Tennsmith SR48 User manual

Model SR48 Shown with Optional Stand

Models SR48 Slip Roll

Operation, Parts and Maintenance Manual

Model: Purchased From:

Serial #: Date Received:

6926 Smithville Hwy., McMinnville, TN 37110

931-934-2211 / Fax: 931-934-2220

www.tennsmith.com

Tennsmith Inc. / 6926 Smithville Hwy. / McMinnville, TN 37110 / 931-934-2211 / Fax 931-934-2220 2

www.tennsmith.com

Tennsmith Inc. / 6926 Smithville Hwy. / McMinnville, TN 37110 / 931-934-2211 / Fax 931-934-2220 3

www.tennsmith.com

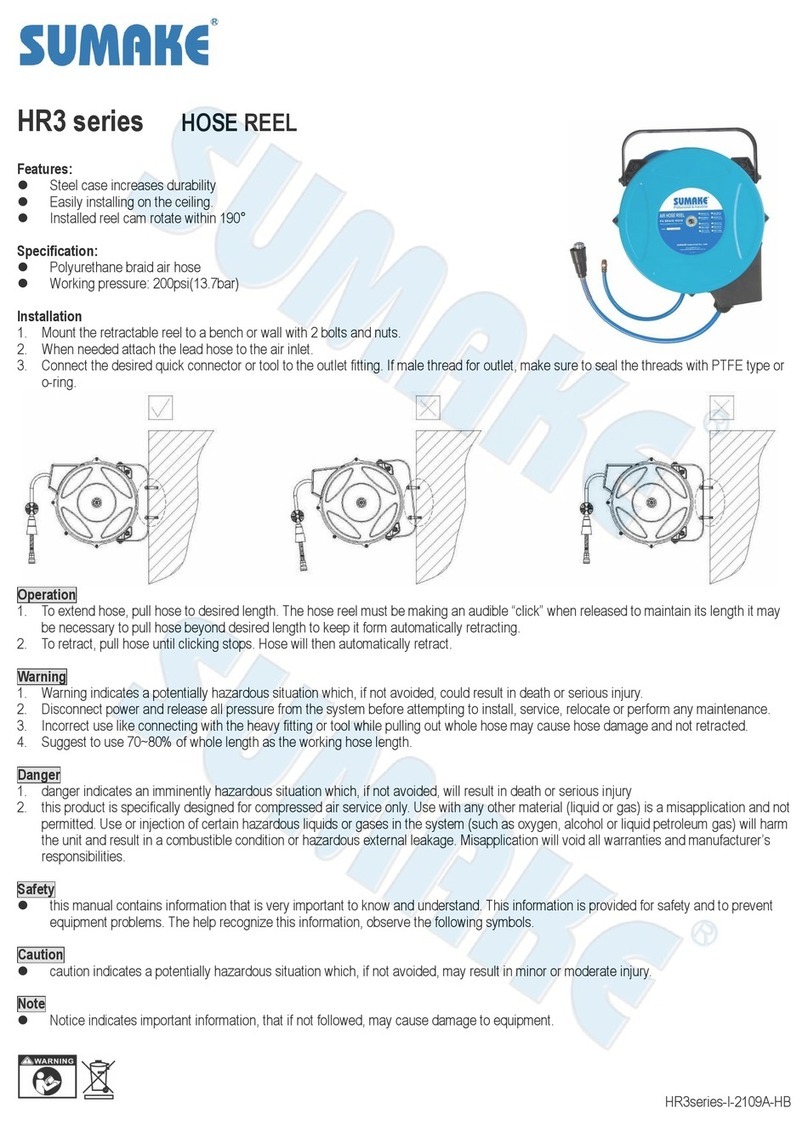

SR48 / Parts List

PART # DESCRIPTION REQ’D # PART # DESCRIPTION REQ’D #

SR48-401 LOCK, TOP LATCH 1 SR48-441 COVER PLATE, TOP R.H. HOUSING 1

SR48-402 TOP LATCH 1 SR48-442 SCREW, COVER PLATE 2

SR48-403 RIGHT HAND SIDE FRAME 1 SR48-443 WASHER, SCREW LOCK 2

SR48-404 LIFT HANDLE 1 SR48-444 PIN, SWIVEL BLOCK 1

SR48-405 LIFT CAM 1 SR48-445 IDLER GEAR-16T 3

SR48-406 BLOCK, ROLL ADJ. 4 SR48-445A IDLER GEAR-18T 1

SR48-407 HANDKNOB, ROLL ADJ. 4 SR48-446 BUSHING, IDLER GEAR 3

SR48-408 HANDCRANK 2 SR48-447 PIN, IDLER GEAR 2

SR48-409 LEFT HAND HOUSING 1 SR48-448 SET SCREW, IDLER PIN 2

SR48-410 BLOCK, TOP ROLL SWIVEL 1 SR48-449 GEAR, LOWER FRONT ROLL 1

SR48-411 LINKS 4 SR48-450 GEAR, BACK ROLL 1

SR48-412 12” GEAR 1 SR48-451 GEAR, TOP ROLL 1

SR48-413 CLEVIS PIN, TOP LATCH 2 SR48-452 GEAR, LOWER IDLER 1

SR48-414 COTTER PIN 3 SR48-453 BUSHING, LOWER IDLER GEAR 1

SR48-415 SET SCREW, LOCK 1 SR48-454 SPACER PIN, GEAR 1

SR48-416 NUT, SET SCREW LOCK 1 SR48-455 PIN, SWIVEL BLOCK IDLER 1

SR48-417 SET SCREW, HANDCRANK 2 SR48-456 SET SCREW, PIN 1

SR48-418 SHAFT, HANDCRANK 2 SR48-457 SCREW, SWIVEL BLOCK 1

SR48-419 HANDLE, HANDCRANK 2 SR48-458 LEVER, LIFTING 1

SR-48-420 WASHER, HANDLE 2 SR48-459 SCREW, LIFTING LEVER 2

SR48-421 NUT, HANDLE LOCK 2 SR48-460 WASHER, SCREW LOCK 2

SR48-422 SCREW, LOWER ROLL ADJ. 2 SR48-461 GEAR, CRANK SHAFT 1

SR48-423 SPLIT PIN, ROLL ADJ. HANDKNOB 4 SR48-462 SET SCREW, GEAR 1

SR48-424 SCREW, LIFT CAM 2 SR48-463 SPACER 1

SR48-425 WASHER, LIFT CAM SCREW LOCK 2 SR48-464 SET SCREW, 12” GEAR 1

SR48-426 NUT, LIFT HANDLE LOCK 2 SR48-465 COVER 1

SR48-427 GREASE FITTING 13 SR48-466 SCREW, COVER 5

SR48-428 SCALE, RIGHT HAND 1 SR48-467 WASHER, SCREW LOCK 5

SR48-429 SCALE, LEFT HAND 1 SR48-468 ROD, LIFTING 1

SR48-430 DRIVE SCREW, SCALE 4 SR48-469 SCREW, LIFTING ROD 1

SR48-431 ROLL, TOP 1 SR48-470 NUT, SCREW LOCK 1

SR48-432 ROLL, LOWER FRONT 1 SR48-471 BASE 1

SR48-433 ROLL, BACK 1 SR48-472 SCREW, BASE LEVELING 4

SR48-434 SHAFT, CRANK 1 SR48-473 NUT, SCREW LOCK 4

SR48-435 BUSHING, CRANK SHAFT 2 SR48-474 SCREW, MOUNTING 6

SR48-436 WOODRUFF KEY 5 SR48-475 WASHER, SCREW LOCK 6

SR48-437 SCREW, BACK ROLL ADJ. 2 SR48-476 DECAL, BASE 1

SR48-438 COLLAR, CRANK SHAFT RETAINING 1 SR48-477 SERIAL PLATE 1

SR48-439 SET SCREW, COLLAR 1 SR48-478 STAND, OPTIONAL 1

SR48-440 COVER PLATE, TOP L.H. HOUSING 1 SR48-479 DECAL, STAND 1

Tennsmith Inc. / 6926 Smithville Hwy. / McMinnville, TN 37110 / 931-934-2211 / Fax 931-934-2220 4

www.tennsmith.com

FORWARD

This manual has been prepared for the owner and operators of the TENNSMITH Model SR48 Slip

Roll. Its purpose, aside from operational instructions, is to promote safety through the use of

accepted operating procedures. Read all instructions thoroughly before operating the slip roll.

Also contained in this manual is the parts list for your slip roll. It is recommended that only TENNSMITH or factory

authorized parts be used for replacement parts.

3-YEAR LIMITED WARRANTY

TENNSMITH machinery and component parts are carefully inspected at various stages of production and are tested and

inspected prior to shipment. We agree that for a period of twelve (12) months from the date of delivery from our

authorized distributor to replace, at our option, any machine (or component part thereof) proving defective within the

above period. Additionally, we agree that for a period of thirty-six (36) months from date of delivery to replace component

parts proving defective within the stated period. All warranty claims are made F.O.B. our plant, providing such machine

(or component part) is returned freight prepaid to our plant, or a designated service center of the undersigned, for our

examination. This warranty does not include repair or replacement required because of misuse, abuse, or because of

normal wear and tear; or electrical components which are warranty by their manufacturer. Further, we cannot be

responsible for the cost of repairs made or attempted outside our factory or designated service center without our

authorization. No claims for defects will be honored if the name and data place has been removed. This warranty is

made expressly in place of all other warranties or guarantees express or implied, with respect to fitness, merchantability,

quality or operative ness. This warranty becomes effective only when the accompanying warranty card is fully and

properly filled out returned to the factory within ten (10) days from date of delivery.

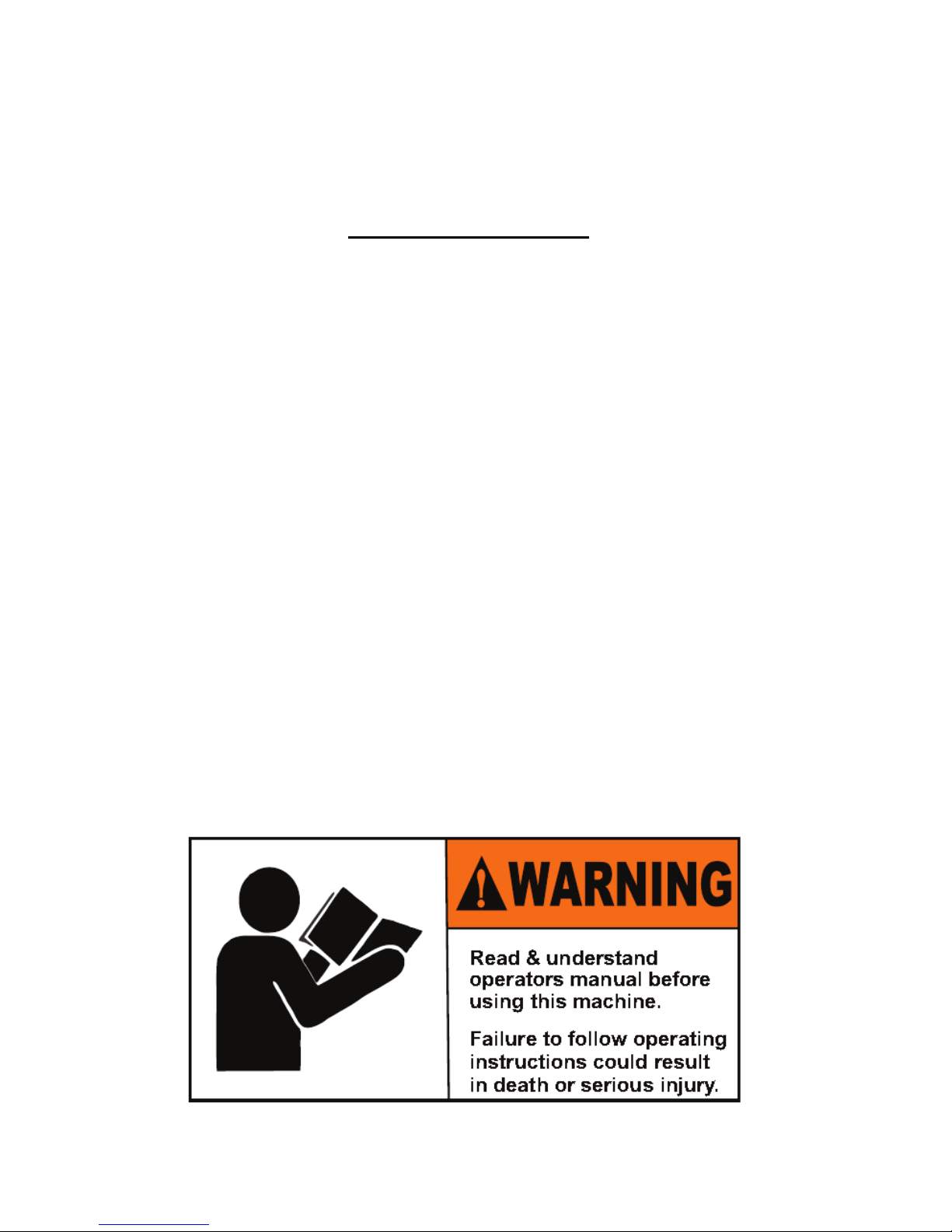

SAFETY PRECAUTIONS

1. Know the safety and operating instructions contained in this manual. Become familiar with and

understand the limitations of this slip roll. Always practice safety.

2. Wear protective foot wear or safety shoes. Jewelry such as rings and watches should be

removed when operating the machine.

3. Rolls should be securely bolted to a work table or bench. The bench should be bolted to the

floor.

4. Always keep hands clear of entry area to rolls while operating.

5. Do not misuse the slip rolls by using them for other than their intended use.

6. Keep the work area clear and clean to avoid tripping or slipping.

7. Remove the second crank handle when only one person is operating the machine.

THESE INSTRUCTIONS MUST BE FOLLOWED OR SEROIUS INJURY OR PROPERTY

DAMAGE COULD OCCUR.

Tennsmith Inc. / 6926 Smithville Hwy. / McMinnville, TN 37110 / 931-934-2211 / Fax 931-934-2220 5

www.tennsmith.com

SAFETY LABELS

Tennsmith Inc. / 6926 Smithville Hwy. / McMinnville, TN 37110 / 931-934-2211 / Fax 931-934-2220 6

www.tennsmith.com

RECEIVING THE MACHINE

Remove the slip roll from its crate and inspect the unit for damage. Any loss or damage should be noted in detail on the

delivery receipt and reported to your distributor immediately.

INSTALLING THE MACHINE

Locate the slip roll in a well lighted area on a solid, level floor. The slip roll must be securely bolted to a work bench or

TENNSMITH manufactured optional stand.

Caution: The Model SR48 slip roll weighs nearly 800 lbs. A heavy-duty work bench is required to support this weight. The

work bench or stand must be securely mounted to the floor. NOTE: The slip roll should be positioned on the work bench so

that both crank handles rotate freely without meeting any obstructions.

Use lag screws or bolts with expandable shields or similar holding devices thru the mounting feet located on the bottom of

the side panels to mount work bench to floor.

The Model SR48 slip roll is equipped with four leveling screws (#72) and lock nuts (#73) to permit the leveling of the

machine on the work bench, thereby eliminating any binding of the various gears or bearing. Use these leveling screws to

remove any twist in the roll base (#71). If the slip roll is mounted on a wood topped bench use metal plates (not provided)

under each leveling screw.

OPERATING THE MACHINE

The full-length capacity of the Model SR48 is shown in the chart below.

The chart (Figure 1) should be used as an approximate material conversion comparison to show equivalent capacities of

material other than mild steel. Do not exceed the capacity of your slip roll as permanent damage to the machine may result.

Figure 1

MAXIMUM CAPACITIES

SR48

Mild Steel 16 ga / .063

Stainless Steel 20 ga / .036

Cold Roll Steel 16 ga / .063

Aluminum, Soft .120

Aluminum, Hard .063

Brass, Soft Yellow .075

Bronze, Phosphor Annealed .075

Copper, Soft .120

Copper, Hard .075

The exact capacity of your slip roll depends on several factors including the nature and uniformity of the material being

worked, the length and diameter of the cylinder or curved part being formed, and the number of passes through the rolls to

obtain the desired diameter of cylinder or radius of bend. As a general rule, when your slip roll is overloaded there will be

deflection at the center of the rolls resulting in a cylinder or curved part that is bulged in the center. The deflection can be

minimized by progressively forming the work piece to the desired radius by making two or more passes through the rolls.

DO NOT try to force the material through the machine as an unsatisfactory work piece and possible damage to the machine

will result.

The two front rolls (#31, #32) feed the material through the machine as the right hand crank handle (#8) is turned in a

clockwise direction. For forming capacity materials an additional left hand crank handle (#8) is provided for two person

operation if necessary. NOTE: if the machine is being operated by only one person, the left hand crank handle should be

removed from the machine for safety. The pinch roll adjustment screws (#22) up and down for a different gauge material

clearance between the two front rolls. The gap between the two front rolls should be equal at both ends of the rolls to insure

an even advancement of the material being worked.

Tennsmith Inc. / 6926 Smithville Hwy. / McMinnville, TN 37110 / 931-934-2211 / Fax 931-934-2220 7

www.tennsmith.com

The rear roll (#33) adjust to control the radius of bend of the material being worked by means of the back roll adjustment

screws (#37). The gap between the rear roll and two front rolls should be equal at both ends of the roll to insure an equal

radius at both ends of the material being worked. The scales (#28, #29) mounted at each side frame are helpful in

maintaining an equal gap. The scales can also be used to record approximate rear roll settings for forming a particular

radius in a particular gauge of material. The rear roll features three full length longitudinal grooves which assist in staring the

work piece through the rolls.

The Model SR48 is an “initial pinch” type slip roll. One forming problem often encountered with any initial pinch type roll is a

small flat spot on the leading edge of the sheet of material being worked. This problem can be minimized by a pre-bending

operation prior to running the work piece through the rolls. With the machine in a non-rotating condition insert the work piece

between the upper and lower rolls (#31, #32) and advance the material slightly by means of the crank handle(s) to the point

where the work piece is held in place between the rolls. Bend the work piece by hand upwards and slightly around the upper

roll approximating the bend radius desired in the finished piece. Crank the work piece through the machine. This pre-

bending operation is also useful in reducing the number of rear roll (#39) adjustments required to form smaller radii in

capacity materials.

Once the material being worked has been formed to the desired shape, removal is accomplished by raising the latch

assembly (#1, #2) to its fully open resting position, and elevating the top roll (#31) by means of the roll lift handle (#4). The

degree of roll lift can be adjusted by moving the handle (#26) in the desired location. The latch pressure can be adjusted by

tightening or loosening the top latch set screw (#15) and locking the bolt in place by tightening the top latch nut (#16).

Wire grooves, 3/8”, 1/2” and 5/8” are provided on the right hand end of the rolls for rolling cylinders with wired edges.

MAINTENANCE

All roll and gear bearing surfaces are equipped with standard grease fittings (#27). Some of these grease fittings are only

accessible by removing the top cover plate (#40) and the rear cover plate (#41). These areas should be lubricated using a

grease gun once each week. We recommend a good of industrial lubricating grease.

After every thirty days of operation, apply grease to the gears (#12, 45, 45A, 50, 51, 52 and #62)) by removing the top cover

plate and main housing end plate. Inspect all bolts and set screws on a regular basis to insure that they are secure.

We recommend that the rolls be lightly oiled when not in use to prevent rusting.

ORDERING PARTS

When ordering parts please furnish the model number and the serial number of your machine.

Tennsmith Inc. / 6926 Smithville Hwy. / McMinnville, TN 37110 / 931-934-2211 / Fax 931-934-2220 8

www.tennsmith.com

Slip Roll Specification

Model

SR48

Maximum capacity, mild steel 16 ga / 1,6 mm

Maximum Forming Length 49 in / 1244 mm

Diameter of Rolls 3 in / 0.76 mm

Minimum Forming Radius 1 1/2 in / 0.38 mm

Wire Grooves

3/8, 1/2, 5/8 in

9.5, 12.7 , 15.8 mm

Gearing Ratio

4 : 1

Shipping Weight

1100 lbs / 500 kg

Table of contents

Other Tennsmith Tools manuals

Popular Tools manuals by other brands

Signode

Signode B/91001 operating instructions

Dafra

Dafra DRPB48 Operation manual

Harbor Freight Tools

Harbor Freight Tools Central Pneumatic 97728 Set up and operating instructions

WilTec

WilTec 61488 Operation manual

Transpak

Transpak H-22 Operation instructions, Spare parts list

Topeak

Topeak MINI 20 PRO user guide