3. Precautions for conductor connections and control circuit wiring

1. For the screw to connect the conductor, be sure

to use a plain washer and a spring waster to

ensure the proper connection.

Otherwise, the screw would be easily loosened,

causing the connection to be burned.

2. To clamp the conductor to be connected, use the

specified torque.

Insufficient clamping would cause overheat or

excessive clamping would cause the screw to be

damaged. Therefore, tighten the screw using the

suitable tool for the screw size.

A

~

・

~

・

~

・

≦

≦

≦40mm

≦

≦

≦26.5mm

≦

≦

≦26.5mm

3. Do not tighten the screw by lubricating it.

This would decrease the friction of the threads,

causing the screw to be easily loosened or

excessively tightened.

4. Firmly support the connected conductor in a

position near the terminal.

The flow of accidental current will cause large

electromagnetic force to be applied between

the connected conductors.

Against this electromagnetic force, the draw-out

cradle alone is not enough to support the

connected conductors.

Draw-out cradle

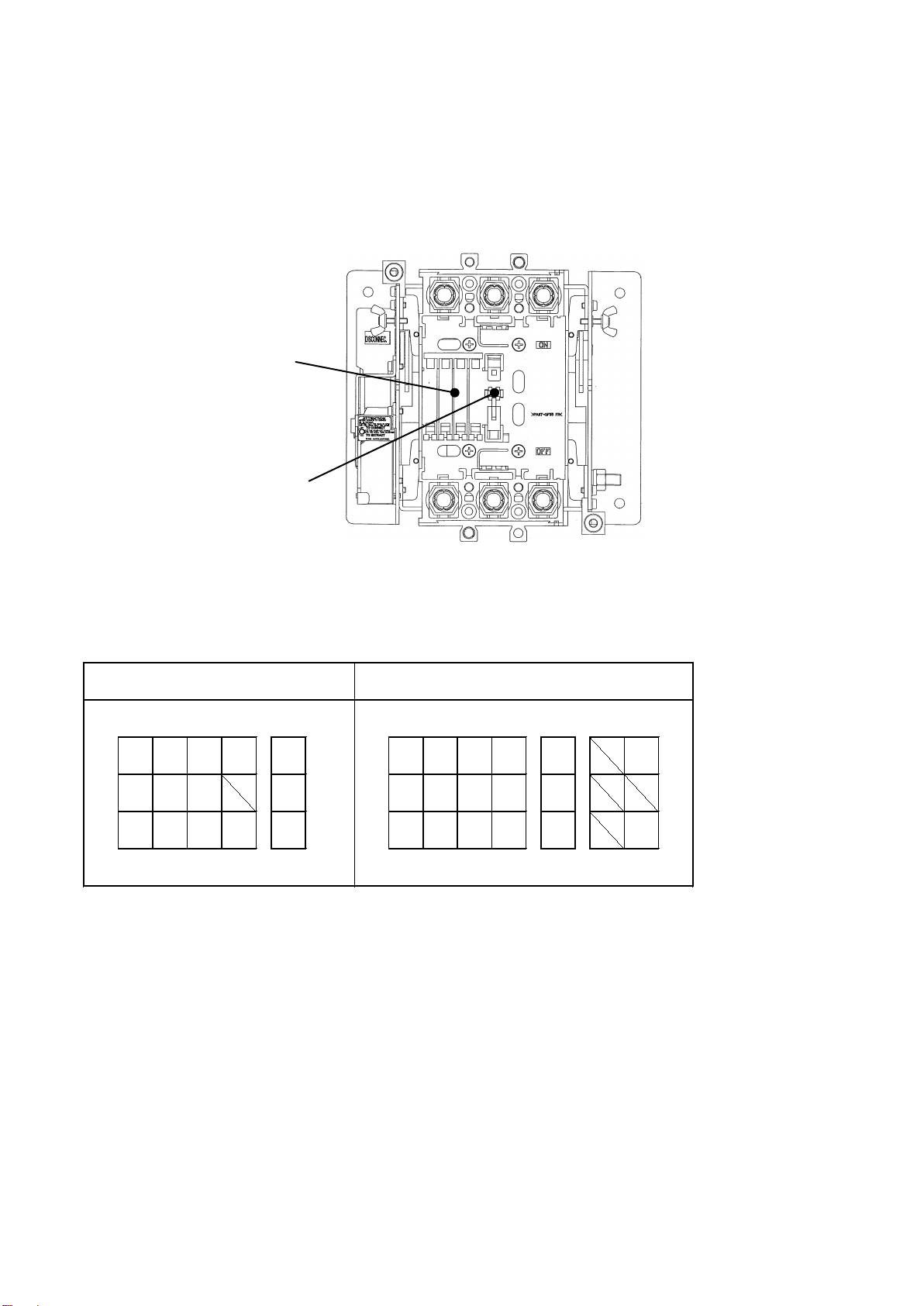

Table 3: Terminal detail dimensions table

KRB-5394b

3