TeST TT AUT-MARSHALL-CBR User manual

INSTRUCTIONS

MANUAL

AUTOMATIC MACHINE FOR CBR AND

MARSHALL WITH LOAD FRAME

(MARSHALL: ASPHALT ANALYSIS

METHOD)

Model: TT AUT-MARSHALL-CBR

File No.: TEST- V2.3-EN

Publication Date: Sept 30 2021

Print Date: Oct 5, 2021

Contents

Section Page

WARNING 3

1 Introduction 5

2 Specification 6

3 Installation 6

4 Controls 7

5 Setting up for CBR tests 10

6 Setting up for Marshall tests 12

7 Setting up for Quick Undrained Triaxial tests 14

8 Maintenance 15

9 Connecting a DSU Readout device 16

CE Declaration of Conformity

WEEE Directive

Original Instructions 2

WARNING:

This equipment can endanger life by exposure to high voltages.

The equipment must be permanently earthed due to the high earth leakage current in the

motor and drive. Use the earth lead on the rear of the unit to connect to a permanent safety

earth. The AC inlet should not be relied on to provide a safe earth.

Service personnel must ensure all incoming supplies are isolated before working on the

equipment.

There may still be dangerous voltages present at power terminals (motor output, supply input

phases, DC bus and the brake, where fitted) when the motor is at standstill or is stopped.

For measurements use only a meter to IEC 61010 (CAT III or higher). Always begin using

the highest range. CAT I and CAT II meters must not be used on this product.

Allow at least 5 minutes for the drive's capacitors to discharge to safe voltage levels (<50V).

Use the specified meter capable of measuring up to 1000V DC and AC RMS to confirm that

less than 50V is present between all power terminals and earth.

Original Instructions 3

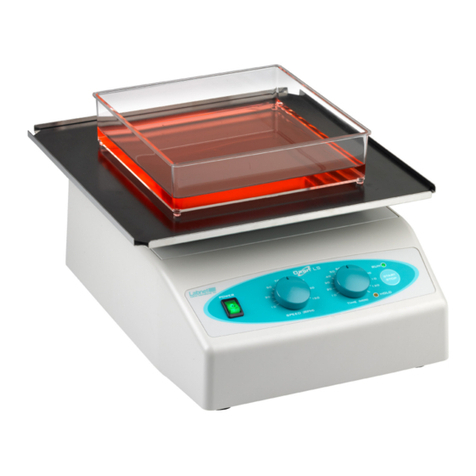

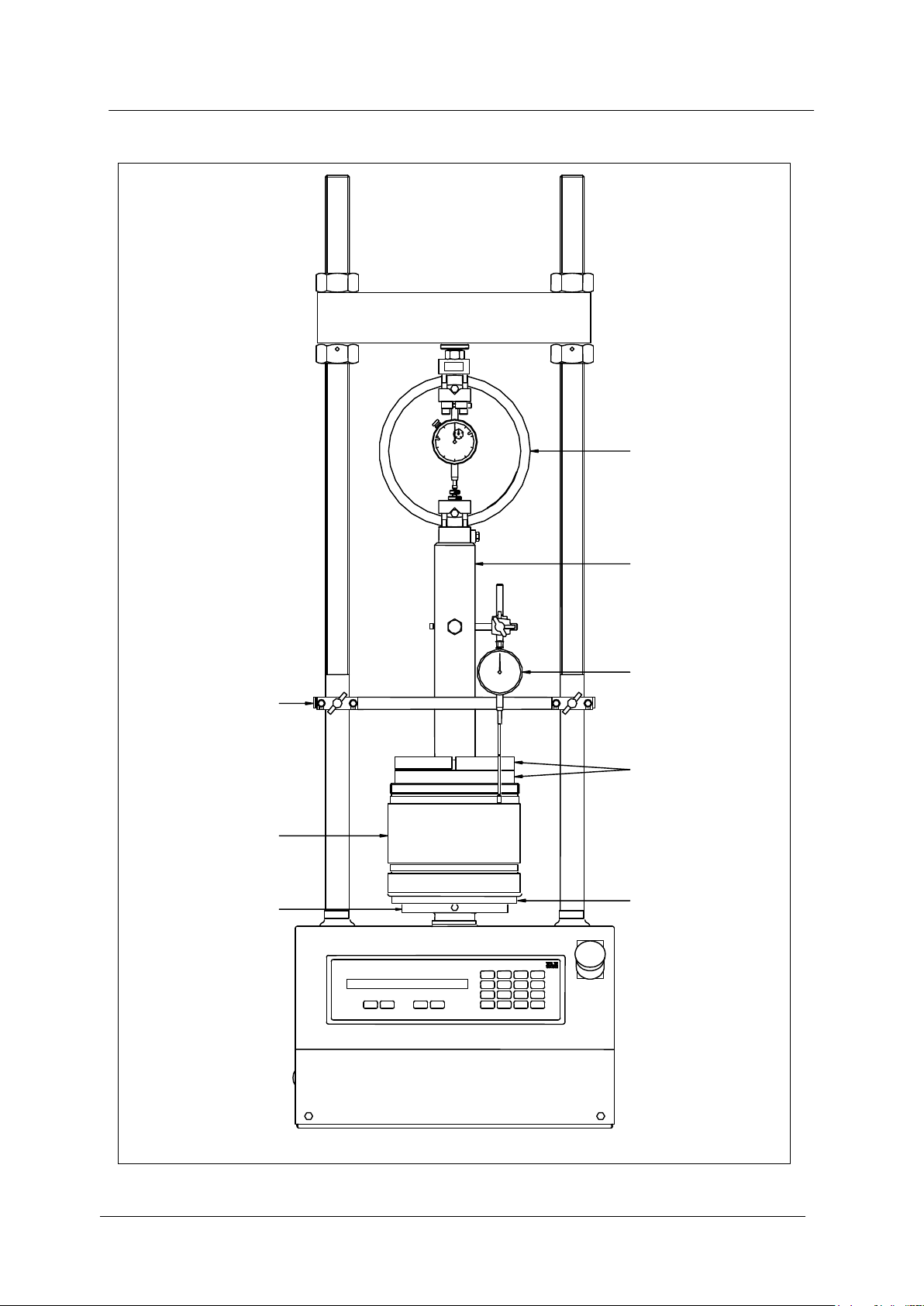

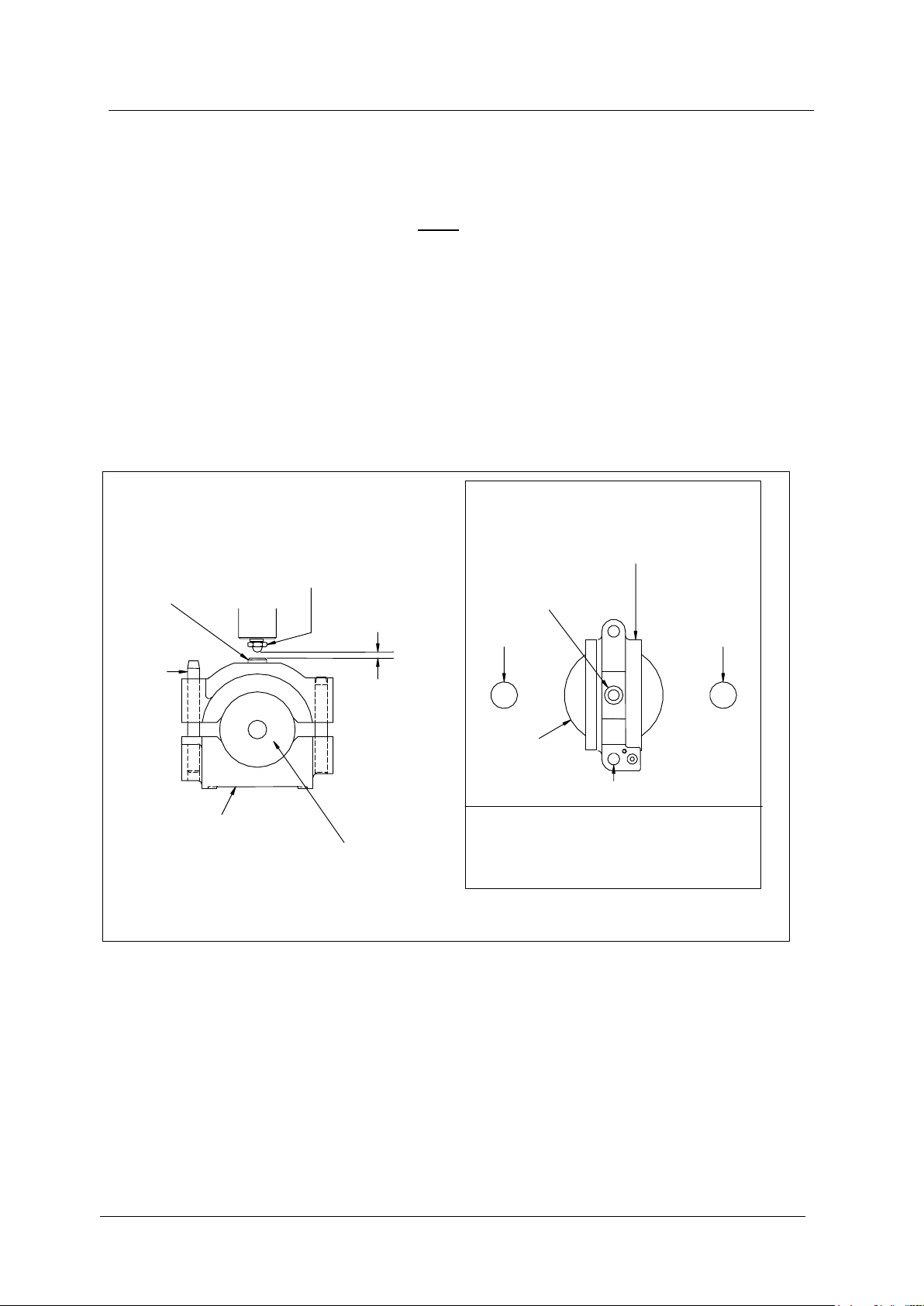

CrossheadColumn

Fitting for load ring

Locking nuts

Adjustment nuts

Alignment studs

Display

Platen

Holes for

tommy bar

Emergency

stop switch

Touch panel

keypad

Manually applied

platen movement

Figure 1.

Original Instructions 4

1 Introduction

These instructions are for machines with a serial number beginning 1895, i.e. of the

format 1895-X-XXXX.

This machine has been designed to perform compressive strength tests on soil and

asphalt samples. The following test types are built into the machine: California

Bearing Ratio (CBR), Marshall and Quick Undrained Triaxial (UU) tests. User-defined

test speeds are also allowed.

The apparatus consists of a load frame with an adjustable top crosshead mounted on

columns attached to a sturdy base casting. Loading forces of up to 50kN are applied

to the sample by means of a motor-driven platen and the speed is accurately

maintained by the control electronics and speed feedback system. The motor, gear

unit and microprocessor-controlled electronics are housed in the machine base.

Limit switches are fitted to prevent over travel on the up and down stroke of the

platen.

The user controls the machine via the front panel display screen and keypad. A

simple menu system provides speed control and all set-up operations

As well as the limit switches, the operator is protected by a stall detection system,

large emergency stop button and electrical fuses. All electrical design complies with

the relevant CE safety and interference directives.

Please note that the motor in this machine is capable of generating loads

greater than 50kN, so the operator must always be aware of the current loading

being applied in order to prevent overload. (Note that connecting the DSU readout

device provides automatic overload protection –see below)

A ball seated screw fitting located on the crosshead accepts load rings and load

transducers up to and including 50 kN.

Original Instructions 5

Two sockets at the rear of the machine provide connections for the Electronic Control

and read-out Unit (DSU). These are for use with electronic load and displacement

transducers (see section 9).

2 Specification

Dimensions

(l x w x h)

550 mm x 400 mm x 1230 mm

Weight

71 kg

Max. vertical clearance

(platen down crosshead up)

795 mm

Min. vertical clearance

(platen up crosshead down)

210 mm

Horizontal clearance

265 mm

Platen diameter

133.3 mm

Platen adaptor diameter

158.5

Platen travel

100 mm (nominal)

Platen speed

Variable 0.5 to 50.8 mm/min (0.020 –2 in/min)

2.1 Items supplied with the machine

Tommy bar for removing the platen

Platen adapter - fits on the platen to locate moulds when conducting CBR tests.

Stabilising bar - used to ensure stability and location of the penetration piston during CBR

tests and the stability piston during Marshall tests.

Stability piston - used in conjunction with the stabilising bar to provide very stable loading

conditions during Marshall tests.

Extended ball nipple - for mounting the axial strain transducer when using a 100mm

triaxial cell and load ring.

Power lead with moulded socket for connecting to the mains supply.

Communications cable (RS232) for connecting the machine to a DSU readout device.

3 Installation

3.1 The machine must be installed on a bench that is both level and designed to support

the gross weight of the machine, samples and ancillary equipment.

3.2 This equipment must be earthed via its mains input cable. A separate earth terminal

screw is provided on the rear of the unit as an optional extra safety earth and for PAT

testing connection point.

3.3 The machine contains a dc motor drive unit and the manufacturer of this drive unit

gives the following service and safety advice:

Never perform high voltage resistance checks on the wiring without first

disconnecting the drive from the circuit being tested.

When replacing a drive in an application and before returning to use, it is essential

that all user defined parameters for the product’s operation are correctly installed.

This equipment contains electrostatic discharge (ESD) sensitive parts. Observe

static control precautions when handling, installing and servicing this product.

Original Instructions 6

3.4 Power Supply

Electrical safety

Warning: Do not operate the unit without a permanent earth connection. Use the

cable provided at the rear of the unit.

Warning: Before removing any covers or performing maintenance repair and service,

isolate from electrical supply by removing mains plug. Where mains supply is

required during these activities, only competent persons should perform the work.

Check that the power supply is compatible with the requirements stated on the label

and connect in accordance with IEE regulations or to local electrical installation

regulations.

The power cable is coded as follows: -

Brown wire L Live or Power

Blue wire N Neutral

Green/Yellow wire E Earth or Ground

Note: Do not use the machine with wet hands. Dry hands before operating.

Organisations have an obligation to ensure equipment is maintained and is safe for

use. Regular Portable Appliance Testing (PAT) is one means of ensuring equipment

continues to be electrically safe. For operator safety, regular earth bonding

checks are recommended.

Do not flash test this electronic equipment.

4 Controls (refer to figures 1 & 2)

4.1 Mains ON/OFF switch (at the rear of the machine).

This will switch on the power to the machine. The display will briefly indicate

“Multiplex 50” before indicating the selected platen speed.

The LCD display has a back light which is illuminated when the machine is switched

on.

4.2 Emergency stop switch

This is the large red knob on the front panel. Pressing this switch stops the platen

from travelling in either direction. When this switch is pressed, the display will read

“EMERGENCY STOP BUTTON PRESSED Release button to proceed”. As a safety

feature, once this switch has been depressed, it latches in the off position and must

be physically pulled out to the on position before any other functions will operate.

This is a non isolated product. The signal plus control connections are not isolated

from the AC supply. [Note that the unit is isolated design of the machine].

Portable Appliance Tests (PAT)

All designed products are tested for electrical safety prior to sale.

An electrical safety test label is fitted, (usually adjacent to the mains input socket).

Should no label be found, please contact Service Department quoting the serial

number of the equipment.

If in doubt as to the most suitable connection point (which will usually be an

earth stud or an external earth connection) contact Service Department for

assistance.

Original Instructions 7

4.3 Set-up Menu

Press the SETUP key to enter set the basic machine parameters. Press the left and

right arrow keys (< and >) to scroll through the options for any particular setting. Press

the up and down arrow keys to select a different function to set. The diagram below

illustrates the use of the set-up menus:

Press the SETUP key to edit operational settings

Use <and > (left/right arrow keys)

to select an option - in this case the

speed.

Press (Enter key) to confirm &

return to main screen

Use and (up/down arrow keys)

to select a different function –in this case variable

speed

Enter a number and press

(Enter key)

and keys to select a different function

<or > to select

<or > to select

<or > to select

(for use with DSU)

CBR (BS): 1.00mm/min

CBR (ASTM): 1.27mm/min

UU 38mm: 1.42mm/min

UU 100mm: 4.00mm/min

Marshall (BS): 50.0mm/min

Standard Speeds

Enter Non-Standard Speed: ……..

Variable Speed

1. mm/min

2. in/min

Speed Units

In all cases press

Enter key ()to

confirm your

selection, or ESC to

return to the main

screen without making

any changes

Enter Pass Code

Diagnostics

< or > toChange1-50

LCD Contrast

< or > toChange

Serial Baud Rate

(For Service use)

Original Instructions 8

4.4 RUN key

Pressing this key causes the platen to rise. The speed indicated on the display will be

preceded by “RUN”. The platen will continue to rise until the STOP key (or the

Emergency stop switch) is pressed. If the platen reaches the end of its travel before

these buttons are pressed, the limit switch will actuate preventing further upward

travel of the paten and the display will indicate “UP LIMIT!”

4.5 STOP key

Pressing this key will stop the platen rising when in RUN or DOWN modes.

(In UP mode the machine stops when the UP key is released)

4.6 UP key

Pressing and holding down this key will cause the platen to rise slowly to allow initial

adjustment of the platen position before a test. Press twice and hold for a rapid

approach upwards. Release the key to stop.

If the platen reaches the end of its travel before this button is released, the limit

switch will actuate preventing further upward travel of the paten and the display will

indicate “Ram Stopped at Upper Limit“.

Ram Stopped at Upper Limit

Press DOWN, RUN or SETUP to Continue

4.7 DOWN key

Pressing this key will cause the platen to lower at maximum speed until the STOP

key is pressed or until the platen reaches the end of its travel, in which case the limit

switch will actuate preventing further downward travel and the display will indicate:

Ram Stopped at Lower Limit

Press UP, RUN or SETUP to Continue

4.8 Manual Movement of the Platen

Note: Always disconnect the machine from the power supply when manually

moving the platen

The platen may be moved manually by means of a 6 mm AF hexagon wrench

inserted into the gearbox pulley via the hole provided in the machine case.

The wrench is turned clockwise to apply load to the sample and anticlockwise to

unload.

Original Instructions 9

5 Setting up for CBR tests

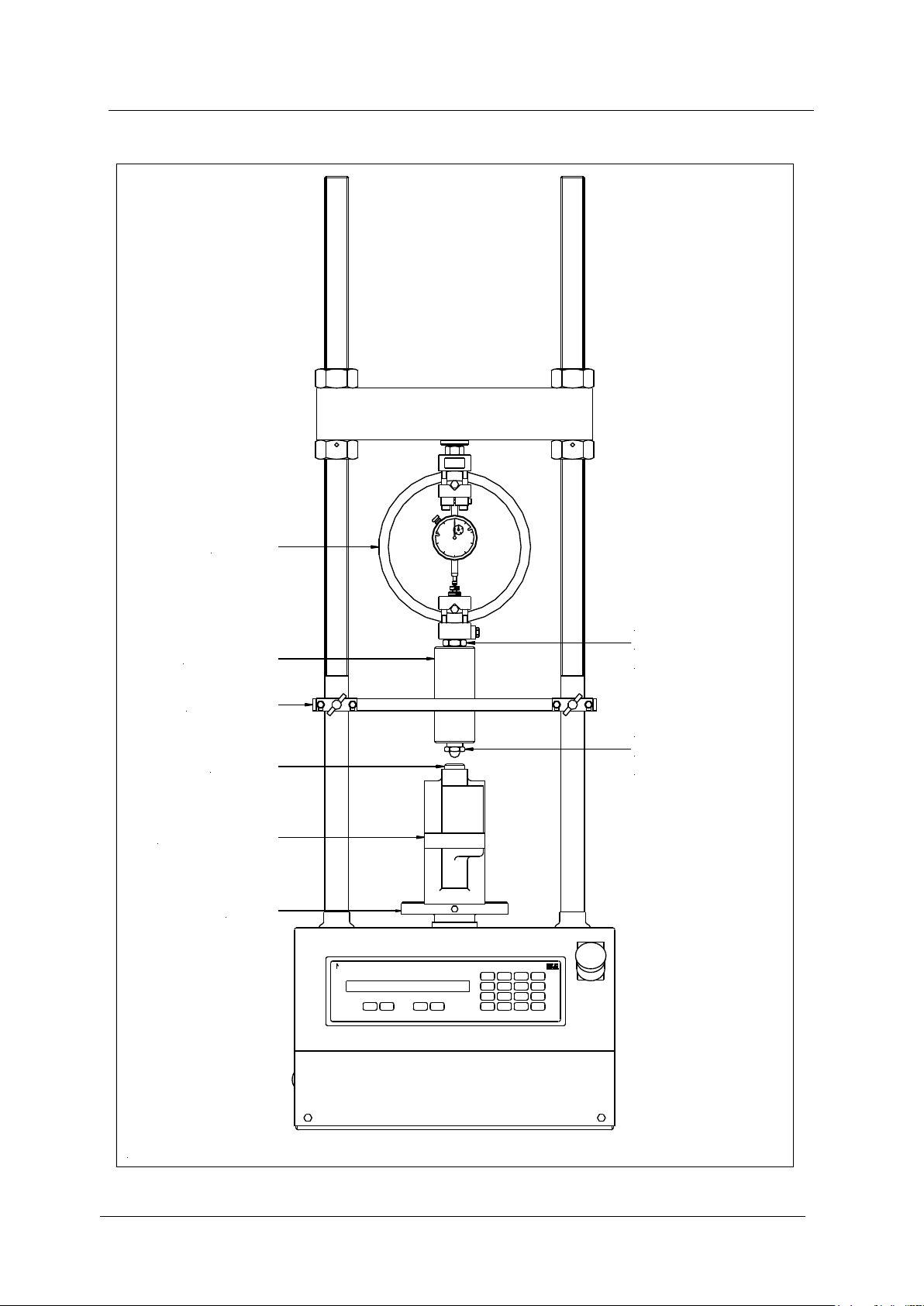

Load ring

Penetration

piston

Platen adaptor

Surcharge

weights

Stabilising bar

CBR Mould

Figure 3. Typical CBR test set up

Platen

Penetration

dial gauge

Original Instructions 10

5.1 Refer to the relevant standard for full details of the CBR test procedure.

5.2 A typical set up for carrying out a CBR penetration test is shown in figure 3.

5.3 The correct location of the CBR mould is achieved by interposing the platen adaptor

(supplied with the Multiplex 50) between the machine platen and the mould.

5.4 It is suggested that the test should be started with the platen set approximately 10

mm up from its lowest position.

5.5 Position the crosshead at the height required by firstly slackening the nuts on either

side of the crosshead and then adjust the crosshead to the required height by using

the adjustment nuts below the crosshead. To ensure that the crosshead is level, the

alignment studs on the lower nuts should be located centrally and at the front of the

machine. Tighten the locking nuts using a spanner.

5.6 To ensure stability and central location of the penetration piston, the stabilising bar

must always be used. When using the maximum number of surcharge weights, it may

be necessary to clamp the stabilising bar to the threaded part of the columns. In this

case it is recommended that packing pieces (i.e. aluminium strips) be placed between

the stabilising bar clamp screws and the column threads.

5.7 With all the equipment correctly located and secured in the machine, press the UP

key to close most of the daylight. See 4.6

5.8 Set the speed according to the standard specified. Press the RUN key to commence

the test.

5.9 At the completion of the test, press the STOP key.

5.10 Press the DOWN key to return the platen to its lowest position or until the STOP key

has been pressed when the platen has descended the required distance.

Original Instructions 11

6 Setting up for Marshall tests

Load ring

Ball nipple

removed from

load ring

Stabilising bar

Load stud

Breaking Head

Platen

Figure 4. Typical Marshall test set up

Adaptor supplied

with the

Stability piston

Stability piston

Original Instructions 12

6.1 Refer to the relevant standard for full details of the Marshall test procedure.

6.2 A typical set up for carrying out a Marshall test is shown in figure 4.

Important: the Stability piston and Stabilising bar should be used as shown in

figure 4 and the breaking head must be placed in the machine with the long

guide post facing the operator as shown in figure 5 to ensure very safe loading

conditions.

6.3 To fit the Stability piston, remove the ball nipple from the load ring (or load

transducer) and replace it with the adaptor supplied with the Stability piston. Fit the

ball nipple removed from the load ring (or load transducer) onto the Stability piston

and then screw the Stability piston onto the adaptor on the load ring (or load

transducer). Ensure that all connections are fully tightened.

6.4 Before commencing tests it is necessary to set the height of the crosshead to obtain

the optimum clearance between the ball nipple and the load stud on the Breaking

head. See figure 5.

6.5 Ensure that the Stabilising bar is in position before commencing the test. It is

important to set the Stabilising bar at a height that will not impede the raising of the

platen and Breaking head.

6.6 Operate the machine so that the platen travels to its lowest position.

With the Breaking head on the platen, fit the calibration disc. See figure 5

Important: do not under any circumstances load the machine with the

calibration disc in position.

6.7 Position the crosshead to give the clearance shown in figure 5. To ensure that the

crosshead is level, the alignment studs on the lower nuts should be located centrally

and at the front of the machine. Tighten the locking nuts using a spanner.

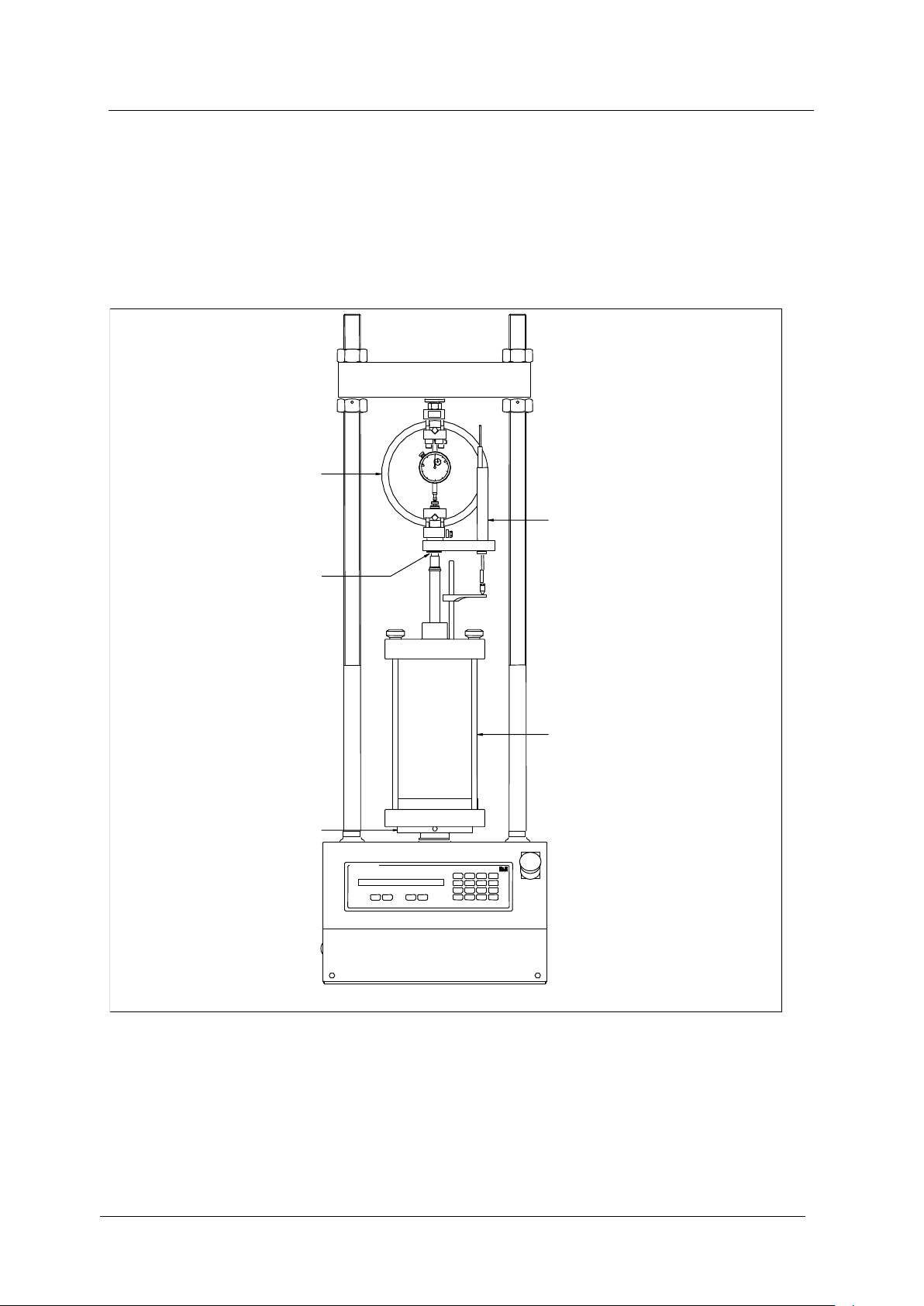

column

column

load stud

breaking head

rear of machine

platen

long guide post

front of machine

view from above showing position

of breaking head on the platen

5 mm minimum

long

guide

post

load stud

ball nipple

view showing clearance between

ball nipple and load stud

Figure 5

calibration disc

breaking head

Original Instructions 13

6.8 It should be possible to remove and replace the Breaking head complete with its

sample without disturbing the ball nipple.

6.9 Set the speed according to the standard specified. Press the RUN key to commence

the test.

6.10 At the completion of the test, press the STOP key and return the platen to its lowest

position.

7 Setting up for Quick Undrained Triaxial tests

Axial strain transducer

Extended ball nipple

Load ring

Triaxial cell

Platen

Figure 6. Typical Quick Undrained Triaxial test set up

(see note below)

PLEASE NOTE: The displacement transducer shown in the diagram can only be

7.1 Refer to the relevant standard for full details of the Quick Undrained Triaxial test

procedure.

connected to a DSU readout unit.

Original Instructions 14

8 Maintenance

8.1 After each series of tests raise the platen to its maximum height and clean the platen

and case removing all debris, spots of binder etc., particularly from under the platen.

8.2 Apply a smear of medium grease to the shaft under the platen where it runs into the

base casting. This is particularly important where a solvent is used for cleaning in this

area.

8.3 After a prolonged period of use, or at least annually, the following internal

maintenance should be carried out.

8.4 Remove the load measuring device from the crosshead. Raise the platen to its

maximum height.

Warning: always disconnect the machine from the power supply before carrying out

maintenance work or making any adjustment.

8.5 Using the tommy bar provided, unscrew the platen from the jacksleeve

(anticlockwise).

8.6 Remove the two screws at the front and the six screws at the rear of the machine. Lift

the case evenly up the columns. A smear of grease on the columns will assist the

grommets to slide smoothly. Caution:Take care as the case can be raised only a

limited amount before being restrained by connecting cables. Support or suspend the

case as convenient or totally remove the crosshead and case. If the case is to be

removed, then firstly disconnect the ribbon type cables from the keypad & display

from the microprocessor PCB, the cable from the Emergency Stop switch from the dc

drive PCB and the earthing lead. It is crucial that all connectors are replaced in the

correct orientation –make a note of their position before disconnecting them.

8.7 Check for any undue play in the

drive belt. If there is, slacken the

four screws holding the motor to

the main casting. Slide the whole

motor assembly until the belt is just

taut.

8.8 Check the alignment of the pulleys

by laying a steel rule across their

faces. Retighten the fixing screws.

(see figure 7)

8.9 If the belt shows any signs of

cracking, fretting or other signs of

wear, it must be replaced

immediately.

8.10 Inspect the tacho-generator drive

belt for signs of wear and replace if

necessary. (see figure 7).

jacksleeve

align pulleys

Figure 7

Motor fixing screws

tacho-generator

electric motor

drive belt

8.11 Refit the case ensuring that any disconnected wires have been reconnected and do

not foul on the drive mechanism. Replace the case fixing screws. Lift the front panel

back into position and replace the fixing screws.

8.12 Screw the platen back onto the jacksleeve and tighten with the tommy bar.

Original Instructions 15

9 Connecting a DSU Readout device

9.1 Multiplex 50 machines fitted with transducers (instead of manual gauges) may be

connected to a transducer readout device called a DSU. This device allows real-time

display of transducer readings and storage of test data, which can then be

downloaded to a PC. The DSU also provides several other features such as

automatic overload shut-off, automatic logging start, automatic checking of speed

selection and peak force / displacement display.

There are 2 DSU connections on the rear –one provides a serial link (9 way RS232

connector) and the other provides machine identification and remote shut-off

functions (round connector). The default serial port speed is 19200 baud. Please

see DSU manual.

Original Instructions 16

DIRECTIVE ON WASTE ELECTRICAL & ELECTRONIC EQUIPMENT (WEEE)

Table of contents