IF.PUG.012 R3

TANGENX™ PRO PD CASSETTE INSTALLATION

1. Lift the end plate off the manifold of the TangenX™ PRO PD cassette holder.

2. Remove the protective blue sheet and rinse the EPDM gaskets with deionized

water or WFI. Place a rinsed gasket flat against the bottom manifold; ensure

that the holes in the gasket line up with the holes in the manifold.

3. Using scissors carefully open the cassette bag to remove cassette.

WARNING: Each cassette is stored in an aqueous solution containing

15-20% glycerin and 0.1% sodium azide, pH 7 – 10. Follow standard

safety procedures for handling aqueous glycerin/sodium azide,

including the use of gloves, safety goggles, and lab coat.

4. Place the cassette into the holder flat against the gasket. Place another gasket

on top of the cassette. Ensure that the holes in the manifold, gaskets, and

cassette are completely aligned. If you are using multiple cassettes, continue

the same gasket/cassette/gasket pattern, ending with a gasket between the

last cassette and the end plate.

5. Place the end plate on top of the last gasket of the cassette or cassette stack.

6. Install the tie-rod spacers (if used) and washers on each bolt leaving a

minimum of 18 mm (0.75 inch) of thread exposed on the rod. By hand, screw

the nut on each bolt and hand tighten evenly by alternating from one nut to

the other. Bolts must be further tightened to within the recommended

torque values using a calibrated manual torque wrench.

7. Proceed to step 8 for a two bolt hardware design or skip to step 9 for a four

bolt hardware design.

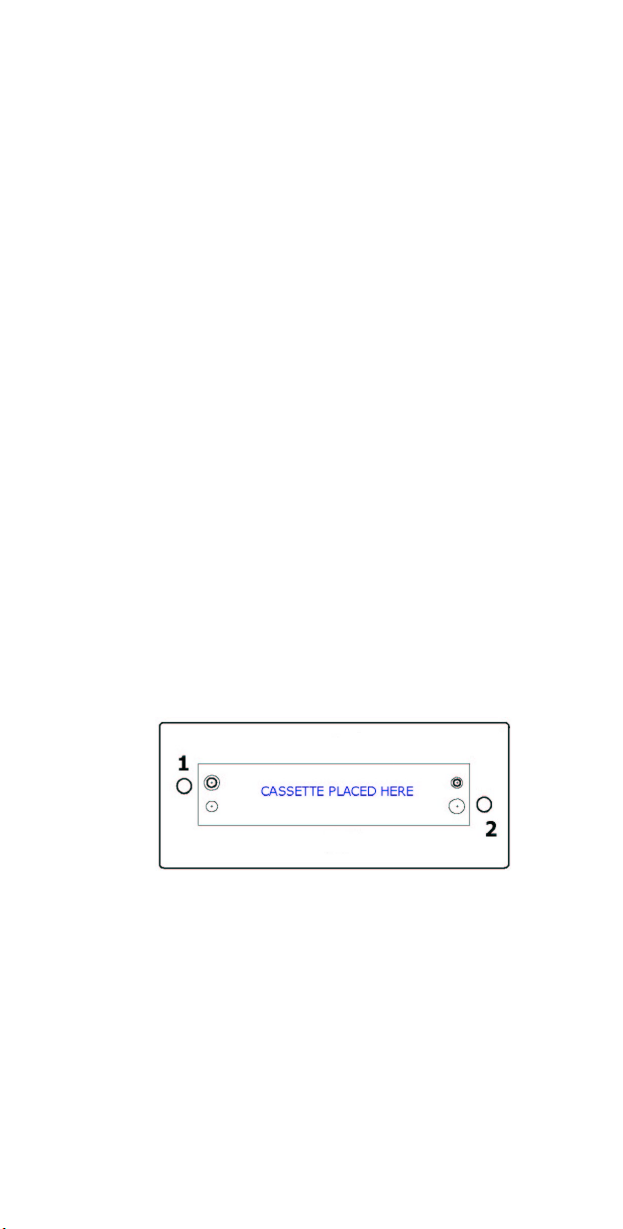

8. Using the calibrated torque wrench with a deep style socket, tighten each hex

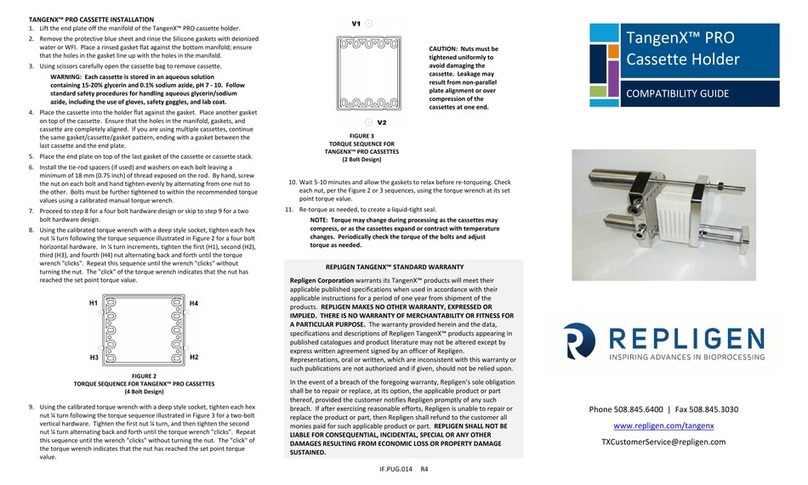

nut ¼ turn following the torque sequence illustrated in Figure 2 for a two bolt

hardware. Tighten the first nut ¼ turn, and then tighten the second nut ¼

turn alternating back and forth until the torque wrench "clicks". Repeat this

sequence until the wrench "clicks" without turning the nut. The "click" of the

torque wrench indicates that the nut has reached the set point torque value.

9. Using the calibrated torque wrench with a deep style socket, tighten each hex

nut ¼ turn following the torque sequence illustrated in Figure 3 for a four bolt

hardware. In ¼ turn increments, tighten the first, second, third, and fourth

nut alternating back and forth until the torque wrench "clicks". Repeat this

sequence until the wrench "clicks" without turning the nut. The "click" of the

torque wrench indicates that the nut has reached the set point torque value.

CAUTION: Nuts must be tightened uniformly to avoid damaging

the cassette. Leakage may result from non-parallel plate

alignment or over compression of the cassettes at one end.

10. Wait 5-10 minutes and allow the gaskets to relax before re-torqueing.

Check each nut, per Figure 1 or 2 sequences, using the torque wrench at

its set point torque value.

11. Re-torque as needed, to create a liquid-tight seal.

NOTE: Torque may change during processing as the cassettes may

compress, or as the cassettes expand or contract with

temperature changes. Periodically check the torque of the bolts

and adjust torque as needed.

FIGURE 2

TORQUE SEQUENCE FOR TANGENX™ PRO PD CASSETTES

(2 Bolt Design)

FIGURE 3

TORQUE SEQUENCE FOR TANGENX™ PRO PD CASSETTES

Repligen Corporation warrants its TangenX™ products will meet their

applicable published specifications when used in accordance with their

applicable instructions for a period of one year from shipment of the

products. REPLIGEN MAKES NO OTHER WARRANTY, EXPRESSED OR

IMPLIED. THERE IS NO WARRANTY OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE. The warranty provided herein and the

data, specifications and descriptions of Repligen TangenX™ products

appearing in published catalogues and product literature may not be

altered except by express written agreement signed by an officer of

Repligen. Representations, oral or written, which are inconsistent with

this warranty or such publications are not authorized and if given,

should not be relied upon.

In the event of a breach of the foregoing warranty, Repligen’s sole

obligation shall be to repair or replace, at its option, the applicable

product or part thereof, provided the customer notifies Repligen

promptly of any such breach. If after exercising reasonable efforts,

Repligen is unable to repair or replace the product or part, then

Repligen shall refund to the customer all monies paid for such

applicable product or part. REPLIGEN SHALL NOT BE LIABLE FOR

CONSEQUENTIAL, INCIDENTAL, SPECIAL OR ANY OTHER DAMAGES

RESULTING FROM ECONOMIC LOSS OR PROPERTY DAMAGE

SUSTAINED.