Terra CleanBooth 1870-03B User manual

Quick-Start Operating Guide Document No. 1800-73

CleanBooth™ Laminar Flow Station

© Copyright 2020 Terra Universal Inc. All rights reserved. • Revised May 2020 Revised May 2020

Terra Universal, Inc. • TerraUniversal.com • 800 S. Raymond Ave. • Fullerton, CA 92831 • TEL: (714) 578-6000 • FAX: (714) 578-6020

Quick-Start Operating Guide

High- CleanBooth™ Laminar Flow Station

© Copyright 2020 Terra Universal Inc. All rights reserved • Revised May 2020 • Document No. 1800-73v2.0tm

Terra Universal, Inc. • TerraUniversal.com • 800 S. Raymond Ave. • Fullerton, CA 92831 • TEL: (714) 578-6000 • FAX: (714) 578-6020 2

Contents

Contents ............................................................................................................................................................ 2

1. Introduction............................................................................................................................................... 3

2. Description ................................................................................................................................................ 3

3. Installation ................................................................................................................................................. 4

3.1. CleanBooth Narrow Version 1870-03B ................................................................................................. 4

3.2. CleanBooth Wide Version 1870-04B: .................................................................................................... 8

4.0 Maintenance........................................................................................................................................ 13

5.0 Specifications....................................................................................................................................... 14

6.0 Warranty.............................................................................................................................................. 16

Quick-Start Operating Guide

High- CleanBooth™ Laminar Flow Station

© Copyright 2020 Terra Universal Inc. All rights reserved • Revised May 2020 • Document No. 1800-73v2.0tm

Terra Universal, Inc. • TerraUniversal.com • 800 S. Raymond Ave. • Fullerton, CA 92831 • TEL: (714) 578-6000 • FAX: (714) 578-6020 3

1. Introduction

This manual provides information on installing and

operating your Terra Universal Cleanbooth™ Laminar

Flow Station.

By studying this document carefully, you can be assured

of a long, efficient service life from the unit.

2. Description

Terra Universal's CleanBooth Laminar Flow Work Station

removes airborne particulate contamination to ensure a

clean work surface.

The backbone of the system is one or more fan filter units

(FFUs), each with a 3-speed, direct-drive electric motor

that forces air through a HEPA filter. The HEPA filter

removes 99.99% of all particles 0.3 microns and larger

from a large-volume air stream. The vertical laminar flow

of clean air to the work surface effectively blocks the

inrush of contaminants. Each 2' x 4' fan filter unit provides

an average of 644 CFM of filtered air @ 90 FPM (2' x 3'

units deliver 477 CFM). For more stringent cleanliness

requirements, ULPA-filtered units are available that

remove particles down to 0.12 microns with 99.999% efficiency.

Flexible anti-static vinyl curtains are available to enclose the work area. These curtains mount to the FFU support

stand by means of a flexible GripTrack™ system.

System options include fluorescent lighting and ionizing bars – see maintenance descriptions below.

Proprietary Notice

This manual pertains to proprietary devices manufactured by Terra

Universal, Inc. Neither this document nor any portion of it may be

reproduced in any way without prior written permission from Terra

Universal.

Terra Universal makes no warranties applying to information contained

in this manual or its suitability for any implied or inferred purpose.

Terra Universal shall not be held liable for any errors this manual

contains or for any damages that result from its use.

Safety Notice

A thorough familiarity with all operating guidelines is essential to safe

operation of the product. Failure to observe safety precautions could

result in poor performance, damage to the system or other property, or

serious bodily injury or death.

The following symbols are intended to call your attention to two levels

of hazard involved in operation:

Cautions are used when failure to observe instructions

could result in significant damage to equipment.

CAUTION

Warnings are used when failure to observe instructions

or precautions could result in injury or death.

WARNING

The information presented here is subject to change without notice.

Quick-Start Operating Guide

High- CleanBooth™ Laminar Flow Station

© Copyright 2020 Terra Universal Inc. All rights reserved • Revised May 2020 • Document No. 1800-73v2.0tm

Terra Universal, Inc. • TerraUniversal.com • 800 S. Raymond Ave. • Fullerton, CA 92831 • TEL: (714) 578-6000 • FAX: (714) 578-6020 4

3. Installation

The CleanBooth is normally shipped with FFUs pre-mounted in the support stand.

FFUs rest on the support frame – no fasteners are required. Optional curtains are installed by raising the outer cover

of the GripTrack mount, seating the curtain bead inside the track, and snapping the cover down to secure the curtain.

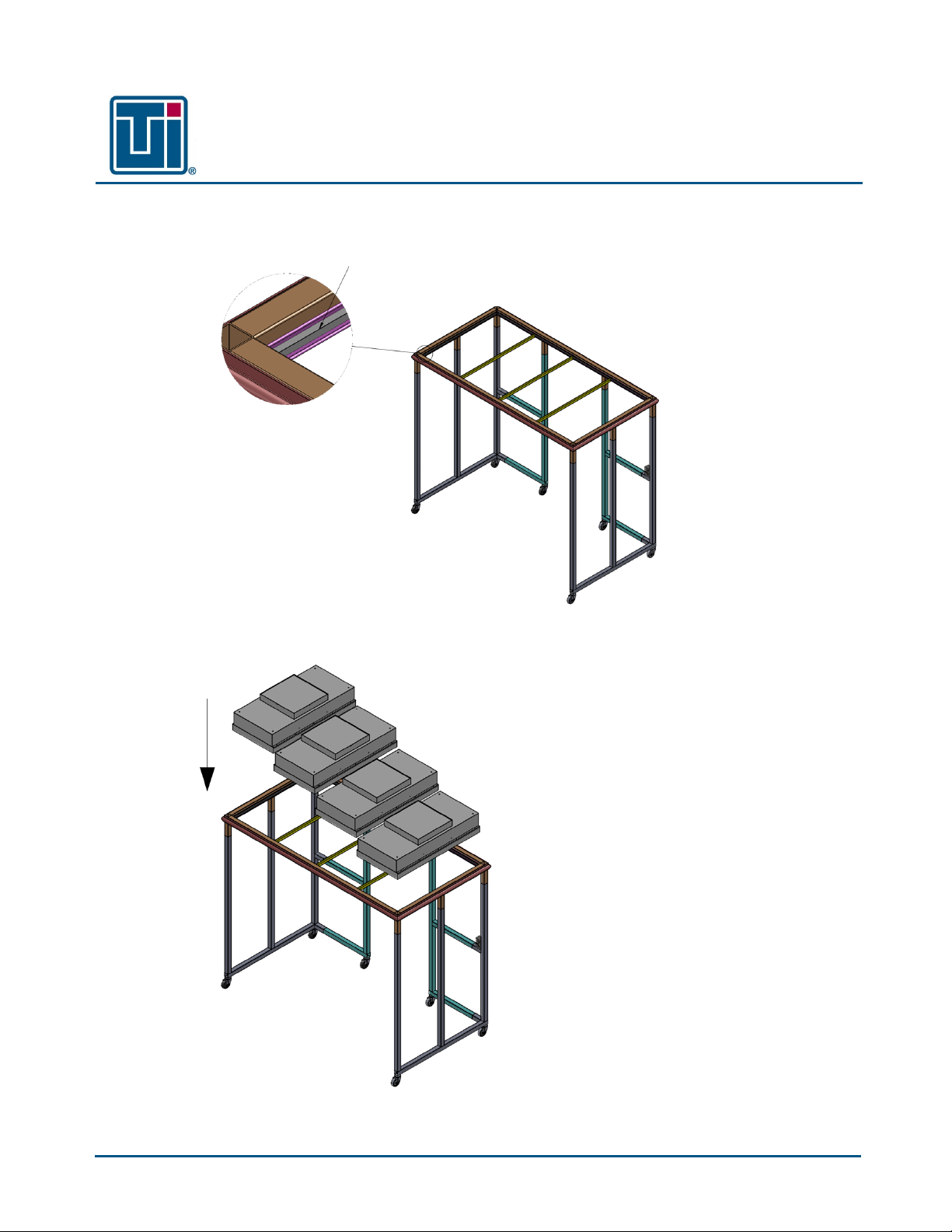

3.1. CleanBooth Narrow Version 1870-03B

Step 1: Connect the two frame members

Quick-Start Operating Guide

High- CleanBooth™ Laminar Flow Station

© Copyright 2020 Terra Universal Inc. All rights reserved • Revised May 2020 • Document No. 1800-73v2.0tm

Terra Universal, Inc. • TerraUniversal.com • 800 S. Raymond Ave. • Fullerton, CA 92831 • TEL: (714) 578-6000 • FAX: (714) 578-6020 5

Step 2 (OPTIONAL): Apply gasketing along the ceiling grid perimeter

Quick-Start Operating Guide

High- CleanBooth™ Laminar Flow Station

© Copyright 2020 Terra Universal Inc. All rights reserved • Revised May 2020 • Document No. 1800-73v2.0tm

Terra Universal, Inc. • TerraUniversal.com • 800 S. Raymond Ave. • Fullerton, CA 92831 • TEL: (714) 578-6000 • FAX: (714) 578-6020 6

Step 3: Place the fan filter units onto the ceiling

Quick-Start Operating Guide

High- CleanBooth™ Laminar Flow Station

© Copyright 2020 Terra Universal Inc. All rights reserved • Revised May 2020 • Document No. 1800-73v2.0tm

Terra Universal, Inc. • TerraUniversal.com • 800 S. Raymond Ave. • Fullerton, CA 92831 • TEL: (714) 578-6000 • FAX: (714) 578-6020 7

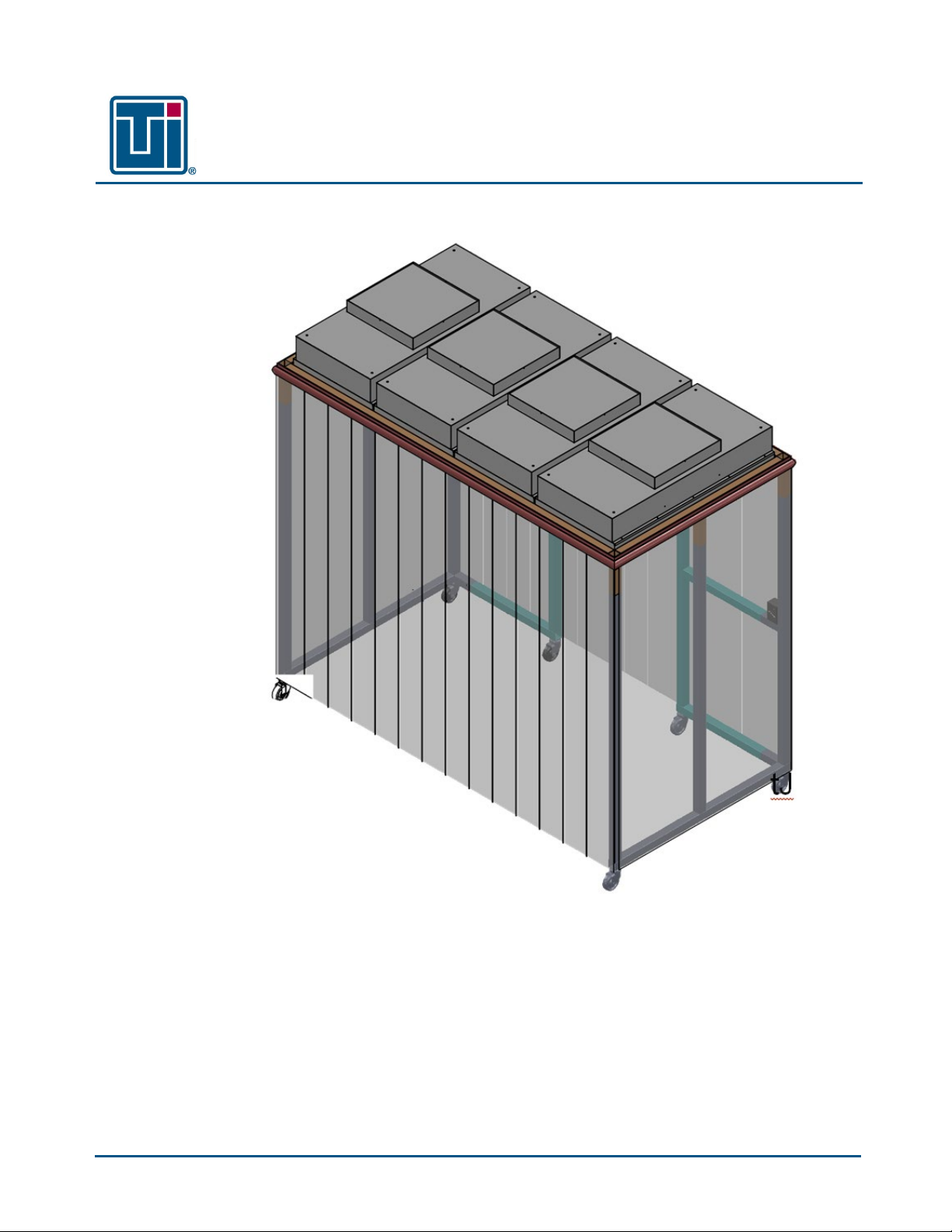

Step 4: Place curtain panels along the left, right, and back side.

Step 5: Completed assembly

Quick-Start Operating Guide

High- CleanBooth™ Laminar Flow Station

© Copyright 2020 Terra Universal Inc. All rights reserved • Revised May 2020 • Document No. 1800-73v2.0tm

Terra Universal, Inc. • TerraUniversal.com • 800 S. Raymond Ave. • Fullerton, CA 92831 • TEL: (714) 578-6000 • FAX: (714) 578-6020 8

3.2. CleanBooth Wide Version 1870-04B:

Step 1: Assemble the base frame as shown below.

Quick-Start Operating Guide

High- CleanBooth™ Laminar Flow Station

© Copyright 2020 Terra Universal Inc. All rights reserved • Revised May 2020 • Document No. 1800-73v2.0tm

Terra Universal, Inc. • TerraUniversal.com • 800 S. Raymond Ave. • Fullerton, CA 92831 • TEL: (714) 578-6000 • FAX: (714) 578-6020 9

Step 2: Connect the top frame onto the base frame assembly.

Quick-Start Operating Guide

High- CleanBooth™ Laminar Flow Station

© Copyright 2020 Terra Universal Inc. All rights reserved • Revised May 2020 • Document No. 1800-73v2.0tm

Terra Universal, Inc. • TerraUniversal.com • 800 S. Raymond Ave. • Fullerton, CA 92831 • TEL: (714) 578-6000 • FAX: (714) 578-6020 10

Step 3 (OPTIONAL): Apply gasketing along the ceiling grid perimeter

Step 4: Place the fan filter units onto the ceiling

Quick-Start Operating Guide

High- CleanBooth™ Laminar Flow Station

© Copyright 2020 Terra Universal Inc. All rights reserved • Revised May 2020 • Document No. 1800-73v2.0tm

Terra Universal, Inc. • TerraUniversal.com • 800 S. Raymond Ave. • Fullerton, CA 92831 • TEL: (714) 578-6000 • FAX: (714) 578-6020 11

Step 5: Place the curtain panels on the left, right, and back sides

Step 6: Place the curtain strips on the entrance of the Cleanbooth

Quick-Start Operating Guide

High- CleanBooth™ Laminar Flow Station

© Copyright 2020 Terra Universal Inc. All rights reserved • Revised May 2020 • Document No. 1800-73v2.0tm

Terra Universal, Inc. • TerraUniversal.com • 800 S. Raymond Ave. • Fullerton, CA 92831 • TEL: (714) 578-6000 • FAX: (714) 578-6020 12

Step 7: Completed assembly

Quick-Start Operating Guide

High- CleanBooth™ Laminar Flow Station

© Copyright 2020 Terra Universal Inc. All rights reserved • Revised May 2020 • Document No. 1800-73v2.0tm

Terra Universal, Inc. • TerraUniversal.com • 800 S. Raymond Ave. • Fullerton, CA 92831 • TEL: (714) 578-6000 • FAX: (714) 578-6020 13

To operate the system,

1. Plug the power cord into an appropriate grounded receptacle (115VAC/60Hz or 230VAC/50Hz).

2. FFUs, light and ionizer are controlled by means of a single ON/OFF switch, located on the right-rear portion of

the work area.

3. The FFUs incorporate a 3-position impeller blower, which is normally shipped in the "High" position. Under

normal operating conditions, this setting should not be changed. The blower speed control is located on the

upper-right side of each unit.

4.0 Maintenance

Fan Replacement

Air velocity should be monitored to ensure effective filtration using an appropriate air-speed monitor. Under typical

conditions (8 hours of operation per day), filters should be replaced every year. As a HEPA filter clogs, you will notice

increased blower noise and vibration, along with decreased air speed.

To replace the filter: first remove the fan filter unit and move it to a safe, convenient location.

1. Use a crossblade screwdriver to remove the eight screws along the top perimeter of the FFU.

2. Carefully lift the top portion of the FFU, including the impeller blower, to expose the HEPA filter.

3. Replace the HEPA filter, which seats against lower edge of the FFU housing.

4. Replace the FFU top and blower assembly.

5. Reposition the FFU on top of the CleanBooth frame.

Replacement Filters 2' x 4' 2' x 3'

Cat. # Cat. #

HEPA (99.99% efficient @ 0.3µm) 6702-04 6702-16

ULPA (99.999% efficient @ 0.12µm) 6702-05 6702-18

Fluorescent Lighting

Simply rotate the 4' fluorescent tube inside the fixture until it disengages and slides free. Replace with tube below

(typical life: two years of continuous operation). When ballast fails, replace entire light fixture (typical life: five years of

continuous operation).

Quick-Start Operating Guide

High- CleanBooth™ Laminar Flow Station

© Copyright 2020 Terra Universal Inc. All rights reserved • Revised May 2020 • Document No. 1800-73v2.0tm

Terra Universal, Inc. • TerraUniversal.com • 800 S. Raymond Ave. • Fullerton, CA 92831 • TEL: (714) 578-6000 • FAX: (714) 578-6020 14

Fluorescent Tube Cat. #

For 47” fixture 3800-60

For 35.5” fixture 3800-61

Replacement Fluorescent Fixture (including bulb)

47” 1870-11

35.5”

Ionizing Bar

The ionizing bar requires periodic replacement of its Tungsten emitter (recommended every two years).

To replace emitter screw, use 1/4-inch hollow socket to remove stainless steel emitter screw from the ionizing bar.

Use care not to damage the whisker emitter when placing the socket over the screw head. Replace with unit below.

Cat. #

Tungsten Emitter 1525-93

Cleaning Frame and Curtains

Periodically, wipe down frame and optional curtain with a clean, non-linting wiper (polyester recommended), using

clean water and a mild detergent, if necessary. Use unidirectional (not circular) motion to remove surface

contaminants from the edges of all surfaces.

5.0 Specifications

Overall Dimensions (see drawings for details)

No. 1870-54 53"W x 30"D (base)/28"D (top) x 63.5 / 91"H

No. 1870-56 77"W x 30"D (base)/28"D (top) x 63.5 / 91"H

Construction

Frame: 1" x 1" and 1" x 3" square CR steel tubing, powder-coated white

FFU: Aluminum housing (see other FFU specs below)

Performance: Meets or exceeds the requirements/specifications of the following industry standards:

ISO Class 4 (Class "100" (M 3.5)) air per the latest I.E.S.T. 14664-1 (Airborne Particulate Cleanliness Classes).

I.E.S.T. Recommended Practices (Laminar Flow Clean Air Devices) Specifications

Fan Filter Unit Specifications:

Airflow Velocity: 90 (±10) FPM (.45 m/s), when measured using a Velgrid (eight readings) 6 in. (152mm)

below the filter face.

Quick-Start Operating Guide

High- CleanBooth™ Laminar Flow Station

© Copyright 2020 Terra Universal Inc. All rights reserved • Revised May 2020 • Document No. 1800-73v2.0tm

Terra Universal, Inc. • TerraUniversal.com • 800 S. Raymond Ave. • Fullerton, CA 92831 • TEL: (714) 578-6000 • FAX: (714) 578-6020 15

Sound Level: Approximately 48 dBA on low speed measure at 30 in. from the filter face, with the fan

delivering an average air flow velocity of 90 FPM (.45 m/s). Ambient sound level less than 35

dBA.

Vibration Level: Will not exceed .09 MILS RMS.

Housing: Both the fan plenum and filter housing have a mill finish (powder coat paint or stainless steel

exterior optional), and sealed airtight.

Prefilter: Furnished with a 16.0 in. x 23.25 in. x 0.25 in. polyurethane foam, washable prefilter.

HEPA Filter: Factory tested and rated 99.99% efficient in removal of particles 0.3 micron and larger; leak

free in accordance with the latest I.E.S.T. Recommended Practices.

Filter Media: Microglass fiber with hot melt separators, sealed to the aluminum housing.

Filter Face Guard: Epoxy powder coated expanded steel.

Fan/Motor: Direct drive; forward curve centrifugal type with permanently lubricated sealed ball bearings.

Motor: Permanent split capacitor type, rated for continuous duty furnished with thermal overload

protection and a three-speed switch.

Full-Load Amp: 3.0 (for 120V, 60Hz, 1 phase); 1.5 (for 220V, 50/60Hz, 1 phase) Wattage Rating @ 90 fpm

(0.45 m/s) – see chart below for other wattage ratings

2 x 4 Models: 160 Watts @ 90 fpm, 60Hz (145 @ 50Hz)

2 x 3 Models: 140 Watts @ 90 fpm, 60Hz (113 @ 50Hz)

2 x 2 Models: 72 Watts @ 90 fpm, 60Hz (67 @ 50Hz)

To calculate sensible heat (in BTUH), multiply watts by 3.412 (e.g., for a 2' x 4' unit, at low speed, 170W x 3.412 =

580 BTUH)

System Options:

Lighting: Fluorescent type, approximately 1,000-foot candles; does not disturb the air flow.

Ionizing Power 110VAC, 50/60 Hz, single-phase; current draw: 0.3 amps (Cat. No. 1600-09A)

Supply Ionizing Bars

Cat. No. 1525-90 48"L brushed stainless steel bar, 8 emitters

Cat. No. 1525-92 72"L brushed stainless steel bar, 12 emitters

HEPA Filters

The filtration medium consists of highly efficient microfiberglass fiber folded over corrugated separators of aluminum

which prevent the media from nesting. This design channels air flow with optimal efficiency to reduce resistance.

All filters are tested for air flow resistance and DOP (dioctylphthalate) smoke penetration (with a mean particle

diameter of 0.3 microns) by measuring upstream and downstream smoke concentrations with a photometer.

Quick-Start Operating Guide

High- CleanBooth™ Laminar Flow Station

© Copyright 2020 Terra Universal Inc. All rights reserved • Revised May 2020 • Document No. 1800-73v2.0tm

Terra Universal, Inc. • TerraUniversal.com • 800 S. Raymond Ave. • Fullerton, CA 92831 • TEL: (714) 578-6000 • FAX: (714) 578-6020 16

6.0 Warranty

Products Manufactured by Terra: Terra Universal, Inc., warrants products that it manufactures to be free from

defects for a period of 12 months for parts and 90 days for labor, commencing from the date of shipment. Terra’s sole

responsibility is to repair or replace, at its option, any part of the product that proves defective or malfunctioning during

this time limit. In some cases, components incorporated in Terra Universal products are covered by additional

warranties from component manufacturers; obtain specific information from Terra sales representatives. This warranty

is void if the equipment is abused or modified by the customer, is operated outside Terra’s operating instructions or

specifications, or is used in any application other than that for which it is specified. This warranty does not include

routine maintenance or service procedures, breakage of quartz baths after 60 days, shipping damage, nor damage

from misuse, intentional or unintentional abuse, neglect, natural disasters, or acts of God.

Products Manufactured by Others: Terra Universal, Inc., warrants that, to the best of its ability, Terra’s

representations of products that are manufactured by others reflect the manufacturer’s representations, subject to

change without notice. Sole warranty for these products is the original manufacturer’s warranty that is passed forward

to the purchaser and constitutes the customer’s sole remedy for these products. Detailed warranties for distributed

products are available through Terra sales representatives.

Freight Shortage or Damage: Upon receipt of any equipment from Terra Universal, Inc., customer shall immediately

unpack and inspect for damage or shortage. The customer shall not accept a damaged package or a short shipment

until the carrier makes a "damage or shortage" notation on both the carrier's and customer's copy of the freight bill or

delivery receipt. Service title passes when the shipment is loaded, so customer is responsible for filing and collecting a

freight claim. Any replacement products must be ordered and paid for separately. For Terra's "Policy and Procedures

for Returning Goods," see Terra's Internet site: www.TerraUniversal.com.

Generally, customers can improve the chance of collecting on a freight claim by following these procedures: 1) formally

requesting that the carrier inspect the shipment immediately upon suspecting damage or shortage to verify condition;

2) notifying the carrier upon discovery of concealed damage and requesting an inspection within 15 days of receipt,

both in person or phone and following up via mail; 3) keeping the shipment as intact as possible, including retaining

original packaging materials and keeping the product as close to the original receiving location as possible; 4) holding

salvage for disposition by the carrier.

All Claims: Terra Universal expressly disclaims all other warranties, expressed or implied or implied by statute,

including the warranties of merchantability or fitness for intended use. Terra Universal is not responsible for

consequential or incidental damages arising out of the purchase or use of the products supplied by Terra Universal.

Terra Universal is not liable for damage to facilities, other equipment, products, property or personnel of others, or of

their agents, suppliers, or affiliated parties, which is caused or alleged to have been caused by products supplied by

Terra Universal. In any event or series of events, Terra Universal’s total liability for any and all damages whatsoever is

limited to the lesser of the actual damages or the original invoice cost of the items alleged to have caused the damage.

The customer’s sole and exclusive remedy for any cause of action whatsoever is repair or replacement of the non-

conforming products or refund of the actual purchase price, at the sole option of Terra Universal. All claims must be

made in writing within 90 days of the date the product was shipped. Any claims not made within this time limit shall be

deemed waived by the customer. Terra Universal is not responsible for any additional costs of repair caused by poor

packaging or in-shipment damage during return.

Warranty Returns: All warranty returns must be authorized in advance by Terra Universal and approved under an

RMA. Unless approved in advance for good reason, all returns must be in original condition, including all manuals, and

must be packaged in original packaging materials. All returned goods are to be shipped to Terra Universal, freight

prepaid at customer’s expense. See Terra’s “Policy and Procedure for Returned Goods.”

Thank you for ordering from Terra Universal!

This manual suits for next models

1

Table of contents

Other Terra Desktop manuals

Popular Desktop manuals by other brands

Digital Equipment

Digital Equipment VAXstation 4000/90 Series Owner's and system installation guide

Dell

Dell INSPIRON Inspiron 5000 Installation and operation manual

HP

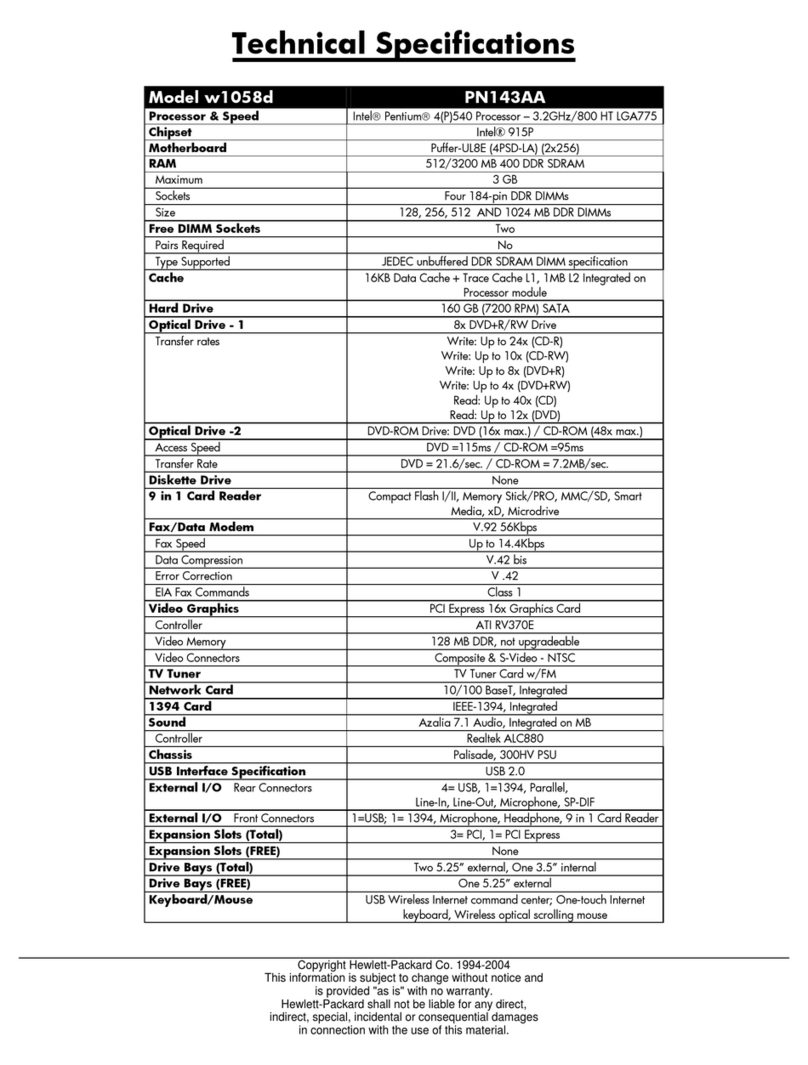

HP Pavilion w1000 - Desktop PC Technical specifications

AVERATEC

AVERATEC D1133 user guide

Lenovo

Lenovo ThinkCentre M90s Setup guide

MSI

MSI Midas 915GM user guide