Teral NX-VFC-e User manual

NX-VFC-e

Estimated Terminal Pressure Constant

Control of Water Supply Unit

Instruction Manual

Important Notice

Thank you very much for purchasing the TERAL water supply unit.

In order to use the water supply nuit appropriately, read this instruction manual

before using, and do not perform operation, maintenance and inspection before

understanding the description in this manual thoroughly.

For safety purpose, observe the cautions and warnings in this instruction manual

and those on the labels affixed on the water supply unit.

Keep this manual carefully at hand where it can be consulted at any time of

operation, maintenance and inspection of the water supply unit.

To whom performing utility work:

Be sure to submit this manual to the customer performing

operation, maintenance and inspection of the water supply unit.

Do not keep combustible materials such as the manual or other drawing inside the

control panel of the water supply unit (except when a drawing holder is inside).

Warning

Limited warranties

1. In the event of failure or breakage under proper use of the product during the warranty period, equipment

supplied by Teral Inc. shall be repaired or replaced free of charge within the scope of the relevant part,

provided that such failure or breakage is attributable to inadequacy of the design or workmanship of the

equipment.

2. The warranty mentioned in the above clause shall be only the mechanical warranty of the defective part,

and shall not cover any expenses or other damage arising from the failure or breakage.

3. In the event of the following failures and breakage, the costs of the repairs and consumables (i.e. parts

whose consumption or wear is expected at the beginning of purchase) shall be borne by the user.

(1) Failures and breakage attributable to equipment that was not delivered by Teral Inc.

(2) Failures and breakage after the expiration of the warranty period

(3) Failures and breakage caused by disasters or force majeure, such as fire, acts of God or earthquakes

(4) Failures and breakage resulting from repairs, disassembly or modifications made without the consent

of Teral Inc.

(5) Failures and breakage when parts other than those designated by Teral Inc. are used

(6) Failures and breakage caused by any use outside the specification limit of the equipment

4. Teral Inc. shall not be liable for any damage caused by incorrect or reckless use of the water supply unit

even if such damage occurs within the warranty period. Cost and expenses incurred for sending engineer(s)

in such a case shall be borne by the user.

5. If the cause of the failure is unclear, necessary actions shall be determined through mutual consultation.

6. In order to improve performance, some parts and/or components of the product may be changed without

prior notice.

In addition, upon repairs of the product, Teral. may use recycled parts that conform to our quality standards

or may use substitutes that are functionally equivalent.

Purpose of this manual / Notice to users

1. The purpose of this manual is to provide the user with detailed information necessary to operate, maintain

and inspect the water supply unit (or “the unit”) properly.

This manual does not cover work that requires highly specialized knowledge (disassembly, repairs, etc.). If

the unit needs to be repaired, be sure to contact Teral. or its relevant service company.

2. This manual is intended for:

xpersons experienced in the operation of water supply units, or those who have been trained by such

experienced operators

xqualified persons, such as licensed electrical engineers, for the content regarding electric wiring work

3. This manual mainly covers standard products. If you have purchased a customized product, some part of

this manual may not be applicable to your unit. In such a case, refer to other documents such as the

delivery specifications to confirm the product specifications.

4. The product specifications and information in this manual are subject to change without prior notice.

5. In the illustrations of this manual, some part of the product is omitted or simplified to make it easy to

understand. Therefore, the illustrations may look different from the actual product you use.

Contents

1. Safety precautions ············································································································1-1

1.1 Explanation of safety indications and graphic symbols························································1-1

1.2 Safety precautions······································································································1-1

2. Before using the water supply unit························································································2-1

2.1 Points to be checked···································································································2-1

2.2 Model type description·································································································2-1

3. Configuration and overview of the water supply unit ·································································3-1

3.1 Specifications of the water supply unit·············································································3-1

3.2 Names and functions of each part··················································································3-2

3.3 Specifications of control panel·······················································································3-6

3.4 Specification tables·····································································································3-7

4. Installation ······················································································································4-1

4.1 Precautions for installation ···························································································4-1

4.2 Precautions for piping work ··························································································4-2

4.3 Precautions for wiring work···························································································4-3

5. Preparation for operation····································································································5-1

5.1 Points to be checked before test operation·······································································5-1

5.2 Turning on the power ··································································································5-2

6. Test operation··················································································································6-1

6.1 Check items related to manual operation·········································································6-1

6.2 Check items related to automatic operation······································································6-1

7. Basic operations and indications/settings···············································································7-1

7.1 Operating the pump ····································································································7-1

7.2 Selecting a receiver tank······························································································7-2

7.3 Selecting the operation of the inflow solenoid valve····························································7-3

7.4 Indications on the display ·····························································································7-4

7.5 Parameter settings ·····································································································7-7

8. Maintenance and inspection································································································8-1

8.1 Precautions for maintenance and inspection ····································································8-1

8.2 Inspection mode·········································································································8-2

8.3 Maintenance check list ································································································8-3

9. How to handle troubles ······································································································9-1

9.1 Alarm handling ··········································································································9-1

9.2 Troubleshooting ·········································································································9-2

10. Special models ··········································································································· 10-1

10.1 Lifting models ·········································································································· 10-1

10.2 Freeze-proof models ································································································· 10-2

1-1

1. Safety precautions

Before using the unit, thoroughly read this “Safety precautions” to properly use the product. Information

described below is vital to safe and proper use of the unit and prevention of hazard and/or damage.

1.1 Explanation of safety indications and graphic symbols

This instruction manual divides safety indications into four categories according to the level of hazard (the

extent of damage/losses and the urgency). In addition, the type of user instructions is indicated with a

graphic symbol.

This manual uses the following signs. Fully understand these terms and symbols before reading this manual

further.

Explanation of the safety indications Explanation of the graphic symbols

Indications Meaning

Don’ts Do not touch Do not

disassemble

Do not touch

with wet hand

Do not expose

to water

Danger

Indicates an imminently hazardous

situation. Failure to observe this will result

in death or serious injury.

These graphic symbols indicate prohibited actions

(that must not be done).

Warning

Indicates a potentially hazardous

situation. Failure to observe this will result

in death or serious injury.

Do’s

This graphic symbol indicates mandatory actions

(that must be done).

Caution

Indicates a potentially hazardous

situation. Failure to observe this will result

in minor or moderate injury or property

damage. Caution Electric shock

hazard

Rotation

hazard

Hot surface

Note

Indicates information that is in particular

to be noted or emphasized.

These graphic symbols indicate existing hazards

to beware of.

1.2 Safety precautions

The following are important instructions about safety. Be sure to observe these precautions.

Danger

Once the main power is turned on, do not touch any live parts inside or outside the control panel.

A high voltage applied to live parts causes a serious electric shock.

Warning

Properly move the unit according to lifting

instructions.

Otherwise, the unit may fall, resulting in injury and/or

damage.

Do not carry out any work by/on the water supply

unit that is being lifted.

Otherwise, the unit may fall, resulting in injury and/or

damage.

Only those who are authorized by the site

manager may operate the water supply unit.

Operation by unskilled personnel may lead to an unforeseen

accident.

Only those who are trained to handle the water

supply unit may install, maintain, and inspect it.

Operation by unskilled personnel may lead to an unforeseen

accident.

Only qualified personnel, such as licensed

electrical engineers, are allowed to carry out any

electric work.

Otherwise, it may lead to an electric shock, fire, failures,

and/or other problems.

Use the wiring equipment and devices compliant

with the use conditions, and carry out wiring work

safely and securely according to the technical

standards for electrical facilities, as well as the

indoor wiring regulations.

Otherwise, it may lead to an electric shock, fire, and/or other

problems.

Before starting wiring work, be sure to turn off the

main power and confirm that the pilot lamp is

turned off. Take measures to prevent erroneous

power supply.

Otherwise, it may lead to an electric shock.

At the power supply source, be sure to install a

ground fault interrupter dedicated to this unit.

Otherwise, it may lead to an electric shock, fire, and/or other

problems.

1-2

Warning

Securely install the ground wire and ensure to

carry out grounding work.

Otherwise, it may lead to an electric leak and/or electric

shock.

Do not connect the ground wire to a gas pipe or

water pipe.

Such a connection is illegal and leads to an electric shock,

explosion and/or fire.

Ensure that all electric wires are securely

connected.

Otherwise, it may lead to fire and/or an electric shock.

Before starting the maintenance or inspection

work, be sure to stop the pump and turn off the

main power of the panel board.

Otherwise, it may lead to an electric shock, injury, damage,

water leakage, and/or other problems.

Before starting the unit or carrying out

maintenance/inspection work, ensure that all the

relevant workers are informed of the operation and

that there are no workers in the dangerous zone

around the unit.

Otherwise, it may lead to an unforeseen accident.

Before rotating the pump shaft by hand to check its

smooth rotation, be sure to disconnect the main

power supply.

Otherwise, it may lead to injury and/or damage.

After turning on the power, do not touch any parts

of the water supply unit other than those required

for operation.

Otherwise, it may lead to an electric shock, injury, and/or

other problems.

Ensure to keep the cover of the control panel

closed during operation.

Otherwise, it may lead to an electric shock, fire, and/or other

problems.

Do not put your fingers or foreign objects into any

openings or rotating part of the motor during

operation.

Otherwise, it may lead to injury and/or damage.

Do not run the pump continuously for over one

minute with the discharge valve shut

(zero-discharge operation).

Otherwise, the temperature and pressure will increase inside

the pump, which may damage the pump and/or cause steam

to blow off.

Do not operate the unit if abnormal condition is

observed in any actions and movement or in any

parts, components, and others.

Otherwise, it may lead to injury, failures and/or various

accidents.

If you need to carry out work that requires

disassembly of the unit—such as replacement of

parts, repairs, or inspection, ask the vendor or the

service center specified by Teral inc.

If unskilled personnel carry out the work that requires special

knowledge, it may lead to an accident and/or failures.

Caution

Do not use the unit outside the range of the

product specifications.

Otherwise, it may lead to an electric shock, fire, water

leakage, failures, and/or other problems.

Do not use the unit at the power voltage other than

the specification.

An incorrect voltage may damage the control panel.

Do not use a single unit as the only means of

directly operating key facilities or sustaining life.

In the event of a failure, the water supply may stop. Ensure

to make a backup unit readily available.

Do not use the unit to deliver pure water.

Otherwise, pure water may be contaminated with impurities.

Pay special attention to nails when opening the

delivered container.

Otherwise, it may lead to injury and/or damage.

As for the installation environment of the unit,

strictly observe the installation instructions.

Otherwise, it may lead to premature failure.

Ensure that the floor at the unit’s installation place

is waterproofed and fitted with drainage.

Otherwise, it may lead to serious damage in the event of

leakage.

Only after detaching a companion flange from

each pump, screw a pipe into it.

Otherwise, it may lead to damage or water leakage.

Do not merge suction pipes.

Otherwise, it may hinder the normal operation.

Do not use any piping materials that are prone to

rust.

Otherwise, it may damage the unit.

Do not install different or other cables or control

wires in one pipe or duct.

Otherwise, it may damage the unit and/or other equipment.

Provide a ground electrode dedicated to the inflow

solenoid valve.

Otherwise, it does not function normally.

Do not step on the control panel, pump, or pipes.

Otherwise, it may lead to injury, damage, and/or other

problems.

Try to prevent the control panel and the motor from

being sprayed water.

Otherwise, it may lead to an electric shock, electric leak,

failures, and/or other problems.

1-3

Caution

For knockout work and wire insertion work, wear

protective equipment, and pay attention to cut

edges of sheet plates.

Otherwise, you may get injured.

Properly make each setting of the control panel

depending on the conditions of use.

Otherwise, it may hinder the normal operation.

Implement each operation carefully.

Otherwise, it may lead to injury and/or damage.

Carefully open and close the cover of the control

panel with both hands.

Otherwise, it may damage the cover.

Before operation, thoroughly clean (flush) the

inside of the piping.

Otherwise, the piping system may be contaminated with

foreign matter, thus leading to an accident or a pump failure.

Do not run the pump without priming.

Otherwise, it may damage the sliding parts inside the pump.

Do not perform automatic operation with the TJ

valve shut.

Otherwise, it may hinder the normal operation and damage

the unit.

Do not touch the motor body or the cooling fins for

the control panel while the unit is running or

immediately after the unit has stopped.

Otherwise, you may get burns from the hot surface.

Do not cover the motor or the control panel with

cloths or other objects.

Otherwise, it may lead to overheat and/or ignition.

Do not place anything on the water supply unit or

do not step on the unit.

Otherwise, it may lead to injury and/or damage.

In the event of an alarm or abnormal condition that

cannot be resolved, immediately contact Teral Inc.

or its service provider.

Otherwise, it may lead to an accident.

Ensure to carry out inspection according to the

maintenance checklist.

Otherwise, you cannot prevent potential failures, thus

leading to a higher risk of accidents.

Replace the packing and O-rings during inspection

involving disassembly.

Otherwise, it may lead to water leakage.

Before disassembling, shut the suction and

discharge sluice valves, and then discharge

pressured water from the pump and the piping.

Otherwise, water may spurt out, thus leading to an accident.

Do not perform an insulation resistance test on the

control panel. (Before performing an insulation

resistance test on the motor, disconnect electric

wires and cables from the control panel.)

Otherwise, it may damage the control panel.

If you do not use the unit for a long time, turn off

the power, drain water from the inside, and then

store the unit.

Otherwise, it may lead to insulation degradation, freeze

cracking, and/or other problems.

When the water supply unit is used outdoors, fit

the outdoor cover in the special accessories.

Failure to observe this may cause damage to the unit.

If lifting operation is necessary, adopt the unit

specified for lifting operation.

Failure to observe this may cause discharge pressure drop

and lead to a water cutoff.

Do not fit an advance phase capacitor to the

secondary wiring in the control panel.

Failure to observe this may damage the control panel.

2-1

2. Before using the water supply unit

Caution

Make sure that the delivered package is placed right-side up before

unpacking. Pay special attention to nails especially when opening a

wooden crate or you may get injured.

Note

After unpacking, ask the vendor to dispose of packaging materials that

are no longer necessary.

2.1 Points to be checked

When you receive the water supply unit, check the following points immediately after unpacking.

(1) Check the nameplate to verify that the delivered product is exactly what you ordered.

(2) Check that no part of the unit has been damaged during transportation.

(3) Check all fastening parts including bolts and nuts are securely tightened.

(4) Check all the accessories that you ordered have been completely delivered.

2.2 Model type description

᳒ᲧᲯᲪ᳐᳀ᲽᲭᲬᲭᲧᲫᲨᲫ᳑Ყ᳟

ijĬĭĮįİıIJ

Ĭ0:2WOR

ĭ 7PKVFKUEJCTIG PQOKPCNFKCOGVGT

Į'UVKOCVGFVGTOKPCNRTGUUWTGEQPUVCPVEQPVTQN

QHYCVGTUWRRN[WPKV

į 2WORPQOKPCNFKCOGVGT

İ 0QQH

R

WO

R

UVC

I

G

ı 1WVRWV

IJ1RGTCVKQP

ij/QVQT

GHHKEKGPE[

Ჾ

Ჴ#WVQOCVKECNVGTPCVKXGQRGTCVKQP

Ჴ

#

WVQOCVKE

R

CTCNNGNQ

R

GTCVKQP

᳟Ჴ 6QR4WPPGTGHHKEKGPE[

Ტ +'GSWKXCNGPV Უ

/QVQTGSWKRRGF

9

Indicated by 8-digits

alphanumeric

Control panel model

e.g. BQNXC-2W-1.1/1

Indicated by 10-digits alphanumeric

Motor output

e.g. 1.1kW

Unit discharge bore

(mm)

Pump suction bore

(mm)

Unit model

e.g. NX-50VFC323-1.1W-e

Pump model

e.g. UNX323-1.1-e

Pump suction/discharge

bore (mm)

Pump rated current (A)

Indicated by 10-digits

alphanumeric

Motor bearing model

Unit nameplate

(Affixed to the base)

Pump nameplate

(Affixed to the motor)

Control panel nameplate

(Affixed to the control panel)

Fig. 2 Information inscribed on the nameplates

Indicated by 10-digits alphanumeric

3-1

3. Configuration and overview of the water supply unit

This chapter describes standard specifications of the water supply unit. If you have purchased a customized

product, some information in this chapter may not be applicable to your unit. Refer to the separately supplied

delivery specifications and other documents to check the product specifications in such a case.

3.1 Specifications of the water supply unit

Caution

Do not use this unit under any conditions other than those provided in

the specifications. Otherwise, electric shock, fire, water leakage, or

property damage may occur.

Note

If the inflow pump head is 5m or more, contact Teral. for consultation.

Table 3-1 Standard specifications of water supply unit

Operation mode Automatic alternate operation Automatic alternate parallel operation

Control system Constant control of estimated terminal pressure based on frequencies/

Constant control of discharge pressure

Liquid

property Fresh water

Applicable

liquid Temperature 0 to 40°C

Installation location Indoors (0 to 40°C, Max. RH85%, no condensation), Altitude: Max. 1,000m

Suction conditions Inflow (Inflow pump head: Max. 5 m)*

Pump

(Material)

Model NX-e stainless steel horizontal multistage centrifugal pump

(Impeller: SUS304, Casing: SCS13, Main shaft: SUS304)

Type Totally-enclosed fan-cooled type for indoor use

Protection

class IP44

Motor

Number of

poles 2 poles

Companion flange Dedicated companion flange

Power supply 0.4 to 1.1 kW: Single-phase 200/200-220 V (50/60 Hz)

0.4 to 7.5 kW: Three-phase 200/200-220 V (50/60 Hz)

Paint color Common base: Munsell N-5

Pressure tank: Munsell 10Y5.5/0.5

Pressure tank Model DPT10 (10-L diaphragm tank)

Pressure detection

device

Pressure transmitter

Transmission system: 5 VDC, 3-wire system

Output voltage: 0.5 to 3.5 VDC

Model BQNXC type

Motor

Protection Inverter (with electronic thermal protection)

Normal

indications

Indicator status: Power, Pump operation (for each), Pump operation blocked (for each),

Alarm (collective)

Other indications: Discharge pressure, Voltage, Current (for each), Operating frequency

(for each), Cumulative operation time (for each), Cumulative number of

starts (for each), Number of starts of the unit on the previous day, Alarm

log (last 5 alarms)

Alarm

indications

Receiver tank full, Receiver tank low, Dry-run prevention, Electrode failure, Start frequency

failure, Pressure transmitter 1 failure, Control panel high temperature, EEPROM error,

Overload (for each), Discharge pressure abnormal drop (for each), Electric leak (for each),

High temperature (for each), Flow switch failure (for each), Overcurrent (for each),

Overvoltage (for each), Anti-stall (for each), Inverter overload (for each), Open-phase output

(for each), Inverter overheat (for each), Communication failure (for each), Inverter trouble 1

(for each), Inverter trouble 2 (for each)

External

outputs

Power for alarm (at power voltage), Inflow solenoid valve output (at power voltage),

Operation/alarm signal (No-voltage a-contact)

Control

panel

External

inputs External stop signal (interlock): supports a/b-contacts

*The lifting models support up to 4 m in the actual pump head and up to 6 m in the total pump head (at 20°C water temperature).

*If a flush valve or the like is used, a sudden pressure drop may occur, thus leading to the problems such as insufficient water

supply, noise, premature damage of the pressure tank, or others. Contact us for such cases.

3-2

3.2 Names and functions of each part

3.2.1 Names and functions of the components of the water supply unit

䐟Control panel

The control panel controls the pump and supplies the power to the motor.

It enables to start/stop the pump, detects the operating status of the pump and automatically switch the No.

of the pump to run.

Also it enables pump variable speed control by a pressure transmitter signal and thereby estimated

terminal pressure constant control is conducted.

䐠Pump

Its motor rotates an impeller to generate pressure for delivering water.

䐡Pressure transmitter

The pressure transmitter converts pressure into an electric signal so as to use it for control.

䐢Pressure tank

The pressure tank maintains the pressure in the piping and reduces the number of start/stop and pressure

fluctuations of the pump.

䐣Junction pipe

The junction pipe joins the discharge pipes of the two pumps into one pipe.

䐤Discharge elbow

The discharge elbow has a built-in cushion check valve and is equipped with the flow switch㻌䐥

.

䐥Flow switch

The flow switch outputs a signal to stop the pump when the water flow rate is not higher than the setup

(stop) flow rate.

䐦High temperature sensor

If the water temperature is not lower than the setup temperature due to zero-discharge operation, the high

temperature sensor outputs a signal to stop the pump.

䐧Priming plug

This plug is used to prime the pump.

䐨TJ valve

This is a three-way valve used to discharge water from the pressure tank when you carry out the

maintenance of the pressure tank and the pressure transmitter.

䐩Air vent plug of pump

This plug is used to release air from the pump.

䐪Pump drain

This drain is used to discharge water from the pump.

Automatic alternate operation

Automatic alternate parallel operation

Fig. 3-2-1 Water supply unit, Model NX-VFC-e

3-3

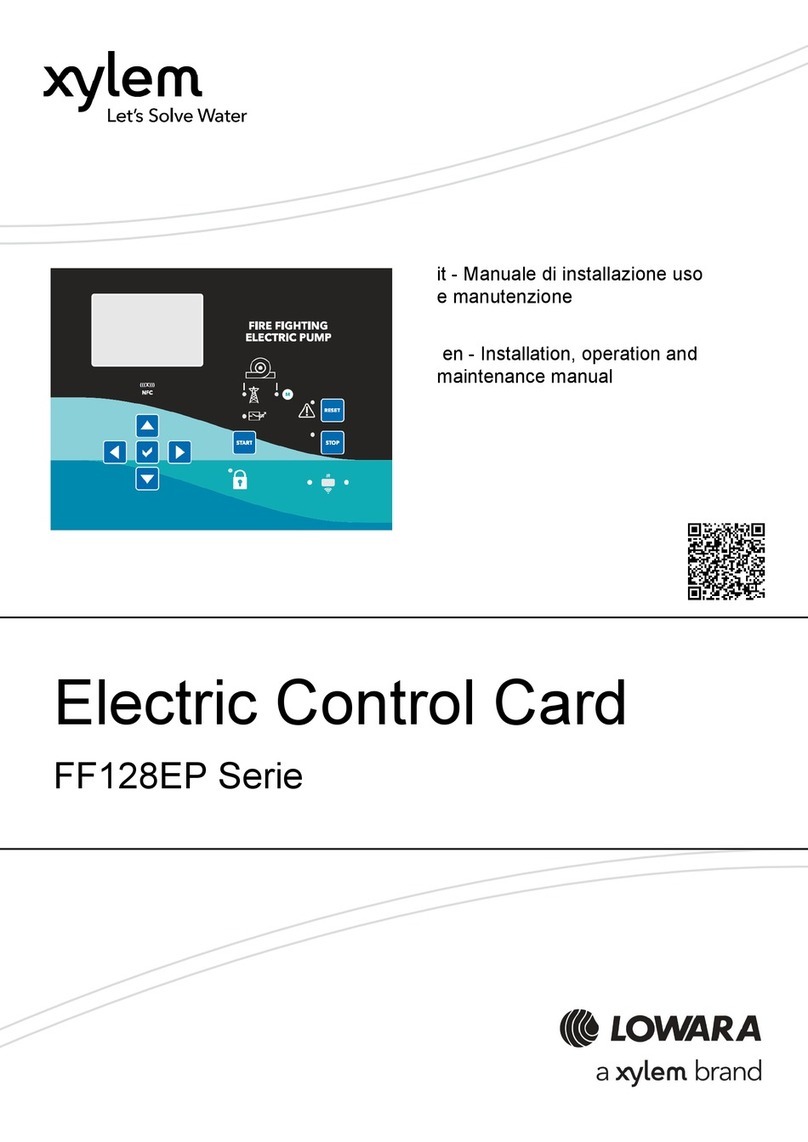

3.2.2 Names and functions of control panel elements

(1) Display

It displays a variety of information about the

water supply unit. (ĺsee 7.4)

(2) Operation selector switch

The switch is to change the operation mode of

the water supply unit. (ĺsee 7.1)

(3) Current mode indicator light

The light is to display the operation mode

currently selected.

(4) Tank selector switch

Press this switch to select the receiver tank(s)

to be used. (ĺsee 7.2)

(5) Current tank indicator light

The indicator light will be on for the receiver

tank currently selected.

(6) Solenoid valve operation selector switch

Press this switch to change the solenoid valve

operation mode. (ĺsee7.3)

(7) Current solenoid valve operation indicator Light

The indicator light will be on for the solenoid valve operation currently selected.

(8) No.1 operation indicator light

The indicator light will be on while the No.1 pump is running, and blinks while the low-flowrate-stop status is

checked in the automatic mode of the No.1 pump.

(9) No.2 operation indicator light

The indicator light will be on while the No.2 pump is running, and blinks while the low-flowrate-stop status is

checked in the automatic mode of the No.2 pump.

(10) No.1 block indicator light and No.2 block indicator light

The indicator light will be on when the Operation Permitted parameter is set to “Operation blocked” for each

pump. (ĺsee 7.5)

(11) Power indicator light

The indicator light will be on while the power is turned ON.

It blinks in the inspection mode (ĺsee 8.2).

(12) Failure indicator light

The indicator light blinks when an alarm occurs.

(13) No. 1 Manual/Confirm switch

Press the switch to run the No.1 pump in the manual mode.

The switch is also used as the “Confirm” switch in the setting and other modes.

(14) No.2 Manual/Back switch

Press the switch to run the No.2 pump in the manual mode.

The switch is also used as the “Back” switch in the setting and other modes.

(15) Reset switch

This switch is used to reset an alarm.

Generated alarms can be reset by pressing the switch once the cause of the alarm is eliminated.

(16) Buzzer stop switch

The switch is used to manually stop the buzzer when an alarm occurs.

The switch is also used in combination with the cursor switch 1 to switch the basic information items on the

display.

(17) Setting switch

The switch is used to switch to or to exit from the setting mode (ĺsee 7.5).

(18) Cursor switch 1

The operating frequency can be changed by pressing the switch in the manual mode of the No.1 pump.

The switch is used to switch the indication items, make the settings, and switch the indication items of the

No.1 pump.

(19) Cursor switch 2

The operating frequency can be changed by pressing this switch in the manual mode of the No.2 pump.

The switch is used to switch the indication items of the No.2 pump.

Reset

Buzzer

stop

Setting

Solenoid

valve

operation

selector

Operation

selector

1 2

1 2

#1 operation

#1 Block

#2 operation

#2 Block

Power

Failure

Manual Stop Auto

Man.

Open

Man.

Close Auto

Confirm

#1 Manual

Back

#2 Manual

12

3

7 6

18

19 17

16

15

12

11

14

13

810

10 9

tank

selector

㻠

No.1 No.2

com

mon

㻡

Fig. 3-2-2 Operation panel on the control panel

3-4

3.2.3 Configuration of the control panel

Warning

Be careful when the control panel is powered on because a high

voltage is running through the parts inside the control panel and it is

very dangerous.

Do not allow any persons other than qualified personnel to open the

cover of the control panel. Otherwise, it may lead to an electric shock.

Caution

Be sure to open or close the cover with both hands to apply roughly the

same amount of force to the right and left sides.

For example, when the cover is opened or closed by using only the

handle on one side, uneven force applied to the right and left sides of

the cover may twist and distort the cover, resulting in disconnection or

damage of the cover.

Caution

When opening the cover, do not let go of the cover until it reaches the

stop position. Otherwise, a resulting impact may damage the cover

and/or other parts.

(1) Opening/closing the cover (for models with a

motor output of up to 3.7 kW)

cOpen the cover.

Put your hands on the handles on the right

and left sides of the cover, and pull the

cover toward you with both hands. At that

time, ensure that roughly the same amount

of force is applied to the right and left sides.

Do not let go of the cover until it reaches

the stop position

dClose the cover.

Put your hands on the areas around the

right and left handles of the cover, and lift

the cover with both hands to close it.

Firmly press the cover until the latch is

securely locked in place.

Fig. 3-2-3(a)

How to open the cover of the control panel

(For the models with a motor output of up to 3.7 kW)

(2) Components

Handle

Stop position

Main unit side

(Output: up to 3.7 kW)

Main unit side

(Output: 5.5, 7.5 kW)

Operation board I/O terminal block

Control board

DCR2

(Back side)

DCR1

(Back side)

Cover side

(Output: up to 3.7 kW) I/O terminal block

Protective cover

Operation board

Control board

Designations of components

TB1 Power terminal block

INV1, 2 Inverter

ELCB1, 2 Ground fault interrupter

DCR1, 2 Power-factor correcting reactor (option)

RNF1, 2 Radio noise filter

Fig. 3-2-3(b) Components in the control panel

3-5

3.2.4 Control board

The following are the details of the control board.

Warning

Do not remove the protective cover on the control board or the cover of

the I/O terminal block when the power is turned on.

Otherwise, it may lead to an electric shock.

Table 3-2-4 (a) Connector assignments

No. Connected to No. Connected to No. Connected to

CN1 Device in panel CN7 Device in panel CN13 Flow switch No.2

CN2 (Not in use) CN8 Device in panel CN14 (Not in use)

CN3 Device in panel CN9 (Not in use) CN15 Control panel

high-temperature sensor *1

CN4 Device in panel CN10 Pressure transmitter CN16 High-temperature sensor

No.1

CN5 (Not in use) CN11 (Not in use) CN17 High-temperature sensor

No.2

CN6 Device in panel CN12 Flow switch No.1 CN18 Low-temperature sensor *2

*1 For models fitted with outdoor cover, this sensor is connected depending on the specifications.

*2 The low-temperature sensor is connected only to freeze-proof models (special specifications).

Table 3-2-4 (b) Designations and applications of I/O terminal block

Designation Application Designation Application

IL1, IL2 Interlocking signal B1 to B5 Alarm signal output

1E0 to 1E4 Receiver tank No.1 level detection

electrode BC Alarm signal output common

2E0 to 2E4 Receiver tank No.2 level detection

electrode VR, VT Alarm power (power voltage)

1N1, 1N2 Receiver tank No.1 solenoid valve

control electrode RH, TH*3Freeze-proof heater (power voltage)

2N1, 2N2 Receiver tank No.2 solenoid valve

control electrode SVC, SV1 Receiver tank No.1 solenoid valve

(power voltage)

M1, M2 No.1, No.2 operation signal SVC, SV2 Receiver tank No.2 solenoid valve

(power voltage)

MC Operation signal common

*3 The freeze-proof heaters are connected only to freeze-proof models (special specifications).

I/O terminal block

Operation

power

switch

Control board

Fig. 3-2-4 Detailed drawing of control board

3-6

3.3 Specifications of control panel

Table 3-3 Specifications of control panel

Item Specifications 1 Specifications 2

Control panel model BQNXC

Operation mode Automatic alternate/automatic alternate parallel

0.4 to 3.7 kW: ACS resin (light gray/material color) +

steel plate (highly corrosion-resistant hot-dip plating)

Material and external color of casing 5.5, 7.5 kW: steel plate (Munsell 5Y7/1

semigloss/baking finish)

Single-phase 200/200-220 V (50/60 Hz) 0.4 to 1.1 kW

Output Range Three-phase 200/200-220 V (50/60 Hz) 0.4 to 7.5 kW

Ground fault interrupter Individual pump systems S

Power-factor correcting reactor (DCR) Individual pump systems 㸫S

Motor protection 㸫Inverter (electronic thermal protection)

Double receiver tank circuit Can be switched on the operation panel S

Inflow solenoid valve circuit Can be operated on the operation panel S

Circuit

configuration

Electrode 5P circuit 㸫S

Dry-run prevention 㸫S

Automatic switching upon failure 㸫S

Pump continuous operation prevention function 㸫S

Pump operation time equalization function 㸫S

Freeze-proof operation function 㸫O

External stop signal (interlock) available a/b-contact available S

Buzzer stop timer setting 1 to 60 min, , no buzzer S

Full/low water alarm automatic recovery setting 㸫S

Inflow solenoid valve automatic alternation setting 㸫S

Inspection mode 㸫S

Alarm buzzer 㸫S

Buzzer stop switch 㸫S

Functions

Energy-saving operation setting 㸫S

Power 㸫S

Operation (for each pump) 㸫S

Block (for each pump) 㸫S

Indicator

li

g

h

t

Alarm (collective) 㸫S

Discharge pressure Unit: mH2O S

Power voltage Unit: V S

Operation current (for each pump) Unit: 0.1 A S

Operation frequency (for each pump) Unit: 0.1 Hz (only automatic) S

Cumulative operation time (for each pump) Unit: Hour S

Cumulative number of starts (for each pump) Unit: times S

Number of starts time of the unit Number of starts on the previous day S

Alarm log 5 latest alarms S

Interlocking in operation 㸫S

Various indications

Freeze-proofing in progress 㸫O

Receiver tank full No: E001 S

Receiver tank low No: E002 S

Dry-run prevention No: E003 S

Electrode failure No: E004 S

Start frequency failure No: E006 S

Pressure transmitter 1 failure No: E051 S

Control panel high temperature No: E070 O

EEPROM error No: E080 S

Overload (for each pump) No: E#01 S

Discharge pressure abnormal drop (for each pump) No: E#02 S

Electric leak (for each pump) No: E#03 S

High temperature (for each pump) No: E#04 S

Flow switch failure (for each pump) No: E#05 S

Overcurrent (for each pump) No: E#11 S

Overvoltage (for each pump) No: E#12 S

Anti-stall (for each pump) No: E#14 S

Inverter overload (for each pump) No: E#15 S

Open-phase output (for each pump) No: E#16 S

Inverter overheat (for each pump) No: E#17 S

Inverter communication failure (for each pump) No: E#18 S

Inverter trouble 1 (for each pump) No: E#19 S

Indications on control panel

Alarm indications

Inverter trouble 2 (for each pump) No: E#20 S

Power for alarm Power voltage S

Freeze-proof heater output Power voltage O

Inflow solenoid valve output Power voltage S (Normally open/closed type available)

Operation signal No-voltage a-contact S (for each)

External

output

Error signal No-voltage a-contact S (5 points: patterns 0 to 4)

“S” indicates standard features, and “O” indicates optional features.

*1 Power voltage and operation current values are estimated values. There is an error of approximately 10% with

respect to the full scale.

*2 “E006” and “E#04” can be disabled using settings. Refer to “7.5 Parameter setting.”

*3 The character “#” is replaced by the corresponding pump number.

*4 The open-phase output error is detected by only the units with the rated output of 5.5 kW or more.

*5 For the patterns to output error signals using external relays, refer to “7.5 Parameter setting.”

3-7

3.4 Specification tables

3.4.1 Standard models (boost models)

Automatic alternate operation <boost models>

Nominal diameter

mm Standard specifications Specified ranges

Suction

condition Pump

suction

Unit

discharge

Model Output

kW

Phase/Voltage

VMaximum

water

supply

m3/min

Total

head

m

Minimum

sustained

head

m

Stop pressure

(approximate

value)

MPa (kgf/cm2)

Water supply

m3/min

Discharge

head

selection

range

m

Pressure tank

pre-charge

pressure

MPa (kgf/cm2)

NX-VFC252-0.4S2D-e 0.4 0.06 23 20 0.25 (2.5) 0.02–0.09 15–27 0.13 (1.3)

NX-VFC252-0.75S2D-e 0.75 0.06 34 29 0.33 (3.4) 0.02–0.09 23-40 0.19 (1.9)

25 25

NX-VFC253-1.1S2D-e 1.1 0.06 55 47 0.54 (5.5) 0.02–0.09 37–64 0.31 (3.2)

NX-VFC322-0.4S2D-e 0.4 0.1 16 14 0.19 (1.9) 0.02–0.11 12–27 0.10 (1.0)

NX-VFC322-0.75S2D-e 0.75 0.1 24 20 0.25 (2.5) 0.02–0.15 15–31 0.12 (1.2)

32 32

NX-VFC323-1.1S2D-e 1.1 0.1 41 35 0.40 (4.1) 0.02–0.15 26–52 0.23 (2.3)

40 40 NX-VFC401-1.1S2D-e 1.1

Single-phase

200 (50 Hz),

single-phase

200 (60 Hz)

0.2 20 17 0.22 (2.2) 0.02–0.26 15–28 0.13 (1.3)

NX-VFC252-0.4D-e 0.4 0.06 23 20 0.25 (2.5) 0.02–0.09 15–27 0.13 (1.3)

NX-VFC252-0.75D-e 0.75 0.06 34 29 0.33 (3.4) 0.02–0.09 23–40 0.20 (2.0)

25 25

NX-VFC253-1.1D-e 1.1 0.06 55 47 0.54 (5.5) 0.02–0.09 37–64 0.31 (3.2)

NX-VFC322-0.4D-e 0.4 0.1 16 14 0.19 (1.9) 0.02–0.11 12–27 0.10 (1.0)

NX-VFC322-0.75D-e 0.75 0.1 26 22 0.26 (2.7) 0.02–0.15 15–33 0.13 (1.3)

NX-VFC323-1.1D-e 1.1 0.1 41 35 0.40 (4.1) 0.02–0.15 26–52 0.23 (2.3)

NX-VFC323-1.5D-e 1.5 0.1 50 43 0.49 (5.0) 0.02–0.15 33–60 0.28 (2.9)

32 32

NX-VFC324-2.2D-e 2.2 0.1 67 57 0.66 (6.7) 0.02–0.15 45–80 0.39 (4.0)

NX-VFC401-1.1D-e 1.1 0.2 20 17 0.22 (2.2) 0.02–0.26 15–28 0.13 (1.3)

NX-VFC402-1.5D-e 1.5 0.2 30 26 0.30 (3.1) 0.02–0.28 21–40 0.18 (1.8)

NX-VFC402-2.2D-e 2.2 0.2 42 36 0.41 (4.2) 0.02–0.28 30–57 0.25 (2.6)

NX-VFC402-3.7D-e 3.7 0.2 57 48 0.56 (5.7) 0.02–0.30 37–67 0.31 (3.2)

NX-VFC403-3.7D-e 3.7 0.2 65 55 0.64 (6.5) 0.02–0.30 45–80 0.39 (4.0)

40 40

NX-VFC403-5.5D-e 5.5 0.2 79 67 0.77 (7.9) 0.02–0.30 50–90 0.44 (4.5)

NX-VFC501-1.5D-e 1.5 0.3 16 14 0.19 (1.9) 0.02–0.38 12–22 0.10 (1.0)

NX-VFC502-2.2D-e 2.2 0.3 27 23 0.27 (2.8) 0.02–0.38 18–42 0.16 (1.6)

NX-VFC502-3.7D-e 3.7 0.3 48 41 0.47 (4.8) 0.02–0.44 30–65 0.25 (2.6)

NX-VFC503-5.5D-e 5.5 0.3 65 55 0.64 (6.5) 0.02–0.44 41–90 0.35 (3.6)

50 50

NX-VFC503-7.5D-e 7.5 0.3 76 65 0.75 (7.6) 0.02–0.45 50–90 0.44 (4.5)

NX-VFC652-3.7D-e 3.7 0.45 26 22 0.26 (2.7) 0.02–0.56 18–38 0.15 (1.5)

NX-VFC652-5.5D-e 5.5 0.45 41 35 0.40 (4.1) 0.02–0.56 30–57 0.25 (2.6)

Boost models

65 65

NX-VFC653-7.5D-e 7.5

Three-phase

200 (50 Hz),

three-phase

200/220 (60 Hz)

0.45 58 49 0.57 (5.8) 0.02–0.58 41–80 0.35 (3.6)

Automatic alternate parallel operation <boost models>

Nominal diameter

mm Standard specifications Specified ranges

Suction

condition Pump

suction

Unit

discharge

Model Output

kW

Phase/Voltage

VMaximum

water

supply

m3/min

Total

head

m

Minimum

sustained

head

m

Stop pressure

(approximate

value)

MPa (kgf/cm2)

Water supply

m3/min

Discharge

head

selection

range

m

Pressure tank

pre-charge

pressure

MPa (kgf/cm2)

NX-40VFC252-0.4S2W-e 0.4 0.12 22 19 0.24 (2.4) 0.04–0.18 15–27 0.13 (1.3)

NX-40VFC252-0.75S2W-e 0.75 0.12 34 29 0.33 (3.4) 0.04–0.18 23-40 0.19 (1.9)

25 40

NX-40VFC253-1.1S2W-e 1.1 0.12 54 46 0.53 (5.4) 0.04–0.18 37–64 0.31 (3.2)

NX-50VFC322-0.4S2W-e 0.4 0.2 16 14 0.19 (1.9) 0.04–0.23 12–27 0.10 (1.0)

NX-50VFC322-0.75S2W-e 0.75 0.2 23 20 0.25 (2.5) 0.04–0.30 15–31 0.12 (1.2)

32 50

NX-50VFC323-1.1S2W-e 1.1 0.2 41 35 0.40 (4.1) 0.04–0.30 26–52 0.23 (2.3)

40 65 NX-65VFC401-1.1S2W-e 1.1

Single-phase

200 (50 Hz),

single-phase

200 (60 Hz)

0.4 19 16 0.21 (2.1) 0.04–0.52 15–28 0.13 (1.3)

NX-40VFC252-0.4W-e 0.4 0.12 22 19 0.24 (2.4) 0.04–0.18 15–27 0.13 (1.3)

NX-40VFC252-0.75W-e 0.75 0.12 34 29 0.33 (3.4) 0.04–0.18 23–40 0.20 (2.0)

25 40

NX-40VFC253-1.1W-e 1.1 0.12 54 46 0.53 (5.4) 0.04–0.18 37–64 0.31 (3.2)

NX-50VFC322-0.4W-e 0.4 0.2 16 14 0.19 (1.9) 0.04–0.23 12–27 0.10 (1.0)

NX-50VFC322-0.75W-e 0.75 0.2 25 21 0.25 (2.6) 0.04–0.30 15–33 0.13 (1.3)

NX-50VFC323-1.1W-e 1.1 0.2 41 35 0.40 (4.1) 0.04–0.30 26–52 0.23 (2.3)

NX-50VFC323-1.5W-e 1.5 0.2 50 43 0.49 (5.0) 0.04–0.30 33–60 0.28 (2.9)

32 50

NX-50VFC324-2.2W-e 2.2 0.2 67 57 0.66 (6.7) 0.04–0.30 45–80 0.39 (4.0)

NX-65VFC401-1.1W-e 1.1 0.4 19 16 0.21 (2.1) 0.04–0.52 15–28 0.13 (1.3)

NX-65VFC402-1.5W-e 1.5 0.4 29 25 0.29 (3.0) 0.04–0.56 21–40 0.18 (1.8)

NX-65VFC402-2.2W-e 2.2 0.4 41 35 0.40 (4.1) 0.04–0.56 30–57 0.25 (2.6)

NX-65VFC402-3.7W-e 3.7 0.4 57 48 0.56 (5.7) 0.04–0.60 37–67 0.31 (3.2)

NX-65VFC403-3.7W-e 3.7 0.4 65 55 0.64 (6.5) 0.04–0.60 45–80 0.39 (4.0)

40 65

NX-65VFC403-5.5W-e 5.5 0.4 78 66 0.76 (7.8) 0.04–0.60 50–90 0.44 (4.5)

NX-65VFC501-1.5W-e 1.5 0.6 15 13 0.18 (1.8) 0.04–0.74 12–22 0.10 (1.0)

NX-65VFC502-2.2W-e 2.2 0.6 27 23 0.27 (2.8) 0.04–0.75 18–42 0.16 (1.6)

NX-65VFC502-3.7W-e 3.7 0.6 48 41 0.47 (4.8) 0.04–0.87 30–65 0.25 (2.6)

NX-65VFC503-5.5W-e 5.5 0.6 65 55 0.64 (6.5) 0.04–0.87 41–90 0.35 (3.6)

50 65

NX-65VFC503-7.5W-e 7.5 0.6 76 65 0.75 (7.6) 0.04–0.90 50–90 0.44 (4.5)

NX-80VFC652-3.7W-e 3.7 0.9 25 21 0.25 (2.6) 0.04–1.08 18–38 0.15 (1.5)

NX-80VFC652-5.5W-e 5.5 0.9 39 33 0.38 (3.9) 0.04–1.09 30–57 0.25 (2.6)

Boost models

65 80

NX-80VFC653-7.5W-e 7.5

Three-phase

200

0.9 57 48 0.56 (5.7) 0.04–1.13 41–80 0.35 (3.6)

3-8

3.4.2 Special models (lifting models)

Automatic alternate operation <lifting models>

Nominal diameter

mm Standard specifications Specified ranges

Suction

condition Pump

suction

Unit

discharge

Model Output

kW

Phase/Voltage

VMaximum

water

supply

m3/min

Total

head

m

Minimum

sustained

head

m

Stop pressure

(approximate

value)

MPa (kgf/cm2)

Water supply

m3/min

Discharge

head

selection

range

m

Pressure tank

pre-charge

pressure

MPa (kgf/cm2)

NX-VFC252-0.4S2D-e 0.4 0.06 21 18 0.23 (2.3) 0.02–0.09 15–26 0.10 (1.0)

NX-VFC252-0.75S2D-e 0.75 0.06 32 27 0.31 (3.2) 0.02–0.09 20-39 0.16 (1.6)

25 25

NX-VFC253-1.1S2D-e 1.1 0.06 51 43 0.50 (5.1) 0.02–0.09 33–62 0.28 (2.9)

NX-VFC322-0.75S2D-e 0.75 0.1 22 19 0.24 (2.4) 0.02–0.14 15–30 0.12 (1.2)

32 32 NX-VFC323-1.1S2D-e 1.1 0.1 39 33 0.38 (3.9) 0.02–0.14 25–51 0.22 (2.2)

40 70 NX-VFC401-1.1S2D-e 1.1

Single-phase

200 (50 Hz),

single-phase

200 (60 Hz)

0.2 19 16 0.21 (2.1) 0.02–0.25 15–27 0.10 (1.0)

NX-VFC252-0.4D-e 0.4 0.06 21 18 0.23 (2.3) 0.02–0.09 15–26 0.10 (1.0)

NX-VFC252-0.75D-e 0.75 0.06 32 27 0.31 (3.2) 0.02–0.09 20–39 0.17 (1.7)

25 25

NX-VFC253-1.1D-e 1.1 0.06 51 43 0.50 (5.1) 0.02–0.09 33–62 0.28 (2.9)

NX-VFC322-0.75D-e 0.75 0.1 24 20 0.25 (2.5) 0.02–0.15 15–32 0.13 (1.3)

NX-VFC323-1.1D-e 1.1 0.1 39 33 0.38 (3.9) 0.02–0.14 25–51 0.22 (2.2)

NX-VFC323-1.5D-e 1.5 0.1 48 41 0.47 (4.8) 0.02–0.15 30–59 0.25 (2.6)

32 32

NX-VFC324-2.2D-e 2.2 0.1 65 55 0.64 (6.5) 0.02–0.15 42–79 0.36 (3.7)

NX-VFC401-1.1D-e 1.1 0.2 19 16 0.21 (2.1) 0.02–0.25 15–27 0.10 (1.0)

NX-VFC402-1.5D-e 1.5 0.2 28 24 0.28 (2.9) 0.02–0.28 19–40 0.16 (1.6)

NX-VFC402-2.2D-e 2.2 0.2 40 34 0.39 (4.0) 0.02–0.28 28–57 0.25 (2.5)

NX-VFC402-3.7D-e 3.7 0.2 56 48 0.55 (5.6) 0.02–0.30 34–66 0.29 (3.0)

NX-VFC403-3.7D-e 3.7 0.2 63 54 0.62 (6.3) 0.02–0.30 42–80 0.36 (3.7)

40 40

NX-VFC403-5.5D-e 5.5 0.2 78 66 0.76 (7.8) 0.02–0.30 47–90 0.41 (4.2)

NX-VFC501-1.5D-e 1.5 0.3 15 13 0.18 (1.8) 0.02–0.31 15–22 0.08 (0.8)

NX-VFC502-2.2D-e 2.2 0.3 27 23 0.27 (2.8) 0.02–0.40 15–42 0.13 (1.3)

NX-VFC502-3.7D-e 3.7 0.3 47 40 0.46 (4.7) 0.02–0.44 28–65 0.25 (2.5)

NX-VFC503-5.5D-e 5.5 0.3 63 54 0.62 (6.3) 0.02–0.44 39–90 0.34 (3.5)

50 50

NX-VFC503-7.5D-e 7.5 0.3 75 64 0.74 (7.5) 0.02–0.45 47–90 0.41 (4.2)

NX-VFC652-3.7D-e 3.7 0.45 25 21 0.25 (2.6) 0.02–0.58 16–37 0.14 (1.4)

NX-VFC652-5.5D-e 5.5 0.45 40 34 0.39 (4.0) 0.02–0.57 28–56 0.25 (2.5)

Lifting models

65 65

NX-VFC653-7.5D-e 7.5

Three-phase

200 (50 Hz),

three-phase

200/220 (60 Hz)

0.45 57 48 0.56 (5.7) 0.02–0.57 41–79 0.35 (3.6)

Automatic alternate parallel operation <lifting models>

Nominal diameter

mm Standard specifications Specified ranges

Suction

condition

Pump

suction

Unit

discharge

Model Output

kW

Phase/Voltage

VMaximum

water

supply

m3/min

Total

head

m

Minimum

sustained

head

m

Stop pressure

(approximate

value)

MPa (kgf/cm2)

Water supply

m3/min

Discharge

head

selection

range

m

Pressure tank

pre-charge

pressure

MPa (kgf/cm2)

NX-40VFC252-0.4S2W-e 0.4 0.12 21 18 0.23 (2.3) 0.04–0.17 15–26 0.10 (1.0)

NX-40VFC252-0.75S2W-e 0.75 0.12 32 27 0.31 (3.2) 0.04–0.18 20-39 0.16 (1.6)

25 4

NX-40VFC253-1.1S2W-e 1.1 0.12 51 43 0.50 (5.1) 0.04–0.18 33–62 0.28 (2.9)

NX-50VFC322-0.75S2W-e 0.75 0.2 22 19 0.24 (2.4) 0.04–0.29 15–30 0.12 (1.2)

32 50 NX-50VFC323-1.1S2W-e 1.1 0.2 38 32 0.37 (3.8) 0.04–0.29 25–51 0.22 (2.2)

40 65 NX-65VFC401-1.1S2W-e 1.1

Single-phase

200 (50 Hz),

single-phase

200 (60 Hz)

0.4 19 16 0.21 (2.1) 0.04–0.50 15–27 0.10 (1.0)

NX-40VFC252-0.4W-e 0.4 0.12 21 18 0.23 (2.3) 0.04–0.17 15–26 0.10 (1.0)

NX-40VFC252-0.75W-e 0.75 0.12 32 27 0.31 (3.2) 0.04–0.18 20–39 0.17 (1.7)

25 40

NX-40VFC253-1.1W-e 1.1 0.12 51 43 0.50 (5.1) 0.04–0.18 33–62 0.28 (2.9)

NX-50VFC322-0.75W-e 0.75 0.2 24 20 0.25 (2.5) 0.04–0.29 15–32 0.13 (1.3)

NX-50VFC323-1.1W-e 1.1 0.2 38 32 0.37 (3.8) 0.04–0.29 25–51 0.22 (2.2)

NX-50VFC323-1.5W-e 1.5 0.2 47 40 0.46 (4.7) 0.04–0.30 30–59 0.25 (2.6)

32 50

NX-50VFC324-2.2W-e 2.2 0.2 64 54 0.63 (6.4) 0.04–0.30 42–79 0.36 (3.7)

NX-65VFC401-1.1W-e 1.1 0.4 19 16 0.21 (2.1) 0.04–0.50 15–27 0.10 (1.0)

NX-65VFC402-1.5W-e 1.5 0.4 28 24 0.28 (2.9) 0.04–0.57 19–40 0.16 (1.6)

NX-65VFC402-2.2W-e 2.2 0.4 40 34 0.39 (4.0) 0.04–0.57 28–57 0.25 (2.5)

NX-65VFC402-3.7W-e 3.7 0.4 56 48 0.55 (5.6) 0.04–0.60 34–66 0.29 (3.0)

NX-65VFC403-3.7W-e 3.7 0.4 63 54 0.62 (6.3) 0.04–0.60 42–80 0.36 (3.7)

40 65

NX-65VFC403-5.5W-e 5.5 0.4 78 66 0.76 (7.8) 0.04–0.60 47–90 0.41 (4.2)

NX-65VFC501-1.5W-e 1.5 0.6 15 13 0.18 (1.8) 0.04–0.60 15–22 0.08 (0.8)

NX-65VFC502-2.2W-e 2.2 0.6 26 22 0.26 (2.7) 0.04–0.78 15–42 0.13 (1.3)

NX-65VFC502-3.7W-e 3.7 0.6 47 40 0.46 (4.7) 0.04–0.87 28–65 0.25 (2.5)

NX-65VFC503-5.5W-e 5.5 0.6 63 54 0.62 (6.3) 0.04–0.87 39–90 0.34 (3.5)

50 65

NX-65VFC503-7.5W-e 7.5 0.6 74 63 0.73 (7.4) 0.04–0.90 47–90 0.41 (4.2)

NX-80VFC652-3.7W-e 3.7 0.9 24 20 0.25 (2.5) 0.04–1.10 16–37 0.14 (1.4)

NX-80VFC652-5.5W-e 5.5 0.9 38 32 0.37 (3.8) 0.04–1.10 28–56 0.25 (2.5)

Lifting models

60 80

NX-80VFC653-7.5W-e 7.5

Three-phase

200 (50 Hz),

three-phase

200/220 (60 Hz)

0.9 56 48 0.55 (5.6) 0.04–1.11 41–79 0.35 (3.6)

4-1

4. Installation

4.1 Precautions for installation

Warning

When moving or installing the unit, never lift it in an unstable condition

or with any load applied to the pressure tank, pipes, or control panel.

Otherwise, the unit may fall, resulting in injury and/or damage.

Before lifting the unit, refer to the catalog, the external dimensions

drawing, or other documents to check the weight of the unit, and use an

appropriate lifting device of which rated load is over the the unit.

Otherwise, the unit may fall, resulting in injury and/or damage.

Caution

For the installation environment, follow the precautions described

below. Otherwise, it may lead to failures and/or other problems as well

as a shorter life of the units.

Caution

This water supply unit is designed for indoor use. For outdoor use,

install the outdoor hood, which is available as a special accessory.

Otherwise, it may lead to failures.

Caution

To suck up water from a lower position, use a water supply unit

designed for lifting operation.

Otherwise, discharge pressure may drop, thus leading to disruption of

water supply.

(1) Install the unit at a place that meets the following conditions:

· a place that meets the requirements in Section “3.1 Specifications of the water supply unit “;

· a place that is not exposed to the wind or rain;

· a dry, well-ventilated environment, which as free of dust or moisture as possible;

· a location where unauthorized persons cannot easily enter or operate the product;

· a location as close to the water source as possible so that the suction pipe can be short.; and

· a location where mainance can be conducted easily and abnormality can be readily coped with.

(2) Fix the water supply unit firmly on a level concrete foundation with anchor bolts.

(3) Be sure to provide a drain ditch around the water supply unit, and waterproof the floor.

(4) If the system could be exposed to the freezing temperature in winter, be sure to take measures to prevent

freezing in the pump room or prevent the pump, valves, piping, pressure transmitter, pressure tank, and

other devices from freezing. We can offer the special models designed to prevent freezing. Contact us.

(5) Use sound insulating materials for the door and walls of the pump room. Particularly when generated noise

may pose a problem, take necessary measures against the noise.

(6) If you need to lift the water supply unit (with motor output: up to 3.7 kW), attach four eyebolts as shown in

the following figure. Separately place an order for the eyebolts as they are optional.

When the motor output is 5.5 or 7.5 kW, there are lifting holes in the common base.

Place cushioning materials to prevent damage to the unit.

(7) If the unit is operated for a long time at low flow rate, a pressure relieving device might be necessary.

Please contact us.

*1) Eyebolt installation diagram

(Pump side)

*2) Eyebolt installation diagram

(Motor side)

Eyebolts

Nut Weld nut

Fig. 4-1 For models with a motor output of up to 3.7 kW

4-2

4.2 Precautions for piping work

Caution

Do not screw a pipe into the pump with the companion flange attached

to the pump. Otherwise, it may damage the pump.

Caution

Do not merge the suction pipes. Do not install the piping with a shape

of upward bend (i.e. providing the piping with a rising slope and then a

descending slope).

Otherwise, it may hinder the normal operation.

Caution

Do not use any piping materials that are prone to rust.

Otherwise, it may damage the unit.

Caution

After work, thoroughly clean (flush) the inside of the receiver tank and

piping.

(1) Attach a companion flange cto the water supply unit after connecting the pipe.

(2) Install an adequate pipe support dso that the weight of the piping system will not be applied to the main

unit.

(3) For test operation and adjustments, be sure to attach sluice valves fand a test pipe gto the discharge

pipe e.

(4) Ensure to install a suction pipe hto each pump.

(5) The suction pipes hmust be as short and straight as possible with minimal bends.

(6) To minimize the piping loss, the bore of the suction pipes hmust be equal to or one size larger than that of

the pump. Pay special attention to an automatic alternate parallel operation type because the flow rate of

the subsequently activated pump exceeds half the maximum flow rate of water to be used.

(7) For maintenance, be sure to attach sluice valves ito the suction pipes h.

(For lifting models, do not attach sluice valves ito the suction pipes.)

(8) Ensure to attach strainers jto the ends of the suction pipes hin order to block the entrance of foreign

matter.

(9) After piping work, be sure to clean the inside of a receiver tank kto prevent the entry of foreign matter into

the pumps.

<Example of piping work>

Maintenance space

Min. 600 mm

Maintenance space

Min. 900 mm

(Control panel side)

Maintenance space

Min. 600 mm

Vibration-isolating

joint

Receiver tank

Maintenance space

Min. 600 mm

Vibration-isolating frame

(Special accessory)

Drain ditch

Note: The minimum maintenance spaces shown here are

the manufacturer’s recommended values.

Fig. 4-2 Example of piping work (for boost models)

Drain ditch

4-3

4.3 Precautions for wiring work

Warning

Use the wiring equipment and devices compliant to use conditions, and

carry out wiring work safely and securely according to the technical

standards for electrical facilities, as well as the indoor wiring

regulations.

Only qualified personnel such as licensed electrical engineers are

allowed to carry out electric wiring work.

Incomplete wiring work by unqualified persons is prohibited by law.

4.3.1 Wiring work for power supply

Warning

Be sure to install a ground fault interrupter dedicated to this unit at the

primary power supply. Otherwise, it may lead to an electric shock

and/or fire.

Warning

Ensure to securely install a ground wire to the control panel. Ensure to

perform grounding work.

Warning

Connecting a ground wire to gas or water pipes is not only prohibited

by law but also extremely dangerous.

Caution

Do not install different or other cables or control wires in one pipe or

conduit.

Caution

Do not attach a phase advance capacitor to the secondary wiring of the

control panel.

Otherwise, it may lead to failures in the inverter or the phase advance

capacitor.

(1) On the primary power supply side of the water supply unit, be sure to install a ground fault interrupter

dedicated to this unit.

Check the capacity of the ground fault interrupter fitted inside the control panel, and then select a ground

fault interrupter on the power supply side in consideration of protection coordination.

(2) Be sure to attach a ground wire to prevent an electric shock.

Connect the ground wire to the ground terminal inside the control panel.

(3) Connect the primary power line to the power terminal block inside the control panel.

Pass each wire through a metal tube or a metal conduit for shielding, and ground the covering of the tube.

(4) Control the fluctuation of the voltage within ±10% of the rated voltage, and the frequency within ±5% of the

rated frequency.

Keep in mind that if you use the unit at a voltage or frequency out of the range, the unit may break down.

Also note that if the power voltage is lower than the rated voltage, an overload may occur even if the flow

rate is within the specified range.

(5) Before running the pump, check the following points again:

xAn appropriate ground fault interrupter is installed.

xWiring is correct.

xThe unit is securely grounded.

xNone of the three wires (two wires for single-phase power) of the motor has come loose or is

disconnected.

Note that poor or incorrect connection of motor terminals may burn out the motor.

4-4

4.3.2 Instrumentation

Carry out wiring work for instrumentation according to the following procedure:

Connect all the wires for instrumentation (hereafter “the instrumentation wires”) to the terminal block on the

control board.

For the models with a motor output of up to 3.7kW, observe the following instructions on connecting the

wires to the control board.

cUse highly flexible electric wires for instrumentation.

dInsert the instrumentation wires into the inlet ports for instrumentation wires, pass them through either

side of the cover, and then connect them to the board.

The inlet ports for instrumentation wires are knockout openings.

Caution

For knockout work and wire insertion work, be sure to wear protective

clothing such as gloves. Otherwise you may get injured by the cut

edges of the sheet plate.

Attach grommets (22 mm in diameter) to the wire inlet ports to protect

the wires, or use conduit tubes.

eTie and fix the instrumentation wires to the right and left sides of two places (i.e. the sheet plate of the

main unit and the cover; thus four places in total). Plastic cable ties are provided with the unit.

(1) Wiring work for water level control

Referring to the following table, connect wires to receiver tank electrodes.

· Ball tap type ··································Table 4-3-2(a)

· Inflow solenoid valve type ·················Table 4-3-2(b)

Note

· The Tank Selection setting is set to “No tank” before shipment. Before

starting the operation of the pumps with receiver tank electrodes connected,

select water tank(s) you use on the operation panel. (ĺsee 7.2.)

· When using an inflow solenoid valve, check the type of the solenoid valve

(normally open or normally closed), and set the type (parameter P103).

(ĺsee 7.5.)

· Set the Solenoid Valve Operation setting to “Auto” on the operation panel

before use. (ĺsee 7.3.)

6 inlet ports for instrumentation wires

Run the wires through either side.

Tie the wires at two places each

on the ri

g

ht and left sides.

Fig. 4-3-2 (a) Connections for instrumentation wires (for motor output of up to 3.7 kW)

4-5

Table 4-3-2 (a) Wiring patterns (ball tap type)

Single receiver tank Double receiver tank

Settings

Tank Selection setting: No.1

Solenoid Valve Operation setting:

Man. Close

Parameter P101: 4

Tank Selection setting: Common

Solenoid Valve Operation setting: Man. Close

Parameter P101: 4

4P type electrode

Wiring pattern

Terminal block for receiver tank No.1

Electrodes for receiver tank

Terminal block for receiver tank No.1

Electrodes for receiver tank No.1

Terminal block for receiver tank No.2

Electrodes for receiver tank No.2

Settings

Tank Selection setting: No.1

Solenoid Valve Operation setting:

Man. Close

Parameter P101: 5

Tank Selection setting: Common

Solenoid Valve Operation setting: Man. Close

Parameter P101: 5

5P type electrode

Wiring pattern

Terminal block for receiver tank No.1

Electrodes for receiver tank

Terminal block for receiver tank No.1

Electrodes for receiver tank No.1

Terminal block for receiver tank No.2

Electrodes for receiver tank No.2

Wires

Full water level

Dry-run recovery

Dry-run prevention

Low water level

Wires

Full water level

Dry-run recovery

Dry-run prevention

Low water level

Wires

Full water level

Dry-run recovery

Dry-run prevention

Low water level

Wires

Full water level

Dry-run recovery

Dry-run prevention

(low water level)

Wires

Full water level

Dry-run recovery

Dry-run prevention

(low water level)

Control panel

City water

Level regulating

valve

Ball tap

Receiver tank

Water supply unit

Control panel

City water

City water

Level regulating

valve

Ball tap Ball tap

Receiver tank #1 Receiver tank #2

Level regulating

valve

Water supply unit

Wires

Full water level

Dry-run recovery

Dry-run prevention

(low water level)

Table of contents

Other Teral Control Unit manuals