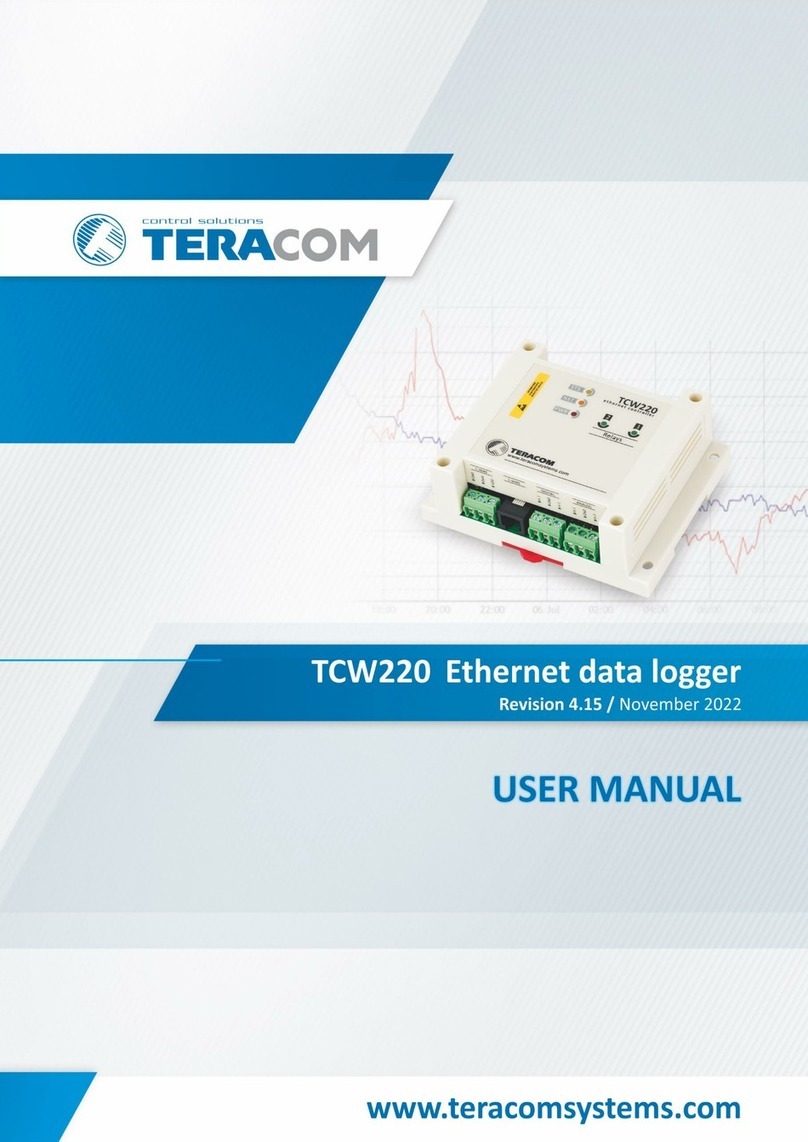

Teracom TCW210-TH User manual

TCW210-TH-R1.16- November 2022 Page 1

1. Introduction

TCW210-TH is a temperature and humidity data logger with an embedded WEB server. Real-time data

and charts of temperature, humidity and dew point can be monitored with a standard web browser

(no special software is needed). Standard protocols as SNMP, MODBUS/TCP, and HTTP/API are

available for M2M applications. The device supports also interface to popular IoT analytics –

ThingSpeak.

The Ethernet temperature logger supports up to eight temperature or humidity-temperature sensors.

All they can be connected either to the 1-Wire interface, popular for home automation or to more

robust MODBUS RTU over RS-485.

All monitored parameters can be recorded, in internal FLASH memory. The records are made on the

previous set time interval and/or on an alarm condition. The memory is large enough for at least 36

days with records on every minute. The log file can be periodically uploaded on a dedicated server by

HTTP/HTTPS Post. The stored data can be monitored on 4 graph pages.

XML/JSON file with all monitored parameters can periodically upload to a dedicated server by

HTTP/HTTPS Post.

For every monitored parameter e-mails and SNMP traps for up to 5 recipients can be sent. Alarm alert

can also be sent by HTTP/HTTPS Post with XML/JSON status files.

2. Features

•Data logger for up to 70000 records;

•1-Wire and MODBUS RTU sensors support;

•HTTP API commands;

•Periodical HTTP/HTTPS Post of XML/JSON status files for client-server systems;

•SNMP v.2 support;

•SNMP traps to up to 5 recipients like alarm alert;

•MODBUS TCP/IP support;

•SMTP with TLS encryption;

•TLS 1.0, TLS 1.1 and TLS 1.2 support;

•e-mails to up to 5 recipients like alarm alert;

•ThingSpeak service support;

•NTP support;

•Back-up/Restore of configurations;

•Dynamic DNS support;

•10/100 Mb Ethernet connectivity;

•Auto-MDIX;

•Port changing for HTTP, SNMP and MODBUS TCP/IP;

•Password protected WEB based configuration and control;

•Extended working temperature range;

•Wide power supply voltage range;

•Remote firmware update.

TCW210-TH-R1.16- November 2022 Page 2

3. Applications

TCW210-TH is suitable for environmental monitoring, building, and industrial automation.

It works very well for monitoring temperature and humidity as a standalone device using a WEB

browser only or as a part of small to large industrial control systems for SCADA (supervisory control

and data acquisition).

A few application examples - pharmaceutical and food processing and storage, clean rooms,

laboratories, HVAC systems, greenhouses and farms, electronic assembly etc.

4. Specifications

•Physical characteristics

Dimensions: 130 x 70 x 30 mm

Weight: 140 g

•Environmental limits

Operating тemperature range: -20 to 55°C

Storage temperature range: -25 to 60°C

Operating relative humidity range: 5 to 85% (non-condensing)

•Warranty

Warranty period: 3 years

•Power requirements

Input Voltage: 10 to 28 VDC

Input Current: 170 mA @ 12 VDC

•1-Wire and RS485 interface

Output voltage (+VW): 5.0 ± 0.3 VDC

Maximum output current (+VW): 0.2 A

•Internal FLASH memory

Endurance: 100 000 cycles (Every settings change is a memory cycle.)

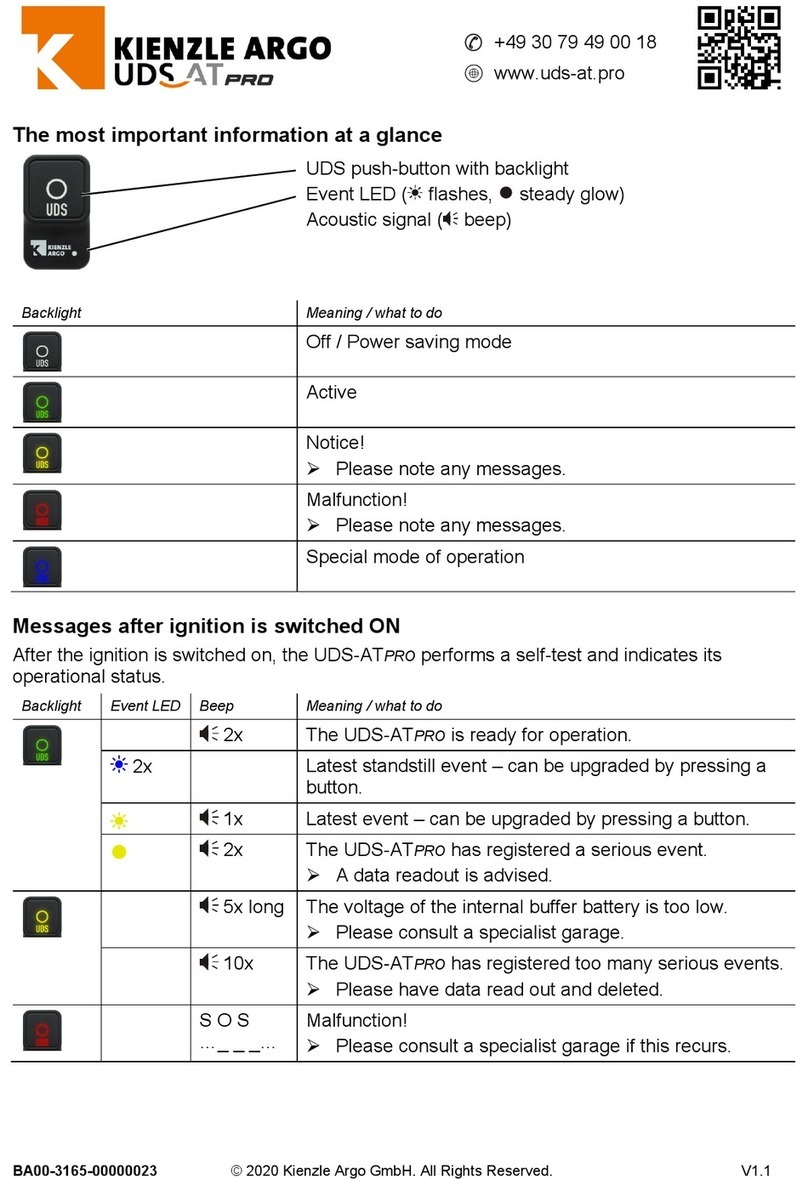

5. LED indicators

The following indicators show the status of the controller:

•PWR (red) –in working mode shines, flashes together with STS if there is a hardware error;

•STS (yellow) –flashes when the main program of the controller is executed;

•NET (orange) –indicates the network connection status - ON when a link is established,

flashing when there is an activity.

TCW210-TH-R1.16- November 2022 Page 3

6. Installation and setup

This device must be installed by qualified personnel.

This device must not be installed directly outdoors.

The installation consists of mounting the device, connecting to an IP network, connecting inputs and

outputs, providing power and configuring via a web browser.

6.1. Mounting

TCW210-TH should be mounted in a clean and dry location on a not flammable surface. Ventilation

is recommended for installations where the ambient air temperature is expected to be high.

Maintain spacing between adjacent equipment. Allow 50 mm of space on all sides, as shown in

Appendix A, this provides ventilation and electrical isolation.

6.2. Connection

Attention! Disconnect power supply before wiring.

The correct wiring procedure is as follows:

•Make sure power is turned off;

•Apply all sensors;

•Apply power.

Make sure that cables are properly attached. Not proper wiring and configuration can cause

permanent damage to TCW210-TH or the equipment to which it is connected or both.

Connector 1

Ethernet - RJ45

Connector 4

Pin1 –not connected (most left)

Connector 2

Power - 2.1x5.5mm connector,

central positive

Pin2 –not connected

Connector 3

Pin1 –GND (most left)

Pin3 –not connected

Pin2 –GND

Pin4 –Line B-

Pin3 –1-Wire Data

Pin5 –Line A+

Pin4 –1-Wire GND

Pin6 –not connected

Pin5 –+VDD

Pin7 –+VDD

Pin6 –+VDD (most right)

Pin8 –GND

6.2.1. Power supply

TCW210-TH is designed to be supplied by adapter SYS1421-0612-W2E or similar, intended for

use in the conditions of overvoltage category II, and prior assessed for compliance with safety

TCW210-TH-R1.16- November 2022 Page 4

requirements. The power supply equipment shall be resistant to short circuit and overload in a

secondary circuit.

When in use, do not position the equipment so that it is difficult to disconnect the device from

the power supply.

6.2.2. 1-Wire interface

1-Wire is a registered trademark of Maxim Integrated Products, Inc. It is designed to connect

several sensors over short wiring. It is not suitable for long distances or environments with EMC

interference.

The maximum number of sensors (1-Wire or RS-485) connected to TCW210-TH is 8.

The device supports temperature and humidity-temperature sensors. Connected sensors are

automatically detected and the appropriate dimension is assigned.

It is strongly recommended to use “daisy-chained” (linear topology) for multi-sensors systems:

It is strongly recommended to use only UTP/FTP cables and keep total cable length up to 30m.

Although functionality has been achieved in the longer distance, we cannot guarantee error-free

operation over mentioned wiring length. We recommend reading Maxim’s 1-Wire tips at

http://www.maxim-ic.com/app-notes/index.mvp/id/148.

We guarantee proper operation only with Teracom 1-Wire sensors.

6.2.3. RS-485 interface

RS-485 is a standard for serial communications systems defined by Telecommunications Industry

Association (TIA) and Electronic Industries Alliance (EIA). Implementing the standard,

communication systems can be used effectively over long distances and in electrically noisy

(industrial) environments.

The maximum number of sensors (1-Wire or RS-485) connected to TCW210-TH is 8.

The device supports temperature and humidity-temperature sensors.

MODBUS RTU protocol specifies that address of the device should be between 1 and 247. The

user should take care of appropriate address settings.

For multi-sensors systems “daisy-chained” (linear topology) should be used:

TCW210-TH-R1.16- November 2022 Page 5

Interconnections are realized by UTP/FTP cables with RJ-45 connectors. The popular Ethernet

wiring standard ANSI/TIA/EIA T568B is used:

It is recommended to use standard patch cables for LAN networks.

Special attention should be paid on termination of the bus in the last sensor.

We recommend keeping total cable length up to 30 m, although the RS-485 interface works over

a much longer distance.

Attention!

Special attention should be paid on termination of the bus.

The last sensor in the chain should have a terminator installed on the free RJ-45 socket.

6.2.4. Network connection

The Ethernet port of TCW210-TH should be connected to 10/100 Base-T Ethernet hub, switch or

router.

For setup, TCW210-TH may be connected directly to the Ethernet port on a computer. The device

support Auto-MDIX and it is not necessary to use “crossover” cable, standard “straight-through”

can be also used.

Pin# RJ45

1

Orange/White

Tracer

2

Orange

3

Green/White

Tracer

4

Blue

5

Blue/White

Tracer

6

Green

7

Brown/White

Tracer

8

Brown

TCW210-TH-R1.16- November 2022 Page 6

TCW210-TH can be used in a wireless network by connecting through a wireless router.

6.3. Communication setup

By default TCW210-TH is delivered with the following network settings:

IP address: 192.168.1.2, Subnet Mask: 255.255.255.0, Default Gateway: 192.168.1.1

Communication with TCW210-TH can be established by assigning a temporary IP address to the

computer. For computers with Windows OS assigning of IP address is made in “Local area

connection properties”:

TCW210-TH-R1.16- November 2022 Page 7

The address should be on the same network - for example 192.168.1.3:

To get access to the web interface, you should type http://192.168.1.2 into the browser:

If the network settings are correct, the login pop-up window will appear:

All TCW controllers connected to LAN can be easily found by the free tool “TCW discoverer”.

It is available for Win and Mac operating systems and can be downloaded from

www.teracomsystems.com.

7. Web interface

The WEB interface allows configuration, monitoring, and control. All pages are UTF-8 encoded.

For the WEB interface, the device supports HTTP only (HTTPS is not supported).

If the controller is properly addressing, login pop-up window appears.

Authorization data must be entered (by default username=admin, password=admin).

It is recommended to change the username and password to prevent unauthorized access to the

controller.

TCW210-TH-R1.16- November 2022 Page 8

The controller supports a few active session.

7.1. Monitoring

Monitoring page displays the current state of TCW210-TH. It has one data and four graphs tabs.

7.1.1. Data

The current state of TCW210-TH can be monitored on this page. There are two sections on the

page - оne for 1-Wire sensors and one for MODBUS RTU sensors.

TCW210-TH supports up to eight sensors. They can be connected to both interfaces in a random

ratio, settable in section “Sensors ratio setup” on Setup->Sensors page. By default, the number

of MODBUS RTU sensors are 4.

All detected 1-Wire sensors are shown in “1-Wire sensors” section. The sensors should be setup

in section “1-Wire sensors setup” on Setup->Sensors page.

Teracom 1-Wire temperature sensors readings are shown in the column “Temperature”, while

for dual sensors (TSH2xx) both column “Temperature” and “Humidity” are used. For dual sensors,

the parameter Dew point is calculated.

All MODBUS RTU sensors are shown in “Modbus sensors” section. The sensors should be added

and set up on Setup->Sensors page.

For every sensor, there are a description, value, and ID information. The description length is up

to 15 characters. Default descriptions can be changed in Setup->Conditions page.

Dual sensors (humidity-temperature) have the two parameters. For these sensors, Dew point

parameter is calculated automatically.

TCW210-TH-R1.16- November 2022 Page 9

The page can be automatically refreshed on an interval of 0 to 253 seconds. Zero means no

automatic refresh. This parameter is set in section Setup->System->Monitoring page automatic

refresh. By default, it is 1 second.

7.1.2. Graphs

Every graph page can display up to 4 parameters with up to 2 different dimension.

For every parameter different color can be set. There are a few checkboxes for display

modification.

Export of monitored parameters can be made from the page.

7.2. Setup

7.2.1. Network

The network parameters are set on this page.

The controller supports static and dynamic IP addresses.

It is good practice to change the default IP address of the controller immediately after first power-

on. This will avoid collisions if many devices are used on the same network.

It may be necessary to clear the arp cache, each time you connect a new device to the network.

This is done by typing arp -d in the command prompt window of the computer.

The “Hostname” is up to 15 characters. It is shown in the search results of TCW discoverer.

TCW210-TH-R1.16- November 2022 Page 10

7.2.2. Sensors

7.2.2.1. Sensors ratio setup

The ratio between 1-Wire and MODBUS RTU sensors can be set here. By default, it is 4:4.

7.2.2.2. 1-Wire sensors setup

Detection is made either after power on or by the button “Scan for new sensors”. All found

sensors are shown in ascending order refer their unique ID number.

It is possible to lock a 1-Wire sensor in a specific position. To do this all sensors should be

added one by one. After every addition, a new scan should be made and a newly found sensor

should be locked in its position. If all sensors are locked, removing one “in the middle” will not

change the positions of other sensors after reset. This option is very useful when TCW210-TH

is used as a part of а monitoring and control system managed either by SNMP or HTTP API

commands.

7.2.2.3. MODBUS RTU communication setup

TCW210-TH supports MODBUS RTU over RS-485 interface. All sensors connected to this

interface should work with the same communication settings.

By default, TCW210-TH works with the standard for MODBUS RTU settings –19200, E, 1.

In the right part of the section, there is a tool for scan the MODBUS RTU interface. To optimize

scan time, the appropriate address segment should be set up after this, the button “Save” on

the bottom of the page should be pressed.

7.2.2.4. MODBUS RTU sensors

TCW210-TH supports Teracom and third-party MODBUS RTU sensors.

TCW210-TH-R1.16- November 2022 Page 11

Before to add MODBUS RTU sensors, the user should take care of their address setting. It is

not allowed to use two sensors with the same address. It is recommended to scan for new

sensors before to make any changes.

For every sensor, an appropriate register address together with the data type and data order

should be set. All changes should be saved. If the settings are OK in the columns “Raw value”

the right data will be shown.

TCW210-TH supports MODBUS RTU sensors with response time-out between 10 and 500mS.

The response time-out for a new sensor is 100mS by default but it is recommended to use

minimum response time guaranteed by the sensor’s manufacturer.

The sum of chosen response time-out for every sensor forms the maximum response time-

out for the system.

The polling time is the time between two sequential readings of the same sensor. The chosen

polling time determines the system's time of reaction. By default, it is 1 second.

Important: The maximum response time-out can’t be lower than the polling time.

7.2.2.5. Sensor setup tool

The link for the tool is available on the bottom of the Modbus RTU sensors paragraph. It can

be used for sensor communication setup changes or just to read information from a register.

7.2.2.5.1. Communication setup

The section is similar to the general MODBUS RTU communication setup. The only new field

is the sensor address.

The changes of settings in this section are not memorized and don’t change the general

settings of TCW210-TH.

7.2.2.5.2. Sensor communication register setup

This part of the tool is used for check and change the status of communication registers of

the sensor.

7.2.2.5.3. Sensor register check

This part of the tool is used for general sensor register check.

TCW210-TH-R1.16- November 2022 Page 12

7.2.3. Conditions

This section is used for parameterization of trigger and alert conditions for 1-Wire and MODBUS

RTU sensors.

For every sensor, a description up to 15 characters can be set.

For all sensors “Offset” field is enabled. The offset is used for simple correction of displayed value.

For all Modbus RTU sensors multiplier is enabled, but for Teracom sensors it should be 1.

For every parameter, there is a field for trigger conditions (“Min”, “Max” and “Hys.”).

“Min” and “Max” indicate the border of the working range for the observed parameter.

A “Max” trigger condition occurs when the value exceeds the trigger set point. A “Min” trigger

condition occurs when the value is lower than the trigger set point. In both cases, the monitored

parameter goes out of range.

Coming back in range for the observed parameter is considered when the value goes higher than

(Min + Hys) or lower than (Max –Hys). Hysteresis (“Hys”) is used to prevent excessively triggering

when the value vacillates around trigger point.

Example:

TCW210-TH and TST103 are used to monitoring of room temperature. The wanted minimum

temperature is 19°C. The initial temperature is 17°C.

TST100 is assigned to the first position for 1-Wire sensors.

Following parameters are set for Sensor1: Min=19, Max=85 and Hys=0.5.

When the controller is switched on, Alarm is immediately activated because the monitored

temperature is out of range.

When the temperature reaches 19.5°C (19.0 + 0.5) it goes in range (trigger condition) and Alarm

is deactivated.

TCW210-TH-R1.16- November 2022 Page 13

The temperature falls and when it reached 19°C it goes out of range (trigger and alert conditions).

E-mail is sent.

The “Max” value is set far enough from the wanted temperature to avoid trigger/alert conditions

around it.

For every sensor, there are 3 independent ways of alert for alarm condition –e-mail, SNMP trap

and HTTP/HTTPS post of an XML/JSON file. Each alarm notification method is activated by a

checkbox.

Globally for all sensors, there is a checkbox “Return notification”. If this option is chosen there

will be notification also when parameter returns in range.

Globally for all sensors, there are “Notification delay” parameter. It is very useful as a filter for

short alarm conditions.

7.2.4. System

On this page, some general settings can be made.

7.2.4.1. General

The system name, location, and contact can be used for automatic identification of device via

M2M protocols.

TCW210-TH-R1.16- November 2022 Page 14

7.2.4.2. WEB access

In this section, WEB access authentication can be deactivated. By default, it is activated with

admin/admin authentication details.

HTTP port for WEB access can be changed. This is useful for some routers which don’t support

different outside/inside ports for port forwarding. By default, HTTP port is 80.

7.2.4.3. HTTP API

In this section, HTTP API access authentication can be activated/deactivated. By default it is

active.

Authentication details are the same for WEB access. The controller support two types of

authentication –see the explanation for HTTP API below.

7.2.4.4. Monitoring page automatic refresh

Monitoring page refresh interval can be set between 0 and 253 seconds. Zero means no

automatic refresh.

7.2.4.5. Display

The unit for observed temperatures can be selected between Celsius and Fahrenheit

temperature scales.

If all sensors are attached to the one interface, the other section can be removed from the

Monitoring page by the appropriate checkbox.

7.2.5. Time

Internal RTC (Real Time clock) of the controller can be set either manually or automatically.

TCW210-TH-R1.16- November 2022 Page 15

For automatic clock synchronization, the controller supports NTP (Network Time Protocol) and

all necessary parameters for automatic synchronization are available in this section.

By default, NTP synchronization is disabled, server –time.google.com, Time zone +0.00 and

interval of 12 hours.

7.3. Services

7.3.1. MODBUS

TCW210-TH supports MODBUS TCP/IP over the Ethernet interface.

By default, MODBUS TCP/IP is disabled. The standard port for this protocol is 502. The table

with the registers' addresses can be found in section 8.3. MODBUS TCP/IP.

7.3.2. SMTP

This page is used to enter valid SMTP settings for email alerts and recipients’ addresses.

7.3.2.1. SMTP setup

The mail server address can be set either by hostname (for example

mail.teracomsystems.com) or IP address.

By default, without an encrypted connection, the SMTP port is 25. Ask ISP if the default port

doesn’t work.

Sender e-mail, username, and password are standard authentication details. For most SMTP

servers, the sender's e-mail and username are the same.

There is a button for server settings test with feedback. In this test sender and recipient of

the e-mail are the same.

Transport Layer Security protocol is used for secure communication with public mail servers.

TCW220 supports TLS 1.0, TLS 1.1, and TLS 1.2 with RSA as a key exchange/agreement and

authentication, which ensures successful operation with almost all public servers. STARTTLS

is not supported.

7.3.2.2. Alarm destination

Up to 5 mail recipients can be set. All they can be activated independently by a checkbox.

TCW210-TH-R1.16- November 2022 Page 16

7.3.2.3. E-mail details

The subject, body header, body and body footer can be customized. For this customization, a

set of keys is used. All they are described on the page.

7.3.3. SNMP

The TCW210-TH supports SNMP v.2.

In this section, all necessary parameters for proper operation of SNMP can be set.

By default SNMP is disabled, the port is 161, read community is public and write community is

private.

In an alarm condition, SNMP trap can be sent up to 5 independent recipients. All they can be with

different port and community. There is an independent button for trap test. SNMP traps can be

sent if:

•the measured parameter of the sensor goes outside the range;

•restart;

•SW reset.

7.3.4. Logger

The TCW210-TH supports logger for all monitored parameters. The records are made in a circular

buffer within the internal flash memory. When the buffer is full, the oldest values are overwritten

with the newest ones.

TCW210-TH-R1.16- November 2022 Page 17

7.3.4.1. Logger

The logger works in three modes –Time, Alarm and Time&Alarm. The mode specifies what

initiates a record in the logger’s memory.

In Time mode, records are made periodically on “Log interval” time. In Alarm mode, records are

made on every alarm condition. In Time&Alarm mode, a mix of both conditions for records is

used.

The log interval determines the time between two log entries. It is good to remember that by

reducing the log interval, we increase the resolution, but we also reduce the past period for which

we have records.

The logger records can be synchronized with a specific minute in an hour. Synchronization is very

useful when monitoring electricity, water, gas meters, etc. The log interval can be chosen from a

drop-down menu between 1 and 60 minutes. The field „Sync to the minute“determines which

minute of every hour is used for synchronization. Although any minute can be selected, it is better

to use the default value - 00.

Example:

The current settings are:

•Current time = 09:12

•Logger record sync = Enable;

•Sync to the minute = 00;

•Sync interval = 15 minutes.

The settings determine 4 records per hour in HH:00, HH:15, HH:30, and HH:45.

The device is powered up.

The first record will be immediately after power-up - 09:12. The next records will be in 09:15,

09:30, 09:45, 10:00, 10:15, etc.

There are two ways to reach the logger records:

•download of the full log file, using “Download full log” in the WEB interface;

•periodical upload the last unsent records to the dedicated HTTP server.

The records are uploaded in CSV file format using HTTP or HTTPS protocol. The HTTPS upload is

over TLS 1.0, TLS 1.1 and TLS 1.2 with RSA as a key exchange/agreement and authentication.

The period of the upload can be chosen from the menu between 1 and 24 hours. If you enable

this service, take care of the real-time clock (NTP service).

The HTTP server for upload can be domain or IP address but take care about DNS settings.

TCW210-TH-R1.16- November 2022 Page 18

“Sync time” is a moment in the day when a period of upload is synchronized.

Example:

Current time is 19:31, Upload period is 3 hours and Sync time is 9:00.

To synchronize the logger to 9:00 it means that time for uploads will be: 09:00, 12:00, 15:00,

18:00, 21:00, 24:00, 03:00 and 06:00. The first upload, after enabling the logger in 19:31, will

be in 21:00.

The button “Force upload” initiates upload recorded information between previous periodical

upload and now.

By default, the logger is disabled.

More about the logger can be found in the Data logger section.

7.3.5. HTTP post

TCW210-TH can periodically upload a file to a dedicated server using HTTP or HTTPS Post.

The HTTPS is over TLS 1.0, TLS 1.1 and TLS 1.2 with RSA as a key exchange/agreement and

authentication.

The posting period is between 10 and 14400 seconds.

The file format can be XML or JSON.

By default, Periodic&Alarm is selected as the mode. In addition to the periodic posts, a file can

be uploaded at any alarm condition.

If Periodic only is selected as the mode, then periodic posts are performed without alarm posts.

If Alarm only is selected as the mode, then alarm posts are performed without periodic posts.

The “Key” field value is sent in the XML/JSON and can be used for device identification.

If “Process Answer” option is enabled, the TCW210-TH will process the answer of the remote

server. The list of valid commands is described in section “HTTP API commands”.

TCW210-TH-R1.16- November 2022 Page 19

7.3.6. Cloud

ThingSpeak server is an open data platform and API for the Internet of Things that enables you

to collect, store, analyze, visualize, and act on data from sensors.

The primary element of ThingSpeak activity is the channel, which contains API key, channel ID,

and eight data fields.

TCW210-TH has four channel sections –Channel 1, Channel 2, Channel 3 and Channel 4.

7.3.7. Dynamic DNS

With dynamic DNS can access TCW210-TH from the public Internet without investing in a

broadband account that has a static IP address.

TCW210-TH supports the following DNS services –DynDNS, No-IP, and DNS-O-Matric.

Other manuals for TCW210-TH

1

Table of contents

Other Teracom Data Logger manuals