Tennsmith U48-22 Guide

OPERATION, PARTS & MAINTENANCE MANUAL

MODELS U48-22 S48-22

Model: Purchased From:

Serial #: Date Received:

6926 Smithville Hwy., McMinnville, TN 37110

931-934-2211 / Fax: 931-934-2220

www.tennsmith.com

ShopRPMachinne

Tennsmith Inc. / 6926 Smithville Hwy. / McMinnville, TN 37110 / 931-934-2211 / Fax 931-934-2220

www.tennsmith.com

2

ShopRPMachinne

Tennsmith Inc. / 6926 Smithville Hwy. / McMinnville, TN 37110 / 931-934-2211 / Fax 931-934-2220

www.tennsmith.com

3

FOREWORD

This manual has been prepared for the owner and operators of Tennsmith U48-22 and S48-22 model bench

brakes. Its purpose, aside from operations instructions, is to promote safety through the use of accepted

operating procedures. Read all instructions thoroughly before operating the brake.

Also contained in this manual is the parts list for your brake. It is recommended that only Tennsmith or factory

authorized parts be used as replacements.

WARRANTY

Your brake has a three year limited warranty from the date of purchase. The terms of the warranty are stated

on the warranty registration card shipped with your machine. Please complete and return this card to activate

your warranty.

SAFETY INSTRUCTIONS

1. Know the safety and operating instructions contained in this brochure. Become familiar with and

understand the limitations of this machine. Always practice safety.

2. Wear approved eye safety protection such as glasses, goggles, etc., when operating the brake

to protect your eyes.

3. Wear protective foot wear or safety shoes.

4. Keep your hands clear of the nose bar and clamping area of the brake. Keep hands clear of the

apron area of the brake when making bends.

5. When bending capacity material use your legs and arms for making the bend, similar to lifting a

heavy object, to avoid back strain. Maximum length and capacity material is a two person job.

Adjust the counterweights to provide maximum assistance on heavy bends.

6. Never use a pipe or bar on the clamp handles or apron handles for additional leverage.

7. Keep clear of the apron swing area while operating the brake.

8. Keep the work area around the brake clear and clean to avoid slipping or tripping.

SAFETY LABEL

ShopRPMachinne

Tennsmith Inc. / 6926 Smithville Hwy. / McMinnville, TN 37110 / 931-934-2211 / Fax 931-934-2220

www.tennsmith.com

4

RECEIVING THE BRAKE

Upon receipt, closely examine the brake for damage during shipment. Report to your distributor any damage

that may have occurred during transit.

USE CAUTION IN HANDLING AND MOVING THIS BRAKE. Please note that brake is top heavy. Lift the

brake only from the ends as it is top heavy. Approximate weights for the respective models are as follows:

U48-22 280lbs / 127kg S48-22 220lbs / 100kg

INSTALLING THE BRAKE

Locate the brake in a well lighted area on a solid workbench capable of supporting the weight of the machine.

The bench should be generally be secured to the floor by bolts or lags screws. Be certain that you have

adequate clearance to swing the apron and that the brake is at a comfortable and convenient working height.

The brake should be removed for the skid. Use lag screws or bolts with expandable shields or similar holding

devices through mounting feet on the bottom of the lag assemblies to bolt the brake to the bench. The brake

must be fastened to the bench for safe operation.

THE BRAKE WILL NOT BEND PROPERLY IF IT IS NOT LEVEL.

ShopRPMachinne

Tennsmith Inc. / 6926 Smithville Hwy. / McMinnville, TN 37110 / 931-934-2211 / Fax 931-934-2220

www.tennsmith.com

5

OPERATING THE BRAKE

CAPACITY: The capacity of the brake is 22 gauge mild steel or 26 gauge stainless.

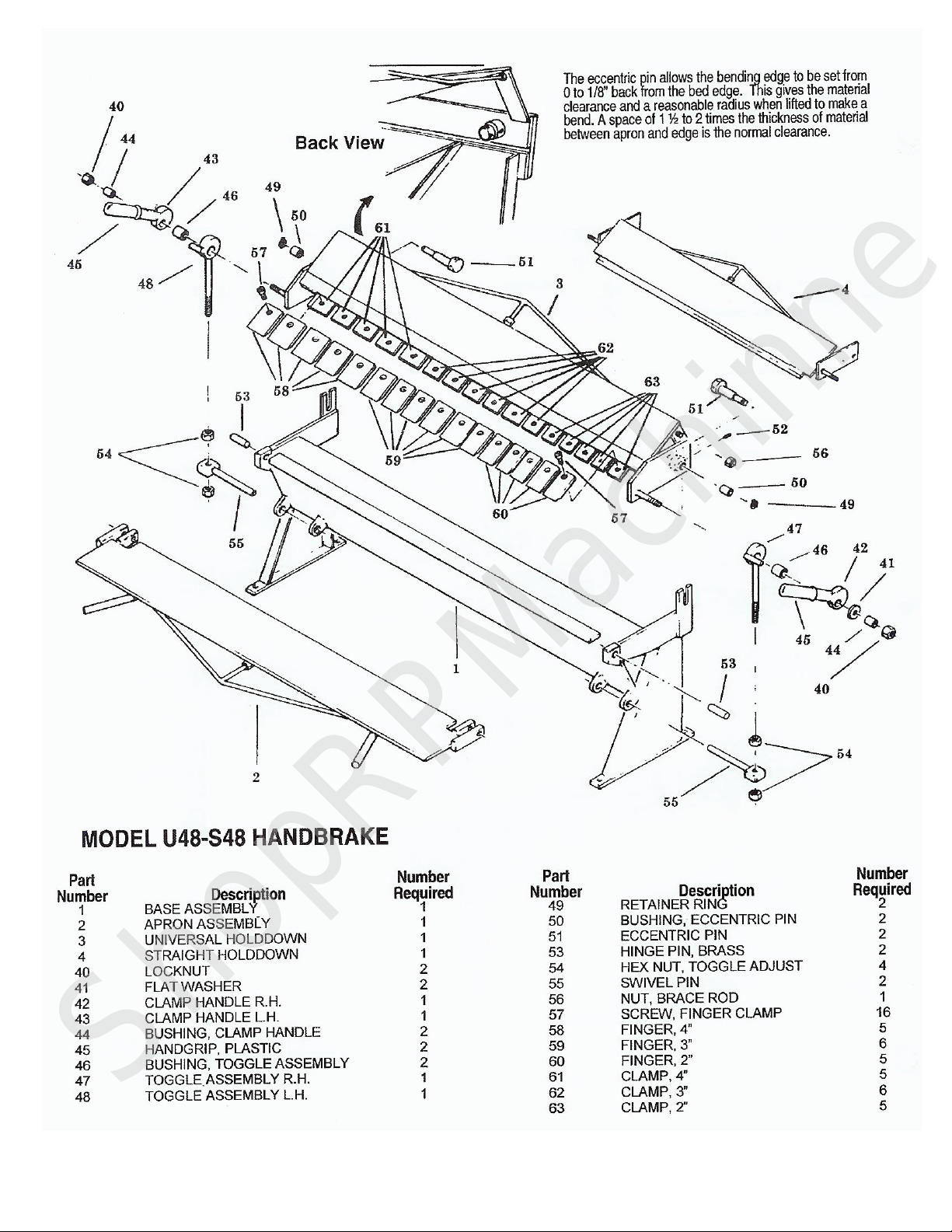

BENDING: This function is accomplished by clamping the work piece under the hold down assembly (3, 4) so

that the line of the bend is held at the forward edge of the nose bar or fingers and by elevating the apron

assembly (2) until the desired degree of bend is obtained. The maximum degree of bend is approximately 130

degrees. Due to the “spring back” in various materials some over bending maybe required to get the desired

bend angle.

ADJUSTING FOR METAL THICKNESS: The hold down assembly (3, 4) must be adjusted to allow for

clearance of the bend material according to the thickness of the material being worked. This adjustment is

made by slightly releasing the clamping pressure and moving the forward edge of the nose bar or fingers back,

away from the edge of the clamp block on the base. This adjustment is made by loosening the set screw

(52) for the eccentric pin (51) one on each end of the hold down assembly and turning the eccentric pin

to move the edge of the hold down toward or away from the edge of the clamp block. For 22 gauge and

lighter material allow a clearance equal to 1.5 to 2 times the thickness of the material. A larger bend radius can

be accomplished by increasing the clearance.

ADJUSTING THE CLAMPING PRESURE: The clamping pressure should be adjusted according to the

thickness of the material being worked. A common cause of forming problems is the result of either

inadequate or excessive clamping pressure. Too much clamping pressure on one or both handles typically

will result in over bending the material on that particular end or relative to the center portion of the brake. Not

enough clamping pressure force will allow the material to slip during the bending process and result in an

under bent section. This under bending is often encountered in the center of the brake.

Clamping pressure should be enough to hold the material securely in place but not so great as to require

undue effort in locking the clamp handles. Clamping pressure on the ends of the brake is adjusted by turning

the nuts (54) on the threaded rod portion of the yoke assembly (47) which is below the clamp swivel (55). The

lift of the hold down assembly is adjusted by turning the nut above the clamp swivel. When the clamping

pressure is properly adjusted, lock the nuts against the clamp swivel to prevent any change in adjustment.

ShopRPMachinne

Tennsmith Inc. / 6926 Smithville Hwy. / McMinnville, TN 37110 / 931-934-2211 / Fax 931-934-2220

www.tennsmith.com

6

HEMMING:

Note: Forming hems is a secondary operation for a hand brake. If you adjust the brake to close a hem in

the center of the work piece, the brake most likely will not bend straight. A hem is formed by making an acute

(reverse) bend in the work piece and then clamping the bent flange in the hold down (1) to press the flange

closed (to 180 degrees). Often the hem will not fully close in the center of a long work piece due to fact that the

outer ends of the brake are more rigid than the center. Here it is especially important that the brake is

sufficiently crowned and that there is proper clamping pressure at the center of the brake. Also the situation

can be improved by inserting a strip of material (of the same thickness as the work piece) between the work

piece and the clamp block slightly longer than the open portion of the hem. Re-clamp the hold down to close

the hem. A tinner’s mallet or hammer is also useful for closing hems. Be cautious not to use excessive force on

the clamp handles to close the hem.

OVERBENDING: The hold down assembly should be moved back on the end where the over bending occurs

by slightly unclamping the clamp handles, loosening the set screw and turning the eccentric pin. When the

correction is made retighten the set screw.

U48-22 BOX AND PAN BENDING: The fingers can be removed and repositioned on the hold down

assembly by moving the clamp handle fully to the rear and loosening the finger clamp screws. Reposition the

fingers to assemble the desired width and secure the fingers to the hold down by tightening the finger clamp

screws. Be certain that the tops of the fingers are flush and parallel with the milled edge on the hold down and

the finger clamps are parallel with the bottom edge of the hold down. As a general rule, use the wider finger

first and fill in with the narrower fingers. Small gaps between the fingers may be left with no adverse effect to

the work piece. The maximum depth of box or pan which can be bent is 3-Inches.

ADJUSTING THE BRAKE

Your brake when assembled at the factory was adjusted for proper operation. Due to handling and

repositioning, the brake my require adjustment and alignment. Read the adjustment and operating instructions

completely before making any adjustments. Operate the brake and bend some material first before attempting

any major adjustments.

BASIC ALIGNMENT: The clamp block on the base of the brake should be straight. This is the reference

point for all of the other alignment operations in adjusting the brake. Raise or lower the center of the brake by

adjusting the center of the brake by adjusting the center truss rod. NOTE: The U48 has four truss rods that

serve as the adjustments of the primary components. The S48 is equipped with three truss rods which facilitate

adjustment of the brake’s three primary weldments. Adjustments are accomplished through rotation of the nut

located on the studs mounted perpendicular to the weldments. The U48 comes with an additional brace which

serves to correct the alignment of the center fingers of the brake with respect to the ends. This adjustment is

made by turning the nut located on the right hand side of the hold down assembly.

ShopRPMachinne

Tennsmith Inc. / 6926 Smithville Hwy. / McMinnville, TN 37110 / 931-934-2211 / Fax 931-934-2220

www.tennsmith.com

7

HOLD DOWN ALIGNMENT: The forward edge of the fingers / nose bar on the hold down assembly should

be even and parallel to the edge of the clamp block on the base. Release any clamping pressure on the hold

down assembly by pushing the clamp handles slightly to the rear. Loosen the set screw located on each end of

the hold down assembly and turn the eccentric to move the forward edge of the clamp block. Check to see that

the edge of the hold down is flush with the edge of the block throughout the entire length of the brake. The

central portion of the hold down assembly can be adjusted forward / backward and up or down via truss rod

adjustment.

PRECAUTIONS

DO NOT USE THE BRAKE TO BEND RODS, NAILS OR WIRE. THIS WILL CAUSE DAMAGE TO THE

EDGE OF THE NOSE BAR AND APRON.

ALWAYS ADJUST THE CLEARANCE AND CLAMPING PRESSURE FOR DIFFERENT THICKNESSES OF

MATERIAL.

DO NOT EXCEED THE CAPACITY OF THE BRAKE. MAKE CERTAIN THAT APRON SUPPORT ANGLE

AND APRON INSERT IS ATTACHED TO THE APRON ASSEMBLY WHEN MAKING CAPACITY BENDS.

OTHERWISE PERMANENT DAMAGE TO THE APRON MAY RESULT.

DO NOT bend seams, hems of locks unless the material is notched or the clearance is adjusted to double the

seam/hem thickness. The capacity of this brake is 22 gauge (0.030). Multiple layers of material which exceed

this dimension are beyond the capacity of the brake.

DO NOT USE PIPE EXTENSIONS TO GAIN ADDITIONAL LEVERAGE ON THE CLAMP HANDLES.

ALWAYS USE MATERIAL WITH SQUARE SHEARED EDGES FOR BEST RESULTS. ROLLED EDGES,

BENT OR WARPED MATERIAL WILL CUASE THE MATERIAL TO BOW WHEN BENT. KEEP SHEAR

BLADES AND SLITTER KNIVES SHARP.

ALWAYS BEND SHORT PIECES OF MATERIAL IN THE CENTER OF THE BRAKE IN ORDER TO

EQUALIZE THE STRESS.

ORDERING PARTS

If you are ordering parts please furnish both the model and serial number of your machine. Part’s can be

obtained directly from Tennsmith Inc.

ShopRPMachinne

Tennsmith Inc. / 6926 Smithville Hwy. / McMinnville, TN 37110 / 931-934-2211 / Fax 931-934-2220

www.tennsmith.com

8

Bench Model Bending Brakes Specification

Models

U48-22

S48-22

Capacity, mild steel 22ga / 0,75mm 22ga / 0,75mm

Bending length 48-1/4in / 1225mm 48-1/4in / 1225mm

Maximum depth of box 3 in / 76.2 mm N/A

Maximum lift of beam 7/8 in / 22.2mm 7/8 in / 22.2mm

Front to rear adjustment ¼ in / 6mm ¼ in / 6mm

Minimum reverse bend 5/16 in / 7.9mm 5/16 in / 7.9 mm

Minimum flange

in capacity material 3/8 in / 9.5mm 3/8 in / 9.5mm

Dimensions, LxWxH

Weight 280 lbs / 127 kg 220 lbs / 100 kg

ShopRPMachinne

This manual suits for next models

1

Table of contents

Other Tennsmith Tools manuals