Content

2

Content

1Declaration of Warranty ............................................................................................... 4

1.1. Type of Designation ....................................................................................................................... 4

1.2. Manufacturer ................................................................................................................................4

1.3. Warranty .......................................................................................................................................4

2Precautions ................................................................................................................... 5

2.1. Foreword.......................................................................................................................................5

2.2. Liabilities .......................................................................................................................................5

2.3. Copyright ©.................................................................................................................................... 5

3Safety ............................................................................................................................ 6

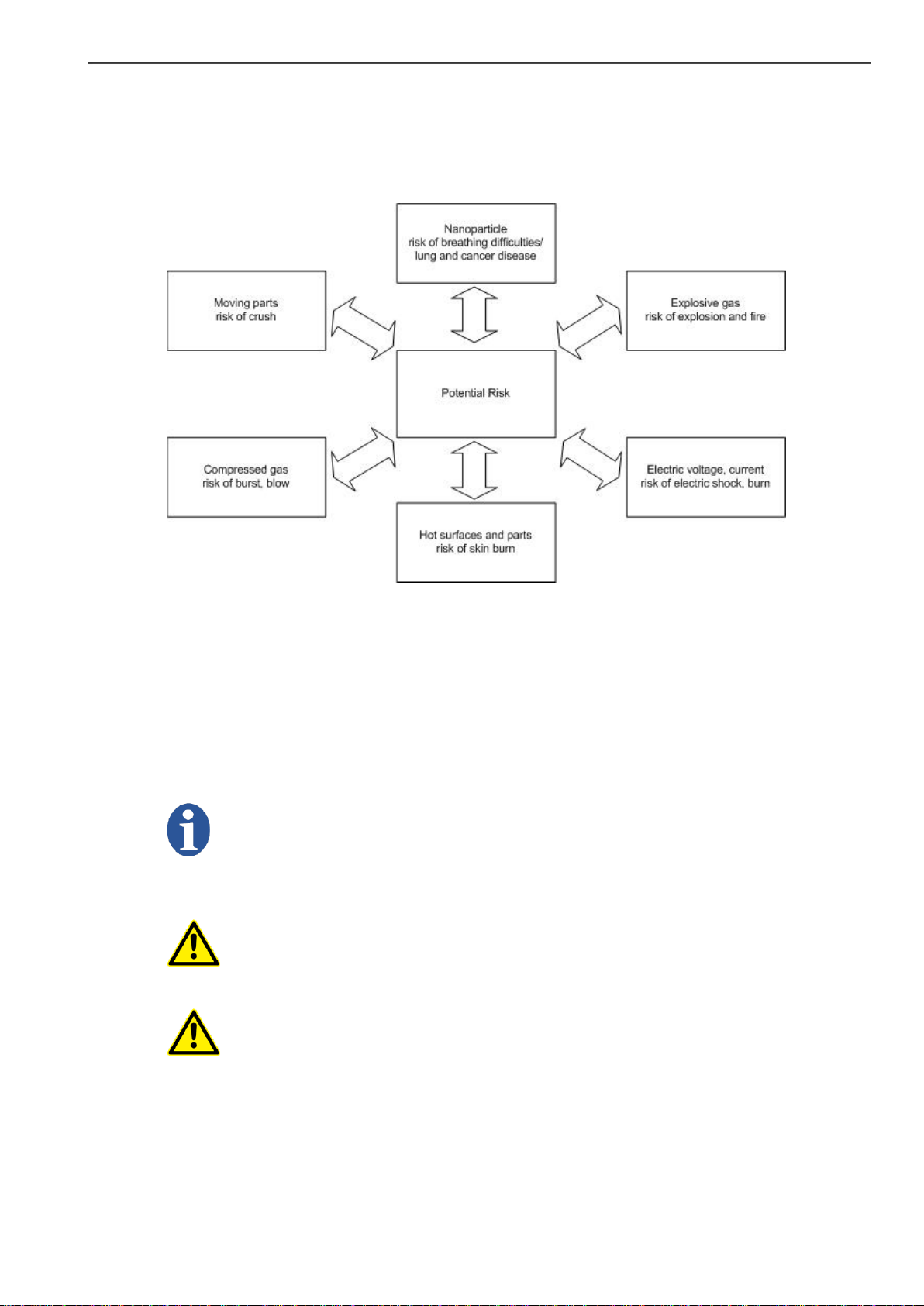

3.1. Risk Types......................................................................................................................................6

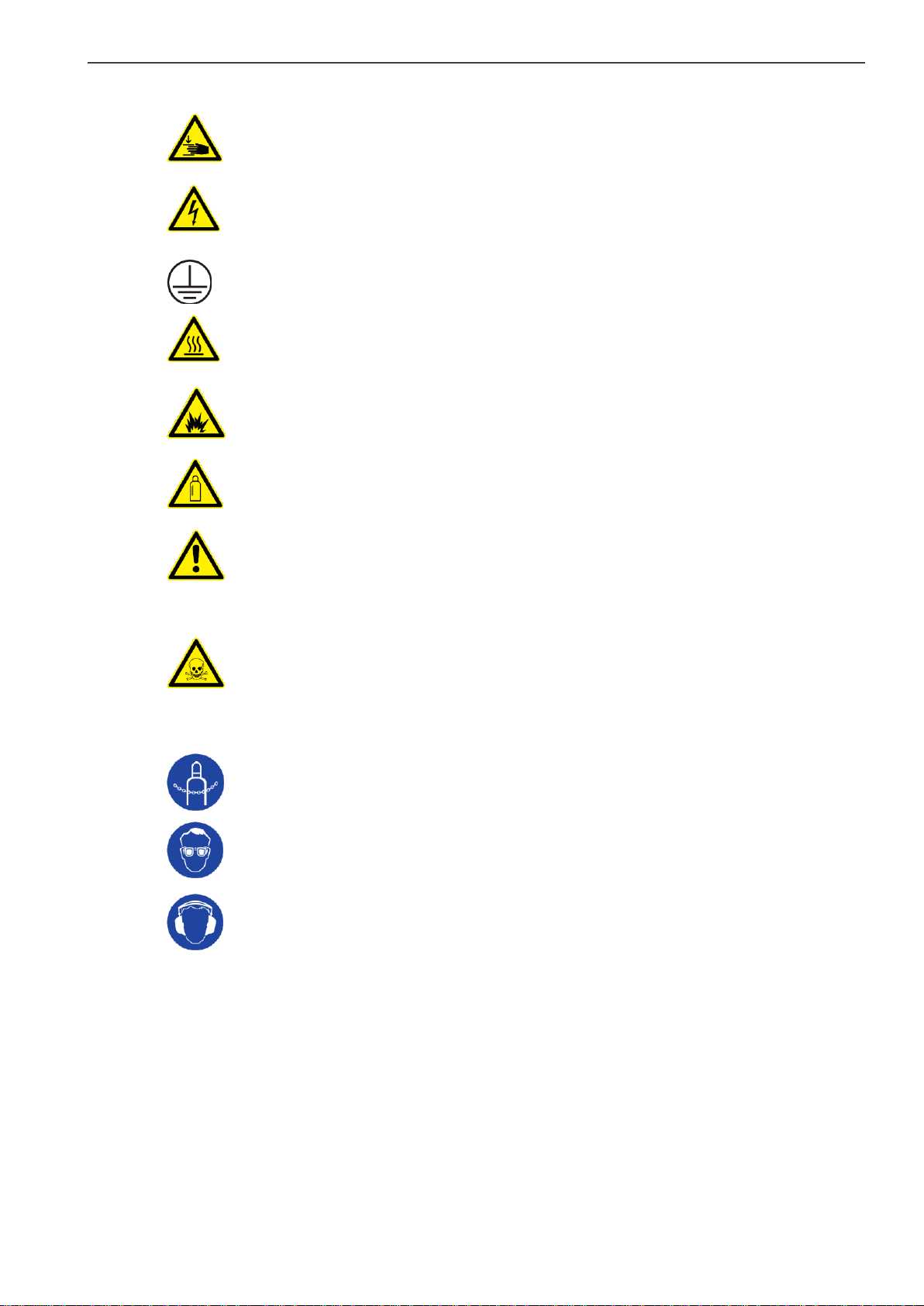

3.2. Labels and Explanations.................................................................................................................6

4System Overview........................................................................................................... 8

4.1. Soot Generation Principle of testo REXS .........................................................................................8

4.1.1. Principle...............................................................................................................................8

4.1.2. Applications .........................................................................................................................8

4.1.3. Functionality ........................................................................................................................ 9

4.2. The Benefits Are ............................................................................................................................ 9

4.3. Function Principle .......................................................................................................................... 9

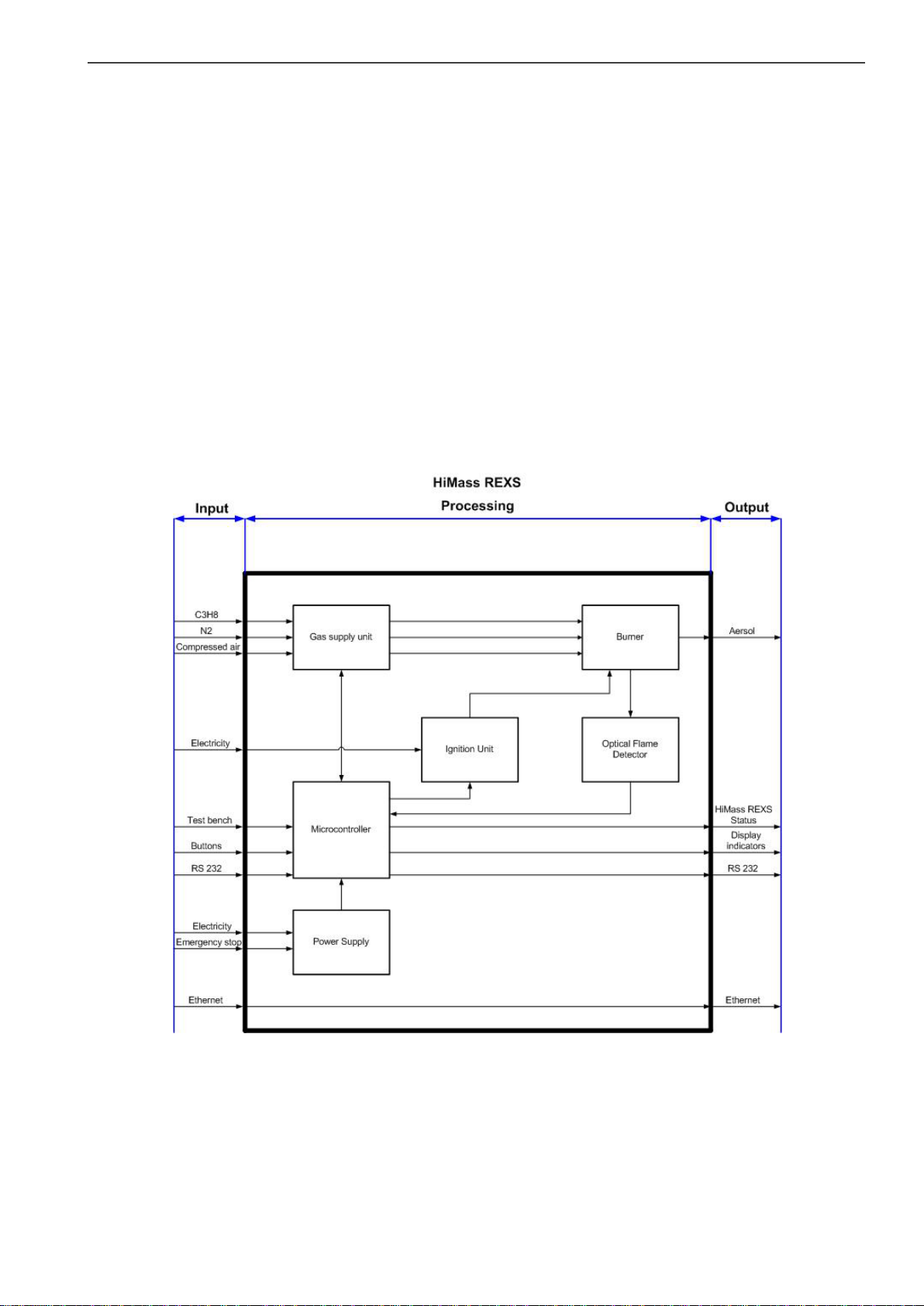

4.4. The System....................................................................................................................................9

4.4.1. Soot Generator .................................................................................................................. 10

4.4.2. Input.................................................................................................................................. 10

4.4.3. Processing.......................................................................................................................... 10

4.4.4. Output ............................................................................................................................... 11

4.5. Front Panel Operational Elements................................................................................................ 12

4.6. Back Panel Operational Elements................................................................................................. 14

4.7. Back Panel Connectors................................................................................................................. 15

5Transportation, Unpacking and Extend of Delivery..................................................... 15

5.1. Transportation............................................................................................................................. 15

5.2. Unpacking.................................................................................................................................... 16

5.3. Storage, Acclimatisarion............................................................................................................... 17

5.4. Extent of Delivery ........................................................................................................................ 18

6Setting up and installation .......................................................................................... 20

6.1. Operation Environment Requirements......................................................................................... 20

6.2. Installation................................................................................................................................... 21

6.3. Test Stand Preparation................................................................................................................. 24

6.4. Operating Instructions ................................................................................................................. 24

6.5. Note ............................................................................................................................................ 25