OPERATION EN

Tennant 2550 (02--01) 9

WHILE OPERATING MACHINE

1. Always operate with caution when burnishing

around walls and obstacles.

2. Always reduce speed to maintain control when

turning.

3. Stay clear of floor obstructions, such as electrical

plates or grates, they will destroy pad. Tilt machine

back to avoid floor obstructions.

NOTE: When machine is tilted back completely,

power to pad motor automatically shuts off.

4. Change or turn pads over when soiled.

5. Check battery meter’s discharge level periodically.

Recharge when needle drops to the red zone.

ATTENTION: Do not operate machine in red zone,

floor damage and brush motor overload may

result.

6. If pad motor circuit breaker trips, reduce pad

pressure and/or replace soiled pad.

FOR SAFETY: Before leaving or servicing

machine, stop on level surface, turn off machine

and set parking brake.

FOR SAFETY: When transporting machine, do not

lift machine if batteries are installed.

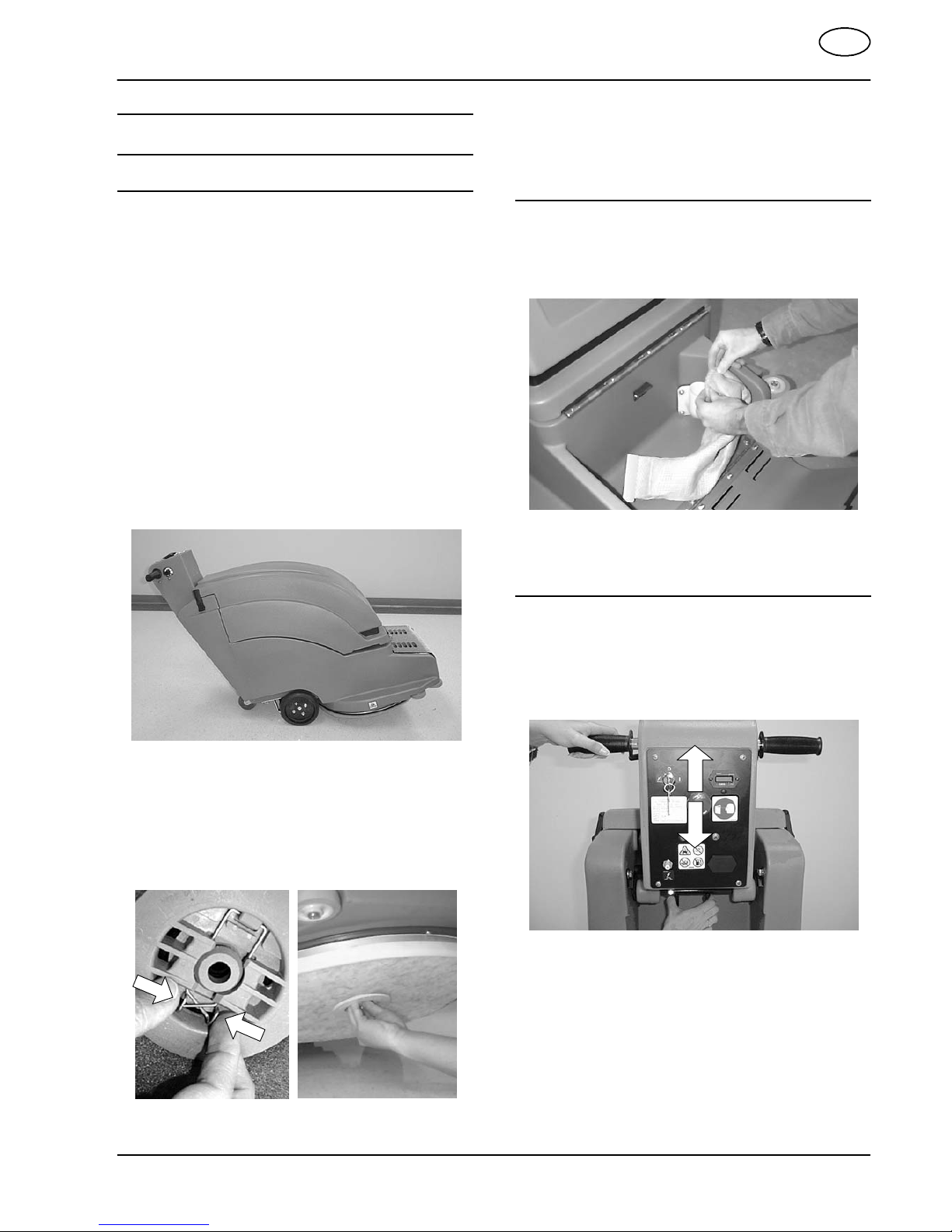

EMERGENCY STOP SWITCH

To stop machine during an emergency, hit the red

emergency stop switch located at rear of control

console. The emergency stop switch immediately

stops all power to machine.

To reset emergency stop switch, shut off all switches

and turn red button to the right. Resume to normal

operation.

Emergency Stop Switch

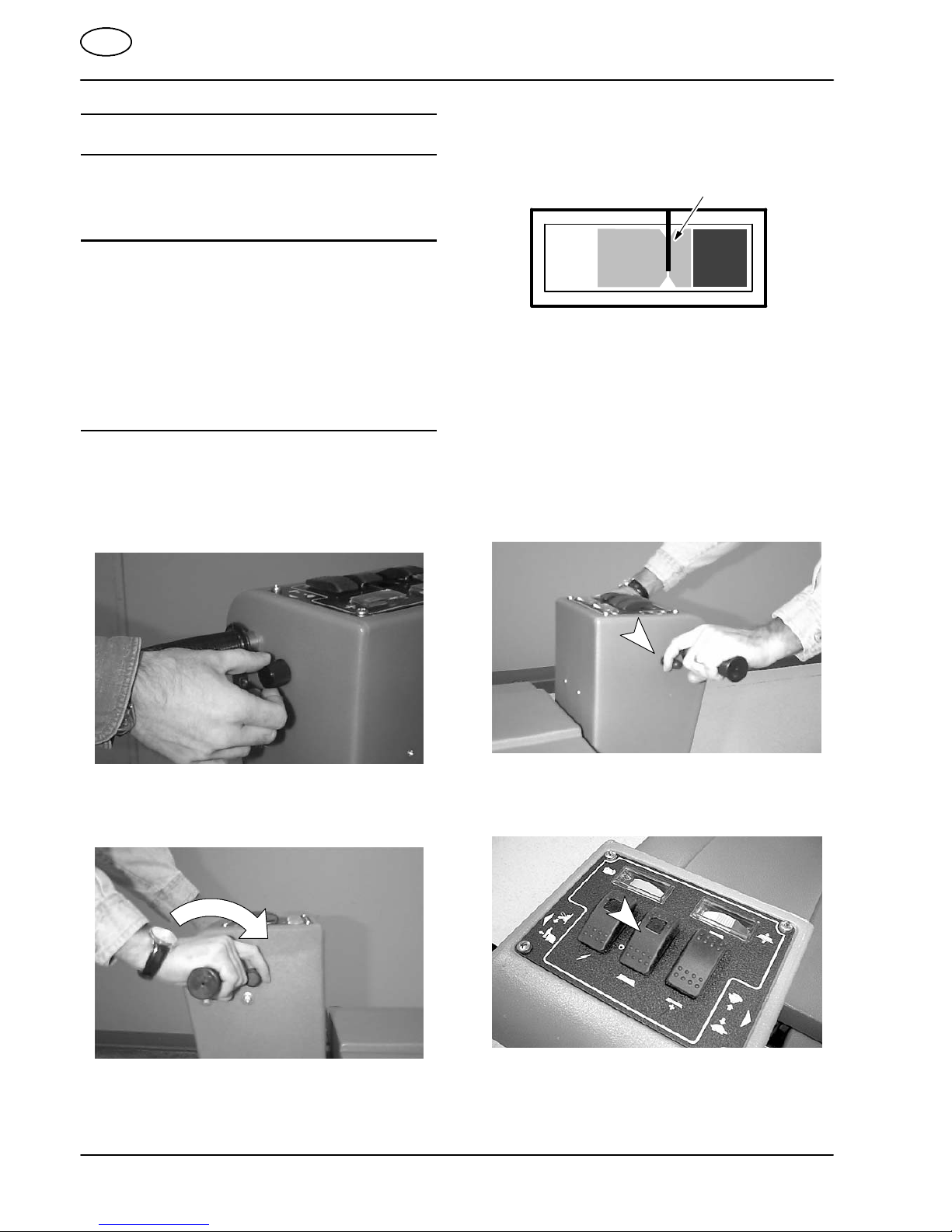

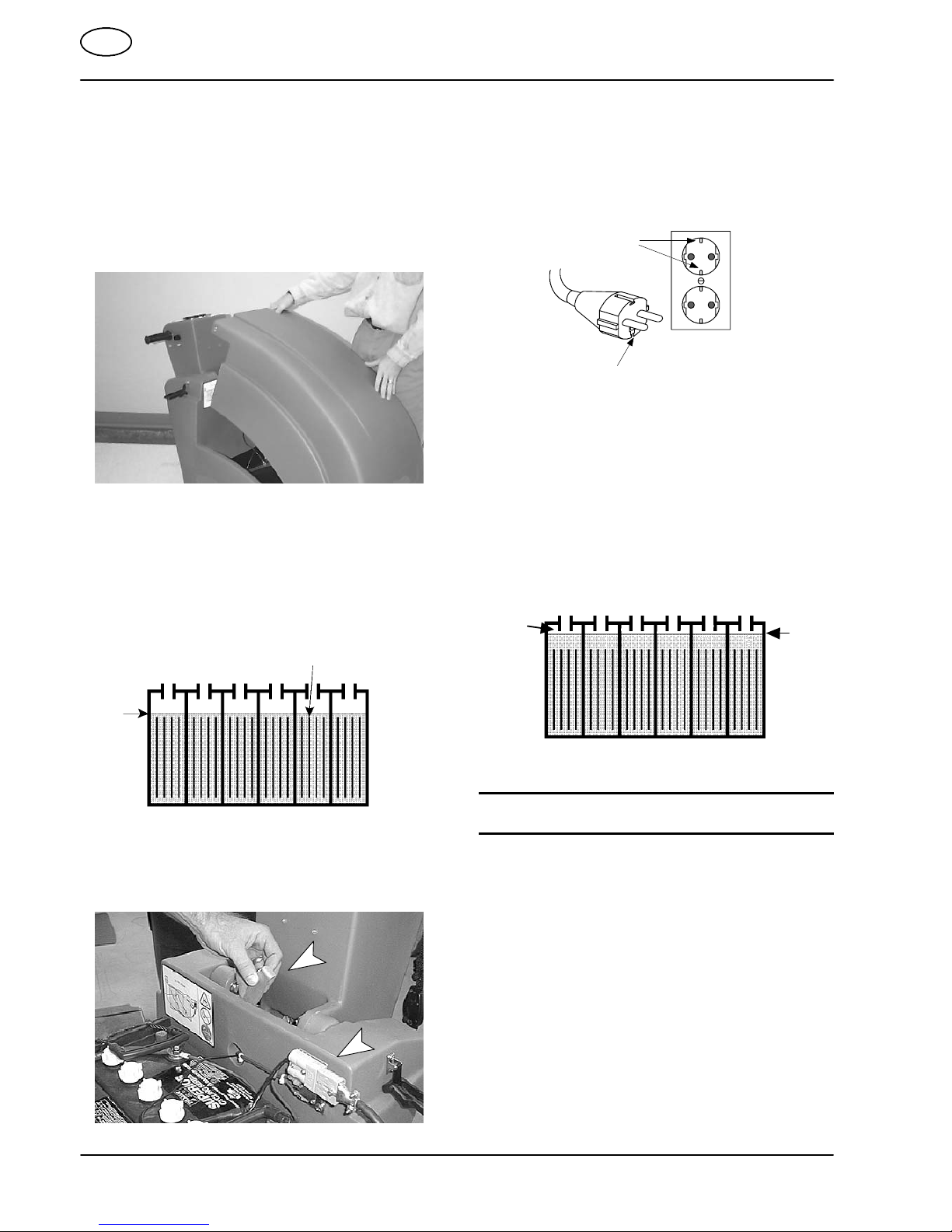

CIRCUIT BREAKERS

Machine is equipped with two resettable circuit

breakers, Main (15A) and Pad Motor (80A), to protect

machine from damage. If pad motor circuit breaker

should trip, determine cause, allow motor to cool, then

reset. Pad circuit breaker will trip due to excessive pad

overload. Change pad or reduce pad pressure if

breaker should trip. Pad motor circuit breaker button is

located under battery hood at front of machine.

Resettable Circuit Breakers

CHARGING BATTERIES

NOTE: Recharge batteries ONLY after a total of 30

minutes of use or more. This will prolong battery life.

The following charging instructions are intended

for supplied 36V chargers only. Only use a

charger with the following specifications to

prevent battery damage.

CHARGER SPECIFICATIONS:

SOUTPUT VOLTAGE - 36 VOLTS

SOUTPUT CURRENT - 25 AMPS MAXIMUM

SAUTOMATIC SHUTOFF CIRCUIT

SFOR DEEP CYCLE BATTERY CHARGING

NOTE: For optimum machine operation, keep

batteries charged at all times. Never let batteries set in

a discharge condition for lengthy periods.

WARNING: Batteries emit hydrogen gas.

Explosion or fire can result. Keep sparks and

open flame away. Keep battery compartment open

when charging.

FOR SAFETY: When servicing machine, wear

protective gloves when handling batteries or

battery cables. Avoid contact with battery acid.