Teseq NSG 435 User manual

1

NSG 435 ESD SIMULATOR

USER MANUAL

601-131H

NSG 435 ESD simulator

NSG 435 ESD SIMULATOR

USER MANUAL

1 General 5

1.1 Explanation of the symbols used in this manual 5

1.2 Safety 6

2 Introduction 8

2.1 Electrostatic discharge (ESD) 8

2.2 Simulation 9

2.3 Effects on the EUT 11

3 NSG 435 12

3.1 System descritpion 12

3.2 The simulator 13

3.2.1 Function modules 13

3.2.2 Block diagram 14

3.2.3 Operating elements 15

3.3 System components 17

3.3.1 Basic set 17

3.3.2 Charging unit/battery-pack 17

3.3.3 Options 19

3.3.4 Mains power supply unit 19

3.3.5 Discharge networks 20

3.3.6 Remote triggering 21

3.3.7 Measurement adapters 22

4 Commissioning 23

4.1 Inspection 23

4.1.1 Function check 23

5 Operation 25

5.1 General 25

5.2 Switching on 25

5.3 Battery monitor 27

CONTENTS

5.4 Air/Contact-discharge 28

5.5 Voltage 29

5.6 Polarity 30

5.7 Repetition frequency 31

5.8 Counter 31

5.9 Preselect counter 32

5.10 Automatic polarity switching 34

5.11 Continuous operation 37

5.12 Storing voltage settings 39

6 Test procedures 41

6.1 Standard-conforms procedures 41

6.2 Other conditions 41

7 Vericationofthepulsedata 43

8 Maintenance 44

8.1 Servicing 44

8.2 Calibration 44

8.3 Exchanging the R/C network 47

8.3.1 Derating of pulse repetition at increased capacitance 49

8.4 Repairs 50

8.5 Disposal 50

9 DeclarationofConformityCE 51

10 Technicalspecications 52

11 ESD standards 54

12 Warranty 55

13 Oderinginformation 56

14 Addresses 57

5

1.1Explanationofthesymbolsusedinthismanual

Please take note of the following explanations of the symbols used in order

to achieve the optimum benet from this manual and to ensure safety during

operation of the equipment.

The following symbol draws your attention to a circumstance where non-

observation of the warning could lead to inconvenience or impairment in the

performance.

Example:

1 GENERAL

Thisconnectionmustnotbeconfusedwiththemains

powerinput.

The following symbol draws your attention to a circumstance where non-

observation of the warning could lead to component damage or danger to the

operating personnel.

Example:

Neverconnectordisconnectthepistolwhilesystemis

performingatest.

Symbols used on the product:

Danger

highvoltage

Protective

earthterminal

Attention

refertomanual

6

NSG 435 ESD simulator

1.2Safety

Onlytrainedpersonnelmayoperatetheinstrument.

Thisitemofequipment,togetherwithitsaccessories,

worksathighvoltagesofupto16.5kV.Anycareless

handlingornon-observanceoftheoperatinginstruc-

tionscanhavedangerousconsequences.

The NSG 435 simulator is not a toy! It is a professional tool and belongs only in

the hands of specialists and appropriately trained personnel.

When powered by its own batteries the simulator can be active even without

any power cable being connected.

The instrument must not be switched on unless a correctly connected earth or

ground cable (pulse current return path) is in place. The original earth cable supplied

with the instrument is to be used. Any replacement cables must be fabricated in

such a way that they cannot be accidentally connected to a mains outlet socket.

Do not touch the test nger! There is a danger of an unpleasant electric shock

if the instrument is switched on (LC-display active).

Personnel tted with a heart-pacemaker must not

operatetheinstrumentnorapproachthetestrigwhile

it is in operation.

These operating instructions form an integral part of the instrument and must

be available to the operating personnel at all times.

The instrument must not be used for any purpose other than testing the ESD

immunity of electronic equipment.

7The construction of the simulator is not designed for use in an explosive env-

ironment.

Eachelectrostaticdischargeproducespowerfulelectro-

magneticinterference.

Nearby electronic equipment can be seriously disrupted unless

the appropriate counter-measures are taken. Perform ESD tests

preferably in a shielded room.

The rechargeable batteries in the handgrip must not be short-circuited under

any circumstances. They must only be recharged with the original charging unit

supplied with the simulator. Should they have to be replaced, kindly observe

the relevant recommendations for the disposal of nickelmetal hybrid batteries

(if delivered before 2002).

The instrument must not be opened. Repairs, maintenance work and internal

adjustments are only to be carried out by a qualied service engineer.

Use the instrument only in dry surroundings. Any condensation that occurs

must be allowed to evaporate before putting the simulator into operation.

Long periods of exposure to sunlight and excessive warming by external energy

sources are to be avoided.

Do not continue to use the instrument should any mechanical damage occur.

The instruments housing has both an insulating and a screening function which

can only be assured while the housing is intact. Return a damaged simulator to

a Teseq service centre immediately for repair.

Teseq AG Luterbach, Switzerland and the associated sales organizations accept

no responsibility for personal or material damage nor for any consequential

damage that may result from irresponsible operation of this instrument.

8

NSG 435 ESD simulator

2.1Electrostaticdischarge(ESD)

Under appropriate ambient conditions, both material objects and even the

human body itself can become charged with electrical energy. This effect is

due to «electrostatics», a phenomenon that has been known since the earliest

times. Thales von Milet (600 BC) noticed how amber attracted very light particles

when it was rubbed. Touching a charged item against a conductive object leads

to a charge equalization through a spark discharge which produces a brief but

powerful electromagnetic eld.

This effect can be explained as follow: Two insulating substances with differing

dielectric constants become charged when rubbed together, i.e. one material

gives electrons to the other one. This effect is known as electrostatic charging.

The same can happen to a person. When somebody walks around in a dry

atmosphere on a carpet with good insulating properties, a charge of several

thousand volts can be built up. If, now, that person comes close to a conductive

surface, the charge that he or she is carrying ows away through a hefty spark

discharge.

The high equalizing current that ows, and the associated large electromagnetic

eld that hence results, can cause electronic devices (computers, terminals,

process controllers, vehicle electronics, solid state devices, credit or memory

cards, etc.) to malfunction or even be destroyed.

2 INTRODUCTION

92.2 Simulation

A systematic investigation of electronic equipment and installations to deter-

mine their electromagnetic compatibility (EMC) is, today, a necessity if one is

not prepared to suffer the economic disadvantages that could otherwise ensue.

As a logical consequence, appropriate testing is now a legal requirement for

the sale of electronic products within the EC.

The ESD test plays an important role in the range of interference sensitivity

tests. It simulates frequently occurring effects and guides the development

engineer to any weak spots in an instrument or item of equipment through a

combination of high voltage and high frequency properties.

A simulation device must be constructed so that it reproduces practical con-

ditions realistically. Furthermore, the results obtained (interference sensitivity

threshold) must be reproducible.

The interference immunity of an instrument is not only dependent on its con-

struction, it is also largely dependent on the quality or the consistency of the

mass production techniques used. Knowing this has led to the demand for

individual testing or at least random sample testing.

Further weak spots, which could affect the overall interference immunity, can

arise through the assembly of instruments into complete systems because

of the installation method used, the cabling and the earthing. An ESD check

on systems is therefore also prescribed. Such tests provide valuable informa-

tion about the immunity of the system to effects that occur only sporadically

under operating conditions and hence represent difcult to detect sources of

disruption.

10

NSG 435 ESD simulator

The ESD simulator NSG 435 fulls the requirements of various applications in

an ideal manner:

Ergonomic shape For nontiring use

Operation Operating elements and display always in view

of the user. Constant check on the test values.

Battery-powered Independence from a mains power feed.

Compact and handheld No bench unit as the high voltage source,

no high voltage cable. Optimal freedom of

movement around the device or system

to be tested.

Carrying case Simulator and accessories can be handily

packed and conveniently transported.

Microprocessor-control All the functions are «on-board», including a pre-

settable counter, pre-programmed test values,

discharge voltage measurement, etc.

Precision The test parameters are maintained precisely

for reliably reproducible tests.

Flexibility The specications prescribed in the standards

are more than fullled in every respect. The

instrument also offers many additional handy

features.

Safety The high voltage simulator is automatically de-

activated if the instrument remains unused for a

period of time.

Longterm operation Automatic longterm operation for stationary

applications with mounting on a tripod.

Application eld Development optimization, type approval, EMC

certication, batch testing (individually), testing

of fully installed systems.

112.3EffectsontheEUT

The most signicant interference components of an electrostatic discharge

are of a high frequency nature. The interference paths and effects have to be

assessed in the range from about 30 MHz to the multi-GHz range.

The extremely rapid rise time of a discharge affects an object under test mostly

through:

magnetic HF-coupling between electrical conductors in the electronics and

the discharge current path.

electrical coupling between the discharge current and signal lines. A dis-

charge current to the EUT ows proportionally through all the associated-

conductors (earth, mains, data lines, screening, etc.) according to their rela-

tive impedance.

Malfunctions in insufciently immune electronic equipment and systems make

themselves apparent through:

program crashes

blocking of command sequences

incorrect commands, statuses or data being processed

partial system resets (e.g. only in peripheral modules which lead to

errors that the system does not recognize)

disturbance or destruction of interface chips

destruction of insufciently protected MOS or other components

ESD testing usually shows up all the weak spots in the HF-range of a piece of

equipment simultaneously. The uses to which the NSG 435 simulator can be put

hence go way beyond those called for in standard-conform applications.

This instrument provides the engineer with a means to detect sources of error

caused by unsuitable earthing, poor ground connections, insulation problems,

etc.

The simulator also serves as a reliable aid for localizing hidden wiring faults

during acceptance trials on installations.

Use can also be made of the instrument as an insulation tester to determine

the breakdown voltage of switches, relay contacts, insulators, etc.

12

NSG 435 ESD simulator

3.1Systemdescription

By using the latest materials, construction methods and manufacturing tech-

niques for the robust housing shell, together with highly insulated modules, the

newest high voltage technology and a control unit built using the SMD-tech-

nique, it has been possible to integrate all the functions that a comprehensive

simulator system should offer into one compact instrument.

Professional industrial designers have ensured an optimized ergonomic concept.

The instrument, with its well-balanced handgrip, sits comfortably in the users

hand and guarantees non-tiring operation. Both the operating elements and the

display window remain in view of the user while work is in progress.

Thanks to its battery pack, the NSG 435 offers optimal freedom of movement

around the workplace and is an ideal test instrument not just for the deve-

lopment engineer but also for quality control purposes, system tests and for

investigations in the eld.

As supplied in the basic set, the system is equipped with a 150 pF/330 Ω

discharge network for the IEC/EN 61000-4-2 standard. The discharge voltage

of up to 16.5 kV for air-discharges and up to 9 kV for contact discharges ensure a

comfortable test margin over and above the levels called for in the standard.

The instrument is well equipped to cope with other (and future) standards. The

accessories include various networks and test ngers that can be attached by

the user himself.

The basic set contains everything necessary for general use. For special tasks

a rich assortment of accessories is available such as a mains power unit for

longterm operation, a remote triggering unit via an optical link, spare battery-

packs, discharge networks, test ngers, etc.

3 NSG 435

133.2Thesimulator

3.2.1 Function modules

The NSG 435 simulator is modularly constructed from a number of function

units that are all housed in a multi-part, molded shell.

HV-generator

discharge network

(exchangeable)

measuring electronics

high voltage relay

polarity changeover

Control section µ-processor,

keypad, display and remote

trigger connection

Test nger

(exchangeable)

Earth cable

connection

Pulse

trigger

Exchangeable

battery pack

Tripod bush

UNC1/4-20

Handgrip

14

NSG 435 ESD simulator

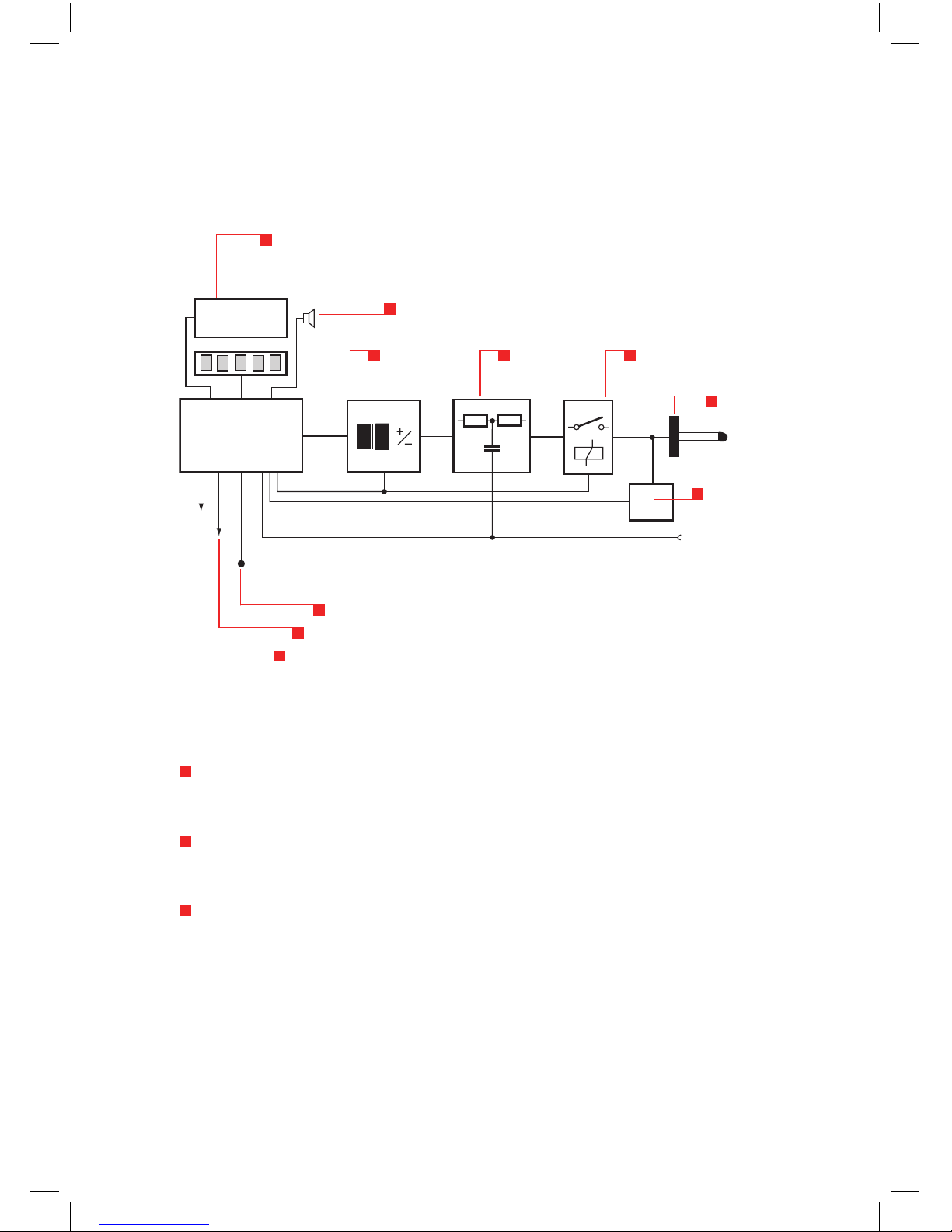

3.2.2Blockdiagram

The function units are shown in the block diagram:

The microprocessor controls and monitors all the generator functions:

Keypad entries are checked for plausibility. Unacceptable entries are rejected

and an acoustic warning noties the user of the error.

Values entered are clearly shown on the large display screen. Further infor-

mation shows the operating status and the counter settings.

The battery charge state is continuously monitored. A tendency towards low

voltage is shown on the display. The instrument’s functions are inhibited

once the battery voltage is insufcient to guarantee the pulse parameters.

High voltage

generator

Test

fingerµP Control unit

±10.0kv Buzzer

Display

Trigger button

Ext. trigger

Batt / Mains PSU

Discharge

network

High voltage

relay

Measurement

circuit

15

The high voltage generation is dynamically controlled by the processor.

Varying load conditions, supply voltages, etc. can thus be taken into account

and have no effect on the pulse parameters.

The instrument switches itself off automatically if it is not used for a while.

The pulse parameters and operating mode remain stored and ready for use

once the simulator is switched on again.

The charge voltage to the network is kept constant as long as the trigger is

active. The high voltage is discharged internally when the trigger is reset.

If no discharge occurs when set for an air-discharge and the trigger is active,

the processor waits for about 15 s then autonomously resets the trigger

and discharges the network internally. An acoustic warning is also sounded.

A measurement facility at the pulse output measures the actual air-voltage

reached during an air-discharge and shows the result on the display.

Pulse triggering is monitored. Once an arc has occurred the network is

discharged internally so that no further arcing is possible.

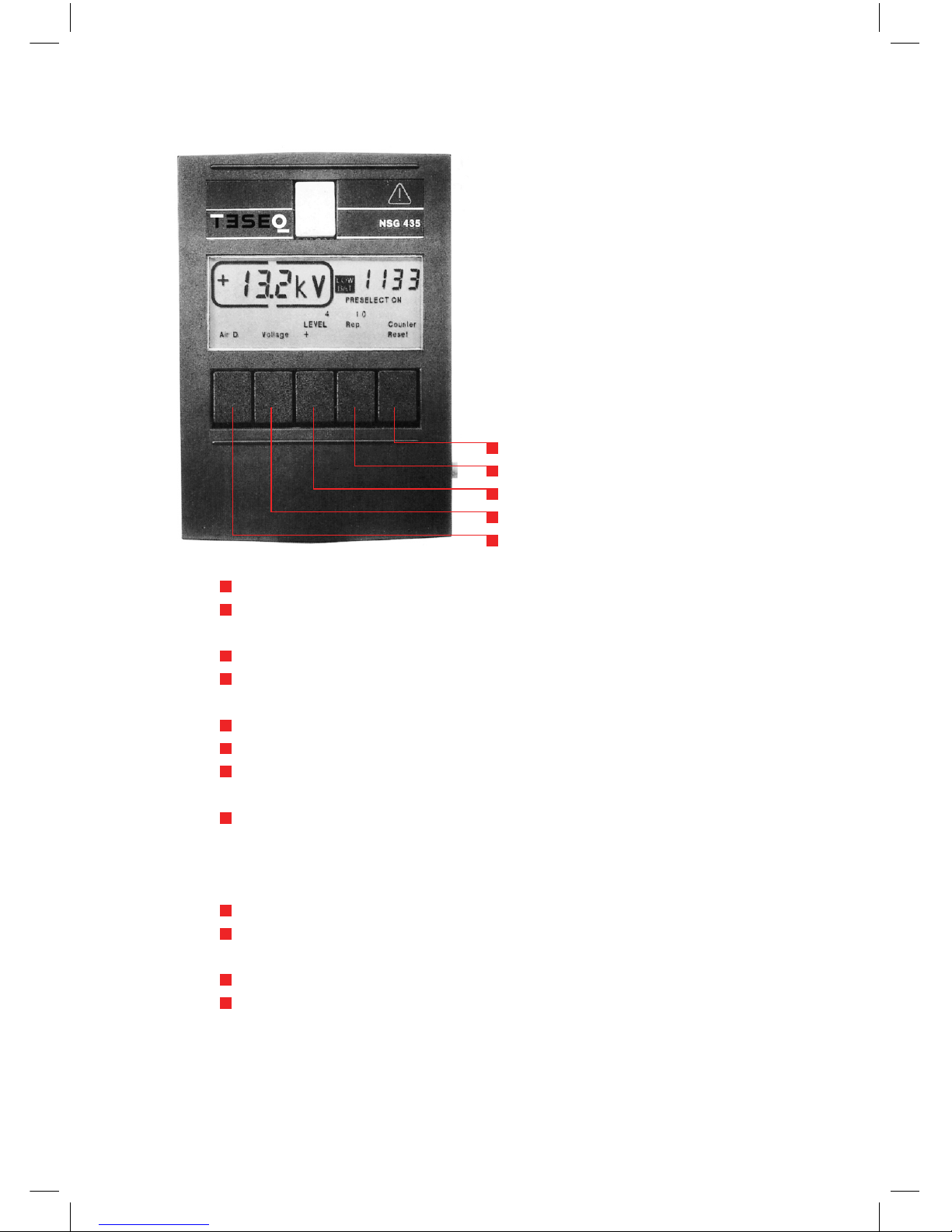

3.2.3 Operating elements

Apart from the trigger button itself (pulse triggering) all the operating elements

are on the surface of the instrument that faces the operator.

The NSG 435 is switched on/off with the main switch.

The signicance of the elements in the display eld can be seen in the following

picture. Further information can be found in section 5 «Operation».

Operation of the whole instrument is effected via the ve multifunction buttons

(soft-keys). These buttons perform different functions depending on the stage

of operation. The current function is shown on the display in each case.

The designation F1 to F5 used for these buttons in the following notes serve to

simplify the descriptions in this manual.

16

NSG 435 ESD simulator

F1 Toggle between air and contact-discharge (and vice versa)

Increment voltage and counter

F2 Activation of voltage setting

Decrement voltage and counter

F3 Polarity switching:

Selection of pre-programmed test levels

Preselect counter on/off

F4 Selection of discharge mode:

Single discharge Repetitive discharge at 0.5, 1, 5, 10, 20, 25 Hz

for air-discharge

Repetitive discharge at 0.5, 1, 5, 10 Hz for contact-discharge

Automatic polarity switching

Storage of programmed test levels

F5 Resets the counter

Return from second function

F1

F2

F3

F4

F5

17The trigger button in the hand-grip works as folIows, depending on the

operating mode selected:

For single discharge as a pulse button

(1 pulse when pressed)

For repetitive discharges as on/off button

(discharge while the button is pressed)

For repetitive discharges with as a holding on/off button

preselect counter active (switch on by pressing the button,

switch off by pressing the button again)

The remote triggering facility is a substitute for the manual trigger button by

producing the relevant control signals.

3.3Systemcomponents

3.3.1 Basic set

The basic set is packed in a practical carrying case and comprises:

Carrying case 42 x 32 x 13.5 cm (16.5 x 12.5 x 5.5 ” approx.)

ESD simulator NSG 435 with battery-pack and 150 pF/330 Ω discharge network

conforming to IEC/EN 61000-4-2, Ed. 1.2:2001

One test nger each for air- and contact-discharges

Earth cable

Battery charger

Operating instructions

Calibration certicate

This set contains all the items necessary under normal conditions to perform

tests conforming to IEC/EN 61000-4-2, Ed. 1.2:2001.

18

NSG 435 ESD simulator

3.3.2Chargingunit/battery-pack

The battery charger supplied in the set is designed for multi-country use and

is coming with various mains adaptors. Green LED shows fully charged battery

status.

Operation range 100 V to 240 V (50/60 Hz)

Charging of the battery takes about 1 hour. For further details please refer to

separate manual.

The battery has to be removed from the NSG 435 for charging via the jack con-

nector. One charge is sufcient for several days of normal test operation.

Battery life expectancy:

Ambient temperatures over 50°C can lead to degradation of the battery. If

treated carefully, more than 300 charge/discharge cycles can be expected

without any noticeable reduction in capacity.

The charger and battery-pack form a matched entity. The battery must not be

charged from any other unit and the charger is to be used exclusively for the

intended purpose.

Operating advice:

Avoid short-circuits. Keep the contacts clean

Use the equipment only in dry surroundings

Do not switch the mains off while charging otherwise the timer will be

restarted

Never leave the battery in a fully discharged state for a long time

Do not attempt to recharge a full battery

Recharge the battery about every 6 months even if the instrument is not

being used

19

The handgrip adapter is an integral part of this power supply unit. It contains

electrical components that are necessary for this mode of operation. It is not per-

missible to operate the NSG 435 with a power supply unit from another system.

The power supply unit can be used on all common AC mains supplies without

having to make any adjustments, thus:

80 to 240 V (50/60 Hz) with 3-pin IEC connector

Matching 3-core mains cable

3.3.3 Options

A range of additional accessories is available for special applications and for

testing to other standards:

Spare battery-pack (space available in carrying case)

Mains power supply with adapter

Remote triggering unit with 5 m (197 ”) optical cable

Discharge networks and test ngers for other standards

Coaxial measurement adapter (target)

3.3.4Mainspowersupplyunit

Instead of using the normal battery-pack, a mains power supply unit type

INA 402 can be used for stationary applications and for longterm test pur-

poses.

20

NSG 435 ESD simulator

The power supply unit must be connected to a mains outlet having a protective

earth.

The protective earth connection does not replace the earth cable for the opera-

tion of the NSG 435. To ensure safe and valid test operation the earth cable must

be correctly connected as the pulse return path in every case.

The mains power supply unit is constructed in conformity with the relevant

safety standards and carries the appropriate test symbol.

3.3.5Dischargenetworks

The basic set contains a discharge network and test ngers that conforms to

IEC/EN 61000-4-2, Ed. 1.2:2001.

Alternative networks can be installed for testing in accordance with other

standards.

The discharge network and test ngers form a mutually matched combination.

They are labeled with a corresponding INA number. The specied pulse data

are only achieved while this combination is maintained.

Several combinations are given in the order list. The C and R values of the

discharge network can also be specied for other applications.

Networks conforming to other standards can be built upon request. The speci-

cations of the standard must be fully dened.

Exchanging the discharge network is described in section «Exchanging the R/C

network».

Table of contents

Other Teseq Test Equipment manuals

Popular Test Equipment manuals by other brands

Apera Instruments

Apera Instruments GroStar GS2 user manual

Agilent Technologies

Agilent Technologies Medalist i3070 Series System installation

Mictel LLC

Mictel LLC ECCT instruction manual

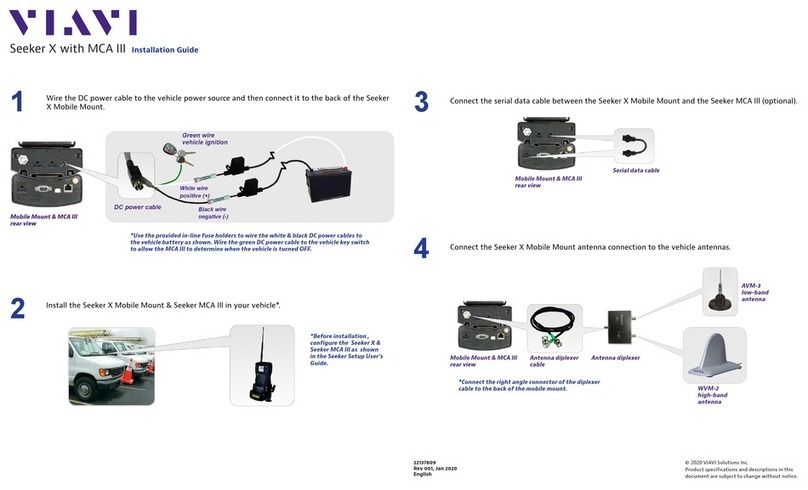

Viavi

Viavi Seeker X with MCA III installation guide

Kane

Kane KANE-VCT instruction manual

GemOro

GemOro AuRACLE Quick operation guide

Image Engineering

Image Engineering LE7 x2 user manual

Gossen MetraWatt

Gossen MetraWatt SECUTEST BASE operating instructions

Rigol

Rigol DS2000A Series Specifications

ROD-L

ROD-L M25 quick start guide

Granite Digital

Granite Digital Save A Battery 1295 Instruction & Diagnostic Manual

Multi

Multi MET-2 instruction manual