Terumo ACS-152 User manual

O

SERVICE

..

MANUAL

TUBE

SEALER

ACS-152

TERUMO

CORPORATION

Vo.

|

EN

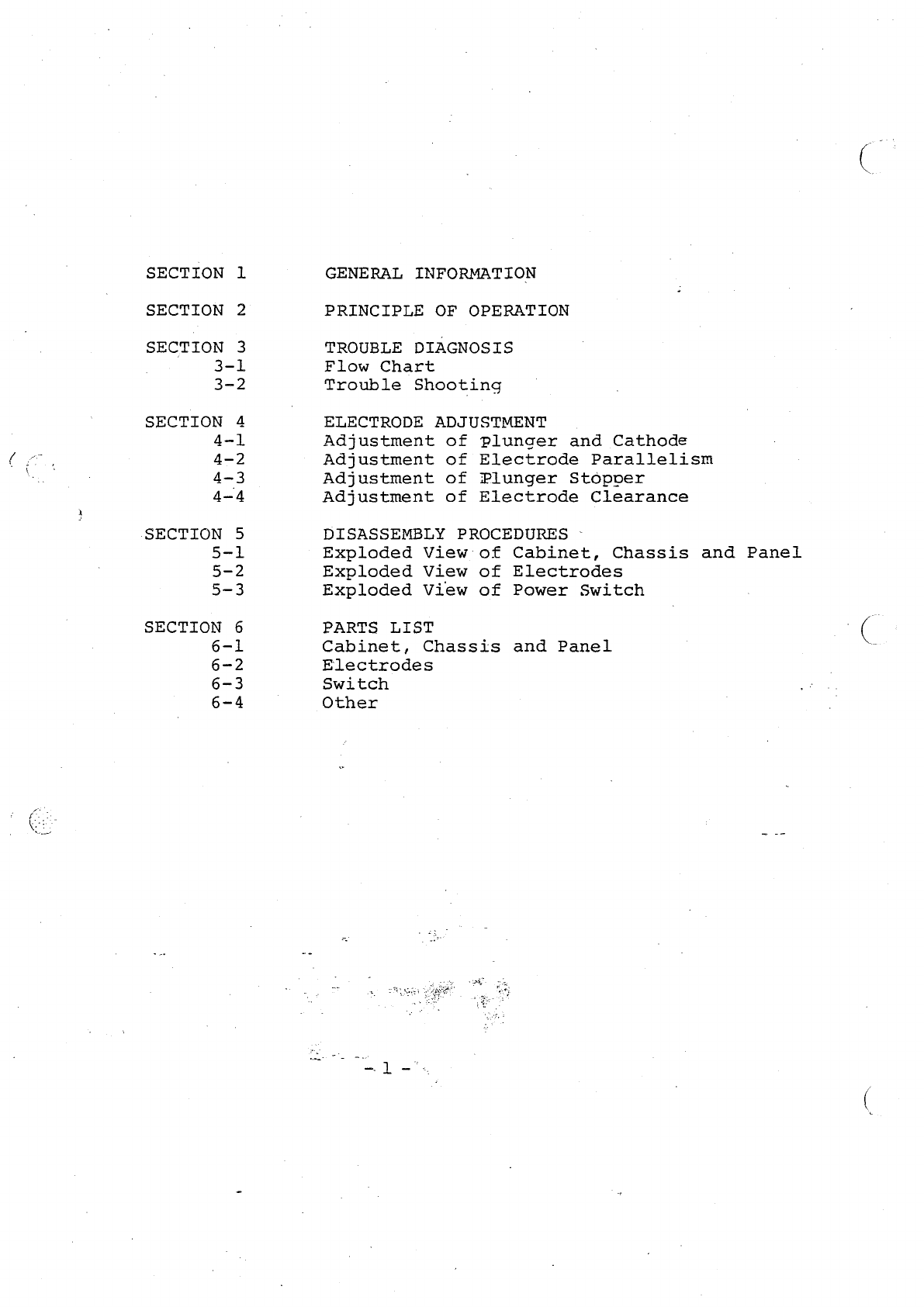

SECTION

1

SECTION

2

SECTION

3

GENERAL

INFORMATION

PRINCIPLE

OF

OPERATION

TROUBLE

DIAGNOSIS

Flow

Chart

Trouble

Shooting

ELECTRODE

ADJUSTMENT

Adjustment

Adjustment

Adjustment

Adjustment

of

Plunger

and

Cathode

of

Electrode

Parallelism

of

Plunger

Stopper

of

Electrode

Clearance

DISASSEMBLY

PROCEDURES

-

Exploded

View

of

Cabinet,

Chassis

and

Panel

Exploded

View

of

Electrodes

Exploded

View

of

Power

Switch

PARTS

LIST

Cabinet,

Chassis

and

Panel

Electrodes

Switch

Other

/

SECTION

1

GENERAL

INFORMATION

This

service

manual

provides

knowledge

required

to

repair

trouble

which

may

occur.

with

ACS-152.

Section

2

covers

the

principle

of

operation.

Read

this

section

before

starting

repairs.

|

Section

3

shows

the

trouble

shooting

flow

chart

and the

diagnosis

table

of

probable

trouble.

Section

4

concerns

the

disassembly

procedures

of

the

major

components

for

reference.

Note:

(1)

Prepare

a

circuit

tester

(2)

High

voltage

power

supply

is

used

in

this

device.

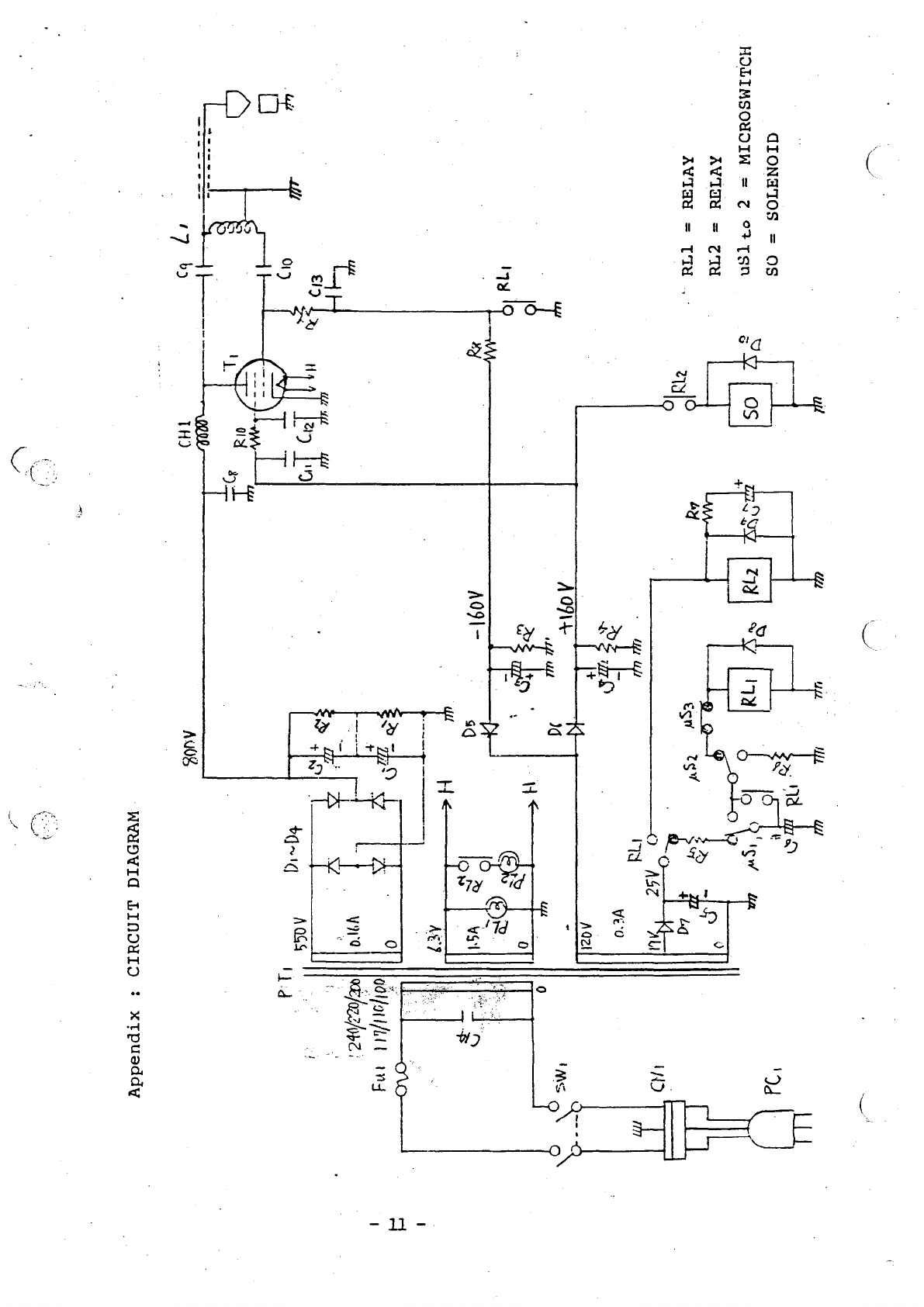

SECTION

2

PRINCIPLE

OF

OPERATION

Normal

operation

Capacitor

C6

is

charged

through

C5

to

operate

RLI

in

the

initial

phase.

When

the

tubing

is

inserted

between

seal

electrodes,

uSl

operates

to

drive

RL1.

At

that

time,

RL2

is

also

operated

by

the

contact

of

RL1,

and

SO(plunger)

pinches

the

tube.

With

RLI

operated,

the

vacuum

tube

operates

to

oscillated

at

40.7

MH

|

The

oscillation

output

dielectrical-ly

heats

the

tubing

to

fuse

it.

When

it

is

fused,

an

electrode

gap

is

shortened.

Then

uS2

operates

to

stop

operation

of

RLl.

When

operation

of

RL1

ends,

.oscillation

stops

and

the

fused

tubing

is

cooled.

Tubing

cool-

ing

time

is

set

by

discharge

of

C7

which

is

connected

to

RL2.

During

this

cooling

time,

SO

(plunger)

which

is

connected

to

RL2

pinches

the

tube.

Operation

under

abnormal

conditions

When

the

tubing

is

wet

by

blood

or

liquids,

high

frequency

short

circuits

between

the

electrodes,

thus

dielectric

heating

of

the

tube

is

not

performed.

If

the

tubing

is

left

under

that

condition,

the

vacuum

tube

can

become

defective.

To

prevent

this,

RL1

operates

only

for

discharge

time

(approx.

4

seconds),

then

oscillation

is

automatically

stopped

,

and

the..plunger

is

returned

to

its

original

position.

ーー

o

Le

Section

3.

Flow

Chart

Turn

Does

Does

Does

TROUBLE

DIAGNOSIS

on

the

power

switch.

|

Yes

|

the

pilot

lamp

come

|

Yes

y

the

plunger

operate

/

the

seal

lamp

light

up

No

>

Table

Table

Table

Table

Table

3-2

Troubleshooting

Table

-

1

:

Pilot

lamp

does

not

come

on..

ne

Power

cable

is

broken

down

Fuse

is

broken

down

Pilot

lamp

is

broken

down.

Check

the

cable

for

continuity

using

circuit

tester.

fa

O

O

O A

a

o

OP

VD

O O

a

аж

инь

UD

ить

O

чить

мии

фито

ши

что

A

NN,

ye

O

O

O

e

O

O o

一

一

ーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーー

Replace

3-A

fuse.

Check

for

fuse

open-

ing

cause.

ニニ

ーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーー…ーーーーーーーーーー…

Wiring

to

Check

6.3-V

terminals

of

pri-

Repair

primary

and

mary

and

secondary

windings

of

opening

secondary

power

transformer

for

voltage.

parts.

„of

power

transformer

‘is

broken

down.

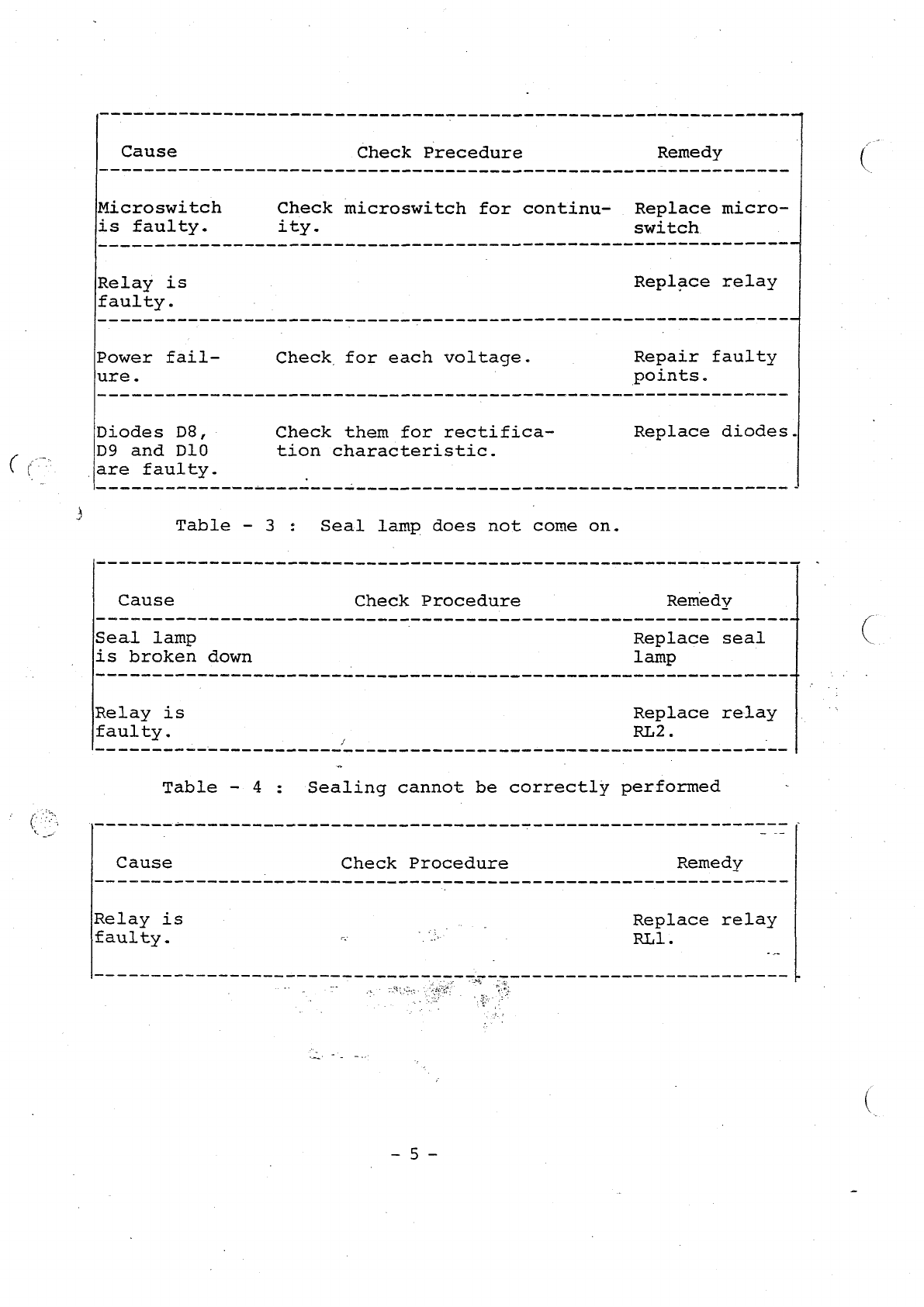

Table

-

2

:

Plunger

does

not

operate.

ーー

Cause

Check

Procedure

Remedy

Place

cove

correctly.

Safety

cover

is

detached.

Cause

Check

Precedure

Remedy

Microswitch

Check

microswitch

for

continu-

Replace

micro-

is

faulty.

ity.

switch

A

σα

σα

σα

σα

σα

mm

ee

ee

eee

4

Relay

is

Replace

relay

faulty.

Power

fail-

Check

for

each

voltage.

Repair faulty

ure.

|

points.

Diodes

D8,

ㆍ

Check

them

for

rectifica-

Replace

diodes.

=

D9

and

D10

tion

characteristic.

(

(

jare

faulty.

3

Table

-

3

:

Seal

lamp does

not

come

on.

Cause

Check

Procedure

Remedy

Seal

lamp

Replace

seal

is

broken

down

|

lamp

Relay

is

Replace

relay

faulty.

.

RL2.

Table

-

4

:

Sealing

cannot

be

correctly

performed

Cause

Check

Procedure

Remedy

Relay

is

m

Replace

relay

faulty.

=

ES

.

RLL.

fo

PT

Cause

Check

Procedure

o

Remedy

Vacuum

tube

is

Replace

vacuum

faulty.

|

Power

is

Check

for

each

voltage

Repair

fauty

points

faulty

Between-

Adjust

the

clearance

|

electrode

clearance

is

improper

Cooling

time

is

RL2

operation

must

end

Renew

C7

deficient

approx.

0.5

sec.

after

RL]

operation

has

ended

SECTION

4

ELECTRODE

ADJUSTMENT

When

electrode

have

been

replaced

and

screws

retightened,

perform

re-adjustment

if

required.

Note

:

When

adjusting

electrode,

always

unplug

the

mit.

Since

there

is

the

potential

of

shock

due

to

electrical.

charge

in

the

capacitor,

discharge

it

before

performing

adjustment.

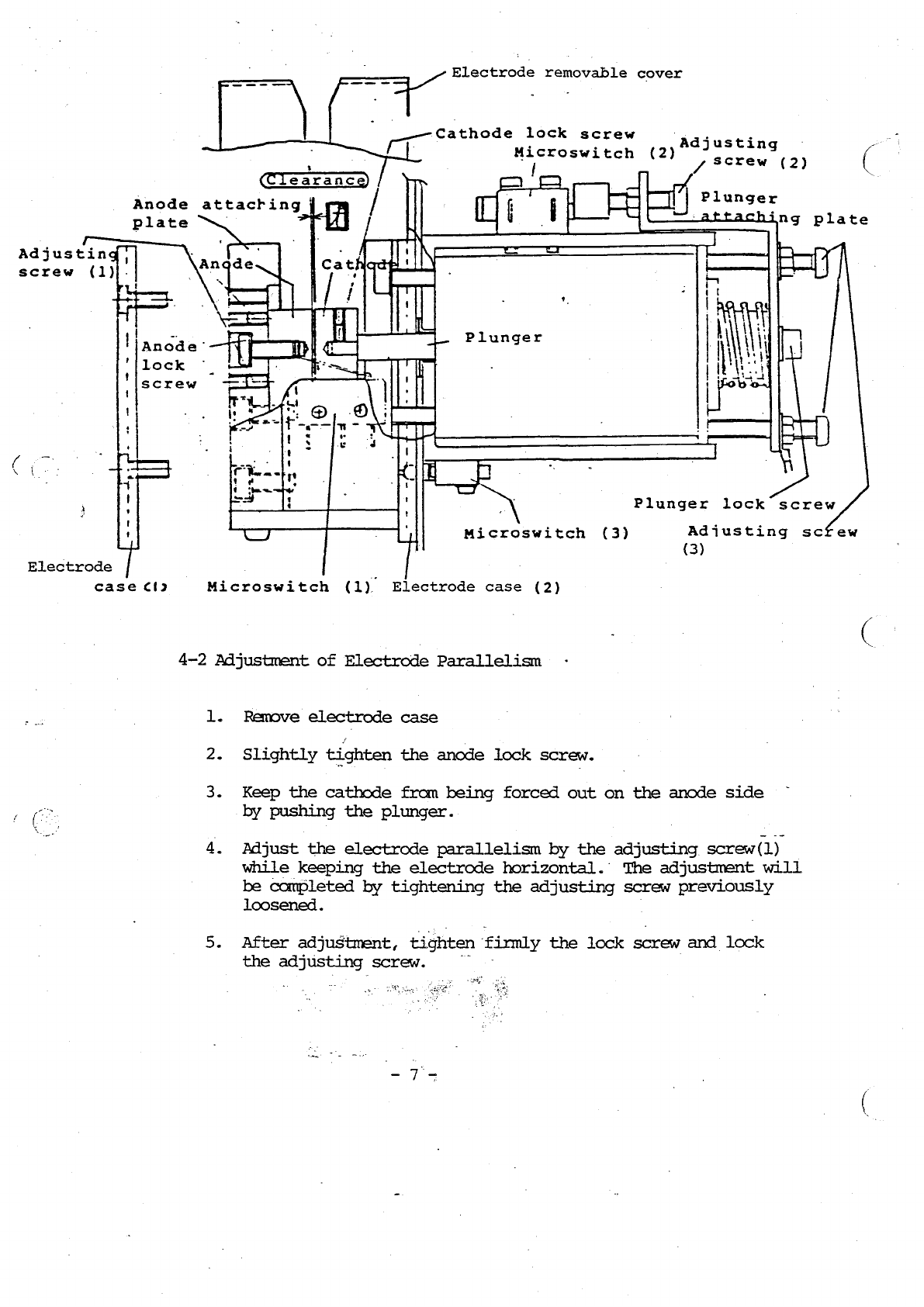

4-1

Adjustment

of

Plunger

and

Cathode

(1.

Tighten

the

plunger

lock

screw.

Plunger

must

move

smoothly

back

and

forth.

However,

the

plunger

attaching

plate

and

the

solenoid

_

should

be

in

goood

contact.

2.

Firmly

tighten

lock

screws

with

the

cathode

and

anode being

parallel.

Electrode

removable

cover

Cathode

lock

screw

‘Adjusting

0

ノ

Screw

(2)

(

Anode

attaching

/

f

il

|]

Plunger

plate

N

>-

/

-

9

plate

+

. - |

1.

Adjusting,

|

c

一

一

一

screw

(1)|.

Angden

|

bea

NİZ

т

ul

VEE

1

Anode:

Plunger

[lock

"|

MHT.

T

!

screw

F

!

“Wd.

1

o

:

5

5

τ

È

!

tos

HT

;

x

i

-İ

I

一

as

..

・

-

.

O

iz

Mm

に

o

|

+

И

3

!

=>

,

N

Plunger

lock’

screw

VI

-

'

Microswitch

(3)

Adiusting

scfew

i

(3)

electrodo

|

|

.

case

Cl?

Microswitch

(1)

Electrode

case

(2)

4-2

Adjustment

of

Electrode

Parallelism

Remove

electrode

case

Slightly

tighten

the

anode

lock

screw.

Keep

the

cathode

from

being

forced

out

on

the

anode

side

‚Бу

pushing

the

plunger.

Adjust

the

electrode

parallelism

by

the

adjusting.

screw(1)

while

keeping

the

electrode

horizontal.

The

adjustment

will

be

completed

by

tightening

the

adjusting

screw

previously

loosened.

After

adjustment,

tighten

firmly

the

lock

screw

and

lock

the

adjusting

|

screw.

/

\

.

4-3

Adjustment

of

plunger

stopper

(

1.

Loosen

lock

nut

for

adjusting

screw

(3).

2.

Push

plunger

in

until

adjusting

screw

reaches’

solenoid.

ego

tim

GT

At

that

time,

adjust

clearance

(Tc)

between

electrodes

to

vob

Gem

G7-

0.08

mm

(using

a

thickness

guage)

by

turning

adjusting

screw

(3).

3.

After

adjustment,

set

adjusting

screw

(3)

using

a

philips

screwdriver

and

tighten

lock

nut..

4-4

Adjustment

of

Electrode

Clearance

1.

Loosen

lock

nut

for

adjusting

screw

(2).

z

De

Av)

aj

に

ー

Sem

TT]

すす

ペー

て

パード

2.

Push

plunger

in

until

adjusting

screw

(2)

pushers

microswitch

ンー

and

operation

is

started.

At

that

time,

adjust

electrode

clearance

i.

Sy

TRG

—s

to

0.23'to

9-28

1

mm

(using

a

thickness

gauge)

by

turning

adjusting

|

,

rew

(3).

am

Cricirede

<

Ü

1

o

の

・

15

ee

-

qf

CI

3.

After

adjustment,

set

adjusting

screw.

(2)

using

a

philips

screw-

driver

and

‘tighten

lock

nut.

Tools

used:

Philips

screwdriver

(

hex

socket

wrench

for

M3

wrench

for

7

mm

Thickness

gauge

(0.04

mm

and

0.23

mm)

“ey

=

Sat

Vue-

ее

Dot

Constr

thon

CRE

AIDS

+

TT

©

k

Casromus

δέ

FT

~

foo

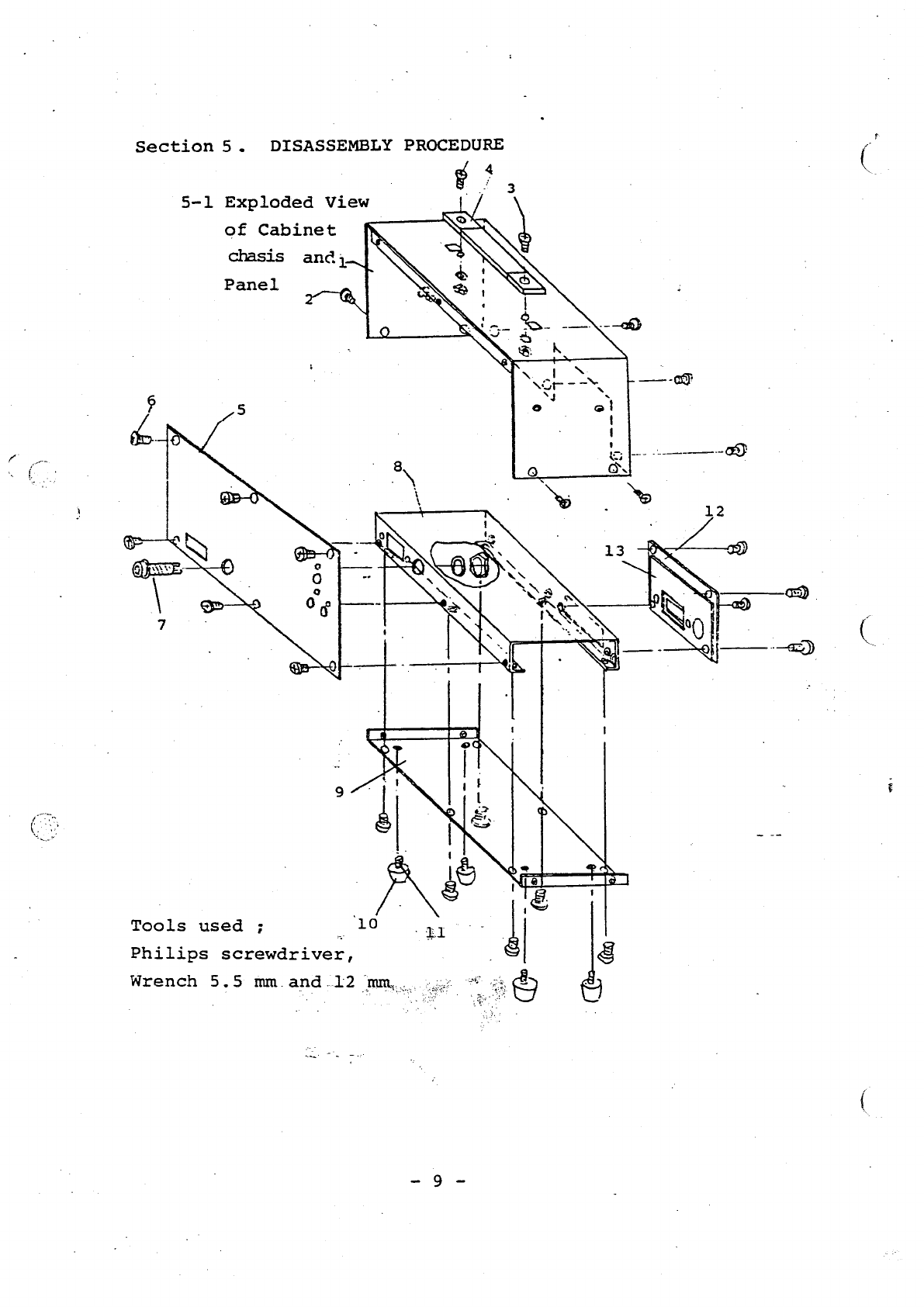

Section

5.

DISASSEMBLY

PROCEDURE

g

4

5-1

Exploded

View

7

of

Cabinet

È

chasis

and;

è

©

1

1

à

t

e

‘

‘

Panel

3

Tools

used

;

Philips

screwdriver,

Wrench

5.5

mm.

and.12

mm...

5-2

Exploded

View

of

Electrodes

(

|

Tools

used

;

cu

Philips

screwdriver

(small),

Hex

socket

“39

for

M3

and

Má

40

(bolts),

Wrench

7

mm

and

Pliers

5-3

Exploded

View

of

Power

Switch

Tools

used

;

Philips

screwdriver

and

Wrench

5.5

mm

PT,

-

10

-

и

4

LU

GIONATOS

=

OS

dd

|

)

D

OS

9

HILIMSOYDIN

=

Z

°F

TSN

5

LS

λνΊπα

-

στᾶ

AVIMI

=

TTU

,

my?

5

|

9

IND

|

T

mM

hy

1

ως

и

a

R

や

29

y

A

9

οδοί

ing

AMO

|

。

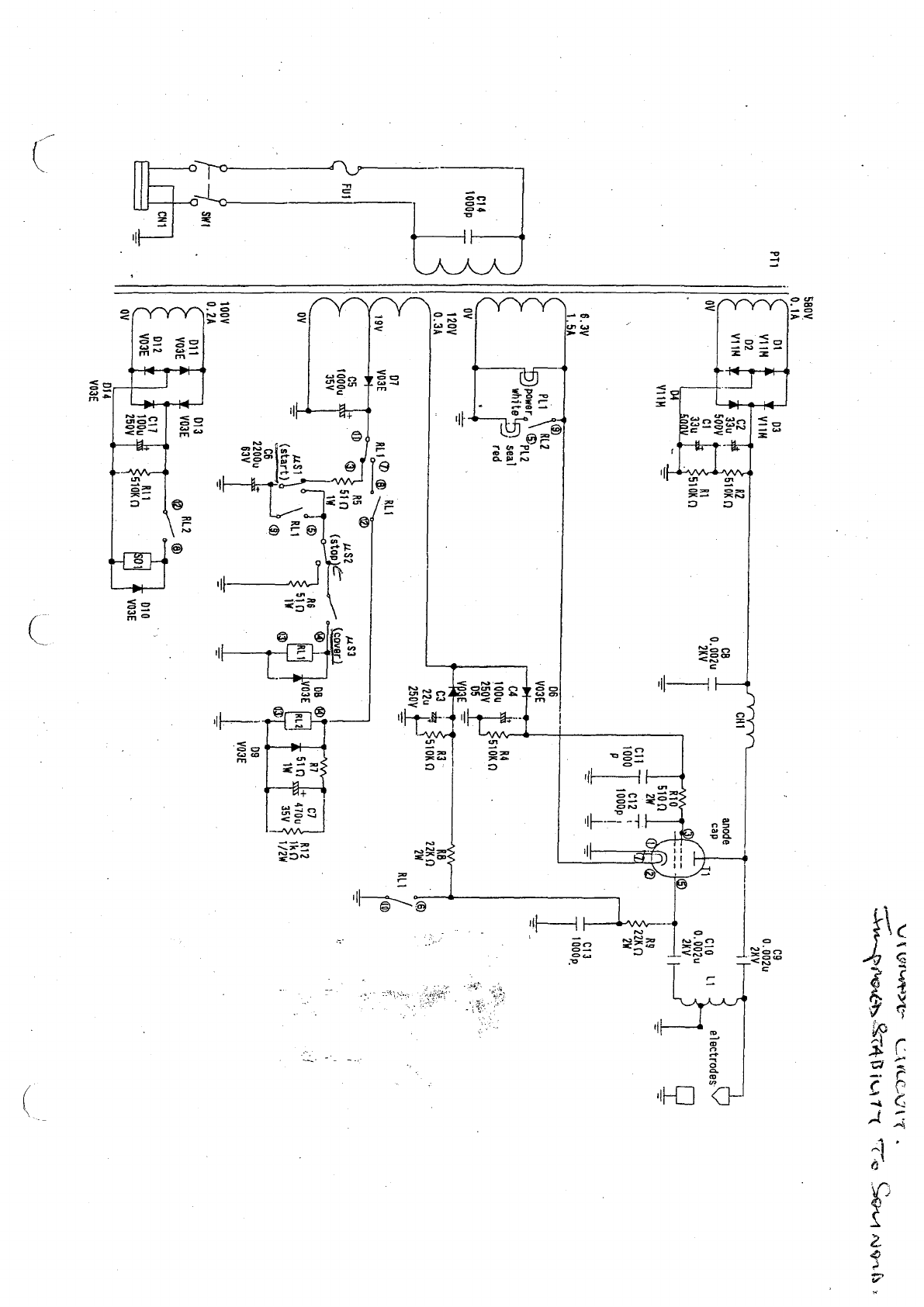

we20Mz:

AJOS

-

VHDVTO

LINOUID

:

XTpuaddy

WRITE

ACOA

To.

gez”

ss

oe

po

STAB

IUT

Te

580V

0.1A

|

pt

09

PT1

VIM

0.002u

02 eK

。

VI

'

y

ov

+

cio

Li

electrodes:

0.002u

品

6.3V

13

ASA

ο,

e

008

1

-29

Pit

|

REZ

powers

Op

7

white

(SY

sea]

C14

1000p

|

@

@

Ευ!

|

;

a

1

(start)

;

C6

22000

r

63V

1009

L

I

m

0.2A

=

9

`

1

VO3E

1

CN1

m2

1

|

1

W3E

후

010

Яя

VO3E

à

DİZ

—

*

VOIE

LY

ИЯ

ια

Л

므

TIE

.

ο

TLd

3°

ロロ

ロゴ

ロゴ

ロロ

MOTA

UO1104

—

С:

Na

SECTION

6

:

PARTS

LIST

6-1

Cabinet,

Chassis

and

Panel

Ref.

Symbol

Ref.

No.

Description

Model

No.

Q'ty

Remarks

1

Cabinet

2

—

252

1

2

Cabinet

bottom

M3

x

0.5

x

6

17

cover

and

rear

panel

lock

screw

3

Handle

H-16,

3555

1

4

Handle

lock

M4

x

0.7

x

12

2(SW,

,

Screw

N)

5

Panel

_

3

=

65

(out)

1

6

Panel

Lock

screw

M3

x

0.5

x

8

6

PL1

7

Power

lamp

B6

1(SW,

Bulb

H-

N)

5513

8

Chassis

2-253

1

9

Bottom

cover

3-650

1

10

Rubber

cushion

leg

80692

(В)

4

11

Rubber

cushion

leg

M3

x

0.5

x

12

4(W)

lock

screw

|

12

Rear

panel

attach-

4

-

1784

1

ing

plate

13

"Rear

panel

attach-

4 -

1615

1

ing

plate

6-2

Electrodes

Ref.

Symbol

Ref.

No.

Description

Model

No.

Q'ty

Remarks

»

14

Sealer

case.

(1)

4

-

1657

1

15

Case

lock

screw

M4

x

0.7

x

10

2

Plastic

16

Anode

lock

screw

M3

x

0.5

x

10

1(SW)

17

Adjusting

screw

Hexagon

M3

x

2

LD

0.5

x

6

-

18

Anode

lock

screw

4

-

1656

1

19

'

Attaching

plate

Hexagon

M4

x

4(SW)

lock

screw

.7

x

10)

20

Sealer

case

(3)

5

-

2002

1

21

-

Case

lock

screw

M4

x

0.7

x

io

2

plastic

uS1

22

5

-

2000

1

一

|

23

5

-

1999

1

"24.

Hexagon

M3

x

1

ーー

0.5

x

6

25

Solenoid

setbolt

Hexagon

M4

x

2(SW)

ON

0.7

x

10

26

Cable

lock

screw

M3

x

0.5

x

6

1(SW)

27

Coaxial

cable

RG-195

A/U

200mm

Teflon

28

Anode

attaching

4

-

1649

1

.

metal

29

Microswitch

(1)

SSSGL

1

For

start

=.

e

de,

Ref.

Symbol

Ref.

No.

|

Description

Model

No.

Q'ty

Remarks

|

30

Microswitch

lock

M2

x

10

2

(SW)

(

31

Sealer

cover

(2)

4

-

1655

1

32

Sealer

case

plate

4

-

1658

1

33

Stainless

steel

1

Terumo

ball

for

pack

blood

bag

34

Spacer

(S)

1

”35

Plunger

1

36

Solenoid

1

©

4-1659

37

Insulation

tape

Teflon

or

vinyl

ps2

38

Microswitch

(2)

V-1A

|

For

ーー

・

TTT

TTT

clerance

detect-

ion

39

Microswitch

lock

M3

x

0.5

x

15

2(SW)

screw

|

R6

É

40

Solid

resistor

517,

lw

41

Regulation

nose

5

-

2003

42

Plunger

attach-

5

-

1998

ing

plate

43

Adjusting

screw

(2)

M4

x

0.7

x

15

1(N)

44

Adjusting

screw

(3)

M4

x

0.7

x

25

2(SW,

N)

45

Metal

lock

bolt

Hexagon

M4

x

1(SW)

때

46

Ground

wire-

0.7

x

10

200mm

|

(

netting

47

Spring

5

-

2005

1

.

1153

48

Microswitch

(3)

SS5GL-13

1

For

..

e

|

|

safety

49,

Microswitch

lock

M2

x

10.

2(SW)

screw

50°

Insulation

tape

Teflon

or

“vinyl

6-3

Switch

Ref.

Symbol

Ref.

No.

Model

No.

Q'ty

Remarks

52

M3

x

0.5

x

15

2(SW,

a

N)

„53

#6

x

0.4

x

5

54

EST

156

ー

13

-

一

一

一

一 一

一 一

一

一

一

一

一 一

一

一

一

一

一

一

一

一

一

一 一 一

一

一

一

一 一 一

一

一

一

一

一

一

一

一

一

一

一

一

一

一

一 一

一

一

一

一

一

一

一

一

一 一

一

一

一

一 一 一 一

一 一

一

一

一

一

一

一

一 一

一

一

m

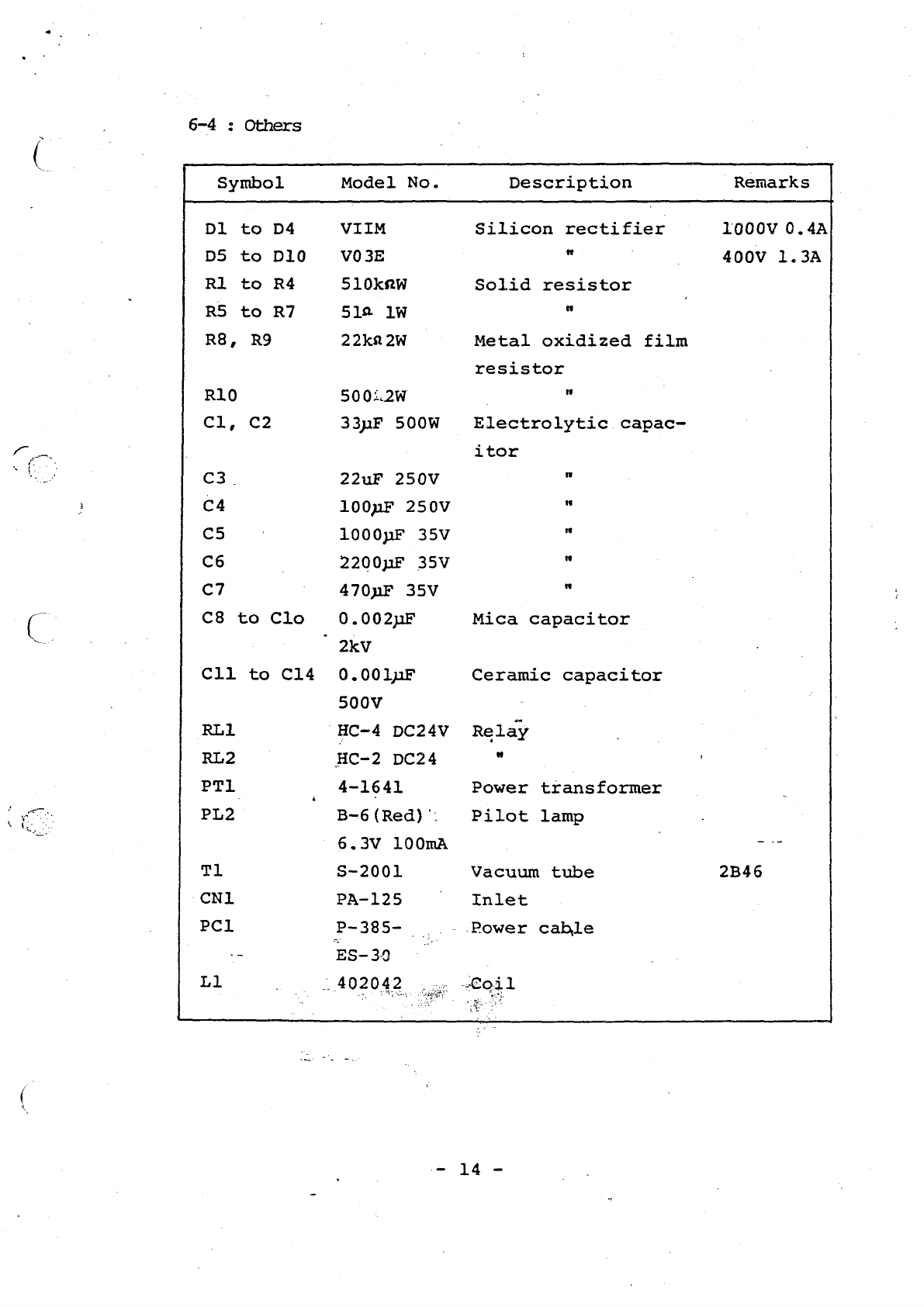

6-4

:

Others

402042-

Symbol

Model

No.

Description

Remarks

01

to

D4

VIIM

Silicon

rectifier

1000

0.4A

DS

to

DIO

VO3E

"

| .

400V

1.3A

RI

to

R4

S10kNW

Solid

resistor

RS

to

R7

512

1W

"

R8,

R9

22k2

2W

Metal

oxidized

film

resistor

R10

500:.2W

|

"

cl,

C2

33uF

500W

Electrolytic

capac-

itor

C3.

22uF

250V

"

C4

100µΕ

250ν

"

C5

1000pF

35V

"

C6

2200µΕ

35ν

"

C7

4701Ε

35V

"

C8

to

Clo

0.002pF

Mica

capacitor

”2kV

611

to

614

0.001pF

Ceramic

capacitor

500V

RLI

(HC-4

DC24V

Relay

RL2

HC-2

DC24

"

|

PTL

_

471641

Power

transformer

PL2

B-6

(Red)

Pilot

lamp

6.3V

100mA

ーー

TI

S-2001

Vacuum

tube

2B46

-CN1

PA-125

Inlet

PCI

P-385-

Oo.

Power

cable

-

ES-39

11

—

14

-

グー

X

Table of contents