Terex T25I and T45I Super Quiet Generator 5

Operating Instructions and Parts Manual

June 2006

REV A

INTRODUCTION

Owners, Users, and Operators:

TEREX appreciates your choice of our product for

your application. Our number one priority is user

safety which is best achieved by our joint efforts.

We feel that you can make a major contribution to

safety if you as the equipment users and opera-

tors:

• Comply with OSHA, Federal, State, and Local

Regulations.

• Read, Understand, and Follow the

instructions in this and other manuals supplied

with this product.

• Use Good, Safe Work Practices in a common

sense way.

• Only have trained operators — directed by

informed and knowledgeable supervision —

operating this product.

If there is anything in this manual that is not clear

or which you believe should be added, please

send your comments to TEREX Service Depart-

ment in Rock Hill, SC.

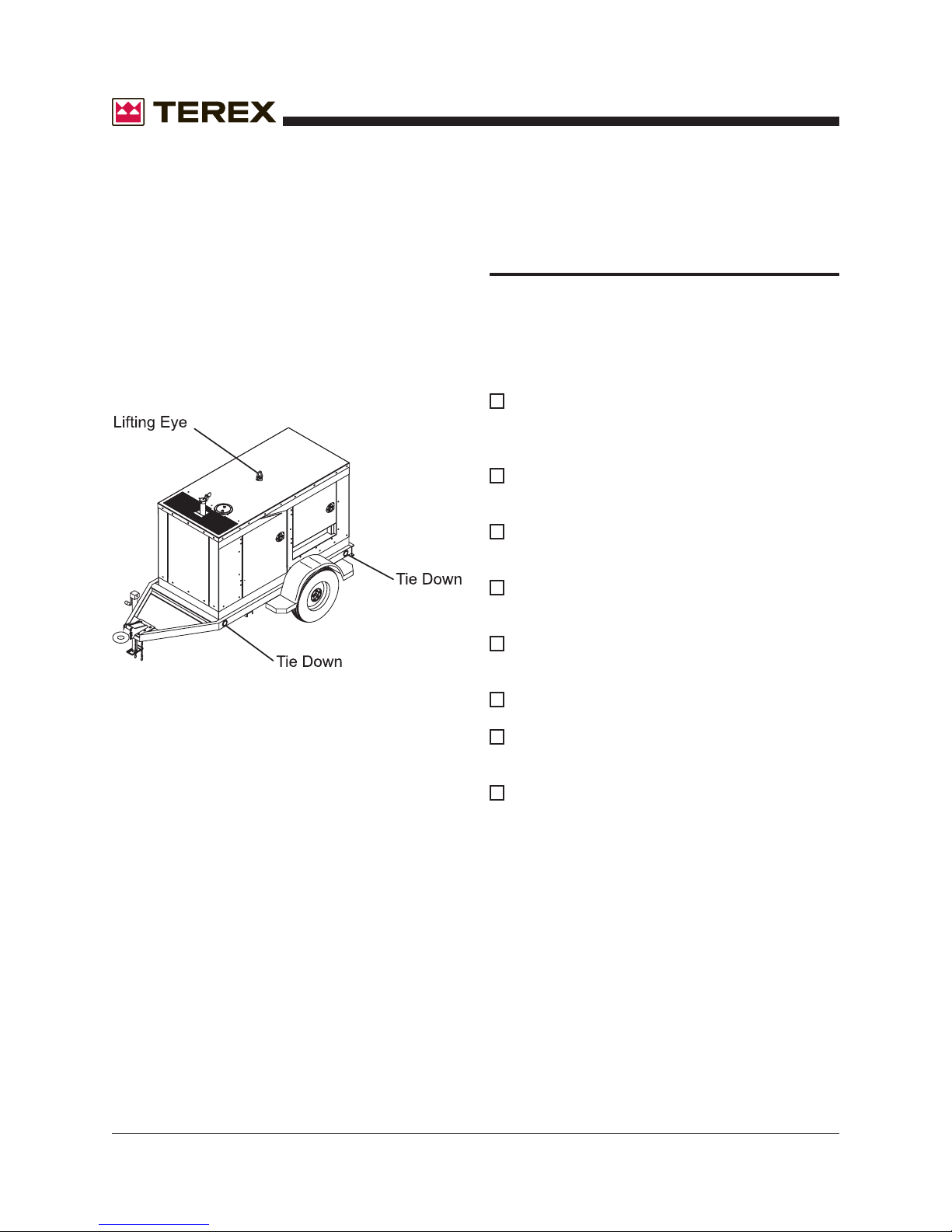

DESCRIPTION OF EQUIPMENT

The engine/generator assembly consists of a

diesel engine combined with an electrical genera-

tor. This assembly is firmly bolted together to form

an integral unit and does not require anything

other than routine maintenance.

The engine is equipped with a 12-volt starter (24-

volt starter optional) and can be wired for remote

starting capability at the control panel.

A dry-element air cleaner is standard equipment to

ensure a clean air supply, and a remote fuel/water

separator is included for additional fuel system

protection.

A governor on the engine provides a stable

operating speed under varying load conditions,

and the generator is equipped with a solid-state

voltage regulator to stabilize the output voltage

under these same conditions. Figures and

schematics of both the governor and regulator are

provided in the ENGINE and GENERATOR

OPERATOR’S MANUALS.

An automatic shutdown system is incorporated in

the generator set to sense low oil pressure and/or

high coolant temperature, and in either case the

engine/generator assembly will automatically

cease operation.

A diesel fuel tank is incorporated within the base

of the unit to ensure an uninterrupted operating

cycle under full load. The engine/generator

assembly is mounted to the base using high

durometer vibration isolators.

The enclosure for the generator set is constructed

from 12 or 14-gauge sheet metal to ensure

maximum rigidity, and is bolted together to allow

easy access to major components if necessary.

Four lockable, hinged access doors are provided

for routine operation and maintenance.

The enclosure on the Super Quiet Generator is

specifically designed for a high degree of sound

attenuation. This allows the generator set to be

operated in noise-sensitive environments. The

interior of the enclosure is coated with sound-

dampening polymer foam that is highly effective in

noise suppression and is impervious to water, fuel,

and oil.

A high ambient temperature radiator and a critical

grade exhaust silencer are contained within the

THE SAFETY ALERT SYMBOL IS USED TO

ALERT YOU TO POTENTIAL PERSONAL

INJURY HAZARDS. OBEY ALL SAFETY

MESSAGES THAT FOLLOW THIS SYMBOL

TO AVOID POSSIBLE INJURY OR DEATH.