener on the contact strips

3. Insert screws through the stiffener, contact strips and rotor bracket (in that

order)

4. Attach the nuts

5. Tighten securely

6. With a pair of needle nose pliers, grasp the stiffener & contact strips just past

the edge of the rotor bracket and bend them slightly as shown below. This will

increase the contact pressure of the contacts to the inductor wire.

19 1215 Antenna Tuner Manual Part # 74449

12.□□ Using a 7/16” nut driver, thread the 1/4” thread cutting fastener on the rear of the

shaft, the end with internal threads for mounting mounting the wiper arm. Thread it

onto the shaft about 3/8” and then back it out until there is just enough room to slip the

rotor onto the end of the shaft (see above). It will be necessary to use a small vise or

Vise-Grips to hold the rod while the fastener is being threaded on.

13.□□ Mount the rotor to the 1/4” shaft with one #4-40 1/4” screw and one #4 lock

washer. Tighten securely.

14.□□ No further work should be done with this inductor assembly until the epoxy is set

per the manufacturers directions. Proceed now to Phase II of this project (SWR Bridge

Circuit Board Assembly). Return when the epoxy bond from the hub to toroid has set.

AFTER THE EPOXY IS SET:

1. □□ Mount the hub / toroid to the aluminum bracket (with the pressed in brass

bushing) using the two #4, 1/4” self tapping screws through the bracket and into the

hub. Do not fully tighten the screws at this time. The bracket faces away from the

toroid, toward the front panel of the tuner. (See drawing)

2. □□ From the rear of the toroid / hub, slide the front end of the rotor shaft / wiper

assembly through the hub until stopped by the thread cutting fastener.

20 1215 Antenna Tuner Manual Part # 74449

Table of contents

Other Ten-Tec Tuner manuals