EN

200-Tb DM20017 (01-2012)

4

The following precautions are used throughout this manual

as indicated in their description. All operators must read,

understand and practice the following safety precautions:

WARNING: To warn of hazards or unsafe

practices that could result in severe personal

injury or death.

Caution: To warn of unsafe practice that could

result in minor or moderate personal injury.

FOR SAFETY: To identify actions that must be

followed for safe operation of equipment.

The following information signals potentially dangerous

conditions to the operator or equipment. Read this manual

carefully. Know when these conditions can exist. Locate

all safety devices on the machine. Then, take necessary

steps to train machine operators. Report machine damage

or faulty operation immediately. Do not use the machine if

it is not in proper operating condition.

WARNING: Electrical Hazard.

• Disconnect battery before servicing machine.

• Do not modify battery or charger connections.

• If the power cord to the charger is damaged or

broken, it must be replaced by the manufacturer or

its service agent or a similarly qualified person in

order to avoid a hazard.

WARNING: Electrical Shock Hazard. DO NOT use

outdoors. DO NOT expose to rain or moisture.

Store indoors.

Follow safety instructions of chemical manufacturer

(MSDS).

FOR SAFETY:

1. Do not operate machine:

• Unless trained and authorized.

• Unless operator manual is read and understood.

• Unless mentally and physically capable of

following machine instructions.

• Unless in proper operating condition.

• With damaged wires or cords.

• Unless on a flat, level surface.

2. Before operating machine:

• Follow safety guidelines concerning wet floors.

• Make sure all safety devices are in place and

operate properly.

3. When using machine:

• Do not push on inclines.

• Always stop the machine on a flat level surface

and engage the wheel lock before dispensing

cleaning solution.

• Report machine damage or faulty operation

immediately.

• Never allow children to play on or around machine.

• Do not point dispensing nozzle at other persons.

4. When servicing machine:

• Always stop machine on a flat level surface

and engage the wheel lock before servicing the

machine.

• Disconnect battery.

• All repairs must be performed by an authorized

service person.

• Use manufacturer supplied or approved

replacement parts.

• Do not modify the machine from its original design.

5. When using cleaning solutions:

• Do not mix 5000-Sc cleaning solution with

conventional cleaning chemicals.

• Do not drink cleaning solution.

• Refer to MSDS (Material Safety Data Sheet) for

additional safety information and precautions.

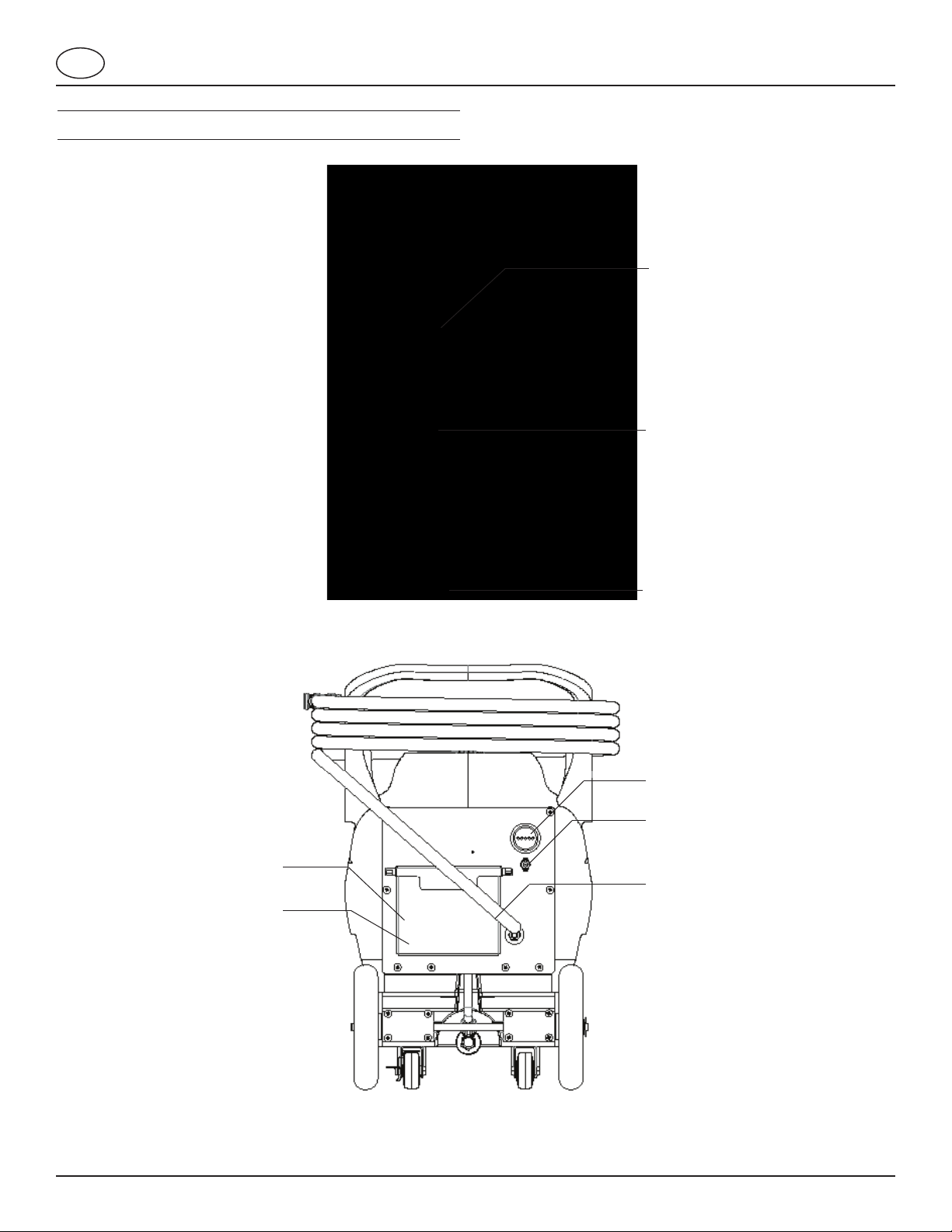

OPERATION

SAFETY PRECAUTIONS

• Wipe up any spills.

• Do not power spray or hose off the machine.

Electrical malfunction may occur.

• In an area where flammable vapors/liquids

or combustable dusts are present.

INTENDED USE

This machine is intended for commercial use only. The

machine is designed for storing and dispensing 5000-Sc

cleaning solution only in an indoor environment. It is not

intended or constructed for any other use.