4

IMPORTANT

READ THESE INSTRUCTIONSCAREFULLYAND RETAINFOR FUTUREREFERENCE

1.ProductInformation

Pleasepassallsafetyinstructionsontoother

personsoperatingthismachine.

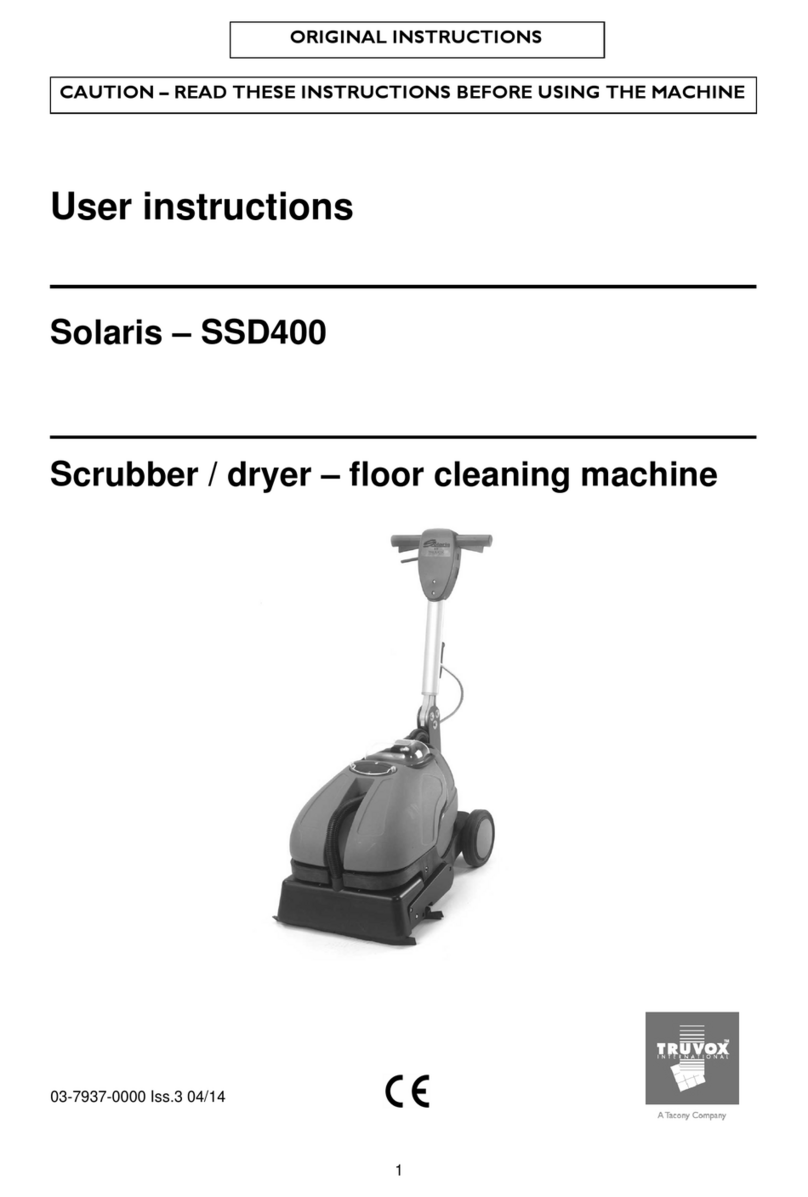

The floorcleaningmachinesaredesigned foruseon

smooth, evenfloorsinindoorareas. Theycanbe

used onmostfloorsurfacesincluding shortpile

carpet, wood,PVC,rubberand stone. Theyshould

benot usedonroughunevensurfaces.

Weareconfidentthemachineswillgiveyearsof

troublefreeservice, coupledwitheaseof useand

minimummaintenance.

Equipmentmust beoperated, servicedand

maintained inaccordancewiththe manufacturer's

instructions.Ifin doubtcontactthesupplierofyour

machine.

The followinginstructionscontain important

informationabout themachine's andsafetyadvicefor

theoperator.

1.1Importantsafetyinstructions

The machinemustbeunpackedandassembledin

accordancewiththeseinstructionsbeforeconnecting

tothe electricalsupply.

Thismachineshould always beconnectedtoafully

earthedpowersupplyof therightvoltage and

frequency.

Keepthepowersupplycordawayfrommovingparts.

During operation, hazardmayoccurwhenrunning

machineoverthe supplycord.

The machinemustbedisconnectedfromthe mains

supply(bypullingtheplugout)beforechangingthe

brushes,cleaningthemachineandformaintenance.

Warning! Onlyusethebrushes/ accessoriesasper

theinstructionmanual.Usageofanyother

brushes/accessoriescancausesafetyproblems.

Periodicallyinspectthecordforpossibledamage. A

damaged cordmust bereplacedwiththe specialcord

available fromthemanufactureroranauthorised

serviceagents.

DONOT leavethemachineconnectedtothepower

supplywhennot inuse;always removetheplugfrom

themainssocket.

DONOT usewherehazardousdustispresent.

DONOT usemachinenearflammableliquids.

DONOT usein anexplosiveatmosphere.

DONOT useonagradient orslopes.

1.2Guidelines fortheoperator

•Operatorsmust befullytrainedinaccordance

withtheseinstructions, abletoperformroutine

upkeepofthemachineandcorrect selectionof

brushes.

•Operatorsshould be physicallycapableto

manoeuvre, transportand operatethemachine.

•DONOT runthemachinedry, asthiscould

damagethefloorsurfaceorthemachineitself.

•Takeadequatecaretohold the machinefirmly

whileinstallingandremovingthebrush.

•Neveruseexcessivefoamingorhighlycorrosive

cleaningsolutions.

•While operatingonafloodedfloor,always ensure

that thewaterlevel doesnot exceed1/4" or

6mm.

•DONOT operatethismachine onroughuneven

surfacese.g.industrialconcretefloors.

•DONOT cleanthe machineusingwatersprays

orjets.

•Ensureallpartsarefittedproperlybefore

operation.

1.3Electricalconnection

Beforeconnectingthemachinetothepowersupply,

checkthatyoursupplyvoltagecorrespondswiththat

markedonthe rating labelonthebodyofthe

machine.

beforeoperatingthe machine.Anyviolationofthe

samewill notonlyinvalidatethewarranty,but may

alsoresult inasafetyhazard.

Thesupplycordisfittedwithanon-rewireable

plugcontaininga13ampfuse.Shouldthefuse

requirereplacementit mustonlybe replacedbya

13ampfuseconformingtoBS1362, andthefuse

covermustberefitted.If the fusecoverislost the

plugmust notbeuseduntilthe correct

replacement coverisfitted.