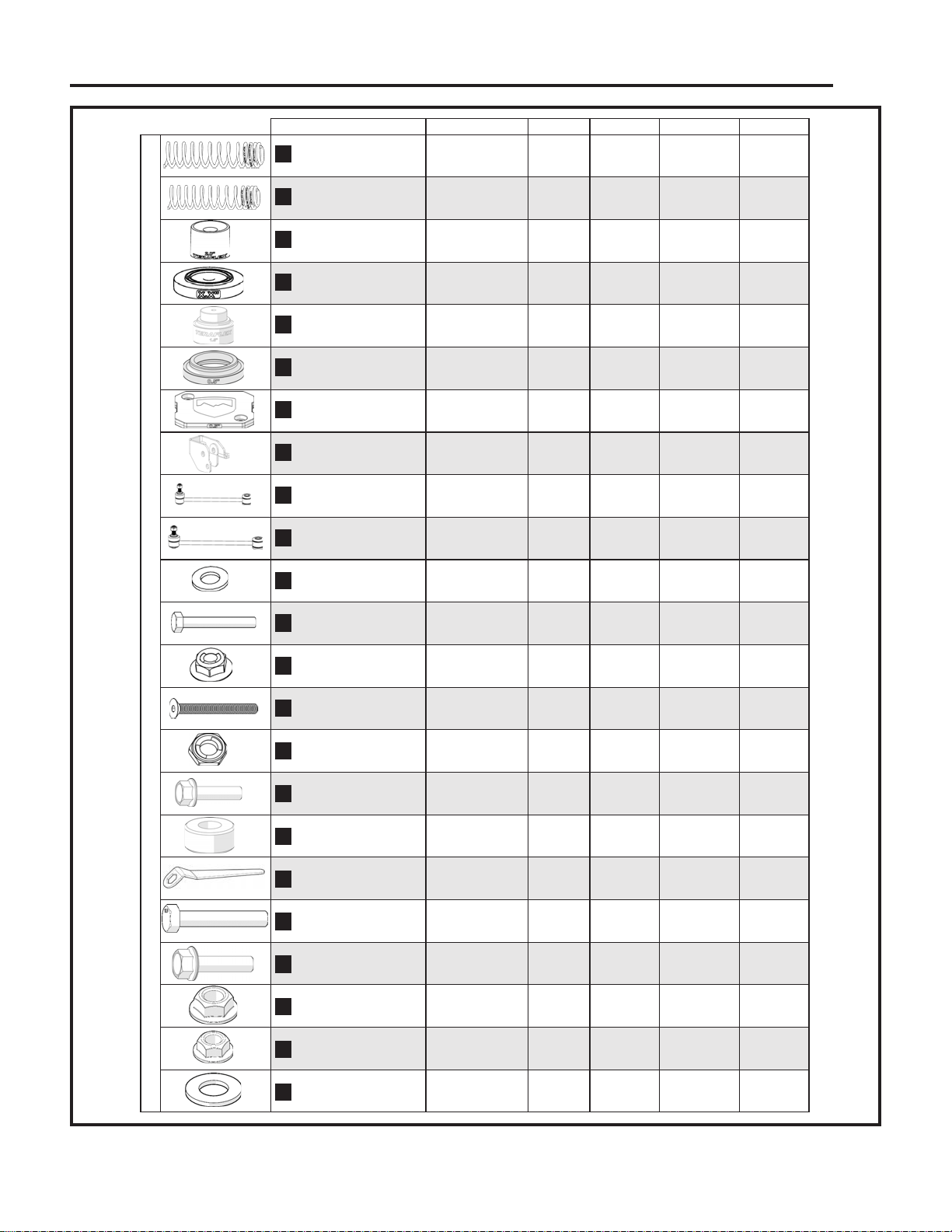

Front Spring 02-21-401-400-1 2 2 2 2

Rear Spring 02-23-401-150-1 2 2 2 2

Front Bumpstops 12-01-109-200 - 2 2 2

Front Bumpstop Spacer 12-02-109-050 - 4 4 4

Rear Top Bumpstop

Spacers 1.5" 12-01-309-150 2 2 2 2

Rear Top Bumpstop

Spacer Rings .5" 12-01-309-050 2 2 2 2

Rear Bumpstop Spacers 12-02-309-050 4 4 4 2

Front Track Bar Bracket 1953250 1 1 1 1

Front Swaybar link 11.50" 21-01-001-115 - - - 2

Rear Swaybar Link 13.0" 21-01-001-130 - - - 2

M10 x 30mm OD

Flat Washer 45-10-003-003 4 4 4 4

M10 X 1.50 X 70mm

Hex Head Bolt 45-21-001-001 2 2 2 2

M10 x 1.5 Fuji Nut 23-07-03-001 2 2 2 2

M10 x 1.5 x 100mm

Flat Socket Cap Screw 45-04-003-001 - 2 2 2

M8 x 1.25mm

Yellow Zinc Fuji Nut 23-07-03-002 - 4 4 4

M8 x 1.25 x 30mm

Hex Flange Bolt 45-02-003-016 4 4 4 4

Rear Upper Bumpstop

Spacer 56-10-05-044-1-1 2 2 2 2

Nut Wrench Tool 600271 - 1 1 1

M14 x 1.5 x 80mm

Hex Cap Screw 45-01-005-002 1 1 1 1

M12 x 1.75 x 25mm

Hex Flange Bolt 45-02-005-003 2 2 2 2

M14 X 1.5 Flange

Top Lock Nut 45-08-004-005 1 1 1 1

M12 X 1.75 Flange

Top Lock Nut 45-08-004-006 1 1 1 1

M14 x 28mm OD

Flat Washer 45-10-005-004 1 1 1 1

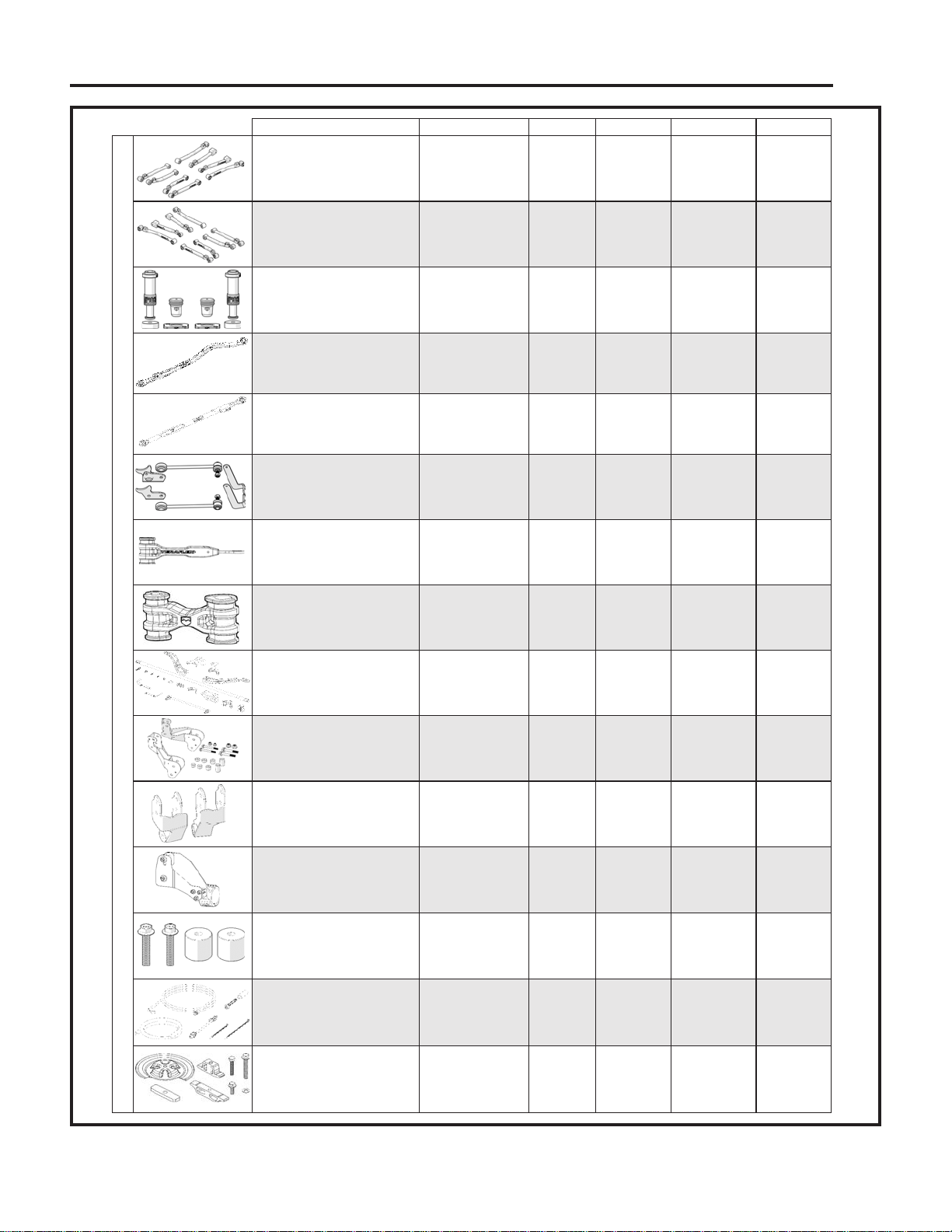

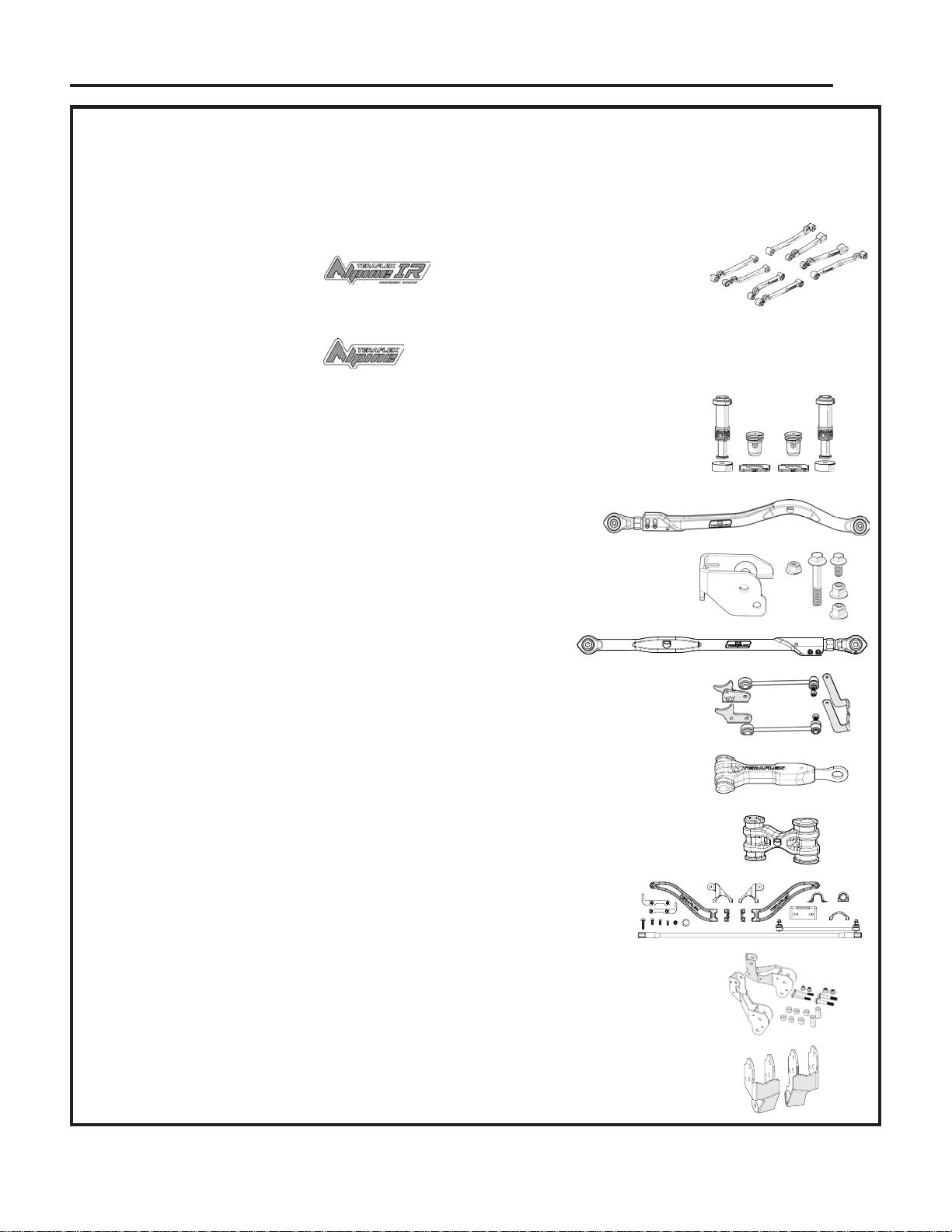

Spring Box Components