The following information signals dangerous conditions to the operator or

equipment. Read this monwl carefully. Know when these conditions can exist.

Locate all safety devices on the machine. Then, take necessary steps

to

tmin machine

operating personnel. Report machine damage or faulty operation immediately.

AWARNING

Keep cigarettes, sparks and open flame oway from fuel tank. Re-

fuel in designated areas only. Do not

fill

fuel tank with engine

running. Makesure fuel container and machine are electrically

connected when refueling. Do not overfill

LP

tank. Check for

odor of escaping

gas

before and during starting

LPG

engines.

AWARNING

Provide adequate ventilation system to properly expel discharged

gases. Check exhaust system regularly for leaks. Carbon Mon-

oxide

is

dangerous.

AWARNING

Keep cigarettes, sparks and open flame away from lead acid

batteries. Batteries emit a highly explosive hydrogen gas.

AamON

Avoid moving

parts

of

the unit. Lwse jackets,

shirts

or sleeves

should not be permitted when working on machine because of the

danger of becoming caught inmwing

park.

Keep shields and

guards inposition.

If

adjustments must be made while the unit

is

running,

use

caution around hot maiiifalds, moving

parts,

V-belts, etc.

AWARNING

Lock hopper in

"UP"

position, udng Sofety Lock, before changing

brushes or working under hopper. See instructions on lock.

ACAUTlON

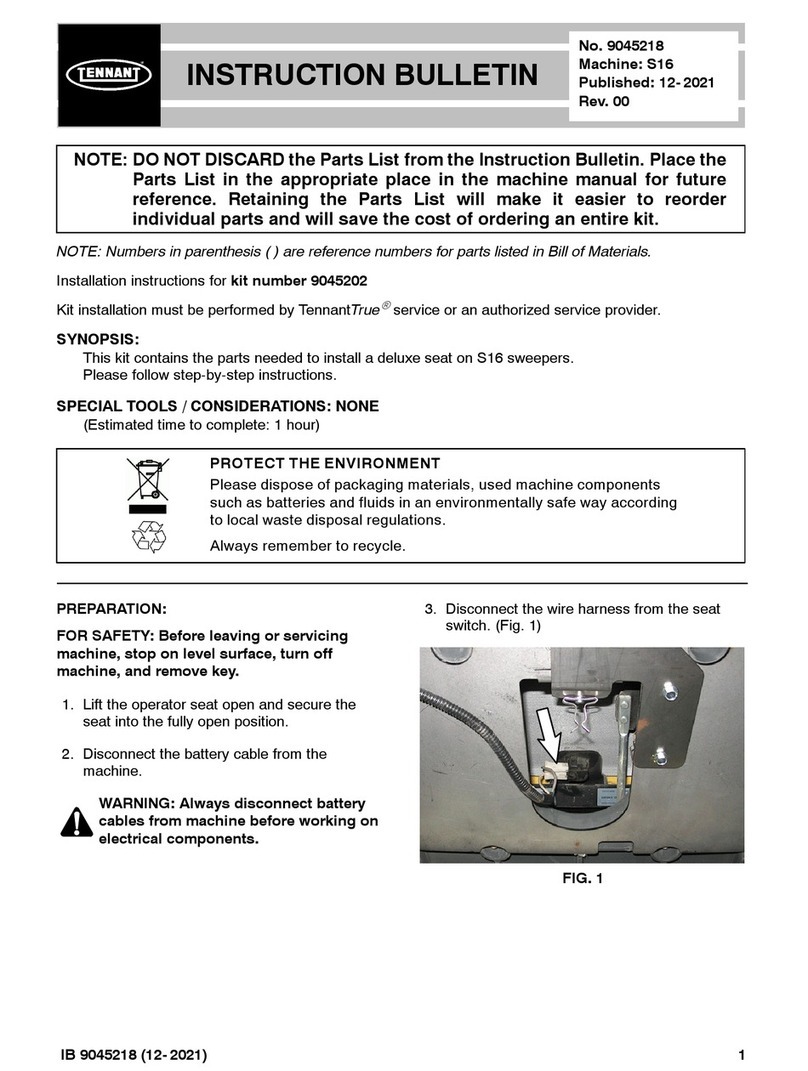

Disconnect battery terminal before servicing electrical components.

AamON

Check brakes and steering control for proper operation. Do not

start machine unless you are indriver's seat, with foot on brake pedal,

or parking brake engaged, ond directional pedal inneutral. Stop

engine and set parking brake before leaving machine.

ACAUTlON

This machine

is

steered by means of the rear wheel, and

is

very re-

s

onsive. Become familiar with this type of steering system. Travel

P

s

owly and use care on grades and slippery surfaces.

AWARNING

Never opemte inareas of overhead danger unless machine

is

equipped

with overhead gwrd.

The following symbols are used throughout this manual as indicated intheir descriptions:

ADANGER

To warn of immediate hazards which will result insevere personal

injury or death.

AWARNING

To warn of hazards or unsafe practices which could result insevere

personal rnjury or death.

ACAUTlON

TO

warn of hazards or unsofe practices which could result inminor

penanalinjury.

ATTENTION!

To warn of unsafe practices which could result in extensive equip-

ment damage.

3/80

NOTE

To give impariunt information or to warn

of

unxlfe pmctices which

could result inequipment damage.

Home

Find

...

GoTo..